Carlsberg Group Sustainability Report

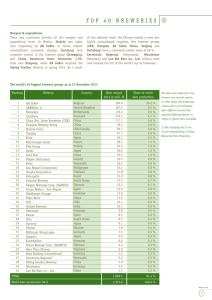

advertisement