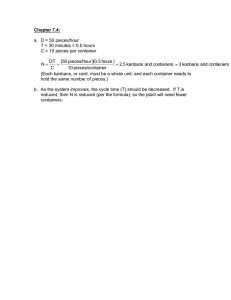

Contracting Parties - BSA

advertisement