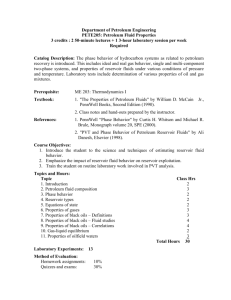

PVT

advertisement

Basic PVT (Fluid behaviour as a function of Pressure, Volume and Temperature) Statoil module – Field development Magnus Nordsveen Status: Draft Content • • • • Phase envelops Gas field Hydrates Characterisations of fluids Equation of states (EOS) Status: Draft Comp Mole% N2 0.95 CO2 0.6 H20 0.35 C1 95 C2 2.86 C3 0.15 iC4 0.22 nC4 0.04 iC5 0.1 nC5 0.03 C6 0.07 C7 0.1 C8 0.08 C9 0.03 C10+ 0.13 Phase diagram for a single component Dense phase P Critical point Solid Liquid Gas Trippel point T Status: Draft Phase envelope of an oil reservoir 2 phase mixture Status: Draft Phase envelope of a gas condensate reservoir Tres, Pres Gas Liquid 2 phase mixture Status: Draft Phase envelops for 3 reservoir types Gas Condensate C C Pressure Oil Heavy oil C C = Critical point Temperature Status: Draft Water-hydrocarbon phase behaviour • Liquid water and hydrocarbons are essentially immiscible in each other • Water vapour in the gas will be governed by gas composition and the vapour pressure of the liquid phase • With water, oil and gas present, there will be two liquid fields and one gas field • A gas reservoir is often saturated with water vapour • When gas is produced through a well and flowline, temperature drops and water condenses • Condensed water amounts to some m3 per MSm3 produced gas Status: Draft Hydrate formation Hydrate domain 400 Access to small molecules Right pressure Pressure (bara) 300 250 200 150 Right temperature Access to free water 350 100 No hydrates can exist in this region 50 0 0 5 10 15 Temperature (°C) Status: Draft 20 25 30 Effect of thermodynamic hydrate inhibitors: Methanol, Ethanol, MEG, salt 400 350 Chemicals move the hydrate curve (bara) Trykk (bar) Pressure 300 250 Hydrate domain 200 No hydrates 150 Normal operational domain 100 50 0 0 5 10 15 20 Temperature (°C) Temperatur (°C) Status: Draft 25 30 Characterisation of fluids • Based on fluid properties (old) • Based on composition Definitions: Standard conditions [STP] for temperature and pressure: 15 oC, 1 atm GOR = Volume of gas/ Volume of oil [Sm3/Sm3] WC = Volume rate of water/ Volume rate of liquid [-] o = o/w at STP (oil density / water density) - specific gravity of oil g = g/a at STP (gas density / air density) - specific gravity of gas API = 141.5/ o – 131.5 (American Petroleum Institute measure of oil density) Status: Draft ‘Old’ type characterization • Useful when no composition exists • The fluid is characterized by: – API gravity / o – g – GOR • Fluid properties as: Bubble point Pressure (Pb), gas-oil ratio (RSGO), densities, viscosities, etc are functions (correlations) of the above parameters Status: Draft Reservoir fluid types (GOR) Fluid type Dry gas Wet gas Gas Condensate Oil Status: Draft Physical behaviour No hydrocarbon liquid condensation during production Hydrocarbon liquid condensation in reservoir is negligible during production. Condensation in wells, flowlines and separators. Condensation of hydrocarbons in reservoir is significant during production. Condensation in wells, flowlines and separators. Gas bubbles is formed in reservoir during production Typical GOR [Sm3/Sm3] > 100 000 (at least)) > 10 000 500 < > 10 000 < 500 Reservoir fluid types (API) Oil type Light oil Oil Heavy oil Extra heavy oil Typical API [-] > 30 22 < > 30 10 < > 22 < 10 Comment: Arguably the most important fluid property for production of heavy oils is viscosity which is very dependent on pressure and temperature. Viscosity could thus be used as classification of reservoir types. However, during production the temperature and pressure (and thus viscosity) can change considerably along the well/flowline to the processing facility. Viscosity typically increases with decreasing API Status: Draft Characterisation of fluids based on composition • Thousands of components from methane to large polycyclic compounds • Carbon numbers from 1 to at least 100 (for heavy oils probably about 200) • Molecular weights range from 16 g/mole to several thousands g/mole Status: Draft Comp Mole% N2 0.95 CO2 0.6 H20 0.35 C1 95 C2 2.86 C3 0.15 iC4 0.22 nC4 0.04 iC5 0.1 nC5 0.03 C6 0.07 C7 0.1 C8 0.08 C9 0.03 C10+ 0.13 Gas chromatography Fingerprint analysis ’Normal’, paraffinic oil Biodegraded oil Status: Draft Waxy oil Characterization challenge • Low carbon number components: –Possible to measure with reasonable accuracy –Known properties • Higher carbon number components: – consists of many variations with different properties – cannot measure individual components • Characterization: Lump C10 and higher into C10+ Status: Draft Comp Mole% N2 0.95 CO2 0.6 H20 0.35 C1 95 C2 2.86 C3 0.15 iC4 0.22 nC4 0.04 iC5 0.1 nC5 0.03 C6 0.07 C7 0.1 C8 0.08 C9 0.03 C10+ 0.13 Fluid properties based on composition • mix xi i Status: Draft Equations of state (EOS) • Any equation correlating P (pressure), V (volume) and T (temperature) is called an equation of state P RT v • Ideal gas law: PV = nRT <=> (good approx. for P < 4 bar) – n: moles, R: gas constant, : molar volume • Van der Waals cubic EOS: P RT a 2 vb v – a: is a measure for the attraction between the particles – b: is the volume excluded from by the particles Status: Draft Equations of state (EOS) & Phase envelope Family of PV isotherms for a pure component Status: Draft Family of PV isotherms for a cubic EOS PVTSim • In the oil industry we typically use software packages to characterize the fluid based on a measured composition • In Statoil we use PVTSim from Calsep • Ref: Phase Behavior of Petroleum Reservoir Fluids (Book), Karen Schou Pedersen and Peter L. Christensen, 2006. Status: Draft Thank you Status: Draft