Psychrometrics - Rocky Mountain ASHRAE

advertisement

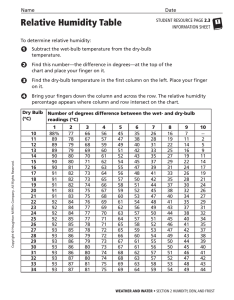

Psychrometrics Scott Laurila ~ Senior Application Engineer Greenheck Fan Corporation Schofield, Wisconsin 1 A Agenda d Properties of Air The Psychrometric y Chart Applications Mixed Air Cooling Dehumidification Energy Recovery 2 C Course Obj Objectives ti At the completion of this session, you should be able to use a Psychrometric Chart to: Identify Id if the h properties i off air i at a given i state condition di i Illustrate the performance characteristics of basic heating and cooling processes Demonstrate how the use of Energy Recovery devices can reduce heating and cooling loads in building designs 3 P Psychrometrics h ti Psychrometrics h i is i the h science i dealing d li with i h the h physical h i l laws or air – water mixtures Important in the design of HVAC systems as numerous air properties can be found over a broad range of conditions 4 P Properties ti off Air Ai Properties of Air Dry-Bulb Temperature Wet-Bulb Temperature Dew-Point Temperature Relative Humidity Humidity Ratio Enthalpy If any two of the above properties are known, the Psychrometric Chart can be used to find the remaining properties 5 Properties of Air Dry-bulb temperature is the temperature read from a standard thermometer Wet-bulb Wet bulb temperature is read from a thermometer with the bulb covered by a wet wick Representative of the sensible heat energy at the given condition "Sling Psychrometer" Difference between dry-bulb and wet wet-bulb bulb represents the dryness of air 6 P Properties ti off Air Ai Dew-point temperature is the temperature at which moisture leaves the air and condenses on objects When the dry-bulb, wet-bulb, and dew-point temperatures are equal, the air is saturated Fog occurs when the air is saturated 7 P Properties ti off Air Ai Relative humidity is the measure of how much moisture the air is holding versus how much moisture the air can hold at a given dry-bulb dry bulb temperature Expressed as a percentage As the dry-bulb dry bulb temperature increases, the amount of moisture the air can hold increases Amountt off moisture A it the th air i is i holding h ldi Relative Humidity = Amount of moisture the air can hold 8 P Properties ti off Air Ai Humidity Ratio is a measure of the weight of water in a given amount of air Also Al referred f d to as S Specific ifi Humidity H idi Can be expressed in grains 7,000 7 000 grains equals one pound of water Pounds P d off moisture it Humidity Ratio = Pounds of dry air 9 Th P The Psychrometric h t i Ch Chartt 10 S t ti Curve Saturation C Saturation Curve 11 D B lb T Dry-Bulb Temperature t 12 W t B lb T Wet-Bulb Temperature t 13 D Dew-Point P i tT Temperature t 14 R l ti H Relative Humidity idit 15 Humidity Ratio 16 S Sensible ibl and dL Latent t tE Energy Sensible Energy is the heat that causes changes in the air's dry bulb temperature L Latent Energy E i the is h heat h associated i d with i h phase h change. h It I is i representative of changes in the air's moisture content with no g to the dry-bulb y temperature p change Enthalpy is the total energy in a given amount of air at its present conditions Enthalpy (h) = Sensible Energy + Latent Energy 17 E th l Enthalpy 18 P Psychrometric h t i Ch Chartt R Reconstructed t t d 19 Example: 93°F DB, 65°F WB E th l Enthalpy Find: Relative Humidity = 24.0% Dew-Point = 50.9°F Hum. Ratio = 66.8 grains/lb dry air Enthalpy = 32.9 Btu/lb Wet-Bulb Dew-Point Humidity Ratio Relative Humidity Dry-Bulb 20 Ai D Air Density it C Corrections ti Do NOT forget about elevation! Above 2,000 feet elevation, the air density is reduced by approximately i t l 3 3.6% 6% per every 1 1,000 000 ffeett A change in air density also changes the physical and thermodynamic properties of air-water air water mixtures 21 P Psychrometric h ti P Processes Air Conditioning Mixed Air Cooling Coils Reheat Calculations Energy Recovery Sensible Devices Total Enthalpy Devices 22 Psychrometric Processes Example Processes Evaporative Cooling Steam Humidification Sensible: Side Side-to-side to side Latent: Up & down Coolingg & Dehumidification 180 160 80 140 Desiccant Dehumidification 120 70 100 60 80 50 60 40 Heat eat 30 40 20 20 30 40 50 60 70 80 90 100 110 Dry Bulb Temp. 23 Use the ASHRAE indoor d i conditions design di i to help h l with ih process calculations ASHRAE IIndoor d D Design i C Conditions diti Summer Indoor Design 75°F, 50% RH Winter Indoor Design 72°F, 35% RH 24 Mi d Ai Mixed Air C Conditions diti Step 1: Identify outdoor condition, indoor condition, and ventilation rate (% outside air) Step 2: Draw a straight line between the outdoor and indoor conditions Step 3: Draw a straight line between points 1 and 2 25 Mi d Ai Mixed Air E Example l Outdoor Air: 95°F DB/75°F WB Room Air: 75°F DB, 50% RH Ventilation: 25% Outdoor Air 95°F x 00.25 25 = 23 23.75°F 75°F 75°F x 0.75 = 56.25°F Mixture = 80°F 26 C li P Cooling Process E Example l Condenser High g Pressure Compressor Expansion Valve E Evaporator t Low Pressure 27 C li C Cooling Coilil P Processes Capacity (Btu/hr) = 4.5 x SCFM x Δh 1 Cooling C li Ton T = 12,000 12 000 Btu/hr B /h Capacity (Tons) = 4.5 x SCFM x Δh / 12,000 28 C li E Cooling Exercise i Exercise 2: A customer wants to cool 4,000 SCFM of outside air from 93°F DB / 65° WB to 50°F saturated air Find the following parameters for 50°F saturated air: Property Value Units Relative Humidity 100 % Dew Point 50 °F Humidity Ratio 64.8 Enthalpy 22 grains / lb dry air Btu / lb dry air What is the change g in enthalpy py from 93DB/65WB to 50DB/50WB? Δh = 10.9 Btu / lb dry air D t Determine i the th cooling li tonnage t required i d in i this thi process. Capacity = 16.4 Tons 29 Deh midification w// Reheat Dehumidification Introducing cold, saturated air directly into an occupied space may be too cool for occupant comfort Reheat can be used to bring the air to a space-neutral condition Reheat Methods Electric Heat Hot Water Coil Hot Gas Reheat 30 C li P Cooling Process E Example l Condenser High g Pressure Compressor Expansion Valve E Evaporator t Low Pressure 31 H t Gas Hot G Reheat R h t Discharge Line Reheat Coil Air Conditions After Reheat Coil: 65°F DBT/56°F WBT (50% RH) Air Conditions After Evaporator: 50°F DBT / 50°F WBT Evaporator Supply Air 32 E Energy R Recovery 33 Traditional HVAC System 34 35 Wh E Why Energy R Recovery? ? Economic Benefits Reduced Initial Costs Reduced R d d Operating O ti Costs C t ASHRAE Standards & Guidelines ASHRAE 62.1 – 2010 – Ventilation for Acceptable p indoor air quality ASHRAE 90.1 – 2010 – Energy Standard for Buildings ASHRAE 189 189.1 1 – Standard for Design of High Performance Green Buildings 36 ASHRAE Standard 62 “Ventilation for Acceptable Indoor Air Quality” Must supply fresh outdoor air to occupied spaces to minimize the potential for adverse health effects. Typical ventilation rates: 15 CFM per person for Classrooms 17 CFM per person for Offices Steven Taylor – Taylor Engineering 37 ASHRAE 90 90.1-2010 1 2010 Exhaust Air Energy Recovery (6.3.6) Supply air is greater than 5000 CFM 70% or more of supply is outdoor air (3500 CFM) Energy recovery system shall have a total effectiveness of greater than 50% 38 ASHRAE Climate Zones 39 ASHRAE 90.1-2010 Table 6.5.6.1 Energy Recovery Requirement (IP) 40 ASHRAE 189.1 “Standard for Design of High-Performance Green Buildings” www.ashrae.org/greenstandard Table 7.4.3.8 Energy Recovery Requirement (IP) 41 E Energy R Recovery B Basic i T Terms Sensible Energy Recovery transfers only sensible energy (no moisture) Also referred to as heat recovery y Total Energy Recovery transfers both sensible and latent energy Effectiveness refers to the efficiency of the energy recovery device (expressed as a percentage) Sensible effectiveness Total effectiveness 42 S Sensible ibl H Heatt R Recovery Sensible Heat Recoveryy Aluminum fixed plate Run-around coils Heat-pipe heat exchangers Sensible S ibl wheels h l (no ( desiccant) Transfers sensible energy gy only (no moisture transfer) 43 S Sensible ibl Pl Plate t HRV 44 Sensible Energy Recovery Sensible Energy gy recoveryy moves the outdoor air dry bulb temperature laterally toward the room dry bulb temperature 180 160 80 140 120 70 Outdoor Air Heat Exchangers 60 100 80 50 60 Room Air 40 40 30 20 20 30 40 50 60 70 Dry Bulb Temp. 80 90 100 110 45 T t l Energy Total E Recovery R Total Energy gy Recoveryy Enthalpy wheels Enthalpy plates (or cores) Transfers sensible energy through the media T Transfers f latent l t t energy through a desiccant (wheel) or molecular transfer (core) 46 E Energy R Recovery Summer Operation w/ Rotary Wheel 47 Total Energy Recovery Total energy recovery shifts OA point towards RA point Total effectiveness 60-80% 60 80% 180 160 80 140 120 70 Outdoor OutdoorAir Air 60 100 80 50 60 Room Air 40 40 30 20 20 30 40 50 60 70 80 90 100 110 Dry Bulb Temp. 48 P tL dC Part-Load Conditions diti 49 Energy gy Recovery y and Cooling g Potential Energy Savings 50 Winter Operation p Supply Air Dry Bulb 54°F Humidity 31 grains/lb. Room Air (to be exhausted) Dry Bulb 72°F Humidity 41 grains/lb grains/lb. Outdoor Air Dry Bulb 0°F Humidity 2 grains/lb. Exhaust Air Dry Bulb 18°F Humidity 12 grains/lb. 51 Winter Operation Sensible vs. Total ERV 52 Energy Recovery and Frost Possibility of condensation forming whenever a warm, moist air stream comes in contact with a cold surface Always consider frost control methods in when winter design temps drop below 55°F F 53 Winter Exhaust Air Process Sensible vs. Total ERV Sensible Total 54 Question? 55 R i Review Psychrometric Charts are useful tool for understanding g HVAC p processes Easily find properties of air across numerous conditions Allows us to plot, predict, and calculate the heating and cooling capacities An understanding of psychrometrics is the foundation of energy recovery 56 THANK YOU! 57