Experiment 2 Thermometry I Expansion

advertisement

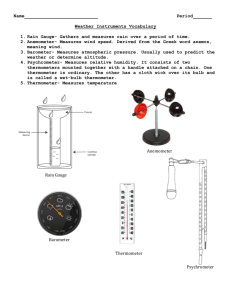

Experiment 2 Thermometry I Expansion-Type Thermometers Objective: To determine the calibration and response time of certain expansion-type thermometers. Apparatus: a. Dewer flask b. stirring device c. Distilled water, ice b. stopwatch e. stands, clamps to support thermometers f. 1 standard, precision mercury-in-glass thermometer g. 1 mercury-in-glass thermometer Theory of Liquid-In-Glass Thermometers The most common expansion-type thermometer is the liquid-in-glass thermometer. In this type of thermometer, the difference in expansion between the liquid and the glass container serves as an indicator of the temperature. Although almost any type of fluid can be used, the most common fluid types are mercury and ethyl alcohol. Although the coefficient of expansion of ethyl alcohol (1.12 x 10-3 at 20°C) is about 6 times greater than that of mercury (0.1819 x 10-3 at 20°C), mercurial thermometers are invariably more accurate than alcohol thermometers and are preferred except when very low temperatures are to be measured (mercury freezes at –38.87°C). The two principal reasons for the lower accuracy of alcohol thermometers are that (1) alcohol is more volatile and thus has a greater tendency to evaporate into the space above the liquid column, and (2) alcohol “wets” the surface of the glass, so that when the temperature drops sharply a small part of the liquid remains on the wall above the column. The errors of temperature measurement can be classified into two general categories: (1) those that are inherent to the particular instrument, and (2) those caused by the lack of thermal equilibrium between the thermometer and the air at the moment the thermometer is read. Of considerable interest is the time that it takes for a given thermometer to reach approximate thermal equilibrium with the surrounding air. The ability of a thermometer to respond to changes in ambient temperature is expressed in terms of its “time constant” or “time lag”. Time lag is also referred to as “response time”, “lag coefficient”, or simply “lag”. The time constant, τ, is defined as the time required for an instrument to reach within 36.8% (i.e., e-1) of equilibrium after the sensor has been subjected to a step input change. This definition of the time constant arises from the fact that the approach of the indicated value to the “true” value will be proportional to e-t/τ , where t is time. The rate at which the indicated value changes with time, dT/dt, when a thermometer bulb is placed in a medium of differing temperature can be expected to be proportional to the rate at which heat flows into the bulb (i.e., dT/dt ∝ 1 q, where q is the heat flux). The heat flux in turn will be proportional to the difference between the environmental temperature, Te, and the temperature of the thermometer, T(t). Thus, the general dynamic response equation of the liquid-in-glass thermometer can be expressed in the following manner: dT Mc p = [Te − T (t )] dt C (1.1) where M is the mass of fluid that the thermometer comes in contact with in the time increment dt cp is the specific heat of the fluid (at constant pressure) that the thermometer is immersed into C is the thermal capacity of the thermometer Te is the environmental temperature T(t) is the temperature reading on the thermometer at time t t is time Integrating equation 1.1 with the assumption that Te is constant, over the limits of T0 (initial temperature) to T(t) results in the following expressions: Mc p T (t ) − Te ln t =− C T0 − Te (1.2) Solving 1.2 for T(t) yields: Mc p T (t ) = (T0 − Te ) exp − t + Te C (1.3) From equation 1.3, it is evident that the time constant for a liquid-in-glass thermometer can be determined by setting the exponential term to -1. This results in the following equation: Mc p T (τ ) − Te τ = exp[−1] = exp − = 0.36788 T0 − Te C (1.4) Determining the time constant of a given instrument is very important because failure to do so can result in significant temperature errors when the environmental temperature varies in time. When measurements are intended to be representative of periods of minutes or more, a relatively long time constant may actually be desirable. However, a short time 2 constant is required when the thermometer is in motion or when short-period temperature oscillations are present. Since the response time of an instrument depends on the heat flux between the medium and the sensor, the time constant can be modified by changing the rate of such heat transfer. The rate of heat transfer can be modified by changing the thermal capacity of the thermometer (i.e., the bulb shape, thermometer length, liquid type, etc.), ventilating the thermometer (i.e., increasing the mass that comes in contact with the bulb), or by immersing the thermometer in a fluid of differing specific heat. Since the choice of immersion fluid and the thermal capacity of the thermometer cannot usually be modified by the user, modifying the degree of ventilation is the only practical way to alter the response time of a given thermometer. In general, the response time decreases very rapidly with even the slightest ventilation. Task #1: Verify Factory Calibration Using Water Baths Goal: To verify the factory calibration of the mercury precision thermometer using two known temperatures (i.e., the freezing and boiling points of water). a) Use a Dewar flask filled to the top with an ice bath of distilled water to calibrate the precision thermometer at 0°C. Immerse as much of the thermometer as possible in the bath, allowing just enough of the scales to protrude to permit reading. Be sure that the thermometer does not touch the sides or bottom of the flask. Record the measurement in lab book only after the thermometer has stabilized. b) Fill the 1000 mL beaker with distilled water and bring to a rolling boil using the gas burner. Immerse as much of the thermometer as possible in the water making sure that the thermometer does not touch the sides or bottom of the beaker. Record the measurement in lab book only after the thermometer has stabilized. c) Discuss any errors associated with these measurements. Task #2 Determine Time Constants Goal: To determine the time constants of the thermometer under unventilated and ventilated conditions a) Record the environmental air temperature of the thermometer. b) Place the thermometers into an ice bath and let it equilibrate. Take the thermometer out of the water, quickly wipe away the excess water, and place it into still air. Record the measured temperature at 5-second intervals for ~3 minutes. c) Repeat procedure (b) except this time place the thermometers in front of the ventilating fan. Record the measured temperature at 5-second intervals for ~2 minutes. d) Plot the response of each of these test thermometers as a function of time for both ventilated and unventilated conditions. 3 e) Use the data to determine the time constants for the thermometer under both ventilated and unventilated conditions. e.1) Compute the ratio T(t)-Te/Ti-Te and then plot the results on semi-logarithmic scale to determine the time lag. T(t) is the temperature at time t, Te is the environmental temperature (temperature of the bath, room), and Ti is the initial temperature of the thermometer. e.2) Plot T(t)-Te/Ti-Te as the ordinate and t(time in sec) as the abscissa. Read from the graph the time lag for each test. f) Discuss your results in your report. Task #3 Calibration of Hobo Loggers Goal: To calibrate each Hobo logger thermistor to one another. a) b) c) d) Collect all 13 logger probes and bundle together Place the bundle into the ice bath (as in Task 1) and let stabilize. Download the data from the Hobo After the data is placed into the course data dir plot each hobo on one plot using Matlab or Excel. Table 1. Calibration at 0 °C Time Standard Thermometer #1 Test Thermometers #2 #1 Test Thermometers #2 Table 2. Calibration at 100 °C Time Standard Thermometer 4 Table 3. Unventilated Air Time (s) 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 Te #1 Temperature C #2 Ratio T-Te/Ti-Te #1 #2 #1 Temperature C #2 Ratio T-Te/Ti-Te #1 #2 Table 4. Ventilated Air Time (s) 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 Te 5 Table 5. Time Lag in sec Ice Bath Air Thermometer 1 2 6