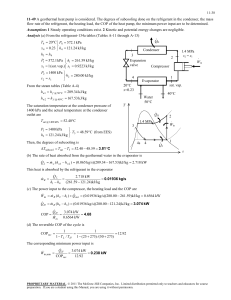

Simulations for thermodynamic analyses of transcritical carbon

advertisement