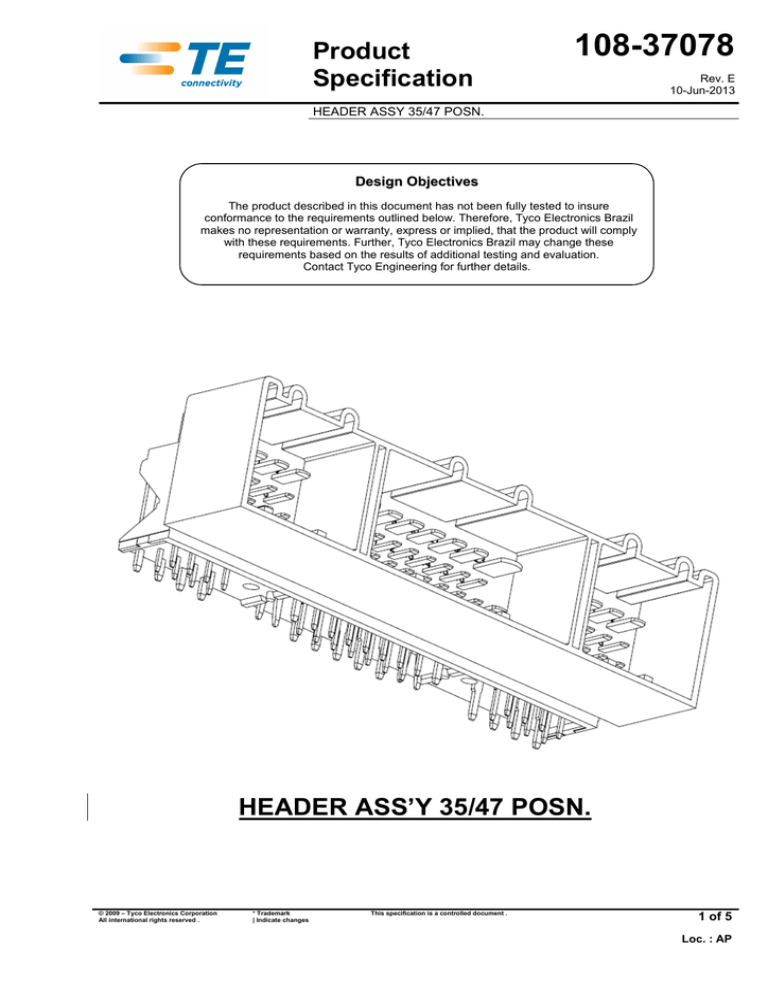

Product

Specification

108-37078

Rev. E

10-Jun-2013

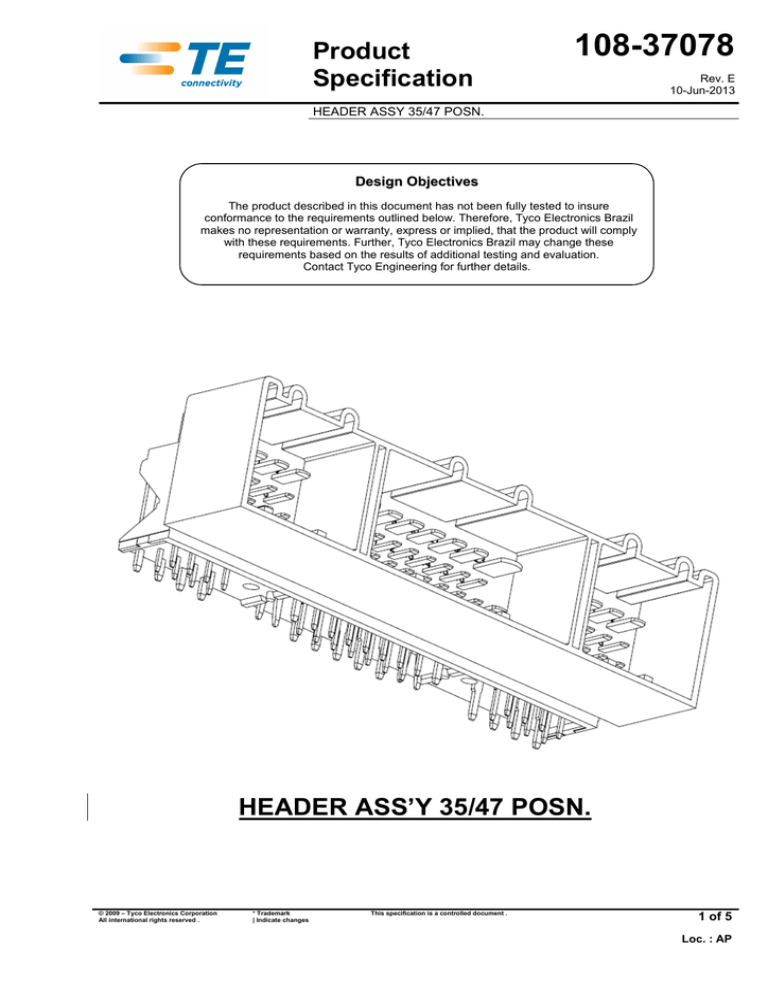

HEADER ASSY 35/47 POSN.

Design Objectives

The product described in this document has not been fully tested to insure

conformance to the requirements outlined below. Therefore, Tyco Electronics Brazil

makes no representation or warranty, express or implied, that the product will comply

with these requirements. Further, Tyco Electronics Brazil may change these

requirements based on the results of additional testing and evaluation.

Contact Tyco Engineering for further details.

HEADER ASS’Y 35/47 POSN.

© 2009 – Tyco Electronics Corporation

All international rights reserved .

* Trademark

| Indicate changes

This specification is a controlled document .

1 of 5

Loc. : AP

108-37078

HEADER ASSY 35/47 POSN.

1.

SCOPE

1.1

Content

This specification covers the performance requirements and test methods of Header

Assembly, 35/47 Posn.

1.2

TE Part Number

"Trade Mark” Description

1989538-1

1989538-6

HEADER ASS’Y 47 POSN.

HEADER ASS’Y 35 POSN.

Qualification

When all the tests have been successfully performed on the subject product line, the product is

qualified according to the present specification.

2.

APPLICABLE DOCUMENTS

The following documents form a part of this specification to the extent specified herein. In the event of

conflict between the requirements of this specification and product drawing, the product drawing shall

take precedence. In the event of conflict between the requirements of this specification and the

referenced documents, this specification shall take precedence.

2.1 Tyco Electronics Documents

a)

109-1: General Requirements for Test Specifications;

b) 109-11:Solderability Dip Test

2.2 Other Documents

a)

b)

ISO 16750-1: Environmental conditions and testing for electrical and electronic equipment – General;

ISO 16750-2: Environmental conditions and testing for electrical and electronic equipment – Electrical

loads;

c)

ISO 16750-3: Environmental conditions and testing for electrical and electronic equipment – Mechanical

loads;

d)

ISO 16750-4: Environmental conditions and testing for electrical and electronic equipment – Climatic

loads;

e)

f)

g)

h)

i)

3.

ISO 16750-5: Environmental conditions and testing for electrical and electronic equipment – Chemical

loads;

MT.BDS2/012: Environmental conditions and testing for electrical and electronic equipment – Buses;

DBL 5420: Supply specification – Plastics Insulation parts for Electrical low tension applications;

DIN 46225: Stamped terminals with embrace of the insulation for insulated cables;

VW 801 01: Unidades Funcionais Elétricas e Eletrônicas em Veículos

REQUIREMENTS

3.1 Design and Construction

Products shall be of the design, construction and physical dimensions specified on the applicable

drawings.

3.2 Materials and Finish

• HEADER, 35/47 POSN

• PIN GUIDE

• TABS

Revision “E”

PPA + GF 33% - Black;

PPA + GF 33% - Black;

BRASS, TIN PLATED

2 of 5

108-37078

HEADER ASSY 35/47 POSN.

3.3 Current Carrying Capacity and maximum operating voltage

a) Individual Continuous Current Carrying Capacity at 70°C for single loaded terminal when used

with Tyco Electronics female terminals. For other loads, please consult Tyco Electronics

Engineering Department:

- Micro Power Timer : 10A

- Junior Power Timer :20A

- Std Power Timer :30ª

b) Voltage 12 VDC.

3.4 Temperature rating

Temperature rating shall be within the range specified as following:

• -30º / +70ºC.

3.5 Sealing class

Sealing rating shall be within the range specified as following:

•

4.

Not sealed

GENERAL TEST CONDITIONS

Unless otherwise specified, all measurements and tests shall be performed at a room temperature of

23 ± 5ºC and a relative humidity of 25 to 75%.

The test voltages shall be in accordance with table 1:

Test Voltage

UA

UB

Volts System (V)

14

(±0,2)

12

(±0,2)

Table 1: Test Voltages

UA = engine /alternator operative;

UB = battery voltage

5.

TEST REQUIREMENTS AND PROCEDURE SUMMARY

TEST DESCRIPTION

5.1

Visual

examination

TEST DESCRIPTION

PRODUCT EXAMINATION

PROCEDURE

Product shall be in accordance with

the requirements of production

drawing

Engaging

connector

force

Operation speed : 50mm/min

5.3

Disengage

connector

force

Apply an axial load to unmate tab/rec

connectors at a rate of 50

mm/minute, with the connector lock

engaged.

Revision “E”

Visual, dimensional and functional check.

MECHANICAL REQUIREMENTS

PROCEDURE

5.2

REQUIREMENT

REQUIREMENT

The mating force shall be:

Connector 12 Pos. ≤ 100N;

Connector 23 Pos. ≤ 180N

For Headers: >150 N.

3 of 5

108-37078

HEADER ASSY 35/47 POSN.

5.4

5.5

Free fall (Drop

test)

Subject Header Ass’y to a drop of

1,0m height on concrete ground or

steel plate. Shall be tested in all six

spatial directions.

Hidden damage is not permitted. Minor

damage of the Header Ass’y is permitted

as long as this does not affect the

performance.

Header Pin

Retention

Measurement shall be taken in both

directions if possible, i.e.force to

push the pin longitudinally through

the connector,and to pull it out as if

removing a female plug from the

header.Pressure or tension must be

applied parallel with the axis of the

pin to achieve accurate results

This test determines the retention of the

male terminal. The minimum force

required to displace the pin longitudinally

in either direction shall meet the values

specified below:

Terminal 1,5mm – 55N min.

Terminal 2,8mm – 80N min.

Terminal 4,8mm – 120N min.

TEST DESCRIPTION

ELECTRICAL REQUIREMENTS

PROCEDURE

REQUIREMENT

5.6

Dieletric

Strength

Apply 500V AC, 60 or 50 Hz for 2

minutes between any two conductive

parts designed to operate at different

potentials.

Determine the leakage current.

This test ensures that any circuit is

sufficiently isolated from adjacent circuits.

The leakage current shall not exceed 1

mA.

5.7

Insulation

Resistance

The insulation resistance shall not be

less than 10 MOhm at 500 VDC.

This test ensures that the material used for

the housing is sufficient for insulating the

current in the EDB with any surrounding

part

Voltage Drop

Terminal 1,5mm 10,0 mΩ

Terminal 2,8mm 5,0 mΩ

Terminal 4,8mm 3,02 mΩ

5.8

TEST DESCRIPTION

This test determines the voltage drop

associated with the electrical resistance of

the conductor crimp and contact interface

regions at nominal current conditions

ENVIRONMENTAL REQUIREMENTS

PROCEDURE

REQUIREMENT

5.9

Corrosion, salt

spray

Subject Header Ass’y assembled to

96 hrs according to ASTM B117

No base metal corrosion;

5.10

Resistance to

low

temperature

Connectors mated samples shall be

kept at -40°C for 2h, then the

samples shall be brought at 0°C in 3’

max and left for thermal stabilization.

Unmate and remate the samples.

No breakage of plastic parts;

5.11

Accelerated

Ageing

On mated connectors,which shall be

submitted to the following cumulative

tests:

A- 50 cycles with

thermal shock:

3 h at + 70°C±2°C

3 h at - 30°C±2°C

Transition time 180s

B- 10 cycles without

shock

2 h at + 70°C±2°C

2 h at – 30°C±2°C

Transition time 2 h

No deformation or cracking of the plastic

parts(change of colour is allowed)

5.12

Soldability

See TE spec 109-11-5

See TE spec 109-11

Note : The tests 5.1; 5.4; 5.5; 5.6; 5.7; 5.12 are referenced to the Header and they are tested by Tyco

Electronics.

The other tests are dependents of the counter-part (Receptacle housing) and they are not guaranteed

by Tyco Electronics.

Revision “E”

4 of 5

108-37078

HEADER ASSY 35/47 POSN.

6.

TEST SEQUENCE

Test Group and Sequence (a)

Item

Description

A

B

C

D

1, 4 1,3 1, 3 1,5

E

F

G

1,3 1, 3 1,3

H

Qty of

samples

I

5.1

Visual examination

1,3 1, 3

5.2

Engaging connector force

2

6

5.3

Disengage connector force

3

6

5.4

Free Fall Drop Test

5.5

Header Pin Retention

5.6

Dieletric strength

5.7

Insulation Resistance

5.8

Voltage Drop

5.9

Corrosion Salt Spray

5.10

Resistance to low temperature

5.11

Accelerated ageing

5.12

Soldability

2

20

6

2

6

2

6

2

6

2,4

6

3

6

2

6

2

6

2

6

(a) Numbers indicate sequence in which tests are performed

Table 2 – Test Sequence

7.

GENERAL TEST CONDITION

According to VW 801 01, must be tested at least 6 samples.

Rev.

B

C

D

E

Date

01-Apr-2009

13-May-2009

30-Jun-2009

10-Jun-2013

Revision “E”

History

Description

Item 5. – added Test Voltage Drop

Item 5.2 - change requirements

Changed Item 5.5

Changed raw material; added new dash number and changed item 5.2

Prepared

M.Ogawa

M.Ogawa

M.Ogawa

G. Oliveira

Approved

A.Metzker

A.Metzker

A.Metzker

D.Oliveira

5 of 5