motor starting methods

advertisement

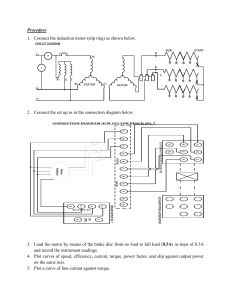

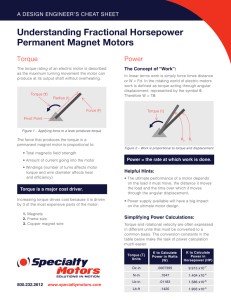

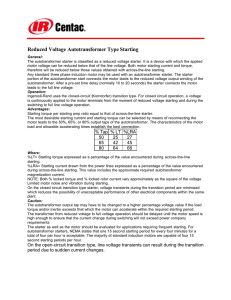

Comparison of Starting Methods for Polyphase A.C. Motors Starting Method Acrossthe-line Part winding Primary resistance reduced voltage Auto-Xfmr reduced voltage Wye-delta Operation Connects motor directly across the power lines. Starts motor with only part of windings connected, then adds remainder for running. Inserts resistance in series with motor for start. Uses autotransformer to reduce voltage, usually in 3 steps. Starts motor connected wye, then reconnects delta for running. LRA = Locked Rotor Amperage LRT = Locked Rotor Torque Xfmr = Transformer % of LRA 100 % of LRT 100 Advantages Disadvantages Lowest cost; highest starting torque; least maintenance; used with any standard motor. Low cost; low inrush current for increment starting; popular method for low starting torque applications; low maintenance. High starting current; high starting torque; may damage driven machine. Not good for frequent starts; can be noisy; may require specially wound motor; low pullup torque; may not come up to speed on first step with load. High power loss because of I2R in resistors; heat must be dissipated; low torque per amp input; high maintenance cost. 60-80 35-60 60-80 35-50 25 42 64 25 42 64 Medium cost up to size 3; smoothest start; least shock to driven machine; highest starting PF; uses any standard motor; most flexible in application. Medium cost; best for hard start loads; adjustable in field; uses any standard motor. 33 33 Low cost; low starting current. Not smooth starting; may shock driven machine. Lowest starting torque; requires delta-wound motor; not adjustable in field.