No. 20016

advertisement

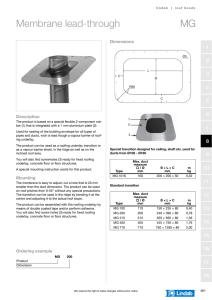

SINTEF Certification No. 20016 01.09.2009 03.11.2009 Valid until: 01.09.2014 Page: 1 of 5 Issued t: Revised: SINTEF Building and Infrastructure confirms that Vempro R+ combined roof underlayer and wind barrier meets the provisions regarding product documentation given in Norwegian building regulations, with properties, fields of application and conditions as stated in this document 1. Holder of the approval DOW Europe GmbH Bachtobelstrasse 3 CH 8810 Horgen Switzerland http://goliath.ecnext.com 2. Manufacturer DOW Europe GmbH Bachtobelstrasse 3 CH 8810 Horgen Switzerland 3. Product description Vempro R+ combined roof underlayer and wind barrier is made from spun bonded nonwoven polypropylene fabric and polypropylene film. The product is UV-stabilized, and intended for use as a combined roofing underlay and an airtight breathable membrane. The weight is about 225 g/m² and the colour is blue. Vempro R+ is supplied as rolls of standard widths of 1,50 m and length of 50 m. Vempro R + has a 50 mm wide adhesive strip at one edge on the top side, and at the opposite edge on the underside. The adhesive strips consist of a heat-melting glue. As supplement to the product the following components can be delivered: − Vempro Tape (Vempro repair tape) − Glava Tettlett − Glava Dobbeltsidig Tettebånd − Glava Monteringslim − Glava Kilrennemembran − Glava Bunnfyllingslist 4. Fields of application Vempro R+ is used as a wind barrier in thermal insulated wooden walls and roof constructions, and as a combined roofing underlay and wind barrier in thermal insulated, pitched wooden roofs with ventilated, discontinuous roofing and external drainage, see Fig. 2. Fig. 1 Installing Vempro R+ with adhered joints mounted crosswise on the rafters or the roof trusses. End joints have to be clamped and folded above the rafters as shown in the figure segment above. The product is particularly suitable for roofs with continuous thermal insulation from eaves to ridge. Vempro R+ may also be applied in pitched wooden roofs with heated rooms in parts of the attic, and above uninsulated attic spaces. The product may also be used in combination with wooden roof sheathing, f.ex. for renovation of old roofs with thermal insulation in the plane of the roof. See chapt. 6 Special conditions for use and installation. 5. Properties Material properties Material and construction properties are shown in Table 1. Vempro R+ complies with the requirements recommended by SINTEF Building and Infrastructure concerning water tightness, air tightness and water vapour permeability. SINTEF is Norwegian member of European Organisation for Technical Approvals, EOTA, and European Union of Agrément, UEAtc Reference: Appr. 3D0226 Contr. 3D0765 Head Office: SINTEF Building and Infrastructure P.O.Box 124 Blindern – NO 0314 Oslo Tel. + 47 22 96 55 55 – Fax + 47 22 69 94 38 © Copyright SINTEF Byggforsk Subject:Combined roof underlay and wind barrier e-mail: byggforsk@sintef.no www.sintef.no/byggforsk Trondheim: SINTEF Building and Infrastructure 7465 Trondheim Tel. +47 73 59 30 00/33 90 – Fax +47 73 59 33 50/80 SINTEF Technical Approval - No. 20016 Page 2 of 5 Table 1 Vempro R+ combined roof underlayer and wind barrier Material and construction data. Test Property Value method Water tightness, Water pressure Rain tightness, construction Air tightness, material Air tightness, construction 1) Tight at 2 kPa Class W1 Tight at 15º slope and 400 Pa pressure 2) difference 0,002 m³/(m²hPa) 1) 0,002 m³/(m²hPa) 2) EN 1928 NT Build 421 Equivalent to NS 3261 EN 12114 9 Water vapour resistance Concentrated load resistance Fig. 2 Basic roof construction using Vempro R+ as a combined roof underlayer and wind barrier Durability Vempro R+ is considered to have satisfactory durability as long as the product is not exposed to direct sunlight. The durability has been tested by artificial weathering/ ageing according to EN 13859-1 and NT Build 495, with testing of water tightness and tensile properties before and after the exposure. Concentrated load resistance Based on performed tests and provided installation according to clause 6, Vempro R+ is considered to have sufficient resistance against “tread through” during the construction period. Environmental declaration No environmental declaration according to ISO 21930 has been worked out for Vempro R+. The product contains no chemical substances listed on the Norwegian environmental authority’s observation list of compounds hazardous to human health or the environment. Waste handling / recycling The product may be sent to ordinary public waste deposits after the end of its working life, and can alternatively be recirculated (material- and energy recycling). 6. Special conditions for use and installation General Vempro R+ shall be installed in a way that provides both an airtight and a watertight layer. The application shall follow the principles showed in Building Research Design Sheet no. 525.102 and the instructions given by the manufacturer. Tensile strength - Longitudinal - Transversal Elongation at break - Longitudinal - Transversal Dimensional stability, - Longitudinal - Transversal Tear resistance (nail shank) - Longitudinal - Transversal Inflammability 1) 2) 0,16 ⋅ 10 (m²sPa)/kg EN ISO 12752 1) Sd-value = 0,03 m (50/93 % RH, 23°C) (air thickness eqv.) 2,5 kN 2) SP0487 1) 500 N/50 mm 1) 500 N/50 mm EN 12311-1 and EN 13859 EN 12311-1 and EN 13859 1) 50 % 1) 50 % 2) < - 0,2 % 2) < 0,1 % 2) 255 N 2) 255 N Inflammable EN 1107-1 EN 12310-1 ISO 1182 Limits for control testing Determined by type testing Design considerations Combined roofing underlays and wind barriers should not be used at very exposed places where experience show that drifting snow often may be accumulated between the roofing and the roofing underlay. The roof pitch must be minimum 15°. The wall cladding and the roofing should be laid as soon as possible after Vempro R+ has been installed, in order to prevent that the underlay is freely exposed for a longer period of time. Thermal insulation, vapour barrier and the ceiling shall not be installed until the roofing has been layed and the underlay is checked to be properly mounted. Installation Vempro R+ shall be installed crosswise the rafters as shown in Fig. 1. The roof underlayer shall be installed continuously from gable to gable and the installation shall always start at the eave. The adhesive strips must adhere continuously to each other along all horizontal joints. Any transversal overlap joints must be folded and clamped above the rafters as shown in Fig. 1. SINTEF Technical Approval - No. 20016 Use of the butyl rubber based Glava Dobbeltsidig Tettebånd beneath the battens increases protection against leaks through the nail holes. Glava Dobbeltsidig Tettebånd is recommended for use in locations exposed to high wind, and will decrease the danger of snow accumulation in the roof construction. Smaller holes in the roof underlay can be repaired from the outside with sheets of Vempro R + bonded with Glava Monteringslim. Smaller holes can be repaired from the inside with Vempro Tape. In order to minimize the pressure at the overlaps due to shrinkage of the rafters, the moisture content of the rafters should be less than 20% when installed. Overlapping joints, connections to other components and structures Vempro R + has a felted underside. Therefore the overlapping joints will not have satisfactory air- and rain tightness as given in Table 1. To ensure sufficient tightness of transversal joints above the rafters and at the ridge, Vempro R+ has to be folded and clamped above the rafters as shown in figure segment in figure 1. In addition, Glava Monteringslim and Glava Dobbeltsideig Tettebånd can be used in overlapping joints in connection to for instance valley gutters and bushings. Page 3 of 5 Connections to other components and structures Vempro R+ shall be installed with airtight connections to the wind barrier of exterior walls, and with airtight joints at the ridge and connections between separate roof planes. Connections towards openings in the roof such as roof windows, chimneys etc. must also be made both waterand airtight. Connections to the wind barrier are shown in Fig. 3 and 4. To avoid the risk of fluttering noise Vempro R+ should not be installed at large eaves where the roof underlay can move freely. Bushings Installed bushings like chimneys, skylights, pipes etc. shall be performed in such way that they are air- and watertight. Fig 5 shows an example of a chimney bushing. Roofs with attics Vempro R+ has sufficient low vapour resistance to be used as roofing underlay in non-ventilated attic spaces, see Building Research Design Sheet no. 525.102. Using wooden sheeting made of plywood or OSB-boards, the water vapour resistance has to be documented. Total water vapour resistance for all the layers in the under roof shall not exceed Sd-value = 0,5 m. Dimensions of counter battens and ventilation space The roofing shall have a ventilated space between the roofing and the underlay. For roofs with a maximum length between eaves and ridge of approx. 7 m the following minimum thicknesses of counter battens should be used depending on the roof pitch α: Pitch < 34°: Pitch 34° - 39°: Pitch ≥ 40°: 36 mm 30 mm 23 mm For larger roofs the distance between the underlay and the roofing battens should be increased, see Building Research Design Sheet no. 525.102. The counter battens are cut just below the adhesive strip and are fixed gradually during the installation of the roof underlayer. Maximum thickness of the counter battens used for clamping shall be 36 mm. The counter battens shall be fixed by screws or nails spaced at maximum 300 mm. It is recommended to use screws with plain shank on the part which penetrates the counter battens. For roof pitches below 18º, alternatively 3,1 mm hot galvanized square nails can be used or also grooved nails with a length of 2,5 times the thickness of the counter battens. Fig 3 Example of connection between roof and external wall where the rafters do not extend outside the plane of the wall. Vempro R+ is installed continuously over the front edge plate and is clamped to Vempro Wind barrier at the wall. SINTEF Technical Approval - No. 20016 Fig 4 Example of connection between roof and external wall where the rafters extend outside the plane of the wall. Vempro R+ is folded around the rafter edge and clamped to Vempro Wind barrier at the wall. Page 4 of 5 Fig. 6 Breathable roofing underlay placed on sarking board, with thermal insulation beneath. The overlap joints are continually clamped between battens and counter battens to ensure air- and water tightness. Fig. 7 Vempro R+ installed on a plane surface and wooden board sheeting, which is insulated on the beneath side, using Glava Dobbeltsidig Tettebånd. Fig. 5 Example of assembling a chimney bushing with use of Glava Tettlett Combination with wooden board sheeting Vempro R+ may be applied as roofing underlay in combination with wooden board sheeting provided a total water vapour resistance of maximum Sd-value = 0,5 m. Vempro R+ can be assembled directly to wooden board sheetings made of spruce or pine in old roofs which are reconstructed and insulated. The insulation can then be placed as shown in Fig. 6 and 7 after the old roofing has been removed. When reconstructing old roofs, the old, not breathable, roofing must be removed. Wooden battens have to be used beneath the overlapping joints to ensure adequate air tightness, se Fig. 6. This is even more important in cases where the substrate is irregular and when the joints are crosswise located on the wooden board sheetings. Wooden board sheetings beneath the counter battens, as shown i Fig. 6, decreases the risk of air leakage through screw- and nail holes. The counter battens can be left out provided use of Glava Dobbeltsidig Tettebånd, and a plane substrate which ensures sufficient clamping of the roofing underlay, see Fig. 7. Counter battens should be fixed by use of screws with plain shank on the part which penetrates the counter battens. 7. Factory production control Vempro R+ is subject to supervisory factory production and product control according to contract between SINTEF Building and Infrastructure and DOW Europe concerning this Technical Approval. SINTEF Technical Approval - No. 20016 Page 5 of 5 The manufacturer’s quality management system is certified by Lloyd’s Register Quality Assurance according to ISO 9001:2000, certificate No. GBG0000094. Glava AS has a quality management system which is certified by Nemco AS according to ISO 9001 and ISO 14001, certificate No. 801014. 8. Basis for the approval The approval is mainly based on verification of product properties from type testing documented in the following reports: - SINTEF Building and Infrastructure: Report 3D0226.01-A, dated 13.07.2009 (material and construction properties) - SP Technical Research Institute of Sweden: Report P804061 rev1 dated 15.10.2009 (concentrated load resistance) - tBU: Report 1.1 / 11400 / 589. 0.1.2006, dated 06.02.2007 (material properties) - tBU: Report 1.1 / 11400 / 0203. 1.1.2009, dated 21.06.2009 (material properties) - tBU: Report 1.3/11400/0743.0.1-2009, dated 01.09.2009 (material properties) TG 20016 Approval mark 10. Liability The holder/manufacturer has sole product responsibility according to existing law. Claims resulting from the use of the product cannot be brought against SINTEF beyond the provisions of Norwegian Standard NS 8402 11. Technical management Project manager for this approval is Noralf Bakken SINTEF Building and Infrastructure, dep. Trondheim 9. Marking Vempro R+ combined roofing underlay and wind barrier shall be marked on the packaging with the brand image of DOW/Glava and the manufacturer’s product name, Vempro R+, printed on the product. The product is also labeled with product type and production number. The approval mark for Technical Approval No. 20016 may also be used. for SINTEF Building and Infrastructure Steinar K. Nilsen Approval Manager