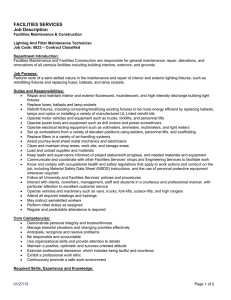

Mar 09 - The University of Iowa Facilities Management

advertisement