The Essentials of

Life Science Research

Globally Delivered™

The Importance of Proficiency

Testing Programs in the Food

Industry

In the food industry, ensuring the nutritional content, the absence of microbiological or

chemical contaminants, and the authenticity of consumable commodities from farm to fork

is an important part in protecting the quality and safety of food products. To meet this need,

food manufacturers often rely on food testing laboratories to examine product samples using

the latest industry regulatory standards. However, though a food testing laboratory may have

validated methods, is accredited, and employs good internal quality control procedures, how

can food manufacturers rest assured that the analytical results they received are accurate? The

answer is simple – proficiency testing.

White

Paper

Cara N. Wilder, Ph.D

What is Proficiency Testing?

Proficiency testing programs, also referred to as interlaboratory

comparisons, are statistical quality assurance programs that enable

laboratories to assess their analytical performance in conducting

routine test methods for a specific homogenous analyte within a

sample matrix as compared to other laboratories throughout the

world1. In a well-designed proficiency testing program, the analyte’s

reference value will be unknown to the participating laboratory

and will have been determined by an accredited program provider

with appropriate traceability to the International System of Units.

Participation in this form of testing provides an external, objective

means of assessing the quality, accuracy, and validity of analytical data

produced, regardless of which laboratory conducted the analyses2,3.

In turn, this provides confidence in the competence of laboratory

personnel as well as the test methods, equipment, and reagents

used, and can identify nonconformities within a laboratory’s quality

system, allowing for process improvements before a customer’s

results are affected.

Proficiency testing programs typically operate on a regular basis,

ranging from two to six rounds per year that last eight weeks

following the distribution of test materials. For any given analyte

or round, the program structure will include the circulation of

homogenous samples by a coordinator, analysis of the samples by

participants using routine test methods employed by that laboratory,

and an assessment of the results2,4.

Depending on the testing need, proficiency testing programs may

be chemical or microbiological in nature and will vary in the type of

matrix used. In the food industry, this can include program rounds

that analyze a laboratory’s ability to detect pathogens, indicator

organisms, spoilage organisms, nutritional content, pesticides,

product authenticity, proximates, minerals, or fat quality in specific

food or beverage matrices. Wherever practical, test materials are

provided in a matrix that is as similar as possible to samples routinely

used by participating laboratories. However, in some cases, test

materials are supplied as concentrated spiking solutions in order to

achieve the required degree of stability and homogeneity.

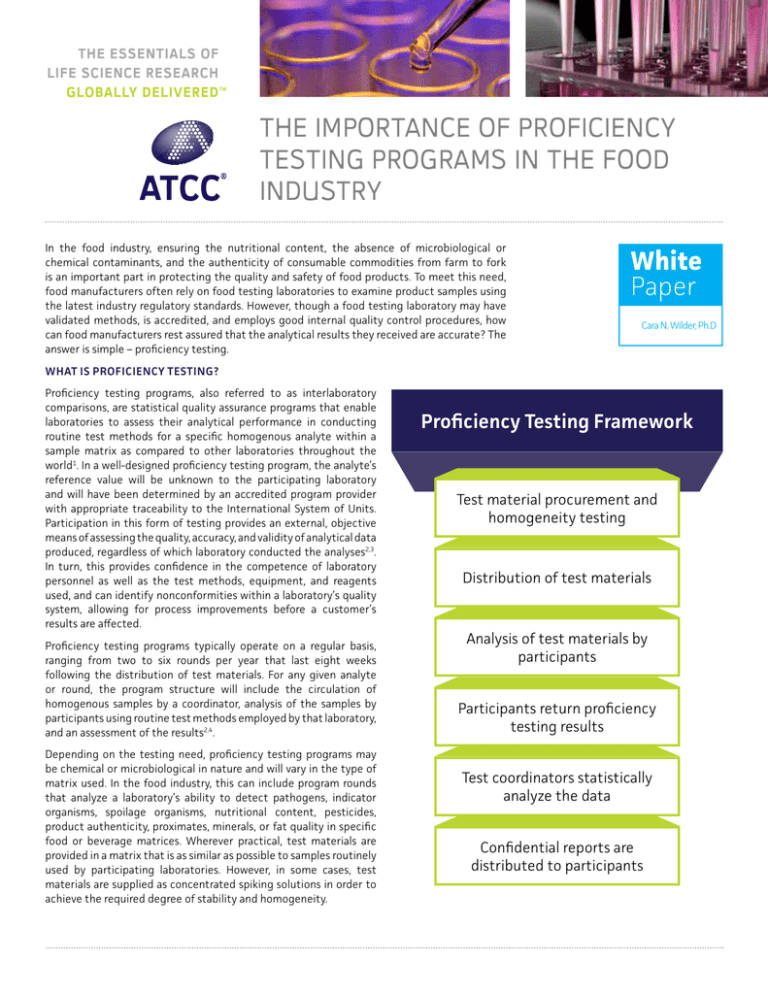

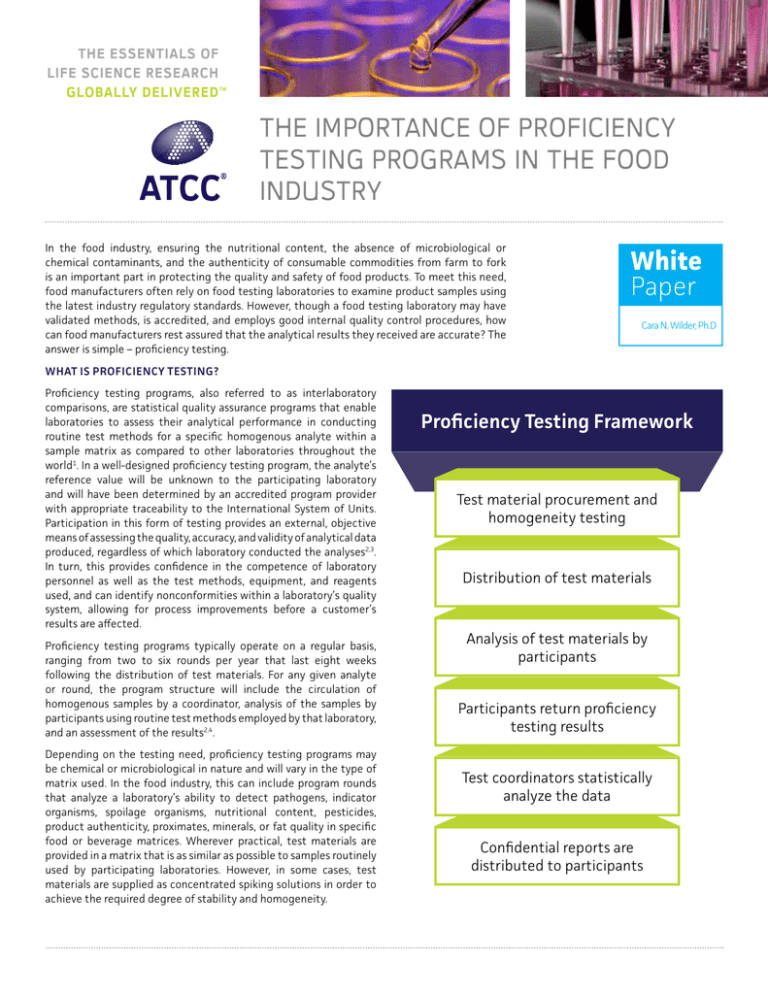

Proficiency Testing Framework

Test material procurement and

homogeneity testing

Distribution of test materials

Analysis of test materials by

participants

Participants return proficiency

testing results

Test coordinators statistically

analyze the data

Confidential reports are

distributed to participants

What are the Benefits of Proficiency Testing?

There are a number of benefits associated with participating in proficiency testing.

For ISO/IEC 17025:2005 accredited laboratories, proficiency testing must be

performed in order to demonstrate compliance with accreditation requirements

regarding the use of “quality control procedures for monitoring the validity of

tests and calibrations undertaken”5. Here, unless otherwise specified, laboratories

must participate in at least two proficiency testing activities per year, every year, to

maintain accreditation.

In addition to regulatory compliance, participating in a proficiency testing program

can help analyze the reliability of a laboratory’s analytical protocols, laboratory

personnel, and equipment. For laboratories that obtain ideal proficiency testing

results, it can foster confidence in the effectiveness of the measurement procedures

and associated materials employed, demonstrate competence of the analysts,

and provide customer assurance regarding the laboratory’s performance in the

accredited test and calibration results. Additionally, proficiency testing provides

an educational aspect in allowing laboratories to remain up-to-date with new and

emerging microorganisms, and challenges established procedures with difficult or

atypical organisms or chemical substances. In contrast, failure of a proficiency testing

program can help identify nonconformities within a laboratory’s quality system,

indicating the need for further personnel training or understanding of legislations

or guidelines; routine maintenance, calibration, or replacement of equipment; or,

the need for the harmonization or modification of analytical procedures.

Monitoring and

improving

measurements

Developing

and training

analysts

Demonstrating

analytical

competence

Benefits of

Proficiency

Testing

Validation of

methods and

instruments

Identifying

non-conformities

within a quality

system

Why is Proficiency Testing Important in the Food Industry?

In the food industry, ensuring the quality and safety of consumable products is

a matter of public health. In the United States alone, foodborne illnesses are

estimated to affect tens of millions of people and kill thousands every year6. These

outbreaks are typically associated with a range of debilitating symptoms that are

dependent on the nature of the contaminant. Of those affected by microbiologicalbased foodborne illnesses, many tend to suffer from severe diarrhea or other

incapacitating infections such as meningitis. In contrast, those affected by chemical

contamination may experience acute food poisoning, allergic reactions, or could

develop long-term diseases such as cancer7,8. All together, these food-associated

illnesses may lead to long-lasting disability or death, and contribute to significant

strain on the healthcare system.

In addition to causing serious health concerns, foodborne illnesses annually pose a

multi-billion dollar economic burden associated with productivity losses, product

recalls, disease surveillance, outbreak response, and diminished international

Salmonella is one of the leading causes of foodborne disease,

trade6,7,9. For food manufacturers, product recalls not only hurt brand reputation,

affecting tens of millions of people worldwide every year.

but can also result in lost sales, government sanctions, and lawsuits. Additionally,

product recalls may cause company shareholders and customers to lose confidence in the brand, potentially resulting in longer-term effects

such as plunging stock prices.

To ensure product safety and quality, food manufacturers frequently rely on food testing laboratories to examine product samples for

microbial and chemical contaminants using applicable methods that are in compliance with regulatory requirements. However, since many

food products are complex systems, it can be challenging to identify and accurately quantify biological and chemical adulterants, and invalid

or false-negative laboratory results may contribute to consumer illness or result in the improper withdrawal of a product. For example, if a

laboratory’s testing methods were inaccurate or not sensitive enough, a sample may be incorrectly perceived as being free of hazardous

chemicals or pathogenic microorganisms. In turn, the product in question would go to the market and be subsequently purchased and

consumed, potentially resulting in serious illness. In contrast, inaccurately reporting the presence of a pathogen in a sample that is safe

for consumption may result in the incorrect withdrawal of a product or inappropriate follow-up treatment, leading to product recalls and

extensive monetary losses.

Participation in proficiency testing allows food testing laboratories to ensure that they are meeting the needs of food manufacturers and

consumers by routinely assessing the quality and accuracy of the testing methods, equipment, and personnel employed. Here, food testing

laboratories can compare their performance against other similar laboratories and objectively determine the extent to which they were able

to carry out an accurate analysis within the limits set for a particular reference method. Regular participation in this form of testing will help

identify problems within the testing laboratory before they affect the quality or safety of products, thus essentially saving time, money, and

lives.

2

Order online at www.atcc.org, call 800.638.6597, 703.365.2700, or contact your local distributor.

How Do You Choose a Food or Beverage Proficiency Testing Program?

Currently, there are a number of proficiency testing programs available for the

microbiological and chemical analysis of food, animal feed, water, and beverages.

These programs can range in the type of analyte used, the sample matrix, and

whether the program is qualitative or quantitative. To meet the analytical needs

of a laboratory, it is recommended that program rounds are carefully selected to

ensure that test materials are as similar as possible to samples routinely used.

Though, in some cases, this may not be possible and concentrated spiking solutions

may need to be acquired. Hence, many proficiency testing program providers

continue to improve current programs and introduce new programs/test materials

when appropriate.

Regardless of the proficiency testing program being used, it is important to also

consider where the program was developed. Preferentially, it is recommended that

programs are purchased from an experienced, accredited provider with professional,

technical, and scientific expertise. Current international standards relevant to proficiency testing include ISO/IEC 17043:2010, “Conformity

assessment – General requirements for proficiency testing”, and ISO 13528:2005, “Statistical methods for use in proficiency testing for

interlaboratory comparisons”10,11. Accredited proficiency testing program providers routinely perform quality control analyses for each

test material to ensure a degree of natural homogeneity, stability of the test material, and the use of process control during production.

Additionally, participants can be assured that the samples are stored and transported under ideal conditions, keeping sample integrity intact.

As part of its ongoing mission to acquire, authenticate, preserve, develop, standardize, and distribute biological materials, ATCC has partnered

with LGC, an international leader in laboratory services, measurement standards, and reference materials, to supply a broad range of both

microbiological and chemical proficiency testing programs to customers in the food industry within the United States. This collaboration will

leverage proficiency testing samples derived from high quality ATCC materials that are developed by ISO/IEC 17043:2010 accredited LGC

facilities with a timely and cost effective reporting capability. ATCC currently offers a variety of proficiency testing programs for the food

sector, including food microbiology (QMS), food chemistry (QFCS), meat and fish (QMAS), water microbiology (QWAS), beverages (QBS), sugar

(SUPS), dairy chemistry (QDCS), chocolate (QCS), gelatin (QGS), and animal feed (AFPS).

Conclusion

Proficiency testing provides an external quality assessment for food testing laboratories to evaluate their performance against preestablished criteria by means of interlaboratory comparisons. Participation in these programs provides laboratories with a means to assess

the quality and accuracy of their results as compared to their peers over time, providing an independent tool for monitoring and verifying

the effectiveness of methods employed in the laboratory. For the food industry, proficiency testing examines the analytical competence of

food testing laboratories, helping to ensure that the laboratory is able to effectively detect and/or quantify chemical and microbiological

contaminants within food products before they go to market and are consumed. Overall, this form of testing helps to minimize the effects

associated with food contamination, including product recalls, illness and associated healthcare expense, government sanctions, lawsuits,

and significant economic expenses.

Order online at www.atcc.org, call 800.638.6597, 703.365.2700, or contact your local distributor.

3

References

1. Vander Heyden Y, Smeyers-Verbeke J. Set-up and evaluation of interlaboratory studies. Journal of Chromatography A 1158: 158-167, 2007.

2. Wood R. in Auditing in the Food Industry: From Safety and Quality to Environmental and Other Audits (eds M Dillon & C Griffith) Ch. 8, Woodhead

Publishing Series in Food Science, Technology and Nutrition, 2001.

3. Thompson M. What is proficiency testing? Guide for end-users of chemical data. AMCTB, 2005.

4. Wood, R., Wallin, H. & Nilsson, A. Quality in the Food Analysis Laboratory. (Royal Society of Chemistry, 1998).

5. ISO/IEC 17025:2005 - General requirements for the competence of testing and calibration laboratories, 2010.

6. CDC. Estimates of Foodborne Illness in the United States, <http://www.cdc.gov/foodborneburden/>, 2014.

7. WHO. Food Safety - Fact sheet N°399, <http://www.who.int/mediacentre/factsheets/fs399/en/>, 2014.

8. Samanidou V, Nisyriou S. Multi-residue methods for confirmatory determination of antibiotics in milk. Journal of separation science 31:

2068-2090, 2008.

9. Scharff RL. Economic burden from health losses due to foodborne illness in the United States. Journal of food protection 75: 123-131, 2012.

10. ISO/IEC 17043:2010 - Conformity assessment – General requirements for proficiency testing, 2010.

11. ISO 13528:2005 - Statistical methods for use in proficiency testing by inter-laboratory comparisons, 2005.

PHONE

800.638.6597

703.365.2700

EMAIL

PTPrograms@atcc.org

WEB

www.atcc.org

PTWP-0215-01

© 2015 American Type Culture Collection. The ATCC trademark and trade name, and any other trademarks listed in this

publication are trademarks owned by the American Type Culture Collection unless indicated otherwise. © LGC Limited,

2015. All rights reserved

10801 University Blvd.

Manassas, VA 20110

These products are for laboratory use only. Not for human or diagnostic use. ATCC products may not be resold, modified for

resale, used to provide commercial services or to manufacture commercial products without prior ATCC written approval.