our top projects - Skemaq`s Press Release

advertisement

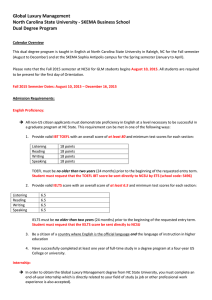

Company Vol. 02 our top projects contents main projects ATYRAU REFINERY / kazakhstan ----------------------------awa paloukou platform / congo------------------------baku Tbilisi ceyhan pipeline / azerbaijan and georgia--chilean lng / CHILE -----------------------------------------chinarevskoye field / KAZAKHSTAN ----------------------corinth refinerY / GREECE - -------------------------------djeno power generation planT / CONGO----------------fpso osx2 / BRAZIL ------------------------------------------HANNIBAL SOUR GAS / TUNISIA-------------------------------kitina and zap platformS / CONGO----------------------LAGGAN TORMORE / NORTH SEA (UK)------------------------mopustor yme / NORWAY-----------------------------------nizhnekamsk REFINERY / RUSSIA---------------------------SATAH FULL FIELD / UAE --------------------------------------TOUT LUI FAUT REFINERY / SURINAME -----------------------utbs / ALGERIA------------------------------------------------- p. 06 p. 07 p. 08 p. 09 p. 10 p. 11 p. 12 p. 13 p. 14 p. 15 p. 16 p. 17 p. 18 p. 19 p. 20 p. 22 ITALY - main projects ONSHORE | OFFSHORE------------- p. 23 top projects + INFO GOLDEN EAGLE / NORTH SEA (UK)----------------------------JASMINE development / NORTH SEA (UK)------------------KARACHAGANAK / KAZAKHSTAN-----------------------------KASHAGAN / KAZAKHSTAN------------------------------------OGD III / UAE---------------------------------------------------QAFCO 5-6 / QATAR -------------------------------------------TENGIZ / KAZAKHSTAN ----------------------------------------- p. 28 p. 30 p. 34 p. 38 p. 48 p. 50 p. 54 CLIENTS AND TESTIMONIAL --------------------------- ADDENDUM Elisabetta Cerveglieri Vice President a-z main projects alphabetical order “The projects we work on are invariably complex, often sited in remote areas with extreme climatic conditions, and are critical to the success of the businesses involved. Our mission is to implement these projects by delivering state-ofthe-art products and solutions, encompassing everything from engineering all the way to commissioning, and to work with our clients throughout the whole process. Always bearing in mind that our objective is to enable them to reach their objectives.” 05 congo ATYRAU REFINERY / KAZAKHSTAN Gabon kazakhstan awa paloukou platform / CONGO Democratic Republic of the Congo Angola Kyrgyzstan Caspian Sea Uzbekistan Saipem was awarded the contract for the engineering, procurement, construction and installation of a platform and associated pipelines for the development of the Awa Paloukou field, located off the coast of the Republic of Congo in 2,730 feet (832 m) of water. This is the second deepest water depth fixed platform project in the world. EPC contractor: JGC corporation / end user: kazmunaigas EPC contractor: Saipem / end user: eni congo SOLUTIONS DELIVERED 06 atyrau a Working closely with its Uralsk-based partner in Kazakhstan, Skema was responsible for the provision of the PMCC switchboards for the Atyrau Refinery. The project proved to be a success thanks both to the experience acquired by Skema in the Kazakh market since 1998, which it was able to leverage fully, and to the important technology transfer program established with its Kazakh partner. The commissioning was carried out by local electrical engineers, under the supervision of Skema’s site services manager. Skema’s supply included: SOLUTIONS DELIVERED >> Power Centers (32 columns) >> Motor Control Centers (57 columns, 371 drawers) Skema was awarded a contract for the supply of: >> Medium Voltage Switchgear (11 columns) >> Power Motor Control Centers (28 columns, 147 drawers) >> RTU (4 columns) >> Integrated Protection and Control System A dual redundant Local Control Unit (LCU) based on redundant PLCs, is installed in the Normal Electrical Room. This LCU is connected, via a redundant Modbus on multimode fiber optic, to a Remote Control Unit (RCU) installed in the Emergency Electri- cal Room. The LCU communicates, via redundant Ethernet network on multimode fiber optic, with an Industrial PC installed in the Main Electrical Room. 07 A awa paloukou The Atyrau Refinery is the oldest petroleum refining plant in Kazakhstan, built more than 60 years ago. The reconstruction of the refinery started in March 2003, as part of the turnkey contract, which was won to JGC Corporation as main contractor, in cooperation with Marubeni Corporation. The scope of the project was to produce oil products that fulfill modern standards and ecological requirements. The total processing capacity of the Refinery is of 4.3 million tons of oil per year. Paraguay 08 baku tbilisi ceyhan B Black Sea Caspian Sea chile Argentina Uruguay AZERBAIJAN Turkey Syria Iraq Iran chilean lng / CHILE South Pacific Ocean The Baku-Tbilisi-Ceyhan pipeline transports crude 1,760 km (1,094 miles) from the Azeri-Chirag-Guneshli oil field in the Caspian Sea to the Mediterranean Sea. It passes through Baku, the capital of Azerbaijan; Tbilisi, the capital of Georgia; and Ceyhan, a port on the south-eastern Mediterranean coast of Turkey, hence its name. It is the second longest oil pipeline in the world and one of the biggest engineering projects. The Chilean LNG Project consists of a new grass-roots LNG receiving terminal located at Quintero Bay, approximately 160 km northwest of Santiago, Chile. LNG carrier ships unload at a new jetty built at Quintero, into two storage tanks. Process facilities are installed to enable the LNG to be pumped from the storage tanks, vaporized and exported into the existing transmission system via a new pipeline. The terminal is expected to meet 40% of Chilean gas demand, with an overall annual supply capacity of 2.5 million tonnes of LNG. EPC contractor: petrofac / end user: British Petroleum EPC contractor: cb&i / end user: gnl quintero / a jv between: british gas, endesa chile, enap, metrogas SOLUTIONS DELIVERED Skema’s supply included: SOLUTIONS DELIVERED Engineering, manufacturing, testing and commissioning of PMCC type LV switchgear and Bus Ducts. > > Power Motor Control Centers (137 columns, 436 drawers) >> 3 DC Panels >> Bus Ducts Skema’s provision included 380V switchgear, interface panels and power transformers: Skema supplied switchgear for Pump stations PS-G2 and PS-G1 and for the intermediate Pigging IP-A1. “All in all the Skema service was very satisfactory.” Contracts Administrator >> 10 Power Motor Control Centers (47 columns and 205 drawers) >> 5 Interface Panels >> 4 Power Transformers For this supply, Skema’s PMCCs were successfully tested for seismic load for the following values: >> Peak Horizontal Ground Acceleration: 0.83 g >> Peak Vertical Ground Acceleration: 0.59 g >> Seismic Design Code: ASCE 7/IBC 2000 The strength of the structures was tested for: >> Resistance and stability for individual modules and for the various configurations >> Ground anchors >> Links between modules (bolts) >> Internal links to modules (rivets) 09 C chilean lng baku tbilisi ceyhan pipeline / AZERBAIJAN AND GEORGIA georgia Kyrgyzstan corinth refinery / GREECE Chinarevskoye Field, approximately 324 square kilometers in size, is situated close to the city of Uralsk in west Kazakhstan and is only 60 km from the border with the Russian Federation. The field consists of an oil processing facility capable of processing 400,000 tpa of crude oil, multiple oil gathering and transportation lines, a gas powered electricity generation system, major warehouse facilities for the storage of oil, materials, machinery and chemicals used in crude oil production, an employee field camp for 180 people as well as 14 existing wells and 4 exploration wells under drilling and test operations. The Corinth Refinery with its ancillary plants and offsite facilities is considered as one of the most modern refineries in Europe. Due to its flexibility it can process crude oils of various characteristics and produce a full range of petroleum products, complying with the most stringent international specifications, serving major petroleum marketing companies in Greece and abroad. The refinery production operations are located in Agii Theodori, in the province of Corinth, about 70 km outside Athens. EPC contractor: Exterran/Belleli Energy / end user: ZhaikhMunai LLP EPC contractor: Technip / end user: Motor Oil Hellas SOLUTIONS DELIVERED 10 chinarevskoye C Skema’s supply included the design, manufacturing, testing and supply of Medium Voltage switchboards and Intelligent Power Motor Control Centers, including: >> 6 kV MV Switchboards (31 sections) >> Intelligent Motor Control Centers (69 columns, 279 drawers) >> Power Centers (24 columns) >> Capacitors Panels Black Sea Albania kazakhstan Turkey greece Caspian Sea Uzbekistan SOLUTIONS DELIVERED Skema provided for the project: Skema was awarded the contract for the design, engineering, manufacturing and installation of Low Voltage switchgear for the new Crude Distillation Unit Complex of the refinery. >> Power Motor Control Centers (53 columns, 188 drawers) >> Distribution Panels >> Bus Ducts >> Power Factor Correction System 11 C corinth chinarevskoye field / KAZAKHSTAN Romania Bulgaria Guyana Suriname French Guiana congo 12 djeno D Democratic Republic of the Congo FPSO OSX2 / BRAZIL Brazil Bolivia Angola Paraguay The thermoelectric power plant in Djeno, near Point Noir in Congo, has a 25 megawatt power capacity. The power plant is fired with associated gas from the offshore plants of Kitina, Djambala and Foukanda, located 65 km from the coast and producing a total of 26,000 barrels of oil per day. Gas is separated onshore at the Djeno terminal close to the new power plant. The project represents the first example of use and exploitation of associated gas otherwise flared. The project aims at reducing gas flaring and at using it in power generation with significant social, economic and environmental benefits. Campos Basin is a petroleum rich area located offshore of Rio de Janeiro. It has a total area of 100,000 square kilometers. The FPSO OSX2 will be used in the Campos basin, Brazil, on one of a string of heavy oilfields discovered by OGX. The OSX2 will be able to produce up to 100,000 barrels per day of oil, with storage capacity for 1.3 million barrels. EPC contractor: renco / end user: eni congo EPC contractor: SBM OFFSHORE / end user: OSX-GRUPO EBX SOLUTIONS DELIVERED Skema supply included: SOLUTIONS DELIVERED Skema was responsible for the design, manufacturing, supply, inspection, testing, export packing, supervision of commissioning on site of Low Voltage Switchgear and Intelligent Motor Control Centers. >> Power Centers (7 columns) >> Motor Control Centers (12 columns, 19 drawers) >> Auxiliary Services Switchboards Skema was awarded the contract for the design, manufacturing, inspection and testing of Power Motor Control Centers, as detailed below: >> 4 Power Centers (14 columns) >> 1 Motor Control Center (66 columns, 275 drawers) The switchgear supplied by Skema, that feature a rated current of 5000 A and rated short-time withstand current of 100 kA, comply with the most stringent requirements of the offshore marine applications: compact dimensions for limited space, handles on the front of the switchgear to prevent personnel’s injuries in case of sudden movements, anti-vibration basement against marine solicitations. Skema used the Bender system, to monitor the electrical network and to reveal defect and problems on the network that can compromise the functioning of the switchgear. 13 f fpso osx2 djeno power generation plant / CONGO Gabon hannibal sour gas / tunisia hannibal a H Algeria Democratic Republic of the Congo Lybia Angola kitina and zap platforms / CONGO The Hannibal Sour Gas Plant located 20 kilometers south of Sfax processes the hydrocarbons brought onshore from the Miskar Gas field, located 125 kilometers offshore in the Gulf of Gabes, Tunisia. This field is 100% operated by BG Tunisia. Sour gas from ten wells is sent through a pipeline and processed at the Hannibal plant and supplied to the Société Tunisienne de l’Electricité et du Gaz (STEG), Tunisia’s state electricity and gas company. During its lifetime, it is estimated that the Miskar field will produce more than 700 billion cubic feet of gas. Skema participated in the revamping of the PMCC switchgear for the Kitina and ZAP platforms, offshore in Congo, around 50 km from Point Noire. The previous switchgear was supplied by Nuova Q.E.M. Quadri Elettrici Milano, from which Skema acquired the expertise, the work order documentation and spare parts for overall projects, in Italy and abroad. This acquisition allows Skema to provide maintenance, extensions, expansion and revamping services for low voltage switchgear supplied by Nuova Q.E.M. thus guaranteeing operational continuity for installed products. EPC contractor: WorleyParsons / end user: BG Tunisia EPC contractor: renco / end user: eni congo SOLUTIONS DELIVERED 14 Morocco Gabon Skema was awarded the contract for the detailed design, supply and installation of a prefabricated metal Local Equipment Room (LER) fully assembled, wired and tested in Skema’s factory in Cesano Maderno, for installation on site. The LER is composed of: > >> >> >> Weather-tight enclosure and supporting structure Electrical equipment room Instrumentation equipment room Small power distribution within the building >> HVAC systems >> PA/GA loudspeaker system facilities >> Fire & Gas detection >> CO2 flood system >> PABX telephone system facilities >> Normal lighting system, including external door lighting >> Escape lighting system on emergency exits and routes >> Cable trays/racks >> Earthing system >> Portable fire extinguishers SOLUTIONS DELIVERED >> 2 Motor Control Centers Skema was awarded the contract for the engineering, manufacturing, commissioning, test and assistance on site of Intelligent Low Voltage Switchgear, in detail: The switchgear was engineered for the integration with existing switchgear, and was commissioned by Skema’s personnel on site. >> 1 Power Center Skema is available for documentation consultation, and to provide any addi- tional information to design, support, provision of spare parts and evaluation of proposed systems that involve the integration of Skema products with those previously installed by Nuova Q.E.M. Quadri Elettrici Milano. 15 k kitina and zap congo tunisia 16 laggan tormore l Ireland Finland Norway Germany France Sweden mopustor yme / NORWAY Laggan and Tormore are two gas and condensate fields situated about 125 km north-west of the Shetland Islands in the UK. The Laggan and Tormore project involves the development of the two fields and construction of a gas processing plant and export pipeline. Here, water depths descend rapidly from an average of 120 m to 600 m and beyond. It is a uniquely challenging environment in which to operate, but also one with great potential. The project consists of the development of a production unit for the Yme Project. The Yme field is located in the Egersund basin in the North Sea, approximately 110 km offshore in the Norwegian Continental Shelf. The Yme field consists of two main reservoirs, Beta and Gamma, which are approximately 12 km apart. The Yme Re-development Project is based on a MOPUstor, which is a Mobile Offshore Production Unit with a subsea storage tank. The MOPUstor will be located at the Gamma reservoir with surface completion of the Gamma wells and tie back of the completed subsea Beta wells. EPC contractor: PETROFAC / end user: TOTAL EPC contractor: SBM-Gusto MSC / end user: Talisman Energy Norge AS SOLUTIONS DELIVERED The supply included: Skema was awarded the contract for the design, manufacturing, inspection and testing of 81 Low Voltage Distribution Boards. >> 26 indoor, arc internal proof Distribution Boards, with ESD functionality and IP31 grade of protection > > 3 outdoor Distribution Boards, IP65 grade of protection >> All electrical details and requirements (short circuit, dielectric, etc.), as per IEC 60439 “We are delighted to work with Skema and the kind of support you extend to us in the critical phase of the project.” Senior Electrical Engineer SOLUTIONS DELIVERED Skema supply included PMCC switchgear, specifically: >> Power Centers (11 columns) >> Motor Control Centers (51 columns, 283 drawers) 17 m “Skema’s performance in terms of the delivery of hardware and the submission of documents was excellent. Particularly in relation to the close-out of the final documentation (Manufacturing Record Books and Technical Operating and Maintenance Manuals), Skema was an example to other suppliers. We would like to take this opportunity to thank Skema for all their efforts in ensuring a successful close-out of the purchase order.” Project Expeditors mopustor yme LAGGAN TORMORE / NORTH SEA (UK) United kingdom nizhnekamsk n Qatar uae Saudi Arabia Oman Kazakhstan Yemen The refining and petrochemical complex in Nizhnekamsk, Republic of Tatarstan, 250 km from the capital city of Kazan, is one of the most ambitious Oil & Gas projects in Russia, which doubled the refined crude run from annual 7 to 14 million tons. The refinery has aromatics units and a deep conversion section with a fluidized catalytic cracker, a distillate hydrocracker, a delayed coker, and a gasification plant. The petrochemical plant includes purified terephthalic acid, polyethylene terephthalate, linear alkylbenzene and polypropylene units, plus the associated power generation facilities. Satah Full Field is located 200 km northwest of Abu Dhabi, United Arab Emirates. The Satah Full Field Development project’s objective is to maximize crude oil production and oil recovery by reducing the well heads’ back pressure and introducing of gas injection and gas lift facilities. The project scope involves offshore brownfield works to the existing well head platforms and production manifold platform, installation of infield pipelines, as well as modifications and installation of new facilities at the Onshore Satah plant at Zirku Island. end user: taneco EPC contractor: NPCC-TECHNIP CONSORTIUM / end user: ZAKUM DEVELOPMENT COMPANY (ZADCO) SOLUTIONS DELIVERED 18 SATAH FULL FIELD / UAE Iran Kuwait Skema was awarded the contract for the supply of: >> Power Centers (124 columns) >> Motor Control Centers (600 columns, 2,529 drawers) >> LV Distribution Boards Skema has been operating actively in Russia, supplying its products for use on projects in an array of different industries: Oil & Gas, petrochemical, energy and utilities, processing and manufacturing. SOLUTIONS DELIVERED “We have been fully content with Skema’s support given to us in any aspect of our activity. Skema’s state-of-the-art products are of great interest to Russian designengineering organizations and end users. High professional skills of Skema’s specialists team that conduct the training sessions is worth mentioning”. Managing Director Skema was awarded the contract for the design, manufacturing, inspection and testing of Power and Lighting Distribution Boards and Lighting Panels (Safe Area) for the onshore portion of the project. The Distribution Boards provided for the project are for both indoor and outdoor usage, they have IP42 degree of protection, meet special requirements for saline ambient and are equipped with a very large number of cables. Skema supplied for the project: >> 14 Distribution Boards >> Cable boxes and glands 19 S satah nizhnekamsk refinery / RUSSIA Iraq russia Guyana TOUT LUI FAUT REFINERY / SURINAME suriname French Guiana Brazil LV SWITCHGEAR / INTELLIGENT MCCs Bolivia Paraguay The Staatsolie Maatschappij Suriname N.V. is located in Suriname, near Paramaribo, in the Wanica District. The project is a major expansion to the existing refinery, and the objective is to increase the crude capacity at the facility to 15,000 barrels per day. Electrical loads for the above units shall be fed from the new electrical substation in the L-01 plant. The Low Voltage Switchgear and Intelligent MCCs supplied for the project are equipped with smart relays that communicate with the ECMS using the IEC 61850 Protocol, which affords a number of benefits, such as interoperability between all the devices in the substations re- the life cycle thanks to the introduction of a standardized substation configuration language (SCL). Since the switchgear is highly modular, the selection of components required by any application is very simple. The result is an appreciable reduction in costs for the secondary system over its life cycle. The LV bus duct is of the compact type with copper lines; it provides a complete solution for connections between power stations and transformers and the main panel board. The switchgear’s functional units are guaranteed arc-proof in accordance with IEC 62271-200 Standards, appendix AA, class A accessibility, criteria 1 to 5. All the installation, operation and maintenance operations can be carried out from the front of the unit. EPC contractor: SAIPEM / end user: STAATSOLiE MAATSCHAPPIJ SURINAME N.V. 20 tout lui faut t Skema was awarded the contract for the design, manufacturing, inspection and testing of the Medium Voltage and Low Voltage Switchboards and the Electrical Integrated Control and Monitoring System as detailed below: >> 5 Power Motor Control Centers (94 MCC, 15 PC type, 461 starters) >> 8 Bus duct lines 3200 A >> 2 MV 6 kV Switchgear (24 columns) >> 3 MV 12.3 kV Switchgear (35 columns) >> 3 RTUs >> ECMS System The ECMS is based on a redundant RTU which operates as a gateway between the electrical users and the DCS. The DCS controls all the process motors via a redundant Ethernet link over Modbus/TCP; the motor activation time is shorter than 200 ms, while the total loop response time is shorter than 400 ms. 21 t tout lui faut SOLUTIONS DELIVERED “I would like to express my complete satisfaction for the activities performed by you during engineering and construction of equipment.” Field Electrical Engineer gardless of the manufacturer, and free allocation of real functions on all levels, allowing for the construction of flexible and open, yet tailored, solutions that are future-proofed to deal with upcoming advances in communication technology. LV switchgear features: >> 13 Incomers REF 615 >> 5 bus-tie REF 630 >> 352 LTMR motor managers The switchgear and earthing switches are operated from the front, with the door closed. The communication protocol for the MV protection relays is IEC 61850, as it is for the LV switchgear. MV switchgear features: MV SWITCHGEAR The IEC 61850 standard provides long-term validity through the dividing of applications and communications, and support throughout The Medium Voltage switchgear for the project is equipped with a metal enclosure suitable for indoor installations. >> Rated current 1250 A >> 1 REF 630 (used for protection and ATS) >> 17 REF 615 Tunisia utbs / ALGERIA Morocco algeria Lybia Western Sahara Mauritania The UTBS (Unité de Traitement de Brut à Hassi Messaoud) consists of three identical treatment trains, each with capacity of 100,000 barrels per day, four 50,000 m3 product storage vats, two aerial electric lines of 30 kV, a station of 30 kV and 45 km pipelines transporting oil, water and gas. The project, which aims to improve crude oil quality and production rates, significantly contributes to Sonatrach’s Hassi Messaoud field optimization production program, given the extent of the field’s reserves, their quality and their complexity. The facility is designed to treat and transport crude oil from six fields south of the main field to a storage center at Haoud El Hamra. Hassi Messaoud is Algeria’s oldest and largest field. 22 utbs O U Skema was awarded the contract for the design, manufacturing, supply, inspection, testing and commissioning of 9 Power Motor Control Centers switchgear, in detail: >> Power Centers (11 columns) >> Motor Control Centers (63 columns, 279 drawers) >> Bus Ducts >> 5 Distribution Boards italy 23 italy main projects SOLUTIONS DELIVERED main projects onshore offshore EPC contractor: saipem / end user: Sonatrach oFFshore projects 07 Agostino A Agostino B Agostino C Amelia B Amelia C Amelia D Anemone B Angela Angelina Angela Cluster Annabella Antares Antonella Arianna A Armida Barbara A Barbara B 43 27 01 64 22 48 63 55 23 14 13 32 03 47 42 05 53 31 16 17 33 08 52 21 36 57 19 11 46 51 20 30 Barbara D Barbara E Barbara F Barbara G Barbara H Barbara T Barbara T2 Basil Calpurnia Cervia B Cervia C Cervia E Daria B Eleonora Garibaldi A Garibaldi C Garibaldi K Gela 1 Giovanna Luna A Pca Pcb Pc-Wa Pc80 Bis Ravenna Regina 10 28 49 39 24 38 59 62 61 58 15 50 12 04 main projects italy end users: Skema’s longstanding END USERs for projects in Italy include: Agip, Edison, Enel, Enichem, Eni Group, ERG, Fiat Engineering, Foster Wheeler, ilva, Saipem, Saras, Snamprogetti, Techint, Technip, Tecnimont 34 06 60 65 40 37 25 italy 54 18 56 main projects 24 41 Since its foundation in 1974, Skema has been one of Italy’s leading names for onshore and offshore applications: Oil & Gas plants, refineries, power plants, offshore platforms, shipping, pipelines and, more generally, processing, manufacturing and services projects. 09 29 35 26 Oil Plant Refinery / Plant Gas Plant Power Plant 02 25 Platform 45 44 oNshore projects 01Arluno 02Augusta 03Bagnolo Mella 04Benevento 05Bordolano 06Brindisi 07Brunico 08Busalla 09Candela 10Carassai 11Casalborsetti 12Cassino 13Casteggio 14Caviaga 15Cavone 16Contarina 17Cortemaggiore 18Crotone 19 Dosso Degli Angeli 20 Falconara 21 Ferrara 22 Ferrera 23Gaggiano 24Gagliano 25Gela 26Giaurone 27Glorenza 28Grottammare 29Hera Lacinia 30Livorno 31Mantova 32Marlengo 33Medesano 34Melfi 35Milazzo 36Minerbio 37Monte Alpi 38 Nera Montoro 39Pineto 40Pisticci 41Pomigliano 42Porto Marghera 43Prati di Vizze 44Priolo Gargallo 45 Ragusa 46 Ravenna 47 Ripalta 48 Rivalta 49 Roseto 50 Rotello 51 Rubicone 52Sabbioncello 53Sarmato 54Sarroch 55Sergnano 56Simeri Crichi 57S. Potito 58S. Salvo 59Sulmona 60Taranto 61Termoli 62Torrevaldaliga 63Torviscosa 64Trecate 65Val D’agri 26 top projects alphabetical order a-z 27 GOLDEN EAGLE / NORTH SEA (UK) SKEMA Motor Control and Management System (MCMS) United kingdom Ireland Germany France Discovered in 2007, the Golden Eagle Area (which is made up of reservoirs Golden Eagle, Hobby and Peregrine), is located in approximately 113 m water depth in the UK sector of the North Sea 70 km offshore (19 km north of the Buzzard Field, 21 km northwest of the Ettrick Field and 4 km south of the Atlantic Field). The field is developed using two platforms - a wellhead platform and a production, utility and quarters (PUQ) platform. The two platforms are connected by a 70 m bridge. The facilities being built at Golden Eagle can act as a future hub for tiebacks. Operator Nexen has estimated the Golden Eagle Area contains 140-150 million barrels of oil equivalent in gross recoverable contingent resources, making it one of the largest oil discoveries in the UK North Sea in recent years. The Motor Control and Management System (MCMS) developed for the platforms integrates the intelligent Motor Control Centers made by Skema with the Process Control System (PCS), the Power Management System (PMS) and the Distribution Management System (DMS), and en- ploits the capabilities of the 400 IEDs (supplied by different manufacturers) which measure, protect and control all the users connected to the MCMS. Importantly, the MCMS not only helps the operator to control the users, but is of great significance to the electrical engineer in verifying the performances of the electrical networks by means of continuous monitoring of the parameters set in the IEDs with special at- otal in ensuring a proactive and cost effective maintenance regime of the plant. All the DCUs components are dual redundant and can survive any individual component failure. The serial links communicating with the downstream IEDs via Modbus-RTU ring (motor managers, measuring devices and protection relays) can survive a fault where the serial cable is broken between two devices. EPC contractor: CB&I / end user: Nexen Petroleum golden eagle g SOLUTIONS DELIVERED The supply consists of: Skema was awarded the contract for the design, engineering and manufacturing of Intelligent Low Voltage switchgear and the Motor Control and Management System (MCMS) for the project. >> Intelligent Motor Control Centers (72 columns, 341 drawers) >> Power Centers (14 Columns) >> 4 Dual Redundant Data Concentrator Units (DCUs) >> Distribution Boards >> Motor Control and Management System (MCMS) 29 g golden eagle 28 ables an integrated and safe management of all the electrical users. The integration is achieved thanks to the communication capabilities of the DCUs which operate as gateways between the upstream PCS/PMS/DMS and the IEDs within the downstream switchgear. The DCUs allow concurrent communication via redundant Modubus-RTU and OPC between the different systems. Such integration completely ex- tention to those which influence the reliability/maintenance of the plant. The MCMS records the running hours, the number of operations of each feeder circuit and analyzes the most frequent causes of tripping/alarms, so that the engineer can plan proactive counter measures to avoid future plant problems which may cause economic losses and, in the worst cases, safety risks to the plant/personnel. This type of intelligent reporting is piv- System response times are of utmost importance, the MCMS is designed for ultimate performance. A command received from the PCS is actuated by the IEDs in less than 100 ms and the change of status is available to the PCS in less than 1 second. These performances are achieved while the DCUs communicate concurrently with the PCS via Modbus-TCP, with the PMS via Modbus-RTU and with the DMS via OPC. JASMINE DEVELOPMENT / NORTH SEA (UK) United kingdom Ireland Germany France Jasmine is a gas condensate reservoir that lies in some 80 m of water at a depth of 4,115 m below the seabed, and is located 240 km south-east of Aberdeen. The Jasmine Development comprized a wellhead platform tied back to the ConocoPhillips operated Judy platform, which is approximately 9 km west of the Jasmine Field, via a multiphase pipeline and riser platform connected to the existing Judy platform via a linking bridge. epc contractor: WorleyParsons / End user: ConocoPhillips jasmine j Skema supply included: Skema was awarded the contract for the design, engineering and manufacturing of 7 Low Voltage Switchboards and the Integrated Protection and Control System. >> Intelligent Motor Control Centers (69 columns, 377 drawers) >> Power Centers (27 columns) >> 3 Remote Terminal Units (RTUs) >> Integrated Protection and Control System (IPCS) “Many thanks for all your good efforts in making this happen. Skema’s proactive approach towards resolving and expediting really helps us and is very much appreciated by the Project.” Senior Expeditor On 22nd February 2012 Skema was invited to attend the Jasmine Supplier Awards for Excellence Ceremony, as a Nominee among the 15 excellent suppliers (out of the over 160 suppliers for the project) to the ConocoPhillips Jasmine development project. ConocoPhillips launched the Jasmine Supplier Awards for Excellence Programme in January 2011, with the aim to develop and recognize the Project’s principal suppliers through setting key metrics, evaluating business performance, identifying gaps and opportunities for improvement and recognizing and rewarding excellence. Being one of the best suppliers to ConocoPhillips is a matter of pride for Skema, whose nomination in the “Planning and Delivery” category was motivated by ConocoPhillips as follows: “Skema was a bright star in Jasmine’s electrical success. Their embrace of SAP’s ERP prior to Jasmine was evident in their planning, scheduling, detailed design, material availability, along with the LV Switchgear’s and MCC’s fabrication.” 31 j jasmine 30 solutions delivered SKEMA NOMINEE FOR THE AWARD FOR EXCELLENCE 32 33 j j jasmine jasmine karachaganak / Kazakhstan kazakhstan Kyrgyzstan Caspian Sea Uzbekistan karachaganak, The enormous gas field - The Karachaganak field, located onshore in western Kazakhstan (around 150 km to the east of the city of Uralsk), was discovered in 1979 and is one of the largest gas condensate fields in the world. Covering an area of 280 km2 and holding over 1.2 billion tons of oil and condensate and 1.35 trillion m3 of gas, the giant Karachaganak field produces an average of 150,000 barrels of condensate and 20 million m3 of gas per day. The expansion of the field has involved an investment of over $ 5.5 billion. epc contractor: JV Bechtel Ltd and Snamprogetti UK END USER: Karachaganak Petroleum Operating B.V.(KPO) / A consortium of: british gas, eni, lukoil, chevron SOLUTIONS DELIVERED 34 karachaganak k Skema supplied for the project: >> 9 Packaged Substations, complete with MV switchboards, transformers, 400 V switchgear/ Motor Control Centers, Battery and Battery Charger, Distribution Boards, HVAC System, Fire and Safety and the Lighting System >> LV Switchgear and Motor Control Centers (20 Switchboards, more than 250 Panels and 1300 Motor Starters) “Skema provided an excellent service in assisting with the commissioning of their supplied equipment on site here in Karachaganak. I can say that the work completed was carried out in a timely manner, to high standards, often in arduous conditions. The working relationship that developed with Skema personnel was excellent, as they were always prepared to go the extra mile to resolve any anomaly that arose on site and meet the end user’s expectations.” Electrical Commissioning Engineer, KPO Key features of Skema’s Intelligent Motor Control Centers are its drawers and incomers equipped with microprocessor relays. In addition Skema developed the Electrical Control System for the Karachaganak project in KPC and Unit 2. Each station is equipped with a Remote Terminal Unit (RTU), which col- lects data from the switchboards and interfaces with DMS and DCS. The accumulated data is then made available for visualization on EWS and on plan DMS. Skema has supplied a total of nine Packaged Substations for Early Works, two 6 kV Packaged Substations for Unit 3, a Packaged Substation for a Flash Gas Compressor Control Room, and a series of eight Packaged Substations for a Waste Management Complex. As for the switchgear, Skema supplied the Karachaganak project alone with some 123 MV panels, 622 LV panels, 38 RTUs, 24 110V DC panels, more than 250 relays, and 2,559 drawers. 35 k karachaganak MV AND LV SWITCHGEAR WASTE MANAGEMENT COMPLEX END USER: Karachaganak Petroleum Operating B.V. (KPO) / A consortium of: british gas, eni, lukoil, chevron karachaganak k EPC contractors: Petrofac END USER: Karachaganak Petroleum Operating B.V.(KPO) / A consortium of: british gas, eni, lukoil, chevron The Karachaganak 4th Stabilization & Sweetening Train Project aims to increase the capacity of the existing Karachaganak Processing Complex (KPC) facilities through the addition of a fourth train. Solutions delivered Skema was responsible for the design, manufacturing, supply, inspection, testing, export packing The transformers and substations were housed within a two-hour fire-rated enclosure, and were supplied as complete pre-wired and assembled modular self-contained units, installed on concrete leg foundations 1,400 mm above ground, and equipped with bolt-on stairs and access platforms. The transformers package included two 6/0.72 kV, 3 MVA each, to allow maintenance of one unit while the oth- and supervision of testing and commissioning of: >> Power Centers (12 columns) >> Intelligent LV Switchgear/Motor Control Centers (78 columns, 266 drawers) >> Bus Ducts >> RTUs (6 columns) >> Integrated Protection and Control System 37 k karachaganak 36 4th stabiliZation & sweetening train As part of its long-term commitment to health, safety and environmental protection, the KPO consortium has completed construction of a new Eco-Centre (Waste Management Complex), which houses stateof-the-art technology and enables the recycling, treatment and safe disposal of drilling fluids and wastes. Solutions delivered Skema was awarded the contract for the design, engineering, manufacturing, inspection and testing of: >> 1 Transformer Packaged Substation >> 1 LV Switchgear Packaged Substation er is in service, as well as power and auxiliary cables for interconnection to the packaged LV substation. The LV substation package included a TCC 690V switchboard, two 690/420 V, 400 kVA each, transformers and a TCC 400 V switchgear. Kashagan / Kazakhstan kazakhstan Kyrgyzstan Caspian Sea Uzbekistan THE GIANT KASHAGAN - Kashagan, 80 km south-east of Atyrau, in the North Caspian Sea, is the largest oil field discovered over the last thirty years worldwide and extends over a surface area of approximately 75 km by 45 km. Its development represents one of the greatest challenges faced by the petroleum industry, given the deep, high-pressure reservoir, the high sulfur content, the shallow waters that freeze in winter and the marked shifts in temperature (from -30°C to +40°C). The potential daily average production amounts to 1.2 million barrels, with estimated reserves of 38 billion barrels. The Kashagan Project consists of two developments: Offshore Complex (artificial islands in the Caspian Sea) and Onshore Complex (Bolashak onshore processing facility). end user: Agip KCO / A consortium of: ConocoPhillips - ENI - ExxonMobil - Inpex - KazMunaIGaS - Shell - Total kashagan k SOLUTIONS DELIVERED Skema supplied for the Kashagan project Local Equipment Rooms, Medium and Low Voltage complete Packaged Substations, Process and Utilities Buildings, all LV Switchgear/Intelligent Power Motor Control Centers, RTUs, LMS/ DMS (onshore) and the Integrated Protection and Control System. “Company congratulates Contractor with the big achievement of meeting the requested delivery date, and thanks for its good work and cooperation.” Contract Holder 510 km 50,000 m3 total area of onshore operations = the size of Amsterdam total length of pipelines = almost the distance between New York and Montreal volume of concrete structures used = the size of the landmark 88-floor building of Petronas Towers in Kuala Lumpur, Malaysia 120,000 tons 5,000 km total weight of steel items and structures used = 1.5 times the weight of the Golden Gate Bridge in San Francisco total length of electric and instrumentation cables = about the distance between Almaty and Rome 39 k kashagan 38 190 km2 mv/lv packaged substations onshore Skema was in charge of the engineering, manufacturing, testing and commissioning of 9 MV/LV Packaged Substations. The Substations feed the infrastructure utilities for the Kashagan field and are part of the Early Works of the Kashagan Experimental Programme. “The products supplied by Skema were able to meet the strict technical standards of the job. Skema’s project team showed competent technical skills and the ability to work and support us at all stages of the project from engineering to commissioning.” Each Substation was equipped with: >> >> >> >> >> >> >> >> 10 kV Switchboards PMCC LV Switchgear Distribution boards Distribution transformers AC and DC UPS batteries Alarm and communication RTUs HVAC system Electrical Control System Project Electrical and Instrumentation Engineer 40 Solutions delivered k kashagan EPC Contract for 13 Offshore Utilities Buildings for Island D. frame agreement onshore / offshore Skema was awarded the frame agreement for the provision of all intelligent LV Switchgear/Intelligent Power Motor Control Centers, RTUs, the Integrated Protection and Control System for both offshore and onshore facilities and LMS / DMS (onshore). 5.5 km = the total length of columns supplied by Skema. EPC contractors: ABB Ps&s - Aker Kvaerner Bateman - Consafe - Fores GE oil & gas np – Gusto MSC Kazstroyservice - Litwin Mss - Punji Lloyd saipem - SBM - Siemens turbomachinery Rosetti Marino - Renco Tekfen - Zafer KEY SUCCESS FACTORS: >> Maximum local content achievable for Modular Substations > > Project delivered on time and without any punch list >> Complete project cycle managed by internal resources: from feasibility studies to the design of structures, electrical HVAC and safety systems, procurement, construction, assembly, pre-commissioning, start-up, commissioning, load out activities and on site supervision and installation 41 k kashagan offshore buIldings / in couNtry end user: Agip KCO / A consortium of: ConocoPhillips - ENI ExxonMobil - Inpex - KazMunaIGaS - Shell - Total Skema was awarded the EPC Contract for the provision of 18 Local Equipment Rooms (LERs). The scope of work includes the coordination and monitoring of every aspect of the project, from feasibility studies and cost/performance optimization to the design of structural, electrical, HVAC and safety systems, procurement, construction, assembly, works, fire-detection and fire-fighting systems and telecoms equipment. Each LER has an average length of 50 m and weight of 1000 t. The LERs were built in Ravenna, shipped to the Caspian Sea on barges and located on artificial islands in the Caspian Sea. SIZE OF THE LERs SCOPE OF WORK DIMENSIONS (m) WEIGHT (t) COMPLEX A LER 36.3 x 15.3 x 8.3 800 DRILLING ISLAND MAIN LER 55.2 x 15.3 x 8.3 1,050 DRILLING ISLAND HVAC LER 35.9 x 11.3 x 8.3 500 PSA1 MAIN LER 48.6 x 15.3 x 8.3 1,000 PSA1 HVAC LER 42.6 x 15.3 x 8.3 800 RISER ISLAND MAIN LER 48.6 x 15.3 x 8.3 1,000 RISER ISLAND HVAC LER 24.6 x 15.3 x 8.3 500 PSA2 MAIN LER 48.6 x 15.3 x 8.3 1,000 43 42 kashagan k commissioning, final inspection and supervision of on-site installation. The LERs are pre-fabricated steelstructure modules, which have the following systems installed: Medium and Low Voltage Switchboards, Transformers, Distribution Switchboards, UPSs and relevant Batteries, supervision and control equipment, HVAC with provisions for explosive/dangerous gas injections, electrical net- “First of all congratulations at completing barge 3 and 4 precommissioning. Your personnel and the support offered to them during their stay here was first class. All concerned were impressed – our subcontractors, our client and all.” Commissioning Superintendent PSA2 HVAC LER 42.6 x 15.3 x 8.3 800 PUA MAIN LER 57.5 x 15.3 x 8.3 1,150 PUA HVAC LER 43.7 x 15.3 x 8.3 850 LSA MAIN LER 42.6 x 15.3 x 8.3 800 LSA HVAC LER 42.6 x 15.3 x 8.3 800 LSA IBEEV LER 33.8 x 17.6 x 11.8 800 DRILLING ISLAND EAST MAIN LER 66.5 x 15.2 x 8.3 1,105 DRILLING ISLAND EAST HVAC LER 48.5 x 15.2 x 8.4 947 PUA EMERGENCY DIESEL GENERATOR LER 35.9 x 15.3 x 8.3 500 6.0 x 4.0 x 4.0 20 COMPLEX A EMERGENCY DIESEL GENERATOR LER TOTAL 11,484 m2 14,422 tons k kashagan local equipment rooms offshore 44 45 k k kashagan kashagan eskene west rail / onshore 18 LERs 13 Pubs 5.5 km Offshore Offshore / Built in Country (Kazakhstan) The total length of columns supplied by Skema All PMCCs IPCS Frame Agreement for all LV Switchgear / Intelligent Power Motor Control Centers and RTUs / Onshore / Offshore Onshore / Offshore 46 kashagan k Early Works / Onshore 10 Pubs Offshore / Built in Italy EPC CONTRACTOR: WORLEYPARSONS END USER: AGIP KCO / A CONSORTIUM OF CONOCOPHILLIPS - ENI - EXXONMOBIL - INPEX - KAZMUNAIGAS SHELL - TOTAL 47 k LMS/DMS kashagan 9 Substations Eskene West Rail consists of three basic facilities linked by a common rail system that require upgrading works to accommodate the increased rail traffic from Rail Loading Facilities (RLF) and Marshalling Yard (MYD). Onshore solutions delivered Skema supply included: Skema was awarded the contract for the design, fabrication, supply and delivery of Medium and Low Voltage Switchgear, Motor Control Centers and RTUs. >> 10 kV Switchboard (37 columns) >> 6 Power Motor Control Centers (45 columns) >> 19 Motor Control Centers (123 columns) >> 8 RTUs (16 columns) >> 33 Distribution Boards >> 51 Junction Boxes ogd III / uae Iraq Iran Kuwait Qatar uae Saudi Arabia Oman Yemen The $ 1.5 billion Onshore Gas Development (OGD) III Project involves the expansion of the production capacity of a massive gas-processing plant in Habshan, approximately 130 km south-west of Abu Dhabi, in the United Arab Emirates. The Habshan complex is one of the largest gas-processing plants in the world. EPC contractor: Bechtel / end user: Gasco 48 ogd iii o Skema was awarded the contract for the supply of Intelligent Low Voltage Switchgear compliant with the most stringent requirements of the Oil & Gas industry, the internationally recognized Shell DEP. The supply included: >> 21 415 V Switchgear systems/ Motor Control Centers (378 columns, 1662 drawers) >> 14 RTUs >> Integrated Protection and Control System (IPCS). “I appreciate all aspects of Skema’s performance, and in particular: your team’s efforts in turning around accurate engineering documentation in a timely fashion, Skema’s proactiveness in dealing with third parties, Skema’s flexible and adaptable manufacturing approach to accommodate EBCL’s construction priorities, and Skema’s swift clear communication with the OGD III Project team and the overall quality of Skema’s work product. Skema’s approach to the OGD III project has been most professional at all times and its high caliber performance has been noted.” Project Director integrated protection and control system (IPCS) The IPCS is based on ICUs (Integrated Control Units) located in each substation, which communicate with the motor starters and the protection relays, making all the information available for the operator workstations and the redundant servers installed in the Main Control Room, and operate as a gateway with the DCS, which sends commands and receives feedback via the TCP/IP interface. The IPCS created for the Gasco OGD III project not only displays the status and alarms of all the components of the electrical network but also greatly assists the operators in maintaining the plant because it stores the parameter settings of all the control units (both motor managers and protection relays) and compiles the sequence of events and the disturbance waves recorded by the protection relays in case of faults. 49 o ogd iii solutions delivered Qafco 5-6 / QATAR Iran Iraq Kuwait qatar Saudi Arabia UAE Oman Yemen The Qatar Fertilizer Company (Qafco) site is located about 40 km south of Doha City and 7 km south of the residential area of Mesaieed. The project facilities include two ammonia plants with a total daily production capacity of 4,600 tons and a urea plant with a daily production capacity of 3,850 tons, along with other support utilities. With these huge production capacities, QAFCO is considered to be the largest ammonia and urea project anywhere in the world, and also the most investment-intensive. epc contractor: saipem / End User: Qafco solutions delivered 50 qafco 5-6 q Skema was awarded the contract for the design, manufacturing, inspection, testing and supervision of the on-site commissioning of highperformance, reliable, flexible solutions. The supply of Intelligent Low Voltage switchgear included: >> 5 Power Centers (193 columns) >> 29 Motor Control Centers (1,223 columns with 1,608 drawers) >> Distribution LV Switchboards (274 columns) >> 11 Interface Monitoring Systems (IMS) 1.5 km = the total length of PMCC columns supplied by Skema. The Intelligent Motor Control Centers were equipped with an on-board touchscreen operator interface to operate the switchboards and compile data on trends, alarms and event sequences. This operator interface acts as a gateway to the DCS (Distributed Control System) to allow the process control system to start/stop motors and record the activation of alarms. The PMCC switchboards were designed to prevent any risk of a short circuit and internal arc fault at 75 kA690 V for 0.3 seconds – to this end, they were fully type-tested by an independent laboratory. Watch the Video! 51 q qafco 5-6 INTELLIGENT PMCCs 52 53 q q qafco qafco tengiz / Kazakhstan kazakhstan Kyrgyzstan Caspian Sea Uzbekistan Tengiz field (Tengiz is Kazakh for “sea”), in western Kazakhstan, is located in the low-lying wetlands along the northeast shores of the Caspian Sea and is one of the biggest oil fields in the world. Discovered in 1979, Tengiz contains 24 billion barrels of high quality oil and six to nine billion barrels (1 km³ and 1.4 km³) of recoverable oil. It is deep, having a target depth of 4,500 m. It also contains significant gas reserves (18,000 billion m3). The processing plant is made up of building blocks. END USER: Tengizchevroil / a consortium of: chevron, exxonmobil, lukarco 54 TENGIZ T Skema supplied its products and solutions for the Tengiz field, and in particular for the Central Power Station, the Central Distribution Substation, for KTL 1 and KTL 2 Load Relief Substations, Sulfur Forming, Train 2.3 Power Station Upgrade, Plant Nitrogen System and Kulsary Rip Sera Rail Yard. Skema supplied for the project: >> 10 MV Switchgear (83 sections) >> Intelligent Power Motor Control Centers Switchgear (140 columns, more than 759 drawers) >> Power Centers (43 columns) >> 4 Remote Terminal Units >> LV Distribution Panels (210 boards) “On behalf of TCO I would like to thank you for your professionalism in all kind of arrangements and communication, adherence to the original shipment dates and for high quality documentation.” Interface Coordinator The Field Substation Replacement Project aims to upgrade and rationalize the existing Field Power Supply System by replacing 6 existing field substations with 3 new substations. SOLUTIONS DELIVERED Skema was awarded the contract for the design, manufacturing, inspection and testing of HV switchboards and Remote Terminal Units (RTUs): >> 3 35 kV, 1250 A, gas insulated switchboards (26 columns) >> 3 6 kV, 1250 A, 20 kA, 1 sec., air insulated switchgear units (74 Columns) >> 4 redundant RTUs (10 columns) and Electrical Control Systems based on PLC >> Switchgear continuous thermal monitoring solution >> Arc fault protection system 55 T TENGIZ SOLUTIONS DELIVERED FIELD SUBSTATION REPLACEMENT The Integrated Protection and Control System (IPCS) for the project was designed to monitor and control HV and LV switchgear located inside the different packaged Substations (North, South and West). Each packaged substation is equipped with a redundant Interface Control tended substations (both through cabled alarms and alarms generated by the video cameras registering unexpected movements), and to communicate with the operators, giving them directions. Data are recorded and are available in real time for an Asset Lifetime Management System (maintenance and energy efficiency management of the plant and its components). the main electrical panels supplied. This solution provides numerous tangible benefits over traditional periodic scans, including greatly increased levels of safety and integrity protection and reliability assurance throughout the lifecycle of the electrical panels. The integrity protection was further enhanced by utilising a Load-Map™ software module which enables TCO to dynamically adjust the thermal alarm combination with other modules, like the REF relays. The REA arc fault protection system function is based on detecting the intense light of an electric arc, alone or on a detection of light and simultaneous phase or neutral overcurrent. On detection of an arc fault, the REA protection system delivers trip commands in less than 2.5 ms to all circuit breakers that feed the fault zone. Furthermore, the system opera- 56 TENGIZ T Unit (ICU) controlling 33 kV and 6.6 kV Switchgear with protocol IEC61850, Low Voltage Switchgear and other utilities (HVAC, UPS, F&G) via Modbus and hardwired interfaces. A SCADA system is installed in the Field Control Room to control and supervise the electrical network. Every substation is also equipped with 4 video cameras and a vocal communication system. This allows to control the unat- SWITCHGEAR CONTINUOUS THERMAL MONITORING SOLUTION Skema provided TCO with Exertherm™, a continuous thermal monitoring solution which allows to monitor, in real time, the thermal health and status of key bus bar joints and critical cable connections. This is achieved by installing small plastic, non-contact, non-powered, lifetime calibrated infrared and cable sensors within tion indicators help localizing faults by selectively guiding the maintenance staff to the fault zone, that was identified by the arc fault protection system. The REA module supplied for the project features: two high-speed, galvanically isolated, insulated gate bipolar transistor (IGBT) outputs (HSO1 and HSO2) for CB tripping purposes; it offers one heavy-duty relay output (TRIP3) to be used, for example, as a circuit-breaker failure protection (CBFP) output for an upstream circuit-breaker, or as an alarm output; it features an adjustable three-phase overcurrent or two-phase and neutral overcurrent condition monitoring function, which enhances the reliability of the arc fault detection by eliminating unwanted CB tripping caused by light not related to any arc fault, e.g. flash light used in photography. levels applicable to the load on the circuit being monitored, which provided TCO with a level of integrity protection even at lower utilized load levels. ARC FAULT PROTECTION SYSTEM The 6 kV switchgear supplied for the project has been equipped with a REA arc fault protection system, which can operate as a stand-alone device or in “Finally a word of thanks to you and your team for an excellent performance and outstanding customer service on our project.” E/I Project Engineer 57 T TENGIZ INTEGRATED PROTECTION AND CONTROL SYSTEM © Skema Milan - Italy www.skemaq.it