2014-01-0305

Published 04/01/2014

Copyright © 2014 SAE International

doi:10.4271/2014-01-0305

saepcelec.saejournals.org

Application of Auto-Coding for Rapid and Efficient

Motor Control Development

James Walters, Cahya Harianto, Edward Kelly, and Tanto Sugiarto

Delphi Automotive

ABSTRACT

In hybrid and electric vehicles, the control of the electric motor is a critical component of vehicle functions such as motoring,

generating, engine-starting and braking. The efficient and accurate control of motor torque is performed by the motor

controller. It is a complex system incorporating sensor sampling, data processing, controls, diagnostics, and 3-phase Pulse

Width Modulation (PWM) generation which are executed in sub-100 uSec periods. Due to the fast execution rates, care must

be taken in the software coding phase to ensure the algorithms will not exceed the target processor's throughput capability.

Production motor control development often still follows the path of customer requirements, component requirements,

simulation, hand-code, and verification test due to the concern for processor throughput. In the case of vehicle system

controls, typically executed no faster than 5-10 mSec periods, auto-coding tools are used for algorithm development as well

as testing. The advantages of auto-coding to greatly speed the development process by linking the tools for simulation,

code generation and testing early in the development process as well as to more easily investigate performance issues late

in the process are well known. It is not uncommon, however, to lose coding efficiency with this approach. While the loss of

efficiency may be tolerable for slow periods, it is not acceptable at faster periods used in motor controls as it will preclude

the algorithms from executing or drive unnecessarily expensive solutions.

This paper will present an auto-coding process applied to motor controls, including full implementation on a production

permanent magnet motor drive. Best practices for implementing requirements into models that generate efficient code will be

highlighted. An overview of the issues associated with model-based documentation will also be covered. The use of test

vectors at the component, model and hardware-in-the-loop (HIL) level will be presented to show the benefits derived from

using a formalized process and the natural linkage to a SPICE® compliant process. A timing study performed during

dynamometer testing detailing the differences between the original hand-code and the model-based code will be presented.

CITATION: Walters, J., Harianto, C., Kelly, E., and Sugiarto, T., "Application of Auto-Coding for Rapid and Efficient Motor

Control Development," SAE Int. J. Passeng. Cars – Electron. Electr. Syst. 7(2):2014, doi:10.4271/2014-01-0305.

INTRODUCTION

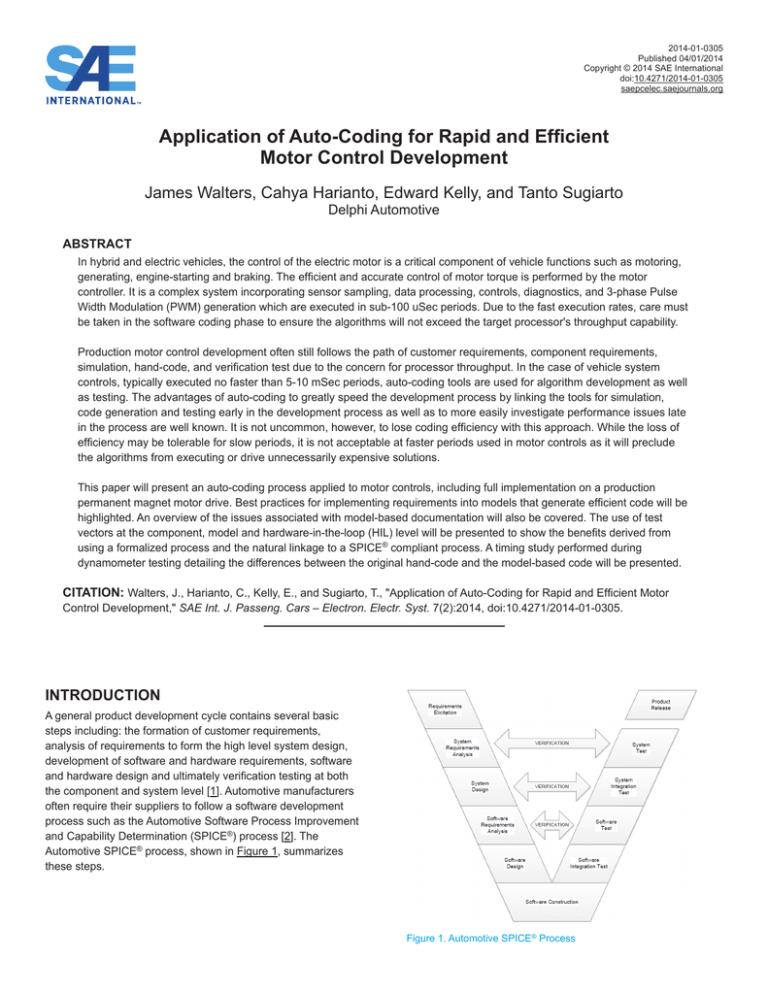

A general product development cycle contains several basic

steps including: the formation of customer requirements,

analysis of requirements to form the high level system design,

development of software and hardware requirements, software

and hardware design and ultimately verification testing at both

the component and system level [1]. Automotive manufacturers

often require their suppliers to follow a software development

process such as the Automotive Software Process Improvement

and Capability Determination (SPICE®) process [2]. The

Automotive SPICE® process, shown in Figure 1, summarizes

these steps.

Figure 1. Automotive SPICE® Process

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

In these steps, there are numerous simulations performed to

verify the system goals will be met by the design. From the

capturing of requirements to the creation of software, it is

desired to directly use the simulations that have been performed

so as not to repeat the effort and potentially introduce errors. In

addition, it is desired that the simulation model accurately

reflects the implementation as it will greatly aid in any

subsequent problem resolution.

The Automotive SPICE® Process recognizes that engineering

development will need to incorporate the contributions from a

variety of engineers including systems, function developers,

software, and test engineers. What is needed is a tool and

methodology that can directly support the translation of the

system and component designs, often simulated early in the

process, efficiently and accurately into an implementation that

can be verified and released quickly. Auto-coding is a tool that

facilitates development by translating simulations, performed in

the System Design step, into the final software implementation

[3]. It has also been used in the last decade to implement many

functions in the vehicle [4] - [6].

evaluated not only for accuracy to requirements, but also for

efficient code generation. The benefits of this approach are

substantial as the simulation tools can now be used to verify

compliance to system requirements and thus allow porting

concepts from simulation directly onto hardware. There are also

other inherent benefits as the already tested concepts are now

easily transferable between different projects and production

hardware can now be utilized as a development platform.

Motor Control Background

In a hybrid vehicle, the motor controller is responsible for the

efficient and accurate production of torque. This torque may be

used to perform a variety of tasks including motoring, generating,

speed regulation, and/or dc voltage regulation, depending upon

the application. An overview of an electric machine drive system

is shown in Figure 2. The input to the system is a command that

is typically obtained from a Hybrid Control Module (HCM) via

communication lines and the outputs are 3-phase voltages

applied to the machine. Typical components of the motor drive

system include: the battery, motor controller, sensors for current,

temperature and position, inverter and motor.

Although auto-coding offers considerable advantages for

development, many of the implemented designs have been for

relatively slow loop control tasks (5-10 mSec or greater period).

Ironically, complicated time-critical components which are

mostly likely to be simulated are not as commonly auto-coded,

thus losing a potential resource saving opportunity. This is due

to the concerns that the auto-coding process may have

additional overhead in algorithm execution causing throughput

issues in the application.

It should be noted that there are Rapid Controls Prototyping

(RCP) tools that allow for quick transitions from a model-based

/ simulation environment to concept testing [7]. RCP does

eliminate the need for the manual hand-coding step when

transitioning from the simulation model to the implementation,

which requires additional effort and is prone to errors; however,

this process involves extra hardware. The RCP approach,

which can be extremely useful for concept testing, is inherently

different though since the goal is concept development and

evaluation rather than efficient code generation in a production

environment.

This paper focuses on the development of an Automotive

SPICE® compliant process using auto-coding techniques for the

torque control of a permanent magnet synchronous machine

(PMSM). By appropriately defining a process and associated

design environment, it will be shown how to directly go from

simulation to implementation for a complicated system involving

many contributors and to naturally perform both system and

software tests in an automated fashion. The process to actually

implement a design in this fashion is non-trivial and necessitates

a requirements focused approach with the implementation being

Figure 2. PMSM Drive System

As shown in Figure 3, the main components in the inverter are

the 3-phase bridge which receives 6 gate signals from the

motor controller and the DC bulk capacitor. The three legs of

the inverter are connected to the electric machine. For many

applications in hybrid and electric vehicles, the PMSM has

emerged as the preferred motor technology, though induction

motors are commonly used as well [8, 9].

Figure 3. 3-Phase Bridge

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

Figure 4. Torque Control Overview

From a vehicle driveline perspective, torque response is needed

within a 30-50 mSec range in order to satisfy performance

requirements for cranking, torque assist, generating, and

braking. In order to create torque that is impervious to voltage or

speed disturbances, it is necessary to control currents in the

machine at a much faster rate, however. Vector control

techniques are commonly employed to perform this task [10]. For

a variety of reasons including motor time constants, the

maximum fundamental frequency in the machine (1000-1400 Hz)

and limiting DC capacitor voltage ripple, it is necessary to run

current control loop rates of approximately 100 uSec. The

sampling of the inputs, current and position, calculation of current

commands, control of current, and the associated transformation

pairs for vector control as well as the center-based PWM

generation must all be performed at this rate of 100 uSec.

The regulation process can be described in Figure 4. Therein,

the commands to / from the controller are denoted with the

starred quantities (e.g., Te* / ωr* denote the commanded torque

/ speed).

In addition to the motor control functions, the protection of the

inverter has to be considered. The diagnostic protection needs

to respond quickly to critical fault conditions (e.g., shorted

devices, loss of current control, etc.) and will require

functionality in the 100 uSec loop. Finally, sufficient throughput

must be available to ensure that slower loops (1, 5 and 10

mSec) have adequate time to execute.

As can be observed, the torque control of an electric machine

is inherently a challenging process. Not only does the control

process require fast data sampling, the execution of the current

control to generate the torque on the machine requires fast and

precise timing. Although auto-coding the PMSM control

algorithm can provide great benefits (e.g., faster and more

efficient development process and quick transitions from

simulation to final product implementation), care must be taken

in this approach so that the resulting code is efficient and does

not consume excessive throughput on the microprocessor.

AUTO-CODING TOOL SELECTION

Conceptually, a simulation model represents the programming

language and an auto-coder is effectively the compiler. The

goal is to select a toolset that enables the transfer of the

‘coding’ responsibility from the software engineer to the actual

function developers. This step is fundamentally important as

the function developers possess the domain knowledge that

allows for a direct implementation to the requirements.

Furthermore, it is also important that the toolset satisfies the

initial goal of performing the pertinent simulations used to

design the system. It is also necessary for the toolset to quickly

and accurately generate code that executes efficiently. Finally,

it is desired, as part of the SPICE® process that the toolset

allows for seamless verification testing of the implementation.

Testing should be performed at each stage, from software

integration test continuing through the complete system test. It

is desired that test vectors, known inputs with expected

outputs, are used to verify each major block as well as the

overall motor control strategy shown in Figure 4.

While there are a variety of options, the MATLAB® toolset was

chosen for this work. First, the system and motor control teams

are already familiar with this tool from their design simulation

work. Next, the toolset can be used from one end of the

development process to the other as the model can be

conceived, simulated, auto-coded and verified all within this

environment.

AUTO-CODING PROCESS FOR PMSM

CONTROL

Per the SPICE® process, product development starts from the

point of the high level requirements being captured continuing

to system requirements analysis which should contain a high

level simulation phase intended to define the system. In

SPICE®, there are also many steps involved with the selection

of tools and methods that should occur, which fall outside of

the intent of this paper. Focusing instead on the development

of requirements, reviews are held to ensure that the proposed

system design will meet the overall requirements and to

establish traceability.

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

Figure 5. High Level Motor Control Architecture

In the specific example of the motor control component, there will

be requirements for control modes such as torque, speed, DC

voltage and fault reactions, performance requirements related to

torque response rate, torque accuracy, torque, voltage, and

current ripple, as well as requirements for overall efficiency. In

order to design a solution to meet these requirements, numerous

control level simulations will be performed to derive software

requirements.

Implementation

The simulations used to form the requirements are now the

basis for the implementation created by the motor control

function developers. An output of the design phase should be

an architecture that captures the functionality shown in Figure

4 and converts it into specific modules. The architecture should

clearly define each module’s inputs and outputs, when it is

executed, and its requirements. Figure 5 provides a high level

overview of the motor control architecture with the major

modules shown. For each module, there will be models

developed to meet the associated requirements.

Once the component architecture has been defined, the focus

now shifts to creating a code-efficient model that meets each

module's requirements and is easy to understand and share

among a team. Simulation tools offer a wide array of options

for implementing algorithms. High-level models, state diagrams

or even near C-code implementations can be formed with each

offering advantages. In order to maintain ‘read-ability’ among

the team as well as to foster a common approach, a style guide

was created. The guide includes not only the recommended

approach for model development but also the standard that will

be used in peer reviews. Furthermore, the guide also includes

example implementations to ensure that the developed models

will generate efficient code. It is a living document meant to

show the best practices of implementation.

In order to highlight the impact of model implementation and

the need for a consistent guide, a few examples will be

presented. In the first example, a portion of the Space Vector

Modulation (SVM) from module 2.8 in Figure 5 is shown. In this

module, an on-time related to the voltage to be applied to the

motor is calculated based upon inputs from the current

regulator's voltage commands and the motor's angle. The

important aspect is that a selector switch is being used to

choose among different cases. Figure 6a shows a common

high level model approach for the implementation where

redundant blocks are avoided to minimize ‘clutter’. The

associated C-code is shown in Figure 6b. In the highlighted

code, it can be seen that all calculations are being performed

regardless of whether they are needed thus minimizing the

benefit of the selector switch.

Figure 6a. Inefficient Model

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

The next example is related to the use of embedded functions.

Embedded functions are often convenient when performing

many complicated mathematical operations. In this example,

an index for an array is calculated using single precision math.

After the index is determined, it is necessary to convert it to an

unsigned 32-bit integer to find the value in the associated

array. When used in an embedded function, the basic

typecasting command uint32(.) was discovered to generate

additional lines of code as shown in Figure 8. As can be seen,

there is additional rounding logic being performed as opposed

to the basic truncation that is expected.

Figure 6b. Inefficient Code

A superior solution can be formed by recognizing how the

auto-coding tool compiles. The model can be reformed as is

shown in Figure 7a. The result of more efficient C-code

generated from the model is shown in Figure 7b. The code

shows that the intent of the selector switch is now being

followed with only the needed calculation being performed on

each loop. Though the model is now slightly more ‘cluttered’

due to the redundancy, the resulting code performs identically

and will execute more quickly. As can be seen, code that

functions exactly the same can execute differently.

Figure 8. Inefficient Typecasting in Embedded MATLAB® and the

Resulting Generated C-Code

By implementing the typecasting via a custom C-code function

SingleToInteger32(.) that can be called from inside embedded

MATLAB®, the limit and rounding checks can be eliminated as

shown in Figure 9. Also therein, the custom C-code function

has been implemented as a #define for maximum efficiency to

avoid the overhead associated with a function call. Thus the

resulting generated C-code is just the typecasting as was

intended in the original embedded MATLAB® code.

Figure 7a. Efficient Model

Figure 9. Efficient Typecasting in Embedded MATLAB®, Resulting

Generated C-Code and Implementation

A final example of improving code efficiency is in the area of

math functions. Performing calculations using custom functions

can often be more computationally efficient than using the

readily available MATLAB® commands or Simulink functions.

Assuming that memory is available, using a lookup table to

perform trigonometric calculations such as sine or cosine is

much more efficient than using MATLAB®'s sin(.) or cos(.)

function. These functions use an algorithm to determine the

result. While using lookup tables to replace math functions is

not new, the savings can be overlooked by function developers

who are not intimately familiar with software implementation

issues.

Figure 7b. Efficient Code

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

In addition to how the model is implemented, the auto-coding

toolset should have features that can assist the development

process and optimize the generated code. As a basic rule, the

toolset should be setup to check the model for errors and

issues by setting diagnostics warnings to quickly identify

problems. Furthermore, the coder should have settings that

can be used to impact the generated code. Optimization for

RAM, ROM or execution efficiency can be selected. As the

primary concern for this work was code execution efficiency, a

higher priority was placed on this objective. It is worth noting

that for these specific models and tool version that the

generated code was relatively insensitive to the objectives that

were set.

Although the examples shown are intentionally basic, they

highlight how by maintaining a recommended implementation

guideline in conjunction with peer reviews from the software

engineers, the toolset can be used to best effect. The basic

step of reviewing the generated code will uncover numerous

areas where improvements can be made to the execution

efficiency. Over time the auto-coding tools have significantly

improved the quality/efficiency of the generated code, but there

is still a need to maintain a knowledge base of best practices

for efficient code. As new modules are created and as new

releases of a tool become available, the best way to implement

concepts will evolve.

Relative to the SPICE® process, the normal peer review to

ensure that requirements are met is also a natural place to

review the implementation for efficiency. The software

engineers are now responsible to carefully track and document

preferred approaches. Their role has also transitioned from the

code implementation to ensuring the auto-coding environment

is set up properly, defining best practices for implementation,

ensuring efficient code implementation, providing expertise in

peer reviews and assisting in the debug of implementation

issues. The motor control engineer has now transitioned from

writing a requirements document and verifying successful

implementation through test to more directly owning the

implementation. While this role does require additional

responsibility to ensure that the selected modeling tool is used

correctly, it minimizes potential misunderstandings of motor

control and software engineers as well as leverages the

existing simulation expertise.

As the model now becomes the implementation, it is important

that each model is easily understandable and consistent with the

models defined in the other modules of Figure 5. It is also

imperative that the overall scope of the full motor control is

clearly visible and easy to understand. With complicated

systems, it is easy to lose visibility of the overall implementation.

As often the highest view of the model will only show function

calls to the various modules, it is necessary to still create a

document that provides additional details on how the

implementation is intended to work.

The architecture, shown in Figure 5, helps to clearly define the

modules and how they relate. Each module will also have an

implementation model associated with it. It was found that

rather than attempting to provide documentation in the model

that an additional document was needed to provide overall

system context as well as module specific implementation

information. This document provides the high level overview of

how the implementation works which may not be easy to

understand from the requirements, architecture or from the

simulation models. It also can be formed in a consistent

fashion for different models to ensure the needed information is

readily accessible and serves as a user's guide on how to

calibrate the associated model. Care, of course, must be taken

to ensure consistency with the implementation, but the overall

benefit of allowing an easy to understand implementation was

found to be worth the additional effort.

Verification

Per SPICE®, it is also necessary to show that the model fully

meets the requirements. This is achieved by creating sets of

test vectors which manipulate the model inputs in the

simulation environment to ensure that the desired outputs

occur per the requirements. Testing of inputs for unexpected

cases should also be performed. As the tool is automated, a

report can be generated at the end of each model modification

to ensure the requirements are still met. Furthermore, the

toolset also offers coverage checks to verify that all appropriate

paths were tested. In addition to this step, a review is held with

the system / software team to verify the requirements were met

and the code efficiently generated. This last step is an

important addition to ensure the implementation is acceptable

and can be naturally added to the normal SPICE® reviews.

While this verification testing was performed in the simulation

environment, it is often necessary to repeat the test on the

production hardware to verify that the final compiled version

executes correctly. The same test vector can often be used in

this phase though additional tools may be required.

Figure 10 shows an example test vector used to verify the

performance of the Torque Mode module (1.3) of Figure 5. This

module is responsible for dynamically determining the proper

d- and q-axis currents commands to the machine to achieve

the commanded torque accounting for speed, temperature,

magnetic saturation and battery voltage constraints. For the

purpose of this example, the motor speed, temperature and

battery voltage are treated as constant inputs to the model,

although they are not shown as part of the input test vector. In

this test vector, the torque commands are being sent from a

variety of inputs including instrumentation to ensure that only

the correct command source is being followed and that the

proper current commands are being calculated for the

simulated voltage, speed and temperature conditions. The

torque command source is determined by ‘Cmd Source’ where

0 denotes Ignore Input, 1 denotes CAN Input and 2 denotes

Instrumentation Input. Note that the torque commands are also

issued during times when they were to be ignored to ensure

proper performance.

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

After each module shown in Figure 5 has been tested with its

associated test vector and reports generated, the complete

motor controller can be tested in simulation. Appropriate

models for the electric machine, inverter, and sensors are

required but they should be readily available from earlier

design work. Using a test vector derived from the Torque Mode

test vector of Figure 10, the response of the full control system

was tested. Based on the accuracy of the model, the torque

control and current regulation can be evaluated against

performance targets to determine if the requirements have

been met. Herein, the first 10 Sec of the commanded input test

vector is applied to the full motor control model in simulation as

shown in Figure 12.

Figure 10. Input Test Vector Commands

The results, shown in Figure 11, indicate that the desired

current commands are correctly calculated consistent with the

expected output. This module has numerous calculations being

performed to dynamically modify the current commands based

upon constraints. In this case, high level models/simulations

are used to develop the Desired output and the actual

implementation model for the module is used to form the

Measured output. These signals are used to verify that the

overall requirements were met.

Figure 12. Input Test Vector to the Complete Motor Control

The results of applying this input are shown in Figure 13. It can

be confirmed that the Measured output values are still

consistent with the Desired values from the requirements. For

cases where exact results may not be easy to predict, such as

when using a motor model, it is important to verify that the

overall performance of the test vector meets expectation rather

than each exact time step meeting a specific numeric result.

Figure 13. Expected Output Current Commands from the Complete

Motor Control (Desired and Measured)

Figure 11. Expected Output Current Commands (Desired and

Measured)

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

DYNAMOMETER TESTING

The concepts developed in this paper were applied to an

existing project using an Allison® H3000 Transmission Hybrid

System intended for the medium duty commercial truck market.

In this system, a permanent magnet motor is integrated into a

transmission using a sandwich configuration. An overview of

the system is shown in Figure 15. For this project, Delphi® was

responsible for the motor controls, inverter, DC/DC converter

and energy storage system.

Figure 13. (cont.) Expected Output Current Commands from the

Complete Motor Control (Desired and Measured)

The complete simulation model also offers the capability to

verify the intermediate signals for the various modules. These

signals should be included in the test vector to ensure that the

various modules are functioning as intended. In Figure 14a, the

resulting A-phase upper device on-time that will create the

PWM signal applied to the A-phase of the inverter is shown.

This signal is magnified in the Figure 14b.

Figure 15. Allison® Transmission H3000 Hybrid Drive

The system was tested on a dynamometer in order to evaluate

the performance of the production hand-code versus the

model-generated code. The dynamometer setup including the

motor, Allison Transmission inverter, and dynamometer is

shown in Figure 16.

Figure 14a. A-Phase PWM Signal

Figure 16. Dynamometer Test Setup with Allison® Transmission

Inverter

The following table summarizes the performance in torque

control mode of the hand-coded and model-generated code. In

this case, a defined operating point was used so that the two

code sets could be directly compared. The execution times for

key modules of Figure 5 as well as the total time for the 100

uSec task are shown in Table 1. The excess time that is not

consumed by the 100 uSec task is required to allow slower

loops to have sufficient time to execute.

Figure 14b. A-Phase PWM Signal - Magnified

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

Table 1. Throughput Comparison between Model-Generated Code and

Hand-Code

From Table 1, it can be observed that the overall modelgenerated code is within 1.5 uSec of the hand-code which

represents a 2.4% penalty. It should also be noted that the

hand-code used as a baseline comparison has been

developed over many projects and has been optimized by the

software team. In general, there is a small but measurable

increase in the required time for the model-generated code.

The benefits of directly using simulation models through the

development process, allowing the domain experts to control

the implementation, and more easily automating the verification

testing are well worth the small penalty.

While the final results are comparable, it did not occur without

the concerted focus of the team. Particularly, the review

process and the new motor control and software team roles

helped to identify and correct numerous instances of model

implementations that led to sub-optimal code. While there was

an initial investment to determine how to best use the autocoding toolset, each subsequent development activity is

expected to be less effort intensive.

SUMMARY/CONCLUSIONS

As the control of the electric machine is one of the more

challenging tasks in a hybrid or electric vehicle due to its fast

execution rates and complex requirements, numerous

simulations are used in the development cycle to appropriately

design the algorithms. Historically, the implementation of the

algorithms into software followed a simulation, requirements

development, hand-coding, and verification process due to

concerns with code throughput. This process is inherently

inefficient and has the potential to introduce errors as the

simulations used to form the requirements are not directly used

in the forming of the software as well as the software

implementation is not directly created by the motor control

engineer.

Auto-coding from simulation models is a natural tool that can be

used to address the process issues though care must be taken

to ensure that an easily understandable and modifiable model

that executes efficiently is developed. By allowing the domain

experts to implement the models a potential source for errors

can be removed. In addition, by transitioning the software

engineers' responsibility to establishing the simulation/modeling

environment, defining the modeling standards for efficient code,

providing input in peer reviews and resolving detailed

implementation issues, complicated control tasks can be coded

with efficiency approaching optimized hand code.

As an Automotive SPICE® development process is already the

norm, when the various reviews should occur for developing

requirements, defining implementations and documenting

verification is already defined. The addition of steps in the

existing reviews to ensure models compliance to requirements

as well as proper model formation is simple and found to be

extremely useful for ensuring that efficient code is generated.

The verification of the model using automated test vectors also

naturally supports a SPICE® process and serves to allow quick

verification that subsequent changes did not impact satisfying

requirements.

The process defined in this paper was applied to an existing

project as the algorithms were ported to the new simulation

environment. The maintaining of the best practices in a style

guide was found not only to improve code efficiency but also to

ensure that models had a common feel which greatly aids

readability, debugging and troubleshooting. Ultimately, the

performance and throughput results were shown to be

sufficiently close to hand-code to justify use on future projects.

REFERENCES

1. Automotive SIG, “Automotive SPICE Process Assessment Model”,

The Procurement Forum, Aug. 21, 2005.

2. Grießer, M., Schreiner, F., and Stölzl, S., “Applying Functional

Safety Management and SPICE for Automotive Functions,” SAE

Technical Paper 2008-01-0109, 2008, doi:10.4271/2008-01-0109.

3. Ueda, K., Uematsu Y., and Baloh, M., “Converting Legacy

Embedded Control Software to Executable Specifications”,

MathWorks' International Automotive Conference, 2006. Retrieved

from: http://www.emmeskay.com/presentation-files/publications/06Ueda-Toyota.pdf

4. Yang, J., Krishnan, S., Bauman, J., and Beydoun, A.,

“Implementation of Auto-Code Generation in Legacy Code for Body

Control Software Applications,” SAE Technical Paper 2008-010749, 2008, doi:10.4271/2008-01-0749.

5. Yan, K. and Trush, C., “Transmission Control Design Approach

Using Simulation, Rapid Prototyping, and Auto Code Generation,”

SAE Technical Paper 2008-01-0536, 2008, doi:10.4271/2008-010536.

6. Hsu, M., El-Jaroudi, M., and Bender, E., “Accelerated Life Cycle

Development for Electronic Throttle Control Software using ModelBased/Auto-Code Technology,” SAE Technical Paper 2004-010276, 2004, doi:10.4271/2004-01-0276.

7. Patil, K. and Muli M., “Model-Based Development of Motor Drive

Controller for Hybrid Electric Vehicles”, E-Drive: The Magazine

of Electric Motor & Drive Technology, Jun. 26, 2013. Retrieved

from: http://www.e-driveonline.com/main/articles/model-baseddevelopment-of-motor-drive-controller-for-hybrid-electricvehicles/

8. Su, G.J., McKeever, J., and Samons, K., “Design of a PM

Brushless Motor Drive for Hybrid Electrical Vehicle Application”,

PCIM 2000, Oct. 1 - 5, 2000, pp. 1-6.

9. Fu, T.J., Xie, W.F., “Torque Control of Induction Motors for Hybrid

Electric Vehicles”, American Control Conference 2006, Jun. 14 16, 2006, pp. 5911-5916.

Walters et al / SAE Int. J. Passeng. Cars – Electron. Electr. Syst. / Volume 7, Issue 2 (August 2014)

10.Krause, P.C., Wasynczuk, O., Sudhoff, S.D (2002). Analysis of

Electric Machinery and Drive Systems. Piscataway, NJ: IEEE

Press.

11. Brogan, W. L. (1991). Modern Control Theory - 3rd Edition. Upper

Saddle River, NJ: Prentice-Hall, Inc.

12.Press, W. H., Vetterling, W. T., Teukolsky, S.A., and Flannery, B. P.

(2002). Numerical Recipes in C: The Art of Scientific Computing

- 2nd Edition. New York, NY: Press Syndicate of the University of

Cambridge.

CONTACT INFORMATION

James Walters

Jim.Walters@delphi.com

Cahya Harianto

Cahya.Harianto@delphi.com

Edward J. Kelly

Edward.J.Kelly@delphi.com

Tanto Sugiarto

Tanto.Sugiarto@delphi.com

DEFINITIONS/ABBREVIATIONS

CAN - Controller Area network

ECM - Engine Control Module

HCM - Hybrid Control Module

HIL - Hardware in the Loop

PMSM - Permanent Magnet Synchronous Machine

PWM - Pulse Width Modulation

RCP - Rapid Controls Prototyping

SPICE - Software Process Improvement and Capability

Determination

SVM - Space Vector Modulation

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written permission of SAE International.

Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE International. The author is solely responsible for the content of the

paper.