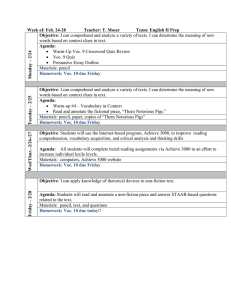

product specification 1-1 - Anti

advertisement

PRODUCT SPECIFICATION 2-4A ® A-H ARIDSIL VOC Economical, Water Repelling Protection Sealer For Concrete & Masonry Surfaces Rev. 06/15 ANTI-HYDRO INTERNATIONAL, INC. Concrete and Masonry Products and Problem Solving Worldwide Since 1904 45 River Road, Flemington, New Jersey 08822, Phone: (800) 777-1773, Fax: (908) 284-9464, Visit www.anti-hydro.com DESCRIPTION: SPECIFICATIONS: A-H ARIDSIL VOC is an environmentally friendly, water borne silane-siloxane based water repelling protection sealer that has been extensively used and recommended, over many decades, for concrete and masonry surfaces to prevent weathering, freeze– thaw damage and water and chloride ion penetration. A-H ARIDSIL VOC is especially effective on natural and synthetic stone, unglazed clay tile, brick, stucco and block, exposed aggregate, precasts, wood and masonry surfaces requiring a clear water repellent material. Complies with AIM VOC Regulations. All surfaces requiring water repelling protection sealer, as indicated on plans and specification, shall be treated with A-H ARIDSIL VOC, as manufactured by Anti-Hydro International, Inc., in strict accordance with manufacturer’s specifications. Refer to our Waterproofing & Industrial Floor Details. <-(click me) A-H ARIDSIL VOC is ready-to-use, water born penetrating silane- siloxane water repelling sealer that reacts with minerals within the substrate to create a hydrophobic barrier against water penetration. It is used on existing and freshly cured concrete and masonry surfaces to prevent weathering, freeze–thaw damage and water and chloride ion penetration. A-H ARIDSIL VOC is applied on all concrete and masonry surfaces above grade. A-H ARIDSIL VOC is an excellent protection from efflorescence and can be used over concrete and masonry prior to painting. A-H ARIDOX 20 VOC & 40 VOC <-(click me SPEC.2-9) are water borne water repellents with higher active ingredients and superior ® performance and may be substituted for A-H ARIDSIL VOC. A-H ARIDOX 40 & 40M <-(click me SPEC.2-7) are solvent borne, AIM VOC compliant water repellents with high solids and outstanding performance and may be substituted for A-H ARIDOX 20 VOC & 40 VOC <-(click me SPEC.2-9). SURFACE PREPARATIONS: All existing concrete and masonry surfaces shall be cleaned and free from laitance, mildew, sand, dust, dirt, oil, grease, chemical films and coatings and other contaminants, prior to application. Use power wash or shot blast, if necessary, to achieve the desired surface condition. Freshly placed concrete and masonry shall be properly finished, cured and cleaned as above if necessary. Curing methods must not inhibit the penetrations of A-H ARIDSIL VOC. Water, chemical, wet burlap or plastic sheet curing methods are recommended. Crack control, caulking, patching, and expansion joint sealant can be installed before application of the sealer. Prior to the application of sealer, allow at least 6 to 12 hours for curing, dependent on field conditions. APPLICATION: Always apply on a test patch to determine actual coverage rates and material compatibility. On new construction, for maximum durability and waterproofing, “ANTI-HYDRO” <-(click me Spec. 1-1) should be integrally added to the concrete and mortar during mixing. Do not apply in windy conditions. Do not apply when substrate and ambient temperatures are expected to be below 40°F (4°C) over a period of 12 hours and above 110°F during application. Typical Uses- It is recommended that surfaces to be treated shall be dry for maximum penetration of A-H ARIDSIL VOC. Slightly damp surface may be permissible, however, do not apply on water saturated surface or if standing water is visible on the surface. A-H ARIDSIL VOC is especially effective on • Brick • Stucco • Tilt-up • Pre-cast • Natural and Synthetic Stone • Block • Unglazed Clay Tile • Sand and Lime Stone • Chimneys • Exposed Aggregate • Masonry Requiring a Clear Water Repellant. Advantages• Water Borne Liquid • Non-Flammable • Non-Toxic • Odorless • Dries Clear • Requires Only Single Coat Coverage • Allows Treated Surface to Breathe (ASTM D-1653) • Solids Will Not Evaporate or Wash Away • Retards Efflorescence • Minimizes Freeze and Thaw Damage • Repels Water Borne Chemicals and Atmospheric Dirt • Environmentally Friendly • UV Stable • Paintable (ASTM D-3359) • Will Not Alter Texture or Appearance of Surface • Complies with AIM VOC Regulations. A-H ARIDSIL VOC is a single coat treatment. Apply A-H ARIDSIL VOC by brush, roller, or low pressure spray. Low pressure spray is recommended, where practical, for rapid and thorough application of A-H ARIDSIL VOC. Apply enough A-H ARIDSIL VOC to allow a slight rundown. Over- spray will not affect glass, metal, vinyl or painted area. Remove any over-spray immediately after application by wiping with a damp cloth. PRECAUTIONS: Application- Do not expose treated surfaces to water, excessive moisture or frost for at least 24 hours. Use clean tools and containers and clean them PRODUCT SPECIFICATION 2-4A A-H ARIDSIL VOC content of container. Do not dilute or add water or solvents of any kind. KEEP FROM FREEZING. Do not apply to new concrete with excessive water vapor as it will prevent adequate penetration. SafetyUse approved safety glasses, rubber gloves, and coveralls breathing mask, work boots, and ventilation methods. Do not drink, eat or smoke in the area. Protect animals, vegetation and food items. Refer to the product Material Safety Data Sheet (MSDS) for more details. StorageStore in a dry cool shaded area. Keep containers tightly closed. KEEP FROM FREEZING. KEEP AWAY FROM CHILDREN OR INCOMPATIBLE MATERIALS. MAINTENANCE: If treated surface becomes dirty, pressure wash with water or soapy water solution. Rinse with a clean water spray. All due diligence must be exercised to provide a regular and frequent maintenance plan to clean and protect the finished surface from severe or prolonged assault from chemical attack, abrasive attack or similar abuse. PACKAGING: 1-gallon, 5-gallon, or 55-gallon containers. Shelf life is approximately 1 year in original, unopened containers stored in a dry, cool area. SERVICES: Our technical staff is available to review product selection and detailing during the design stage, provide proper field guidance during the installation stage, evaluate concrete construction problems on-site and make recommendations. ESTIMATOR’S DATA GUIDE: Hard Brick (Fired): Soft Brick: Concrete: Block: Stucco: Pavers: Stone: Dryvit®: after application with water. Before using, thoroughly mix the 3.68-4.91 m²/liter (150-200 ft²/gallon) 1.96-2.45 m²/liter (80-100 ft²/gallon) 3.07-4.91 m²/liter (125-200 ft²/gallon) 1.84-2.45 m²/liter (75-100 ft²/gallon) 2.45-3.68 m²/liter (100-125 ft²/gallon) 3.07-4.29 m²/liter (125-175 ft²/gallon) 3.07-4.29 m²/liter (125-175 ft²/gallon) 3.07-4.91 m²/liter (125-200 ft²/gallon) Note- Coverage may vary depending upon the substrate conditions. Dryvit® is a registered trade name of Dryvit, Inc. WARRANTY: Anti-Hydro International, Inc. (Anti-Hydro) warrants its products to be free of manufacturing defects at the time of delivery to its customer and will, at its option, replace or refund the invoiced price of any materials proven to be defective. This limited warranty is in lieu of any other warranty or guarantee, expressed or implied, including warranties of merchantability and fitness for a particular purpose. Anti-Hydro disclaims liability for any incidental, consequential, or other damages, including but not limited to, loss of profits or damages to a structure or its contents, arising under any theory of law whatsoever beyond the invoiced price of the material to its customer. Page 2 of 2, Rev. 06/15 To the best of our knowledge, the information contained herein is accurate. However Anti-Hydro International, Inc. does not assume liability whatsoever for the accuracy or completeness of information contained herein. Final determination of suitability of any material is the sole responsibility of the user. All materials may present known or unknown hazards, please refer to the Material Safety Data Sheet (MSDS) for this product. This notification may not be detached from the specification. Any copying and redistribution of the specification shall also include copying and redistribution of this notice. Our sales persons or representatives, distributors and their personnel have no authority to change the recommendations contained herein.