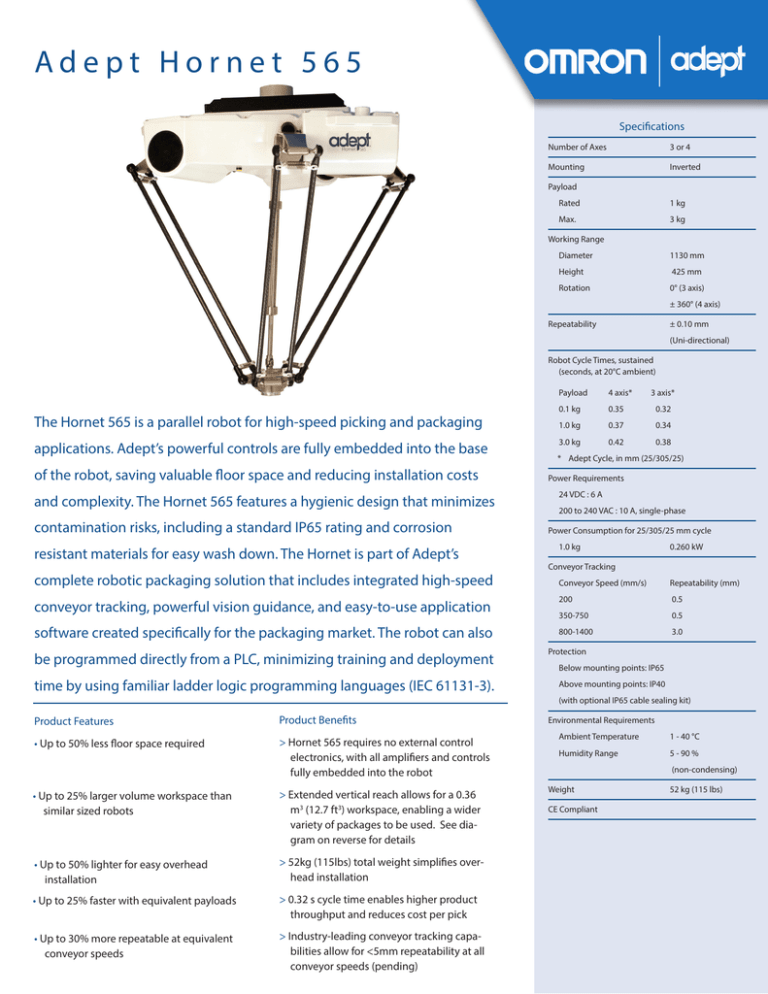

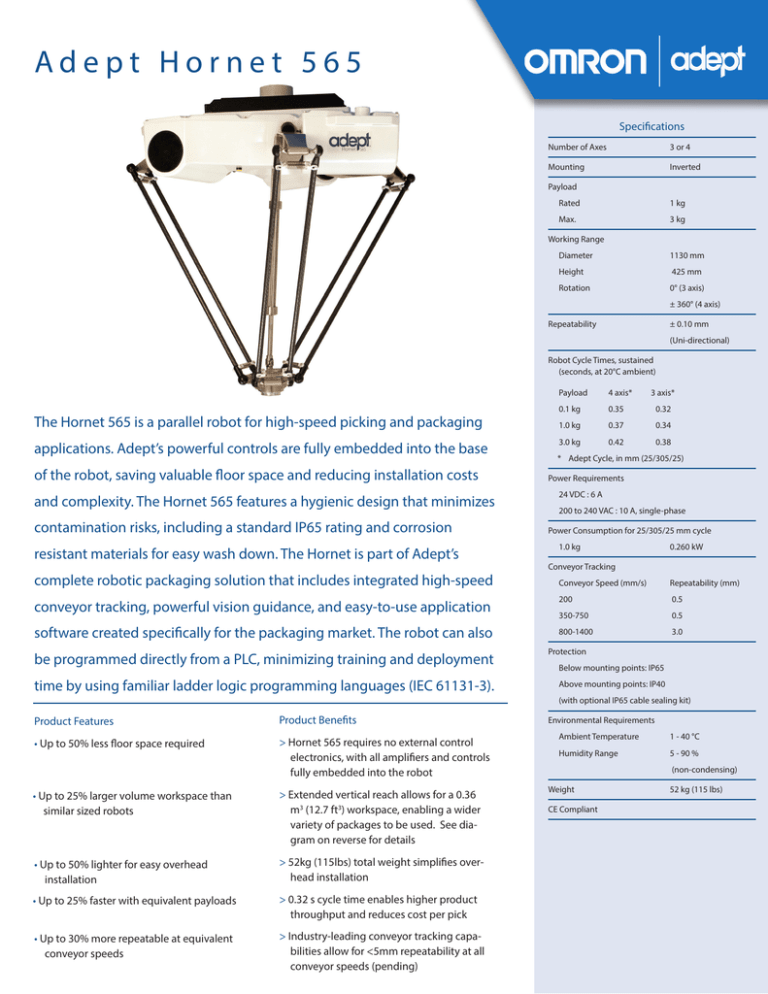

Adept Hornet 565

Specifications

Number of Axes

3 or 4

Mounting Inverted

Payload

Rated

1 kg

Max.

3 kg

Working Range

Diameter

1130 mm

Height

425 mm

Rotation

0° (3 axis)

± 360° (4 axis)

Repeatability ± 0.10 mm

(Uni-directional)

Robot Cycle Times, sustained

(seconds, at 20°C ambient)

The Hornet 565 is a parallel robot for high-speed picking and packaging

applications. Adept’s powerful controls are fully embedded into the base

of the robot, saving valuable floor space and reducing installation costs

and complexity. The Hornet 565 features a hygienic design that minimizes

contamination risks, including a standard IP65 rating and corrosion

resistant materials for easy wash down. The Hornet is part of Adept’s

complete robotic packaging solution that includes integrated high-speed

Payload 4 axis*

3 axis*

0.1 kg

0.35

0.32

1.0 kg

0.37

0.34

3.0 kg

0.42 0.38

* Adept Cycle, in mm (25/305/25)

Power Requirements

24 VDC : 6 A

200 to 240 VAC : 10 A, single-phase

Power Consumption for 25/305/25 mm cycle

1.0 kg

0.260 kW

Conveyor Tracking

Conveyor Speed (mm/s)

Repeatability (mm)

conveyor tracking, powerful vision guidance, and easy-to-use application

200

0.5 350-750

0.5

software created specifically for the packaging market. The robot can also

800-1400

3.0

be programmed directly from a PLC, minimizing training and deployment

Protection

Below mounting points: IP65

time by using familiar ladder logic programming languages (IEC 61131-3).

Above mounting points: IP40

(with optional IP65 cable sealing kit)

Product Features

Product Benefits

Environmental Requirements

• Up to 50% less floor space required

> Hornet 565 requires no external control

electronics, with all amplifiers and controls

fully embedded into the robot

Ambient Temperature 1 - 40 °C

Humidity Range

5 - 90 %

•U

p to 25% larger volume workspace than

similar sized robots

> E xtended vertical reach allows for a 0.36

m3 (12.7 ft3) workspace, enabling a wider

variety of packages to be used. See diagram on reverse for details

Weight

• Up to 50% lighter for easy overhead

installation

> 52kg (115lbs) total weight simplifies overhead installation

• Up to 25% faster with equivalent payloads

> 0.32 s cycle time enables higher product

throughput and reduces cost per pick

• Up to 30% more repeatable at equivalent

conveyor speeds

> Industry-leading conveyor tracking capabilities allow for <5mm repeatability at all

conveyor speeds (pending)

CE Compliant

(non-condensing)

52 kg (115 lbs)

7

4

5

6

3

5.35

1.50

0.50

0

8

NOTES: (UNLESS OTHERWISE SPECIFIED)

ADEPT HORNET 565

1. DEBURR AND BREAK ALL SHARP EDGES BETWEEN .10 - .20 MAX

DETAIL B

SCALE 2 : 1

2 BAG AND TAG FINISHED PART WITH:

PART NUMBER, REVISION, DATE, AND VENDOR IDENTIFICATION

2

1

REVISIONS

REV:

DETAIL C

SCALE 2 : 1

DESCRIPTION OF CHANGE:

A

INITIAL RELEASE FOR QUOTE

DATE:

APPROVED BY:

09-25-2014

T. VICKROY

3. MATERIAL: ALUMINUM 6061-T6

D

4. MASK ALL THREADED HOLES FROM FINISH

5 SURFACE FINISH TO BE BETWEEN

8

AND

D

17

45°

6. FINISH: ANODIZE MIL-A-8625F, TYPE II, CLASS 1

7. WHERE APPLICIABLE, FINISH PART MUST MEET ADEPT COSMETIC

SPECIFICATION NUMBER 03220-000

45°

10°

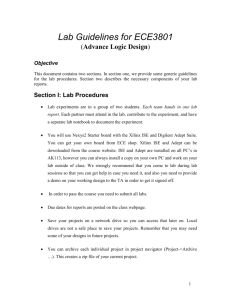

Dimensions: Adept Hornet (mm)

Dimensions: Flange (mm)

.03 A

M45 X 1.5

A

C

A

58.00

52.00

44.995

44.985

6.02

6.01

25°

C

8.00

50.00 B.C.

A

C

45°

59.70

59.50

.03 A

40.00

63.00

62.80

.03 A

65.00±0.03

.03 A

4X 90°

11.00

4X M6X1.0

B

Ø38 through hole

4.05

4.02 SLOT

0

8.00

5

Dimensions: Footprint (mm)

747 (4axis)

B

886

0

7.00

19.50

27.00

26.50

2X 40.00

B

52.50

2X 49.00

722 (3axis)

62.00

2X

B.C.

740

A

JOINT 2

Radius 565

20.30±0.05

A

SECTION A-A

---

8

7

A

JOINT 3

ADEPT TECHNOLOGY PROPRIETARY, 2012

THIS DRAWING CONTAINS PROPRIETARY

INTELLECTUAL PROPERTY OF ADEPT TECHNOLOGY

INC. AND MAY NOT BE COPIED, MODIFIED,OR

OTHERWISE DUPLICATED, PRODUCED

OR CHANGED WITHOUT THE EXPRESSED WRITTEN

PERMISSION OF ADEPT TECHNOLOGY INC.

6

Radius 205

100

THIRD ANGLE PROJECTION

5

4

A

UNLESS OTHERWISE SPECIFIED:

APPROVALS

* REMOVE ALL BURRS AND SHARP EDGES. DRAWN:

* DIMENSIONS APPLY AFTER PROCESS.

T. VICKROY

* INTERPRET DRAWING PER ANSI Y14.5.

* DIMENSION ARE IN MILLIMETERS.

CHECKED:

X.XXXXXXX

TOLERANCES:

1 PLACE DECIMALS:

2 PLACE DECIMALS:

3 PLACE DECIMALS:

ANGULAR DIMS:

45

Radius 375

41.17

41.15

.03 A

38.00

275

20.30±0.05

DRAWING VIEW SCALE:

(UNLESS OTHERWISE NOTED)

T. VICKROY

X.XXXXXXX

1:1

5960 INGLEWOOD DRIVE - PLEASANTON, CA 94588

925-245-3400

TITLE

mm-dd-yy

SIZE

APPROVED:

X.XXXXXXX

TECHNOLOGY, INC.

SPINDLE, FLANGE,

3X 120° PLATFORM,

HORNET s565

09-25-2014

PROJECT ENG:

3

R

mm-dd-yy

DESIGN:

.50

.10

.05

.5

ROBOTICS DIVISION

DATE

09-25-2014

mm-dd-yy

2

B

DWG. NO.

14233-000

REV.

A

SHEET

1 OF 1

1

50

3X

43

M12X1.75

24

3X

+0.03

24 0.00

.2

JOINT 1

Options and Peripherals

5±0.1

36°

SECTION A-A

SCALE 1 : 2

• ACE PackXpert™ is a powerful software package designed to rapidly deploy packaging automation solutions. The software wizard walks you through the configuration

of packaging applications and generates all of the underlying robot programming;

synchronizing cameras, conveyors, grippers and robots. ACE PackXpert also features a

powerful 3D emulator that allows complete system configuration and testing in a virtual

environment.

• The SmartVision MX™ is the easiest and most dependable way to add powerful vision

guidance and inspection to your robotic packaging applications. The Adept SmartVision MX vision processor is a ruggedized, industrial computer optimized for demanding

machine vision applications. It is compatible with a wide range of GigE and USB 3.0

machine vision cameras. AdeptSight software adds powerful vision tools that quickly

identify and inspect randomly oriented products and provides their precise location to

the robot.

• GigE Power-over-Ethernet and USB 3.0 machine vision cameras

• T20 manual control pendant

The Adept Hornet system includes the following:

• Adept Hornet 565 robot with fully integrated amplifiers and controls

• Cable to connect optional front panel, pendant, and external safety systems

• Adept ACE™ software - an integrated, point-and-click development

environment for Adept’s entire product portfolio of robots and controls

• User documentation

Downloads:

Download CAD files for the Adept Hornet 565 Robot from

http://www.adept.com

Omron Adept Technologies, Inc.

Tel: 925-245-3400 Fax: 925-960-0452 Email: info@adept.com

omron247.com

adept.com

Specifications subject to change without notice.

©2015 Adept Technology, Inc. ALL RIGHTS RESERVED. The information provided in this communication or

document is the property of Adept Technology, Inc. and is protected by copyright and other intellectual property laws. In addition, any references to any Adept Technology, Inc. products are the marks and property

of Adept Technology, Inc. [and may be registered trademarks]. All other trademarks or tradenames are the

property of their respective holders.

09366-073 Rev. A