fit for thE futurE lifE cyclE SuPPort lcvP for Navy

advertisement

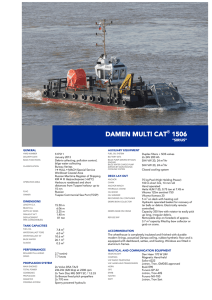

NEWS 13 2010 / 2 three more damen tugs for Port of fujairah page 4 damen shipyards galati fit for the future 8 damen services life cycle support 21 damen product development LCVP for navy 27 page 4 Customer & DAMEN Fujairah Port Authority The Port of Fujairah continues to expand its tug fleet as three more Damen ASD tugs head to this rapidly expanding port. The port authority will then have a 16-strong fleet and all of its tugs are Damen vessels. page 8 Damen yard Damen shipyards galati gets fit for the future Damen Shipyards Galati (DSGa) is just completing a restructuring process that has been designed to see that it is streamlined and more efficient for the future. To ensure that it will emerge stronger after the recession the Romania-based yard is investing both in the facilities and in improving productivity levels. page 11 Damen & Environment sustainability high on the damen agenda “Sustainability is very important in the maritime industry and at Damen a lot of our R&D efforts are looking into this issue, both in terms of manufacturing processes at the shipyard and in terms of our products. page 14 Damen marine components innovative products open up new markets Continuous innovation is proving key for Damen Marine Components. Even in these challenging economic times, this Damen company has managed to expand its international presence and stabilise turnover. page 18 Damen Technical Cooperation (DTC) DTC and Wilson, Sons see cooperation intensify A 17-year cooperation between Damen and Wilson, Sons is set to further intensify as the next generation of offshore vessels and tugboats starts to emerge and the shipbuilding boom continues. It is estimated that around 400 vessels will be built for the Brazilian offshore market in the next few years. page 21 damen services complete life cycle support Mr Heino Westdijk, Director Damen Services, is proud to announce the recent awards of new service agreements from clients in the UK, Nigeria and Germany. page 24 africa for africa damen quality wherever customers are in the world ‘Africa for Africa’ is a unique Damen initiative where vessels are built in Africa for customers in Africa and always to Damen quality standards. Damen is investing millions in capital investment and in people to further develop Damen Shipyards Cape Town. page 27 Product Development Visser design for new faster, lighter LCVP Visser Shipyard build 12 Landing Craft Vehicles Personnel (LCVP) for the Royal Netherlands Navy. As the project nears completion in early 2011, Damen News asks Visser and the Defence Material Organisation (DMO) to reflect on this challenging project. page 30 damen customer finance providing help when financial possibilities shrink away As the credit squeeze has taken hold during the last few years it has become harder for owners to go to traditional banks for their financing needs. Damen offers a wide range of financial packages through its Customer Finance Department. 2 damen news – no 13 – 2010 NEWS foreword three more damen tugs for Port of fujairah 13 2010 / 2 page 4 damen shipyards galati fit for the future 8 damen services life cycle support 24 damen product development LCVP for navy 27 COLOphON Damen News is a publication of the Damen Shipyards Group intended for broad distribution. The purpose of the newsletter is to provide interested parties with optimum information about the worldwide activities of our company. Damen News is distributed by controlled circulation to clients and business partners of the Damen Shipyards Group. Editor and Coordination: PR department Damen Texts: Heldere Taal, Public Relations department Damen, Helen Hill Photography: Flying Focus, Van der Kloet a.o. Design: KETEN Lithography and printing: Grafisch Bedrijf Tuijtel © No part of this newsletter may be reproduced in any form, by print, photo print, microfilm or any other means, without written permission from the Damen Shipyards Group. For remarks / copy: Public Relations department, phone +31 (0)183 63 92 20, pr@damen.nl D A M E N shipyards group P.O. Box 1 4200 AA Gorinchem The Netherlands phone +31 (0)183 63 99 22 fax +31 (0)183 63 21 89 info.group@damen.nl www.damen.nl The financial crisis, which started in 2007, was triggered by a liquidity shortfall in the United States banking system caused by the overvaluation of assets. As readers know it has resulted in the collapse of large financial institutions, bank bailouts by national governments and downturns in stock markets around the world. Considered by many economists to be the worst financial crisis since the Great Depression of the 1930s, the recent slump has contributed to the failure of key businesses, declines in consumer wealth estimated at trillions of U.S. dollars, a significant decline in economic activity and governments have incurred substantial financial commitments. The United States and Europe are suffering the most and significant risks remain for the world economy for at least this year and next. At the same time, we can observe GDP growth rates for quite a number of countries in Latin America, Africa, Central Europe and Asia. And although the global shipbuilding and shipping industry have been hit very hard by the financial crisis, there are still opportunities to be successful in this competitive environment. One of the important features of the Damen Shipyards Group is our global presence. We are always close to our customers wherever they are in the world. In this edition of Damen News almost all continents are featured and we take pleasure in highlighting our global activities in Fujairah, Romania, Brazil, the UK and Nigeria in this issue. You will also find information about the broad-ranging services portfolio of our Customer Finance Department. We are also addressing the increasingly important issue of sustainability and this will help us to focus on managing the Damen Shipyards Group in a responsible way. Despite the financial crisis and the challenges we are facing, we are confident that the ‘Damen approach’ will enable us to be successful in supporting our customers around the world in every possible way we can. We hope you enjoy reading this issue of Damen News and whenever we can be of assistance, please let us know. Bernard Tijs Chief Financial Officer damen news – no 13 – 2010 3 fujairah All-Damen tug fleet Captain Masoud stresses that although the port has an all-Damen tug fleet, Damen has always won the contracts through a tender procedure. “These contracts have never gone directly to Damen. In the last tender we had a shortlist of around six yards, two from Spain, one from the Netherlands, one from Germany and two from Turkey. And we always specify everything, incuding the main engine, the electronics and the auxiliaries.” Trust, competitive prices and an excellent after-sales service are the reasons the Port of Fujairah continues to choose Damen, says Captain Masoud. “The after-sales service is well organised, with great staff. When we have ever asked for spare parts, technical assistance, drawings, they have been provided immediately.” Captain Masoud has a high regard for Mr Kommer Damen, the Chairman of Damen Shipyards Group. “Even though Mr Damen heads up a very big company, he still has time to visit the port regularly and Mr Damen really wants to listen to the customer. I have a great deal of respect for him, it is not every man running a large company that would do that. He doesn’t forget the customer.” There are many examples of Damen being a quality organisation, ▼ Port of Fujairah started with two 1800 HP tugs in 1982 and now they are typically 5700 HP, ranging from 15 tonnes Bollard Pull to 66 tonnes Bollard Pull. Port of Fujairah Harbour Master, Captain Tamer Masoud, says: “It is vital to stay ahead of the marine market to serve our customers needs so we aim to build ahead of demand. To offer a good service we must have a policy of no delays. And because Fujairah is not based on one site, the tugs are needed to offer fast services between the oil terminals inside and outside Port of Fujairah, SPM’s terminals and the ship-to-ship transfer at Fujairah’s anchorage area.” The various pilotage locations was one of the reasons the port made its latest Damen order for seven Damen tugs (three ASD Tugs 2411 and four Stan Tugs) in August, 2008. Four have been handed over and three of these are under final construction in Vietnam. These are expected to arrive in September after performing sea trials in Vietnam. The sister tugs have 66 tonnes BP, 5700 HP and FiFi Class 1 to serve VLCC tankers calling at the new ADCOP SPMs. When the trio arrives, Fujairah will then have a 16 vessel fleet, excluding two Damen workboats, five mooring boats and five pollution control boats. 4 damen news – no 13 – 2010 port authority Port of fujairah continues to expand and Damen vessels are likely to play a role in this future The Port of Fujairah continues to expand its tug fleet as three more Damen ASD tugs head to this rapidly expanding port. When the latest vessels arrive, the port authority will then have a 16-strong fleet and all of its tugs are Damen vessels. An interview with Captain Tamer Masoud, the Harbour Master of Port of Fujairah. ▲▲ Port of Fujairah ▲Damen Stan Tug1606 damen news – no 13 – 2010 5 fujairah port authority he says. On one occasion, one vessel was in the middle of an eight-day drydocking and the port authority found that a certain spare part was needed and not available locally and it was on a Saturday afternoon. “I had a hotline to Spare Parts and Support Damen managers but I wasn’t hopeful being as it was a Saturday and everything was closed. Within a short time I received a phone call saying that the part had been found in Belgium and was being sent to the airport. It arrived in 24 hours. That is the meaning of after-sales service! Damen never runs away from its customers.” Port of Fujairah’s relationship with Damen has grown along with the port. Built in 1984, the port started with a small quay of just 380 m and a draught of 10 m. Now the port authority controls a vast port area, with a total quay length of 5.2 km and it is recognised as one of the top oil and bulk ports worldwide. This is particularly the case when it comes to bunkering, with Fujairah in the Number Two spot. In 2009, the Fujairah Anchorage Area received 11,290 vessels, 70% of which were tankers. And then an amazing 69% of these received bunkering services from the port’s 45 bunker barges. Captain Masoud has also seen the port grow extensively while he has been at the helm. When he joined the port it only had a quay length of 800 m. He says Fujairah is pretty much unrecognisable from the early days. “We now handle containers, bulk, oil products, crude oil, car carriers. In 2009, the port handled 16 m tonnes of aggregate (the port had two ship loaders with a capacity of 2,000 and 4,000 tonnes an hour) and some 37 cu m of oil.” The success of the port is due to its strategic location, going out of the Arabian Gulf towards the Straits of Hormuz, the availability of all the required marine services, low operation and handling charges and the port’s increasing oil terminal capacity, he adds. “And if there is any conflict in the Gulf any shipowner knows that 26 degrees latitude further means that their insurance premium ▼ Damen ASD tug 2411, during tials in Vietnam ▼ Captain Tamer Masoud Port of Fujairah Harbour Master, Captain Tamer Masoud In 1988 Captain Masoud joined Port of Fujairah as a pilot and then in 1992 Captain Masoud became Harbour Master. His other ‘hats’ include being a member of DNV’s technical committee and he was a founding member of the International Harbour Masters’ Association and also a member of the Commercial Arbitration Centre of Abu Dhabi and of Bahrain. Other roles include being a member of the Arab Institute of Navigation, the Society of Naval Architects and the Egyptian Quality Association. Captain Masoud was recently proclaimed Man of the Year of Arab Maritime Excellence in recognition of his services to technical development in the maritime world. 6 damen news – no 13 – 2010 could be increased 300%! So they prefer to stay at the one-stopshop service in our port and anchorage area.” The future of Port of Fujairah Port of Fujairah is recognised worldwide as one of the top oil handling facilities. Currently, it boasts two oil terminals. Terminal 1 has a quay of 840 m, a draught of 15 m and 20 marine loading arms. The first phase of Terminal 2 includes a 1,400 m quay length, a draught of 18 m and 32 marine loading arms. Tankers of 180,000 dwt can be handled or partly loaded VLCCs of up to 300 m. Under a planned second phase, Terminal 2 could be extended by a further 800 m. ADCOP SPMs are able to load three VLCCs at one time to export Abu Dhabi crude oil. “Fujairah’s strategic location and facilities, as well as its ability to offer a one-stop-shop service has seen it expand and this growth is set to continue.” Currently, the port has 122 onshore tanks, representing 3.1 cu m but there are plans that could see this expand to 264 tanks, representing 8.2 m cu m by end-2012. VOPAK Horizon Fujairah has 48 tanks representing a further 1.5 cu m. And another 20 tanks are under construction which will lead to a capacity expansion of 606 cu m. Fujairah Refinery Company wil have 43 tanks with a capacity of 1.1 m cu m. This expansion will be completed by early 2012. “Our policy of always staying ahead of our customer’s needs, means that we do have plans to operate 12 SBMs eventually and clearly, if we go-ahead, we will need more tugs to allow us to serve our customers at different locations. We must have enough tugs to operate a speedy service. We need a specific power at a specific time, if we cannot do that it is useless therefore powerful tugs are required to serve customers’ vessels.” “Oil means energy and demand will not stop so I am very positive about the future. And if Damen continues to operate such a service, Damen vessels are likely to play a role in this future.” ■ damen news – no 13 – 2010 7 damen ship fit for the future Damen Shipyards Galati (DSGa), which is the largest yard in the Damen group, is just completing a restructuring process that has been designed to see that it is streamlined and more efficient for the future as the industry faces the largest crisis it has had in many years. To ensure that it will emerge stronger after the recession the Romania-based yard is investing both in the facilities and in improving productivity levels. Mr Flemming Sørensen, Managing Director, joined DSGa in January. Mr Sørensen has a background in shipbuilding and engineering, having previously worked for Maersk Shipyards in both Estonia and Lithuania for the last 15 years. For Mr Sørensen investing in infrastructure and people are equally important. ‘Back to basics’ DSGa pretty much had to go ‘back to basics’. “The yard’s management and the works council took a good look at productivity, getting more control of subcontractors and bringing everything into balance with our costs.” Crucially, it was important to “try to close projects in the proper way”. “After delivery we draw lessons from each project and make sure that the customer leaves our yard with a good impression. They know we are professional 8 damen news – no 13 – 2010 and that they can have peace of mind knowing their vessel is in good hands.” The yard went on to make big investments in training programmes, both for blue and white-collar workers. Several exchange-oftechnology programmes have taken place with colleagues in the Netherlands and project management courses were introduced. “We depend very heavily on very good project managers, they have years of expertise,” he emphasises. Flexibility Overall, employees are being trained to make them more multi­ functional, while maintaining their core skills, says Mr Sørensen. Training courses are very practical – ‘learning by doing’, he stresses. “We aim to give each individual more scope and expertise. Traditionally at shipyards people want to specialise, which is of course good but also this comes at a price. Sometimes you can lose your flexibility.” It can be healthy for many to try something else, he adds and we have found that everyone is more motivated because they are ▼ E 15 m investment In terms of infrastructure investments, DSGa just opened a new panel line and workshop for assembly work. And last year it opened a huge new hall for vessels up to 115 m. This is one of the largest halls in the group. “It is a big selling point that we can do all the outfitting under one roof,” he says. Already, Damen has invested E 15 m in infrastructure and equipment for Galati. But deemed equally important are investments in people, so several training courses are underway. “It is crucial to maintain our core capacity, we are doing everything we can to retain the skills of our employees.” Mr Sørensen knows that tackling this depressed market is not easy. “My biggest challenge is building up the business in the worst low we have seen in decades and providing work for our 1,500 employees.” But when the process is complete, the shipyard will be leaner and better prepared for future challenges, he stresses. DSGa did not necessarily follow the general trend in that it had several good years between 2003-2007 but 2008 was already a difficult year. However, this was not because the shipyard had no work. Just the opposite in fact, it was simply overloaded. Mr Sørensen says unfortunately many employees left Romania in the boom to work in other parts of Europe or the US and at the same time, the shipyard was overloaded with orders. “Continuity fell away and this led to delays and some quality problems.” Generally, in the peak of the market, shipyards did not have time to analyse their projects, it was a case of capacity and getting as many vessels delivered as possible, he says. But in Romania, it was clear things had to change internally, he stresses, so a restructuring plan was initiated to make working methods more efficient. Then the crisis hit and this led to a sharp decline in activity. “The restructuring then became even more urgent. We had to make the yard more efficient.” pyards galati ▲ Launching of ‘SD Victoria’ (Worldwide Support Ship 8316), built for Serco Mr Flemming Sørensen, Managing Director DSGa Rendering of the Joint Support Ship (JSS) ▼ ▲ Joint support ship foR royal netherlands navy DSGa was awarded a big order for a Joint Support Ship for the Royal Netherlands Navy. The Zuiderkruis-class support ship is a multifunctional vessel designed for amphibious operations. The vessel, due to enter service in 2014, has a large ro-ro deck and it has two landing spots for large helicopters such as Chinooks. The JSS will be used for many support functions such as fuel and food supply, it can accommodate several hundred people and operate as a hospital with some 20 treatment rooms. Work is due to start in March 2011 and set to be completed in 2013. DSGa has also worked on two Landing Platform Dock vessels for the Dutch Navy as well, which were delivered in 2004/5. The JSS will have much of its machinery and equipment installed in Romania, as well as its accommodation units. Naval work is part of a new strategic focus for the Romanian shipyard and it is currently working on two patrol vessels for the Royal Netherlands Navy and participating in an order from the Moroccan Navy. “Damen has a very good name in the Navy sector and we are going for contracts where we compete at the highest level.” A very large project such as the JSS shows our capabilities, stresses Mr Sørensen. But that is not to say DSGa is interested in only navy work, the shipyard now has extra capacity and therefore, a very flexible approach so it also has hopes for various special vessels. ■ damen news – no 13 – 2010 9 taking on a new challenge. For instance, perhaps someone that was welding pipes can also turn their hand to welding structures. “With the new skills employees can then do a little bit of everything, giving much more flexibility.” administration and production. Harmonisation of standards is crucial to the success of any production company, he adds. “We focus on the production side, production-friendly designs, but it is a long term process.” Productivity increase Improved productivity is a fundamental goal of the restructuring. Mr Sørensen says every part of the process was re-examined. “In the boom times, it is easy to lose focus. We had to bring this back, ask how many tonnes of steel we can produce, how much can we paint, how can we improve outfitting and project management etc.” This is relatively easy to measure but the software part of the process is more difficult. The whole design and engineering process is also being examined. “Can we make the engineering more efficient? How can the design process be speeded up while improving quality at the same time?” If a project starts up and the engineering is not ready this has a devastating impact on the whole project, he emphasises. This is not an easy process, admits Mr Sørensen. “It is a real change of culture. People in production are more used to being monitored but it is more unusual for white-collar employees. But we have to maintain our focus for our survival and hope better times come back.” Versatility key Mr Sørensen stresses that the yard should not “be too traditional in its approach and should look at each new horizon”. “We do not have to just think about newbuilds, we have to think flexibly. We could work on conversions, infrastructure projects or even scrapping. In this very difficult market we are focused on keeping Galati versatile.” Harmonisation of standards Damen Shipyards Group has essentially been built up from many companies over the years, he adds. “And many of the companies have different ways of doing something, their drawings may be different for example. No one way is necessarily better, just different.” However, this can mean that a lot of time is wasted in 10 damen news – no 13 – 2010 ‘One for all and all for One’ It is a case of ‘One for all and all for One!’ he stresses. “We are here to produce for the Damen Shipyards Group and the group sells our capacity, so we depend on each other.” Essentially DSGa’s competition comes from Asia for the most part, he adds. “We aim to build to high European standards and at a good price and then squeeze in between the European and Asian market.” And even though times are tough, DSGa is in good spirit, he says. “By focusing on the basics; improving productivity, better engineering, sharper sales, keeping the quality and not least: making customers happy, we are prepared for the future. We are making sure this is all properly addressed. “The market will recover. I don’t know when but we have become a stronger organisation and are well prepared when demand is back,” he stresses. ■ damen & environment sustainability high on the damen agenda Sustainability is high on the agenda from the initial vessel design right through the entire shipbuilding process. Mr Peter van Terwisga, Research Coordinator Damen Shipyards Group, comments: “Sustainability is very important in the maritime industry and at Damen a lot of our Research & Development efforts are looking into this issue, both in terms of manufacturing processes at the shipyard and in terms of our products.” E3 has been underway for many years and several alternative design concepts have been developed for a new hybrid tug. Currently, the project group is making detailed cost calculations, along with a thorough examination of the emissions performance. The results will be made public in a few months. “Environmental performance is often presented as the ratio of benefit to cost and it is much more difficult to define the performance of a workboat when compared to a cargo vessel for instance. But now we have the Damen ASD 2810 as a benchmark and this will further the industry’s knowledge about sustainability issues.” In a similar project, Damen is looking at inland waterway vessels together with Pon Power, Alewijnse and the Dutch research institute Marin. “We are looking at energy usage of the different systems and optimising them.” And in yet another project where Damen works together with three ship operators, Delft University of Technology and Marin, ▼ E3 Tug project One of the most well known projects in which Damen plays a leading role is the E3 Tug initiative. E3 stands for Environmentally friendly, Efficient in Operations and Economically Feasible and here, Damen is working with Smit International, Alewijnse and research institutes in a bid to see if such a tug can be developed. “Smit represents the end-user but importantly, the whole ship­ building chain is involved in the project,” he says. A Damen ASD Tug 2810 operated by Smit and working in the Port of Rotterdam is being used as the “benchmark” tug from which to measure the emissions profile. Damen is aiming to improve the sustainability of the ship by optimising the design in relation to its operational use. “By looking very closely at the operational profile we are asking how can we reduce the amount of energy needed and cut down on emissions.” This has included a detailed investigation into the design of the propulsion system. ▲E3 ASD Tug 2810 – Hybrid propulsion system damen news – no 13 – 2010 11 ▼ Mr Peter van Terwisga, Research Coordinator Damen Shipyards Group ▲ ▲ Air Lubrication – PELS and SMOOTH projects Another interesting development Damen is involved in within the Netherlands project PELS (a Dutch acronym for Energy Saving by Air Lubrication) and in the European 6th Framework Programme project SMOOTH, concerns the air lubrication concept. “To improve the sustainability of any vessel it is important to try and reduce the resistance of the ship to use less fuel to reach a certain speed. And this also cuts back on CO2 and other emissions.” The concept has now been agreed and patented and the final design of the air lubrication system is currently being worked on. Final trials are taking place on the inland waterways in the Netherlands. “Results so far have been very successful in achieving real resistance reduction but we will be carrying out more model tests and looking for a launching customer.” Of course, there are several air lubrication methods, using either the bubble method where a layer of air bubbles or an air sheet is created along the hull, or alternatively, a recess in the bottom of the ship is filled with air. The bubble method is still largely in the laboratory phase but the air chamber approach is being tested by various initiatives. But the PELS project has found, both in trials and at full-scale, that it offers a good way of saving fuel and on cutting back emissions, resulting in a real cost benefit, he stresses. In addition, installing the system would mean limited extra construction costs, adds Mr Van Terwisga. Steef Staal, Managing Director DMC. ▲ Xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx. ▲ cargo vessels are also being examined in terms of sustainability. But Mr Van Terwisga admits this project is challenging because it needs a certain change in mindset. “Contracts often specify the design speed in calm water at full load conditions but of course, when it actually sails it will be operating in many different conditions. Our research has to look at how to optimise the design but this is decoupled from these ideal trial conditions specified in the contract,” he explains. “This means that the operator has to take a different perspective. They have to accept that the speed may be less than specified but in the longer-term, they will be saving money because the design is optimised for its actual service profile.” Every aspect is optimised he stresses, from the bulbous bow, the aft ship and the hull/propulsor interaction. There is a great deal to be gained from this process, he stresses. Xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx. Alternative fuels Alternative fuels are another factor in the sustainability debate and Damen is looking at options here. “LNG is very promising, CO2 is cut by 20% and Nox output will be reduced by 85%. And of course, there is are no Sox or particulate matter emissions. Use of LNG is a very effective way of improving air quality and in many ports this is becoming an increasingly important issue,” he says. Damen, along with Pon Power, Alewijnse and Marin, is looking at LNG possibilities in both the inland sector and for ferries. However, he admits the biggest issue is still the availability of LNG bunkering fuel which is not really established yet, together with the regulatory framework which should make bunkering of LNG operational performance scatter 1 1 0,9 0,8 0,7 0,95 0,6 0,5 0,4 0,90 normalised Rt T=6m 0,3 0,2 0,1 0 0,85 0,90 0,95 normalised Rt T=4,3m 1 ▲Installing Air Lubriation 12 damen news – no 13 – 2010 damen & environment Origins of the AXE BOW SEA AXE development began in 1995 with TU Delft studies of the effect of hull lengthening on efficiency, operability, and operating costs. Tank tests of bows with fine sections and a deep forefoot resulted in the AXE BOW, which reduces vertical acceleration and slamming in heavy weather, causes of seasickness and crews having to slow down. The AXE BOW is also more efficient in smooth water, has better seakeeping in large waves, and resists broaching. The SEA AXE has a true AXE BOW, and should not be confused with yachts that merely have fine bows. ■ Damen’s Sea Axe concept The Sea Axe concept is also proving itself when it comes to sustainability because it dramatically reduces resistance in waves. This unique innovation was developed for high-speed vessels initially to improve operability and for the comfort and safety of the crew. “Fuel usage is cut by 20% because of the optimisation of the hull form in real operating conditions. Although it was initially optimised for seakeeping conditions, it not only has superior motion behaviour but also much lower resistance, consequently improved fuel consumption and lower emissions.” Composite materials Damen has been using composite materials for hulls and wheel­ houses for many years but increasingly, it is seeing if they can be used in other applications. “For instance in our new Water Taxi in Dubai and for the fast Interceptor range, carbon composite material was used to reduce water displacement.” In cooperation with Delft University, (the Maritime Technology, Marine Engineering and Aerospace Technology faculties), Light Weight Structures, DSM and Teijin, Damen is working on new structural design concepts, both when it comes to products and materials. “We are looking at combinations of the choice of material, the structural design and the production process. “Damen is really paying a lot of attention to this issue and spending a great deal of effort in improving the sustainability of our products. Any improvement in sustainability saves money by cutting back on fuel usage and maintenance costs. And we are showing that these developments, that will greatly improve the environment, are now technically feasible.” ■ calm water resistance added resistance in water possible at relevant locations. But as emission regulations get more stringent it could be that there is more demand for LNG, he adds. “The potential benefit to air quality is immense but the safety regulations are still lagging behind the technological developments. But if we can show that this is technically feasible and how these developments can be integrated into ship design that is a huge step forward.” 100 10 80 8 60 6 40 4 20 2 5 10 n Sea Axe Concept n Conventional hull 15 20 25 30 35 40 speed added resistance 12 resistance 120 0,5 1,0 1,5 2,0 waveheight n Sea Axe Concept n Conventional hull damen news – no 13 – 2010 13 damen innovative new products open up new markets for dmc Continuous innovation is proving key for Damen Marine Components (DMC). Even in these challenging economic times, the Damen company has managed to expand its international presence and stabilise turnover. Recent products of the company’s innovation programme include the Optima 0.4 D nozzle, especially suitable for the shortsea sector and the Optima 0.6 D, which has been developed for push boats. Based in Hardinxveld-Giessendam, DMC typically produces around 700 nozzles a year and it already has a renowned name in the inland waterways market. Managing director Mr Steef Staal comments: “Even before the crisis we could see it was an ending story, Optima nozzles are already very well known in the inland sector so we had really reached saturation point. When the recession came along it was also doubtful that there would be many newbuilds constructed. Consequently we are working very hard to find new clients and new markets.” New shortsea and push boat nozzles Working together with the well-respected Dutch maritime research institute, Marin, the new 0.4 D nozzle was relentlessly tested. The evidence was clear: the new shortsea nozzle offered less resistance, better thrust, better performance and all at higher speeds. Currently, four 8,000 dwt vessels which will use the high speed, shortsea nozzle are being built in China. Alongside the new 0.4 D nozzle, DMC also developed the 0.6 D, a longer version of the 0.4 D aimed at the push boat industry. This nozzle has much more thrust at lower speeds. 14 damen news – no 13 – 2010 The 0.6 D nozzle is already deployed on the Veerhaven XI, a push barge operated by Thyssen Krupp Veerhaven, a company specialising in the dry bulk sector and operating on the River Rhine. Mr Staal says: “The 0.6 D has proved very successful. The vessel can now push six barges up river with two engines rather than three.” He points out that both of the new nozzles are also suited for rebuilds. Coolwater nozzle Another recently developed nozzle is the coolwater nozzle. “We have developed the possibility to use the nozzle as a cooling unit. The run through of the water is very efficient,” stresses Mr Staal. A number of Damen workboats are already using the new coolwater nozzle. ▲ marine components ▲ Optima nozzle ø 6050 mm ‘Vox Maxima’ Hopper Dredger ▲New production ficility in Suzhou, China ▲ Mr Steef Staal, Managing Director DMC Optispec Another nozzle developed by Damen is the Optispec. Essentially the Optispec is a free hanging, steering nozzle that can rotate around the fixed propeller with attached rudder blade. Optispec is very compact and it is fully compatible with conventional rudders and vessels such as self-propelled cutter suction dredgers. Mr Staal is very pleased that the new nozzles have opened new markets. The Far East particularly is a growing market. “Damen Marine Components supplies most of the leading European companies, the major rudder and propeller builders and slowly many of these companies are moving their production to the Far East.” Brazil too, is growing. DMC has teamed up with Damen Technical Cooperation and a leading producer in Brazil so vessels and nozzles can be produced in Brazil but to Damen designs. One of the strengths of DMC is its production capacity. The company has two major production sites, one in Poland (Gdansk) and one in Suzhou, China. In its China facility Damen Marine Components can produce nozzles of up to 4.5 m inside diameter and in Poland the possibilities are endless. Suzhou was recently expanded when a second hall opened in the summer last year. China totals some 7,000 sq m and the Poland production facility is twice the size and has the advantage that units can be delivered over the water. As well as expanding capacity, DMC strives to innovate. Using its in-house expertise DMC is developing a new machine that makes it much easier to make nozzles. “We will soon be able to produce very specialised profiles that we could never have done before.” Under construction, the new machine can handle 1 m D to 4.3 m D nozzles, with an unlimited plate thickness. Mr Staal comments: “We believe that the new machine can result in time savings of at least 20% to 25%. It is a huge investment, represents a much smoother production operation and it is a greener process because less welding and grinding are involved. “And the run-through time is much shorter so it will allow us to expand our delivery.” DMC is also developing a new robotics production method. Another innovation is the development of a composite nozzle. “Clearly nozzles produce a lot of electrolysing because they are made from steel. If they can be made from Epoxy then there is not this problem.” Innovation, whether evident in products or production processes, is at the heart of the company and fundamental to its future growth, emphasises Mr Staal. ■ damen news – no 13 – 2010 15 Successful launch of the first Multi-Mission Frigate for the Moroccan Navy latest news On 12 July 2010, the signal sounded at Damen Schelde Naval Shipbuilding (DSNS) to start the operation to launch the first Multi Mission Frigate to be built for the Moroccan Navy. The 105 m long ship has been built in Vlissingen-East on ground-level and according to plan, it is now ready to undergo further outfitting in the shipyard in Vlissingen City. Working in close cooperation with Mammoet, the 2,000 dwt vessel first departed from the hall towards the water and then it was placed on a pontoon. After that the vessel was transported to deeper water and the pontoon was sunk down until the frigate could float by itself. This ‘direct water launch’ is especially unique in the total operation. With the help of tug boats the ship was then towed to Vlissingen City where it will undergo further construction during the coming year. In the last two years DSNS has made several diverse investments to build up the yard in Vlissingen-East in order to make this unique construction. The area has undergone a complete metamorphosis. For example, the existing production hall has been extended by 120 m and a Ro-Ro facility was built so ships can be transported from the hall on the pontoon and can then be ‘driven’ into the water. The second and third frigates for the Moroccan Navy, both 98 m long, will be launched into the water in exactly the same way next year. ■ ▲ Mr Maarten Hulshoff ▲ Launch of the first Multi Mission frigate Photo: Jorrit Lousberg 16 damen news – march 2010 meet damen at new damen Executive Board member Maarten Hulshoff, the successor of the Executive Board Member Cor van Zadelhoff, does not like bureaucracy, political shenanigans and inaction. He loves direct, head-on action and entrepreneurship. He wants to have an impact, also at Damen. At the beginning of August he officially became Executive Board Member but Mr Hulshoff (1947) has been making himself familiar with the world of Damen for quite some time already. Shipbuilding is new to him, so he wants to take as much as possible in during this time. He has visited several diverse shipyards, deepening his knowledge of the Damen portfolio and he has spent time getting to know the Board of directors and the other members of the Executive Board. “I have great respect for what has been achieved”, he stresses. “It is incredibly impressive that one generation built such a firm and has such a clear vision. I consider it a great honour to be part of Damen.” In the coming time, Mr Hulshoff wants to visit more yards to get a feeling for the production process and for the people that work for Damen. He was pleasantly surprised by the wide diversity of Damen’s products. “I have received the catalogue with all sorts of boats and ships. Unbelievable, it does not stop. It is not bulk, its products with added value. That is the strength of Damen I think.” Incidentally, his predecessor Mr Zadelhoff will still be involved with Damen in an advisory role. ■ SMM 2010 7 – 10 September 2010 Hamburg, Germany Offshore Europe 15 September 2010 Aberdeen, UK Monaco Boatshow 22 – 25 September 2010 Monaco Interferry 3 – 5 October 2010 New York, USA Defendory 5- 9 October 2010 Athene, Greece Offshore Energy 7 October 2010 Den Helder, Netherlands Fort Lauderdale Boatshow 29 October – 2 November 2010 Fort Lauderdale, USA Indo Defence 3 - 6 November 2010 Jakarta, Indonesia METS 16 - 18 November 2010 Amsterdam, Netherlands New Orleans Workboatshow 1 - 3 December 2010 New Orleans, USA Inmex 8 - 10 December 2010 China ▲ The monohull dredger ‘Amoris’ Launch of ‘Amoris’ On the 9th of June last the hull of the Damen dredger was christened and launched. The monuhull dredger, which is to work on the ‘Amoris’ contaminated sludge project in the Antwerp Harbour, has been built on the Damen yard in Kozle, Poland. The hull has been fitted out with the Damen dredge pumps and their electric drives plus the dredge piping. Currently further outfitting is taking place in Poland, and it will continue in the Netherlands in a few weeks time. The dredger is scheduled to be delivered to Sereant (being the combined forces of DEME and Jan de Nul) in October of this year. ■ damen news – no 13 – 2010 17 dTC and cooperation intensifies on back of A 17-year cooperation between Wilson, Sons and Damen, one of Brazil’s largest shipping and offshore companies, is set to further intensify as the next generation of offshore vessels and tugboats starts to emerge and the shipbuilding boom continues. Damen Technical Cooperation (DTC) and the Brazilian company have worked closely for many years, with Wilson, Sons buying the material package and design from DTC and building its tugboats and Platform Supply Vessels (PSV) entirely based on Damen designs. Damen’s well-known ASD 2411 and ASD 3211 are built in Brazil, together with the PSV 3000 and PSV 4500 supply vessels. Huge demand for offshore vessels Until now, tugboats have typically had a Bollard Pull of 40-55 tonnes or 70 tonnes and the PSV suppliers, 120 and 130 tonnes BP. But as the shipbuilding boom in Brazil continues apace there is more demand for larger, stronger vessels, says Mr Adalberto Souza, Wilson, Sons Director. “In the offshore sector it is now all about being further from the coast, more powerful vessels are needed. We hope to work with Damen on the development of designs for these larger vessels.” 18 damen news – march 2010 For Wilson, Sons, the biggest advantage of working with DTC is it enables the company to develop its shipbuilding knowledge. “We have boosted our technological knowledge and improved our shipyard over the years,” adds Mr Souza. Trust is key Mr Bram Verwijs, Senior Project Manager at Damen Shipyards Gorinchem, comments: “Damen has always been totally open about how it builds. Damen standardisation is fundamental. As much as possible has been standardised, whether it is mechanical, electrical, ventilation etc. And at Wilson Sons everything is made in advance along these standardised concepts as well. For instance, all the piping is finished beforehand and then built into the vessel sections. Everything is essentially prefabricated, built in blocks and fitted at the yard. “For example Wilson, Sons has built an ASD 2411 Tugboat by wilson, sons brazil’s shipbuilding boom building up the hull including the wheelhouse, without the stern and the bow attached to the midsection to make it easier to install all of the equipment in the engine room, including the main engines and generator sets. After that they fitted the bow and the stern section and installed the Aquamasters.” Initially, the relationship was just a straight client-shipyard relationship but now it is a very friendly cooperation, completely different, says Mr Verwijs. “The most important thing is that we both try to find good solutions for both parties. It is a win-win situation.” At 173 years old, Wilson, Sons is now the largest builder and operator of tugboats in the country. Originally, the company was established by two brothers who distributed British coal through­out Brazil. But many years later the company diversified into the ships agency business and then into the towage sector. Wilson, Sons was in fact, one of the first companies to build diesel electric vessels in the country. It wasn’t until 1991 that Wilson took the step to build its own fleet. But this was originally to Brazilian designs. Mr Souza says to remain Number One, the company has to continually upgrade and the Brazilian designs did not lead to the most efficient, manoeuvrable vessels. Then Damen came along with its designs, allowing for an immediate improvement. Since that time the relationship has gone from strength to strength, says Mr Souza, describing the relationship “as a truthful friendship”. “We have a very open relationship based on trust. This is very important.” Two new shipyards So far, Wilson, Sons has been building to serve its own fleet but the company is considering building to sell to third parties as well. Around 50 ASD tugboats have been built and eight PSVs over the years. A further 10 tugs are under construction and three PSVs. “And we are not finished, there is more to come!” quips Mr Souza. The 10 tugs are due for completion end-2011 and the yard is full to 2012. Demand has also led Wilson, Sons to make the decision to expand capacity by building two new shipyards. This will allow the company to build around 14 PSVs a year and more than 10 tugs. The new yards, one of which will be near the existing yard and one that will be in the south, will be fully operational in five years time. ▼ Opting for Damen designs Mr Souza is looking forward to the future and to the further deepening of the Wilson-Damen cooperation. Already, the relationship has led to several innovations, he points out. In 2001, DTC did not yet have a design for a PSV so the first came from Rolls Royce. But when the oil giant Petrobras put out a tender for future PSVs, Damen created its own, diesel electric design. Subsequently, this design using diesel electric propulsion became the favoured design of Petrobras and the energy giant led the trend to switch to diesel electric systems. In 2006, eight PSVs were ordered to this design and this was followed by an order for another three that are just being completed. These days Wilson, Sons now only works with DTC designs. ▲ Mr Bram Verwijs (left) and Mr Adalberto Souza (right) ▲ Damen ASD tug 2411 damen news – no 13 – 2010 19 dTC and wilson, sons “I think Wilson, Sons chose Damen because we have a good way of understanding each other. Our relationship is the added value,” adds Mr Verwijs. One time, Wilson asked if there was any possibility if some of their employees could be sent over to a Damen Yard in China, adds Mr Verwijs. “Everything was arranged by Damen Gorinchem, all the flights, accommodation, the work-week in China and some sightseeing.” Wilson engineers have also visited Damen for two weeks to look at the Damen’s design and drawing office and to work with its engineers. 70% local content This open cooperation has also allowed them both to successfully adapt to the legal requirement in Brazil that demands that at least 50% of materials should be sourced locally. “For instance, Damen has cooperated with WEG facilitating technology transfer. This meant that WEG could carry out the electrical and automation work in Brazil. And in fact, Wilson was ▲Damen Platform Supply Vessel 7216 20 damen news – no 13 – 2010 the first company to produce an offshore vessel with more than 60% local sourcing! And for the new generation of vessels, we are also expecting to be able to have around 70% local content,” stresses Mr Souza. DTC packages in demand worldwide Mr Verwijs comments that both the DTC material package and licence agreement are ideal, depending on the region where a company operates. For instance, in the US because of the Jones Act, DTC sells a lot of licensing agreements. The US coastguard has had around 70 plus fast crew suppliers built under a Damen licence at the Bollinger Shipyards. In Brazil, material packages are favoured, together with local supply. There is a similar preference in Asia. “A DTC package allows yards to employ the local workforce and the employees spend their money in the country itself, so this is a big boost to the local economy.” ■ damen services complete life cycle support Mr Heino Westdijk, Director Damen Services, is proud to announce the recent awards of new service agreements from clients in the UK, Nigeria and Germany. “Train and maintain” Customers looking for autonomy and cost optimisation benefit from Damen’s “train and maintain” concept. Within this concept Damen performs maintenance to meet customer’s requirements, while at the same time, training the customer’s crew. The customer’s maintenance competence level rises and consequently, maintenance hours start to decrease. Although Damen Services works hard to improve its performance, we know we can do better. Currently, Damen Services is continuing to work on the integration of our service products into a customerfriendly service solution. Within this concept our customers share benefits from our system integrating knowledge. ▼ “One-stop-shop” For customers having an excellent service organisation in place, Damen helps to increase maintenance efficiency. The Damen Asset Management Operating System (DAMOS), in combination with a spare part delivery solution, supplies the right material at the right time at the touch of a button. COMPLETE LIFE CYCLE SUPPORT SOLUTION OUR CUSTOMER DAMEN SERVICES OUR SUPPLIERS DAMEN MAINTENANCE MANAGEMENT SPARE PARTS DELIVERY DAMEN FIELD SERVICES ▲ Joining Damen in 2008, Mr Westdijk focused on the internal service organisation and searching for an answer to an increasing demand for after-sales support, Damen Services developed a wide-ranging portfolio covering the entire vessel’s life cycle. How can Damen, as a global player, deliver the right services to its broad customer base? Working closely with the customer was key to finding synergies. By combining and integrating the right products and knowledge, Damen Services is able to provide a solution for a diverse customer demand, ranging from periodic surveys up to complete out­sourcing of all maintenance activities. Mr Heino Westdijk, Director Damen Services ▲ Life Cycle Support Solution damen news – no 13 – 2010 21 damen services UK Border Agency Since the final delivery of the fourth Damen Stan Patrol 4207 in 2004, the UK Border Agency visits Damen regularly to carry out major maintenance. For more than six years, Damen has carried out all of the scheduled, and a number of unscheduled dockings, for all of the UK Border Agencies Cutters. This includes a nonDamen built cutter as well. As well as dockings, Damen Services performs the following maintenance activities based on a Damos Planned Maintenance System: n Periodic oil sample analysis n A nnual Life Saving Appliances surveys and inspections with certificate updates and renewals n M ajor Engine maintenance (main and auxiliary) based on running hours and manufacturers recommendations In addition, Damen allocates the spares and consumables necessary to perform the work. Damen and the UK Border Agency developed a good working relationship resulting in a contract extension for another two years in May, 2009. Damen Services is proud of the UK Border Agency credits they received concerning the first five-year contract period. “To date, Damen have delivered every vessel back to us on time after each docking period. This is attributable to detailed planning in advance of the docking, an enthusiastic and knowledgeable workforce and excellent project management during the docking period. We have been very satisfied with the maintenance contract and UKBA will be looking to extend this contract on its expiry in 2011.” Starzs Investments of Nigeria In September, Damen successfully handed over the MV ‘Osayame’, a Damen ASD Tug 3211 to Starzs, A company owned by Greg H. Ogbeifun. The ‘Osayame’ is named after Mr Ogbeifun’s two-yearold daughter. ‘Osayame’, means God’s Gift in the Nigerian native Bini tongue. The Damen ASD Tug 3211 is currently operating as a line handling tug near a Floating Production Storage and Offloading unit operated by Total E&P Nigeria Limited, for at least the next five years. Mr Westdijk emphasises that operating offshore for an oil and gas company, which involves more than 6,000 running hours a year, requires a high maintenance standard. Having the right maintenance organisation in place, meeting the availability, reliability and Health, Safety and Environment requirements is a challenge. To illustrate our commitment, the Damen Services staff completed all necessary training, including Helicopter Underwater Escape Training. Starzs and Damen Services faced this challenge and worked out a solution. The Starzs crew is responsible for all the first-line maintenance and Damen Services delivers the second-line maintenance in close cooperation with the vessel’s crew four times a year. The delivery of all necessary spare parts and consumables are also included in this maintenance agreement. In addition, a DAMOS Planned Maintenance System has been delivered and installed using a data exchange module, enabling both shore and Damen personnel to monitor the vessel’s maintenance performance. 22 damen news – no 13 – 2010 daily inspections. Wasserschutz Polizei and Damen had to find an affordable, efficient solution. On the delivery of the first Stan Patrol, a three-year maintenance agreement was signed for all three vessels. This agreement contains, amongst other things, the planned maintenance system DAMOS, monthly check and maintenance visits, in combination with training sessions to enable the Wasserschutz Polizei to carry out visual inspections. As a result, maintenance of the vessels is almost entirely outsourced and all within the customer’s budget. Continue working together to improve (y)our success in the future As you may know, Damen Services changed course in early 2008. We are grateful to our customers and wish to thank them for their confidence and hospitality. They assisted us to a better understanding of the business, which allowed us to customize the solutions we offer. Delivering a result to the satisfaction of both parties continues to drive us, with increased added value and complete life cycle support. Heino Westdijk and his team expects to be of service to more customers in the near future, offering the full Damen Services life cycle support, creating clear benefits for all parties involved. ‘Damen Services grows globally, enabling us to provide better services locally,’ he stresses. ■ ▲Damen ASD Tug 3211 – Nigeria Damen Stan Patrol 4207 – UK Border Agency Damen Stan Patrol 2005 – Wasserschutz Polizei ▲ ▲ ▲ Wasserschutz Polizei of Niedersachsen The first out of three Stan Patrols 2005 for the Wasserschutz Polizei (Water Police) of Niedersachsen, Germany, was delivered in February this year. After waiting for more than a month for all the rivers to be free of ice, the vessel sailed with its own crew from Delfzijl Holland to Brake. Meanwhile, the second one was delivered in June and afterwards it sailed to its homeport in Emden. Focusing on the core business is becoming more and more important in the maritime sector. Following this trend, the Wasserschutz Polizei closed down its maintenance and repair yard by the end of 2009. The Wasserschutz Polizei wanted to outsource all of its maintenance activities on the Stan Patrols, except for the damen news – no 13 – 2010 23 africa Damen Training Centre opens in South Africa Damen’s commitment to Africa is clear as the company continues to invest. This was further demonstrated when Damen opened its new Training Centre in July. Mr Frank Rebel became the Managing Director of Damen Shipyards Cape Town around a year ago. South African-born and with experience of shipbuilding in the Benelux countries, Mr Rebel says he has identified an urgent need for skills development in South Africa. “Damen builds hi-tech vessels to very high quality standards and this can only be accomplished with skilled personnel at all levels within the organisation.” The first 10 apprentices started in August and Mr Rebel stresses that they will undergo a very practical training programme where they will actively be involved in manufacturing components for vessels under construction. “Our aim is to have between 10-15% of our workforce on the apprenticeship programme, whilst current personnel are also given the opportunity to develop and 24 damen news – no 13 – 2010 hone their skills. Employees are encouraged to regularly participate in training courses.” Belonging to a multinational such as the Damen Shipyards Group is a great advantage, he says. “Damen has some 34 companies worldwide, so we can call on Damen experts from other countries to help with training.” There are also considerable capital investments going on in both new plant equipment and in infrastructure. “To build quality products one has to have the correct tools. For example, welding technology is constantly developing and we should keep up with, and make use of, these latest technologies.” Restructuring the workflow within the facilities, combined with the refurbishment of the three major building sheds, piping workshop, painting shed, small steel workshop, carpentry workshop and stores, has resulted in a much-improved working environment. Damen’s commitment to South Africa was recently recognised when the shipyard was awarded the Black Economic Empowerment Level 3, which is one of the highest levels. This South African programme looks at factors such as procurement, ownership, equality, enterprise, skills and socioeconomic development. “We are very proud of this achievement. It recognises what we are doing in respect of training, as well as our commitment to the shipbuilding industry in South Africa,” stresses Mr Rebel. ■ for africa damen quality wherever customers are in the world ‘Africa for Africa’ is a unique Damen initiative where vessels are built in Africa for customers in Africa and always to Damen quality standards. Damen Shipyards Cape Town is the hub of the Damen operation in Africa and Damen is investing millions in capital investment and in people to further develop the shipyard. ‘Africa for Africa’ is the brainchild of Mr Lorenz Winkel, Board Member of Damen Shipyards Cape Town and Sales Director Africa. “We want to be closer to our clients in South Africa and on the Continent. Having a presence in Africa is very important to our customers,” says Mr Winkel. Previously, Damen would serve Africa from the Netherlands but now there is a full sales and services team in Cape Town. “Our team has many years of experience and now we can react much faster when it comes to maintenance, service and support. We can also be more cost-effective because we can service the market locally. The lines of communication are shorter and we speak the same language and understand the culture.” ▼ Currently, some 800 Damen-built vessels are operational in Africa. Of these, around a quarter were built under Damen Technical Cooperation contracts in Africa. Now, many of the vessels can be serviced from Cape Town as well. Damen Shipyards Cape Town operates as a full service hub and can offer everything from a single survey to dockings, or a full maintenance service package for Damen and non-Damen vessels. This gives Damen’s customers full insight and control of the total cost of ownership during the vessel’s entire lifespan. ▲▲ Mr Lorenz Winkel, Sales Director Africa ▲ ▲ Stan Tug 2208 for Tanzania Ports Authority Mr Frank Rebel, Managing Director Damen Shipyards Cape Town damen news – no 13 – 2010 25 africa for africa Damen has had a long history in the African market. For more than 20 years Damen worked with Farocean Marine under the Damen Technical Cooperation structure. This partnership worked very well and when the opportunity presented itself, Damen successfully acquired the business. Mr Winkel says Africa offers huge potential and because, unlike most of Europe, it has continued to show growth, Damen Shipyards Cape Town is building stock vessels so it can service this rapidly developing market quickly. Around half of the yard’s capacity is already dedicated to building standardised vessels so it has enough in stock. “This means we can deliver the vessel in four to eight weeks rather than the 18 to 24 months it would usually take!” stresses Mr Winkel. And this rapid-response concept has proved itself time and again. Recently, Cape Town supplied a 22 metre, 40 tonne Bollard Pull tug to the Tanzania Ports Authority that was required urgently. The tug was delivered from stock in just five weeks. The shipyard is building a series of these tugs. The other half of the yard’s capacity is used for specific contracts. Damen Shipyards Cape Town recently built and delivered a ▲ Transporting a Damen ASD Tug 26 damen news – no 13 – 2010 69 tonne Bollard Pull ASD Tug 3211 for a private Nigerian company. “It made a huge difference to our customer that we are based in Africa. His company is the first indigenous operator to be involved in the oil business, so his vessel could be built here and serviced from Africa.” Currently, two, 10 metre Mooring Launches are under construction for the Kenya Ports Authority for delivery early 2011 and a 50 tonne passenger landing pontoon is being built for the Zanzibar Port Authority. Damen’s Modular Barge concept is also proving very popular. Modules, built to standard container sizes, can be quickly assembled on the spot, to create a whole array of vessels or platforms including dredgers, tugboats, ferries, barges and jetties. Five of these modular barges are now on stock. Mr Winkel says the market is a very exciting one and moving fast. The group would certainly like to see the ‘Africa for Africa’ concept grow, both through Damen’s own investment and by working with strong partners. Damen aims to expand in South Africa and eventually it may consider increasing its presence in other African countries as well. ■ visser design for new faster, lighter lcvp proves its worth to the navy Before the LCVP contract, the yard had built other naval vessels including three diving support vessels in 1992. Two of them were also later lengthened by the Den Helder-based yard. A few years later Visser built five Landing Craft Utility (LCU) vessels. This contract was completed in 2002 and in 2006 the LCUs were also lengthened. And although this build meant that the shipyard had formed a close working relationship with the DMO, Visser could take nothing for granted. Visser had to fight off stiff competition when it came to the LCVP tender, especially from the builder of the Britishdesigned Mark 5B, the LCVP currently used by the British navy. Mr Willem Burger, Senior Project Manager of the Sea Systems Branch of the DMO says: “We were looking for a shipyard with very good occupational health and safety levels and very high environmental standards. This took some extra effort from Visser but the yard was always very forthcoming.” There also had to be a good price of course! he quips. product development Weight requirements were to govern the project After a year of discussions, Visser was awarded the contract in December 2006. Already before the contract was signed, it damen news – no 13 – 2010 ▼ Visser Den Helder, a full subsidiary of Damen, will soon complete a large contract which has seen the yard build 12 Landing Craft Vehicles Personnel (LCVP) over a four year period for the Royal Netherlands Navy. Weight issues played a crucial role in every aspect of the build. And as the project nears completion in early 2011, Damen News asks Visser and the Defence Material Organisation (DMO) – the procurement representative of the Dutch Ministry of Defence – to reflect on this challenging project. 27 became clear that one issue was to govern the build – the exacting weight requirements. And this really meant that Visser and all the suppliers had to examine every single aspect of the design and engineering process and make sure the strict weight limitations were met. The LCVPs are used onboard the two Royal Netherlands Navy’s Landing Platform Docks, HNLMS Rotterdam and the HNLMS Johan de Witt. This meant the new LCVP could not weigh more than 23.5 tonnes loaded with troops, otherwise there would be problems hoisting the vessels. The DMO did not demand that the Mark 5B should be copied or improved on but it was always clear that the basic outlines of the new landing craft had to be the same as the Mark 5B so the Netherlands and British navies could use it on their mother ships. Although the requirements mentioned in the Dutch specification exceeded the UK requirements in many aspects. New design However, Visser did not look to improve on the existing LCVP, instead it decided to create an entirely new design. “We did not look at the original design. To make a better vessel we needed to start afresh, with the weight factor always taken into account,” says Mr Peter van den Berg, Deputy Director of Visser. A crucial part of the project and certainly a reason for its success was Visser’s insistence on a six-month engineering phase. This resulted in a design that had been completely worked out before the build of the pre-series model started. Mr Jelle Loosman, Visser Managing Director comments: “This half-year of engineering was part of the contract. With the LCU project we built and engineered at the same time and we did not want to do that again, particularly because of the weight issue. So after the six months, we had a design review and then it came to the go, or no-go decision. “These six months were very beneficial and helped identify potential problems,” he adds. The Visser directors admit that the contract presented a challenge but they were confident that they could meet the very exacting requirements of the DMO. “Absolutely nothing was standard issue, every aspect had to be reconsidered,” says Mr Van den Berg. “Certain choices were made from propulsors and engines, down to the smallest bolt.” All possible efforts were made in order to reduce weight before and during the building process. In the engine room, Visser made use of plastic piping for the first time ever to get the weight down. Lloyd’s agreed to include this new development under the Class specifications. All construction was based on Finite Element Calculations, the wheelhouse was made from Glass Reinforced Polyester and even bolts within the fendering were made from plastic, all with the goal of reducing weight. A ‘weighty challenge’ As well as Visser, suppliers too, had to take up the weighty challenge. Some could not manage, they admit. Some of the engine suppliers simply could not come up with a lighter engine but Volvo managed to find a solution. Dutch firm Imtech, the supplier of the electrical systems, took part in the initial engineering phase and it managed to reduce the weight of its systems as well. Many other changes were made during the process. Differences in the Royal Netherlands Navy’s requirements from those of the British meant that the hull form had to be changed to adhere to the 28 damen news – no 13 – 2010 very strict stability requirements. As the landing craft has quite a flat bottom, there was more slamming initially so another small hull was added underneath to improve the seakeeping behaviour and to offer more bottom protection. A thicker bottom plate was also added to make the vessel less noisy. Rigorous testing in four countries The new LCVP underwent a period of rigorous testing. Initially model testing took place in the towing tank of the Maritime Research Institute Netherlands (Marin). Damen Research also gave input for the resistance and propulsion tests. The Sea acceptance tests, in June 2008, went as expected but in real life the landing craft performed even better than the towing tank tests had shown. The LCVP underwent sea and landing trials in three different countries; Norway for Arctic conditions, West Africa for warm water tests and the famous beach at Instow in the UK for the landing tests. “Speeds were 10%-15% higher than the towing tank tests. Under tests the vessel performed up to 18 knots but in real life it was well above 25 knots and this was even in Arctic loading conditions with 16 marines and their equipment,” says Mr Burger. Under “normal” conditions with 10 marines onboard and some Arctic trailers, speeds of 30 knots could even be achieved and this increased to 31 knots in Somalia. Versatility Visser’s versatility has certainly been proven during the build, says Mr Burger. After the hoisting tests in October 2008, the DMO decided the vessels should be lengthened near the aft hook. This was purely a safety aspect to move away from the mothership’s rigging, he says. The vessels were extended by 20 cm, which was the optimum given the weight distribution. In Somalia, where the LCVP is already widely deployed to combat piracy, a few other requirements presented themselves. The need product development ▲ The LCVP in action during Operation Atalanta off the Somalian coast for air conditioning became clear and more ballistic protection was added at the gunners’ positions. “Visser made these changes in just three weeks on four vessels,” he emphasises. The hood was also heightened to accommodate the tall Dutchmen and to allow an improved line of sight for the coxswain. The shape of the landing ramp was changed and the anchoring winch allows safer operation. In addition, the positions of antennae were moved to improve safety onboard. Visser deploys a dedicated team and project leader on the project. “The door was nearly always open, we had a direct line to channel all of the requests to the yard. They showed a lot of flexibility at very short notice,” stresses Mr Burger. As well as the DMO, the marines themselves had a lot of input into the project. Every fortnight meetings were held between the yard, the DMO and usually the coxswains and an experienced officer so they could channel their feedback into the build. ▲▲ The LCVP during cold weather trials in Norway ▲ Mr Peter van den Berg (left) and Mr Willem Burger (right) visser den helder Established in 1923, Visser was originally established to serve the Dutch fishing fleet but as the fisheries industry declined Visser broadened its portfolio to include other markets. In addition to fishing vessels, the yard has built research vessels, Arctic trawlers, coasters, buoy-laying vessels, patrol vessels and several other naval vessels. Visser has been a member of the Damen Shipyards Group since 1993. Quick deployment Already, the LCVP is proving useful in Somalia where four are deployed. This LCVP is much more flexible and can pick up and return to the ship very quickly, adds Mr Burger. Often used as the “eyes and ears of the fleet”, the LCVP can also be deployed very quickly. For instance, the Johan de Witt does not have to use its docking facilities, with the craft able to launch almost immediately. The yard, which could work on four vessels simultaneously, is very proud of this true Dutch vessel. “And even though there were many changes, we are still ahead of schedule. We do what it takes to make the customer happy,” adds Mr Loosman. Currently, the tenth LCVP is nearing completion. ■ damen news – no 13 – 2010 29 damen damen customer finance provides help when financing possibilities shrink away As the credit squeeze has taken hold during the last few years it has become harder for owners to go to traditional banks for their financing needs. Damen is very aware of the problem and in a bid to assist clients it offers a wide range of financial packages through its Customer Finance Department. Mr Bastiaan Kooistra, Damen Manager Customer Finance, says although Damen has offered financial assistance for many years, there has certainly been more demand for these services since end-2008 because traditional banks are shying away from the maritime industry as they clamp down on lending. “Not every shipyard is prepared to offer such a facility,” he says. The Customer Finance portfolio is broad ranging. “We can help private operators that perhaps need help with purchasing one tugboat or foreign public buyers such as the Ministry of Defence or Transportation in deals worth E 200 m - E 300 m. Deals have covered a wide range of ship types including fast crew supply vessels, dredgers, tugs, workboats, cargo ships, naval vessels and patrol vessels. “We are very competitive but the main advantage is our ability to be able to access the export credit risk insurance offered by the Dutch State.” Damen mostly arranges export finance and it works very closely with the government’s Export Credit Agency, Atradius Dutch State Business. The Dutch Ministry of Finance takes on part 30 damen news – no 13 – 2010 of the risk associated with the loan in a bid to promote Dutch exports when the commercial banks are not willing to offer the finance. Long-term loans On the whole, this involves long-term loans to customers outside of Europe, though not exclusively. Mr Kooistra comments: “Nowadays customers ask us more and more what we can offer, they want to check all the possibilities open to them. Before the crisis this was mainly customers outside of Europe in developing countries but now European and US companies are looking to Damen for help as well.” For instance, Damen has just helped arrange a loan for a Damen Modular Barge for a customer in the US. “But this facility customer finance Added value Damen’s Customer Finance facilities are not just for private, small companies, it also assists government bodies such as the coastguard, police or port authorities. For instance, Customer Finance recently helped Tanzania Ports Authority (TPA). Damen, together with Atradius, helped back the financing of a Stan Tug 2208, Stan Tender 1905 and an ASD Tug 2810 in a seven-year financing deal. In addition, Damen can facilitate financing with some of its major suppliers such as Caterpillar Finance. If a Damen vessel is being built with a Caterpillar engine, Caterpillar is willing to offer financial help to Damen customers with long-term loans and this is not just for the engine but the whole vessel. As well as this Damen has started making arrangements with the German Development Bank, DEG. “It is quite something that DEG is willing to finance a Netherlands-built vessel for a customer located in Mexico”, quips Mr Kooistra. The financing arrangement was for a Fast Crew Supplier 5009 for the Mexican operator Naviera Integral. Customer Finance can also offer a buy-back guarantee either, to customers or the financing bank. Customers can sell the vessel back to us against an agreed sum, says Mr Kooistra. It could be that a customer is not sure they will have work for the vessel after a certain period so they could re-sell it back to the group, he adds. On the other hand, Damen can issue a buy-back guarantee to the financing bank as extra collateral. In case of a default under the loan the bank can exercise its rights under the mortgage and then resell the vessel to Damen. Economic development Damen can also apply for Dutch export subsidies. Currently three Stan Patrol 4207 vessels are being built for the Albanian Coast­guard with the help of a grant. Here, the Dutch government subsidises 35% of the contract price. On the one hand Dutch exports are stimulated but also these grants promote local economic development in the receiving country. Similarly, four buoy-laying vessels were recently built in Indonesia. Damen makes all the arrangements with Atradius, the Ministry of Finance and the commercial bank involved, delivering the feasibility studies, financials and the relevant information. Usually handling around 10 to 15 vessels a year, Damen has arranged hundreds of financial packages across the globe. “We can do all the applications, customers save time and effort and this adds to their financing means and bank lines. We can do all the work for our customers, they do not have to negotiate with the banks. A real advantage is that these loans are really long-term whereas most banks would only come up with one or two year offers,” stresses Mr Kooistra. ■ ▲ is still mainly interesting for customers in developing countries where they may face extremely high interest and inflation rates.” “We offer this Dutch State insurance as an additional way of financing, next to existing bank lines as an added value service to our customers,” says Mr Kooistra, who was formerly working for Atradius. It is very gratifying to see customers develop their business, he says. There are examples of customers that originally purchased a Damen tug with our financial assistance and then they have grown over the years to operate a substantial Damen fleet. Now they can attract financing in their own right, adds Mr Kooistra. Mr Bastiaan Kooistra, Manager Customer Finance ▲Damen Fast Crew Supplier 5009 damen news – no 13 – 2010 31 damen latests recent deliveries, a selection ▲ top to bottom DAMEN SHOALBUSTER 3009 DAMEN AZIMUTH TRACTOR DRIVE TUG 2909 DAMEN CUTTER SUCTION DREDGER 450 DAMEN FAST YACHT SUPPORT VESSEL 5009 32 damen news – no 13 – 2010 ▲ top to bottom DAMEN MULTI PURPOSE VESSEL 5212 damen COMBI FREIGHTER 12000 DAMEN ASD TUG 2411 DAMEN STAN TENDER 2306