Electrical Drive Systems 324

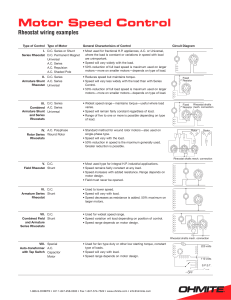

advertisement

Outline

Electrical Drive Systems 324

1

DC Motors & Generators

Dr. P.J. Randewijk

Stellenbosch University

Dep. of Electrical & Electronic Engineering

Stephan J. Chapman

Chapter 8 (5th Edition)

Chapter 8 – DC Motors and Generators

8.1 – Introduction to DC Motors

8.2 – The Equivalent Circuit of a DC Motor

8.3 – The Magnetization Curve of a DC Machine

8.4 – Separately Excited and Shunt DC Motors

8.5 – The Permanent-Magnet DC Motor

8.8 – DC Motor Starters

8.10 – DC Motor Efficiency Calculations

8.11 – Introduction to DC Generators

8.12 – The Separately Excited DC Generator

8.13 – The Shunt DC Generator

1 / 48

8.1 Introduction to DC Motors

8.2 DC Motor Equivalent Circuit

The speed regulation (SR) of a DC motor is defined as

SR =

nm,nl − nm,fl

× 100%

nm,fl

(8–2)

with nl ≡ no-load & fl ≡ full-load

The equivalent electrical circuit of the DC machine look

as follows,

F1

A1

LA

RF

The different types of DC motor that exist are:

Ê

Ë

Ì

Í

Î

2 / 48

RA

separately excited

shunt

permanent-magnet

series

compound

+

LF

−

+

EA =K φωm

φ =⇒

−

ωm

F2

A2

LA , RA & EA is the Thévenin equivalent circuit of the

armature, and

RF & LF is the equivalent impedance of the field

3 / 48

4 / 48

8.2 DC Motor Equivalent Circuit (cont.)

8.2 DC Motor Equivalent Circuit (cont.)

The dynamic model, including that for the mechanical

shaft, will look as follows:

A1

For the mechanical side, we can thus write:

τind = τb + τJ + τload

dωm

+ τload

= bωm + J

dt

iA

+

iA RA

RA

−

+

LA

diA

dt

LA

+

−

−

+

m

For steady state operation, i.e. dω

dt =0 (no acceleration),

the above equation simplifies to

VT

EA =K φωm

τind = bωm + τload

−

τind =K φiA

ωm

A2

b

For no-load operation, the only load is the viscous

friction component, so that at no-load

τb =bωm

dωm

τJ =J

dt

J

τind = bωm

τload

5 / 48

8.2 DC Motor Equivalent Circuit (cont.)

6 / 48

8.2 DC Motor Equivalent Circuit (cont.)

VT = EA + Vbrush + IA RA

All the DC machine’s mechanical (i.e. windage & friction)

losses and core/iron (i.e. eddy & hysteresis) losses can

usually be modelled a viscous frictional losses. . .

If we were to ignore the brush losses, the above

equation simplifies to

Pwindage & friction + core = PNL

VT = EA + IA RA

= Pviscous

The steady state equivalent circuit of the DC machine

can thus be simplified to:

2

= bωm

For the electrical side, we can thus write (KVL):

VT = EA + Vbrush + iA RA + LA

F1

diA

dt

A1

RF

For steady state operation, i.e. didtA =0 (with iA =IA

constant), the above equation simplifies to

+

LF

RA

−

+

EA =K φωm

φ =⇒

−

ωm

F2

7 / 48

A2

8 / 48

8.3 DC Machine Magnetisation Curve

8.3 DC Machine Magnetisation Curve (cont.)

With an increase in field current, the flux in the DC

machine would increase linearly if saturation were to be

ignored

The flux produced by the field of the DC machine will

depend on the MMF of the field circuit,

F = NF IF

The relationship would ultimately be determined by the

magnetic core’s B–H relationship

And the total reluctance, R of the DC machine, so that

we can write

F

R

N I

= F F

R

NF VF

=

RRF

φ=

with VF the voltage applied to the field circuit and RF the

resistance of the field circuit

9 / 48

8.3 DC Machine Magnetisation Curve (cont.)

10 / 48

8.3 DC Machine Magnetisation Curve (cont.)

If we were to drive the DC machine at a constant speed

(e.g. ωm =ω0 ) whilst varying the field current

The internal generated voltage will exhibit the same

B–H relationship as shown on the previous slide. . .

With the relationship between the internal generated

voltage and speed given by

EA = K φωm

(7–38)

The value of K φ for each value of the field current (IF

can be determined from the graph

As long as IF remains constant, K φ will remain constant

as K φ is only a function of field current, i.e. K φ = f (IF )

Thus with IF constant, we can determine EA at a

different speed directly from (7–38)

Alternatively, with IF constant, if we know EA at one

speed,

EA|1 = K φωm|1

11 / 48

12 / 48

8.3 DC Machine Magnetisation Curve (cont.)

8.4 SEPEX and Shunt DC Motors

We can also determine EA at a different speed, by using

the following relationship

For a Shunt DC Machine, the field circuit is connected in

shunt / parallel with the armature circuit

EA|2 = K φωm|2

EA|1

ω

=

ωm|1 m|2

= EA|1

The Terminal Characteristic of a Shunt DC Motor

nm|1 ( 2π

60 )

+ A SEPEX DC Machine’s characteristics will be the

same. . .

We are interested in the output speed versus torque of

the DC machine, i.e. torque as a function of speed. . .

nm|2 ( 2π

60 )

nm|1

= EA|1

nm|2

of

nm|2 = nm|1

EA|1

EA|2

For a Separately Excited (SEPEX) DC Machine, the

field circuit is connected to a separate supply

(8–9)

Ê Write down the Kirchoff’s voltage law (KVL) equation for

the armature circuit

Ë Make use of (7–39) & (7–49) to substitute EA & IA

Ì Rewrite the equation so that we have ωm as a function of

τind

13 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

14 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

Thus:

Speed Control of Shunt DC Motors

VT = EA + IA RA

τ

= K φωm + ind RA

Kφ

(8–3)

(8–6)

resulting in the following equation

ωm =

RA

VT

−

τind

K φ (K φ)2

(8–7)

Speed control of SEPEX and Shunt DC Motors can

accomplished by:

Ê Inserting an external resistor in series with the armature

circuit

Ë Adjusting the terminal voltage applied to the armature

circuit

Ì Inserting an external resistor in series with the field

circuit in order to change the field current and hence the

field flux

which is the equation for a straight line, see Fig. 8–6 (a)

+ We will ignore the effect of armature reaction, see Fig.

8–6 (b)

Nonlinear Analysis of a Shunt DC Motor – ignore

15 / 48

16 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

8.4 SEPEX and Shunt DC Motors (cont.)

Equation (8–7) can thus be rewritten as

INSERTING A RESISTOR IN SERIES WITH THE

ARMATURE CIRCUIT

An external variable resistor / rheostat is inserted in

series with the armature circuit

ωm =

The y–intersect is not affected by RA|ext , only the slope

of the graph as RA|ext is adjusted (see next slide)

RA|ext

F1

A1

The advantage of rheostatic control is

RF

VF

+

−

+

RA + RA|ext

VT

−

τind

Kφ

(K φ)2

4 simple and easy to implement

RA

LF

+

−

+

−

EA =K φωm

φ =⇒

VT

The disadvantage of rheostatic control is

8 it is usually manual control, i.e. difficult to automate

8 not very energy efficient, i.e. additional IA|ext 2 RA losses

−

ωm

F2

A2

17 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

18 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

Sometimes it is more convenient to express torque as a

function of speed

2.0

1.8

Speed [p.u.]

1.6

RA|ext

1.4

τind =

1.2

1.0

Now the x–intersect is constant, but again with a

changing slope as RA|ext is adjusted (see next slide)

0.00 p.u.

0.8

0.05 p.u.

0.10 p.u.

0.6

0.15 p.u.

Specifically were one has load with a known torque vs.

speed characteristic (e.g. a pump or a fan, were we

know τload =k 2 ωm )

0.20 p.u.

0.4

0.25 p.u.

0.2

0.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

(K φ)2

Kφ

VT −

ωm

(RA + RA|ext )

(RA + RA|ext )

This is done in order to determine the operating point of

the system, i.e. were the load’s characteristic curve

intersects the motor’s characteristic curve

2.0

Torque [p.u.]

19 / 48

20 / 48

0.05 p.u.

8.4 SEPEX and Shunt DC Motors (cont.)

CHANGING THE ARMATURE VOLTAGE

0.00 p.u.

0.10 p.u.

0.15 p.u.

0.20 p.u.

0.25 p.u.

8.4 SEPEX and Shunt DC Motors (cont.)

This requires that the voltage applied to the terminals of

the armature circuit, VT , be variable

2.0

1.8

Torque [p.u.]

1.6

F1

1.4

A1

RA|ext

1.2

1.0

RF

0.8

VF

0.6

+

−

+

RA

LF

+

−

+

−

EA =K φωm

φ =⇒

VT

−

0.4

ωm

0.2

0.0

F2

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

A2

2.0

Speed [p.u.]

21 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

22 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

Equation (8–7) can thus be used as is

2.0

1.8

V

RA

ωm = T −

τind

K φ (K φ)2

We can now see that only the y –intersect is affected by

adjusting VT , whilst the slope remains constant (see

next slide)

The advantage of armature terminal voltage control is

Spoed [p.e.]

1.6

VT

1.4

1.2

1.0

1.00 p.e.

0.8

0.90 p.e.

0.80 p.e.

0.6

0.70 p.e.

0.60 p.e.

0.4

4 more energy efficient that rheostatic control

4 there is a “nice” linear relationship between terminal

voltage and speed (will be shown later)

0.50 p.e.

0.2

0.0

0.0

The disadvantage of armature terminal voltage control

is

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Draaimoment [p.e.]

8 a variable voltage source is not that trivial and

8 it can be expensive

23 / 48

24 / 48

1.0 p.e.

0.9 p.e.

0.8 p.e.

0.5 p.e.

Again sometimes it is more convenient to express

torque as a function of speed

0.7 p.e.

8.4 SEPEX and Shunt DC Motors (cont.)

0.6 p.e.

8.4 SEPEX and Shunt DC Motors (cont.)

2.0

τind =

(K φ)2

Kφ

VT −

ωm

RA

RA

We can now see that only the x–intersect is affected by

adjusting VT , whilst again the slope remains constant

(see next slide)

Draaimoment [p.e.]

1.8

1.6

1.4

VT

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Spoed [p.e.]

25 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

Yet another way of looking at armature terminal voltage

control is by plotting VT as a function of ωm for different

values of τm (see next slide)

Again we start by writing down the KVL equation and

then substituting (7–38) & (7–49) into it

IA

EA

z}|{

z }| {

τm

VT =

RA + K φωm

Kφ

2.0

1.0 p.u.

0.5 p.u.

1.8

Terminal Voltage [p.u.]

8.4 SEPEX and Shunt DC Motors (cont.)

26 / 48

0.0 p.u.

1.6

τm

1.4

1.2

1.0

0.8

0.6

0.4

N.B.

0.2

There is a “nice” linear relationship between the speed of a

DC motor and the applied Armature-Terminal Voltage

0.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Speed [p.u.]

+ If RA → 0, the the three graphs will be on top of one

another. . .

27 / 48

28 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

8.4 SEPEX and Shunt DC Motors (cont.)

Equation (8–7) can again be used as is

CHANGING THE FIELD RESISTANCE (OR FIELD

VOLTAGE)

This requires that the voltage applied to the terminals of

the field circuit, VF , be variable, or an external resistor in

series with the field circuit being used (as shown in Fig.

8–7)

F1

VF

+

−

+

LF

RA

+

−

+

−

EA =K φωm

φ =⇒

VT

but now with

We can now see that both the y–intersect and the slope

is affected by the change in flux, i.e. the change in IF

(see next slide)

−

ωm

F2

VT

RA

−

τind

K φ (K φ)2

K φ = f (IF )

V

= f( F )

RF

A1

RF

ωm =

A2

29 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

30 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

The advantage of field current control is

2.0

4 can operate above rated speed

4 easier to control due to the lower current value of the

field current compared to the armature current – the

power and current rating of RF |ext or VF is much smaller

than that of RA|ext or VT

IF

1.8

Speed [p.u.]

1.6

1.4

0.60 p.u.

1.2

0.70 p.u.

The disadvantage of field current control is

0.80 p.u.

1.0

0.90 p.u.

1.00 p.u.

8 if the field current and hence the flux goes to zero, i.e.

φ → 0, the speed of the machine can “run away”, i.e.

ωm → ∞

0.8

0.6

0.4

0.2

0.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Torque [p.u.]

31 / 48

32 / 48

0.6 p.u.

1.0 p.u.

0.9 p.u.

Again sometimes it is more convenient to express

torque as a function of speed

0.8 p.u.

8.4 SEPEX and Shunt DC Motors (cont.)

0.7 p.u.

8.4 SEPEX and Shunt DC Motors (cont.)

2.0

1.8

(K φ)2

Kφ

VT −

ωm

RA

RA

1.6

Torque [p.u.]

τind =

but again now with

K φ = f (IF )

V

= f( F )

RF

IF

1.4

1.2

1.0

0.8

0.6

0.4

0.2

We can again now see that both the y–intersect and the

slope is affected by the change in flux, i.e. the change in

IF (see next slide)

0.0

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Speed [p.u.]

33 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

34 / 48

8.4 SEPEX and Shunt DC Motors (cont.)

Below rated / base speed, speed control is done by

TORQUE AND POWER LIMITS OF A DC MOTOR

armature terminal voltage control

armature external resistance (rheostatic) control

In all the graphs shown in die previous slides, there

were a “dot” in the middle. . .

Above rated / base speed, speed control is done by

This is the rated operating point of the DC machine

field current control

Which occurs when,

Electrical motors different somewhat from Internal

Combustion Engines (ICEs) in terms of their

4 the rated terminal voltage is applied,

4 the rated field current is drawn and

4 the rated armature current is drawn,

“maximum developed torque” and

“maximum developed power”

So that the DC machine will be

Defined in Chapman as

+ developing its rated torque and

+ developing its rated power and

+ running at rated (or base) speed

τmax = K φIA|max

(8–14)

Pmax = τmax ωm

(8–15)

and

35 / 48

36 / 48

Loads

8.4 SEPEX and Shunt DC Motors (cont.)

and Power

Electronics

Series

1

8.4 SEPEX and Shunt DC Motors (cont.)

Functional block diagram of power conversion components in generator set.

So that I would redefine (8–14) conditions.

& (8–15) toIt is also possible to control the engine to run

τrated

Prated = τrated ωm|rated

(8–15’)

Gen-Set Operation

The interesting thing about electrical

motors

is that

A block

diagram

of theitelectronic power conversion system

can develop more than its ratedfor

torque.

..

the proof-of-concept

gen-set developed at the Oak

Ridge

National

Laboratory (ORNL) is shown in Figure 1

It however implies that more than

the rated

armature

[6],

[7].

The

military

gen-set uses an internal combustion

current needs to be drawn. . .

(IC) diesel engine to drive a radial-gap permanent magnet

Which could result in the motor (PM)

burning

out. . . at variable speed. The speed of the engine

alternator

8.4

50

45

40

35

30

25

20

15

10

5

0

1,800

Torque

Fuel Consumption

Power

2,200 2,600 3,000 3,400

Engine Speed (r/min)

0.40

0.38

0.36

0.34

0.32

0.30

0.28

0.26

0.24

0.22

0.20

3,800

2

Peak torque, power, and fuel consumption for the diesel

engine in the proof-of-concept gen-set.

is determined from a user-selectable interface that allows

the engine to run at its most

efficient operating point for a

37 / 48

38 / 48

given load and ambient thermal conditions. The variable

frequency, variable voltage produced by the PM alternator

is diode-rectified to dc voltage, and an inverter is used to

SEPEX and Shunt DC Motors

(cont.)

produce selectable-frequency,

controllable ac voltage. 8.4 SEPEX and Shunt DC Motors (cont.)

The user is allowed to select single-phase 120-V,

For a DC motor, the maximum (or

rated) torque–speed

dual-phase

120/240-V, or three-phase 120/208-V. Each of+ Below rated / base speed,

voltage configurations can be generated at 50, 60,

and power–speed curves, looksthese

as follows

Ê the applied armature terminal voltage increases linearly

and 400 Hz such that the unit can be compatible with

with speed,

equipment produced from around the world or for aero­

Ë but the armature current can be at its maximum / rated

space applications. The power-conversion system also in­

value, even from standstill

Ì thus the maximum power increases linearly with speed

corporates a bidirectional dc-dc converter that can charge

Í where as the maximum torque the DC motor can

24-V batteries that are used to start the IC engine and to

develop will be constant

power auxiliary loads [8]. The converter can also draw

power from the batteries to help maintain the dc link dur­

ing severe load transients.

+ Above rated / base speed,

Engine and Alternator Description

Each gen-set size was determined by selecting an advanced

diesel engine that had a high power-to-weight ratio. For

the smallest gen-set, an air-cooled Ruggerini MD 191

rated at 13 kW was used as the prime mover. The engine

39 / 48

Ê the applied armature terminal voltage can’t increase any

more,

Ë neither can the armature current,

Ì thus the maximum power stays constant (it can’t 3

increase)

PM alternator mounted to gen-set engine.

Í and hence the maximum torque the DC motor can

develop, will decrease hyperbolically (k = xy )

40 / 48

I EEE I NDUSTRY A PPLI CA TI ONS MA GA ZI NE • MA R|A PR 2003 • WWW.I EEE.ORG/I A S

and

where it is most audibly quiet, at its least-polluting operat­

ing point (from an emissions

= K φIA|rated

(8–14’) point of view), or at its most

reliable, stiffest point such that it is less sensitive to load

transients. This article describes a proof-of-concept devel­

opment for a 7.5-kW gen-set in a family of military

gen-sets in the 5- to 60-kW range.

Fuel Consumption (kg/kWh)

For an ICE, this is not possible

Torque (N⋅m) or Power (kW)

I prefer (and it is less confusing) to rather refer to it as

rated torque and rated speed. . .

49

8.5 The Permanent-Magnet DC Motor

8.8 DC Motor Starters

A Permanent-Magnet (PM) DC motor uses PMs to

generate the flux in the motor

From the KVL equation for the armature circuit,

IA =

Thus the flux is fixed and hence K φ is constant

For PM DC motors, manufacturers sometimes refer to

K φ as motor or machine constant, Km

VT − EA

RA

We can see that at start-up,

Advantages of PM DC Motors are

we don’t have to worry about the field

Km = K φ = constant

Disadvantages of PM DC Motors are

PM DC motors are expensive

we can’t operate the PM DC motor above rated speed

because we can’t reduce the flux in the machine

Ignore rest of this section. . .

the speed ωm =0, and thus the back-EMF, EA =0

coupled with the fact that armature resistance, RA , is

usually very small

we can see that the armature current, IA

and hence the torque developed at standstill, τind , will be

extremely high

+ which could lead to “something breaking” on the

mechanical side

Hence a starting resistor in series with armature circuit

or a lower starting armature terminal voltage is required

Ignore rest of this section. . .

41 / 48

8.10 DC Motor Efficiency Calculations

42 / 48

8.11 Introduction to DC Generators

+ Have a look again at Chapman Section 7.7

For DC motor, speed regulation is important, but for a

DC generator (similar to a transformer) voltage

regulation (VR) is important

The efficiency of a DC motor at a certain operating

point, is given by

Pout

× 100%

Pin

Pconv − Pno-load

=

× 100%

Parmature + Pfield

(τ − bωm )ωm

= ind

× 100%

VT IA + VF IF

VR =

η=

Vnl − Vfl

× 100%

Vfl

(8–39)

with nl ≡ no-load & fl ≡ full-load

The different types of DC generators that exist are:

Ê

Ë

Ì

Í

Î

Ï

+ Don’t forget about the losses in the field winding. . .

+ Chapman doesn’t calculate the viscous friction

coefficient, b, and assumes the no-load losses

(Pmech + Pcore ) stays constant and is not affected by

speed

43 / 48

separately excited

shunt

permanent-magnet

series

cumulatively compound

differential compound

44 / 48

8.12 The Separately Excited Generator

8.12 The Separately Excited Generator (cont.)

Also for a motor we were interested in the speed vs.

torque, or torque vs. speed characteristics

The equivalent circuit for the SEPEX DC generator

looks exactly the same as for a SEPEX DC motor

The only difference is that a motor is electrically driven

and mechanically loaded

Where as a generator is mechanically driven and

electrically loaded

F1

from the KVL equation for the armature circuit and with

IA = IL

IL

A1

Where as for a generator, we are interested in the

terminal voltage, VT vs. the load current, IL ,

characteristics

VT = EA − IA RA

RF

VF

+

−

+

LF

RA

−

EA =K φωm

φ =⇒

Furthermore, with EA = K φωm , with the flux being kept

constant, i.e. IF being kept constant, and the rotational

speed, ωm , constant

+

Rload

+

VT

−

−

And hence the terminal voltage VT will vary linearly with

the load current, IL – see Fig. 8–45 (a)

ωm

F2

(8–41)

A2

45 / 48

8.12 The Separately Excited Generator (cont.)

46 / 48

8.13 The Shunt DC Generator

+ The only thing that is important to understand here, is

that the voltage buildup during starting of the shunt DC

generator occurs due to the remanent or residual

magnetic flux in the core of the machine. . .

Control of the Terminal Voltage

Also with EA = K φωm , it follow that the terminal voltage

of the SEPEX generator can be controlled by, either

Ê Changing the speed of rotation

Ë Changing the field current

Nonlinear Analysis of a Separately Excited DC Generator

– ignore (i.e. ignore the effect of armature reaction)

47 / 48

48 / 48