Lab Information -- Direct Current Machine Experiments

advertisement

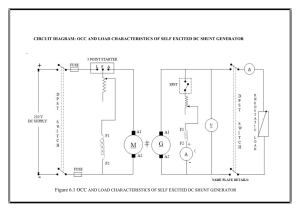

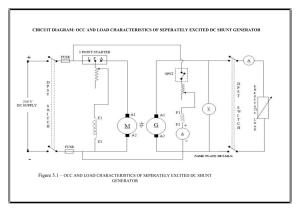

Lab Information -- Direct Current Machine Experiments EXPERIMENT NO. 13 SPEED CONTROL OF DC MOTORS PURPOSE: To study and compare the various methods of speed control of DC motors. APPARATUS REQUIRED: 1. One DM-100 DC Machine as motor. 2. One SLA-100 Strobe Tachometer. 3. One 0 to 150 volt DC voltmeter. 4. One 0 to 0.5 amp DC ammeter. 5. One 0 to 125 volt/5 amp DC power supply. PROCEDURE: 1. Connect the DC motor as shown in Figure 13. Adjust its field rheostat to its minimum resistance fully CCW position. 2. Have the instructor check your connections. Start the motor by slowly increasing the supply voltage to 125 volts DC. 3. Using the field rheostat, adjust the motor's speed to 2400 RPM. Record the field current for various speeds from 2400 RPM down to the full shunt speed. The DC armature voltage should be maintained at 125 volts DC. 4. Leaving the field rheostat in its minimum resistance position, record the voltage and speed for various settings of the DC supply voltage from 125 volt DC to zero volts. REPORT: 1. Show the data obtained. 2. On the same set of areas, plot the armature voltage and shunt field current as ordinates versus the speed as abscissa. 3. All speed control methods are based on the basic principle that the speed of the motor is directly proportional to the armature counter EMF and inversely proportional to the flux, i.e.: S = kEc/ where S = speed Ec = counter EMF = flux k = constant Does your curve support this principle? 4. Can the counter EMF ever be equal to the applied voltage in a motor? Explain. FIGURE 13