National Fenestration Rating Council Incorporated

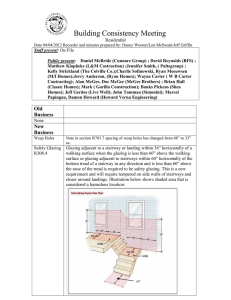

advertisement