1. General 2. Type Designation 3. Technical Data NJR1 Soft Starter

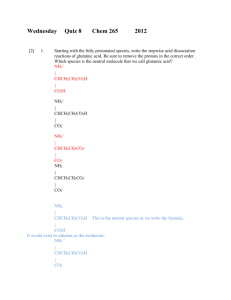

advertisement

Soft Starter NJR1 Soft Starter 1. General NJR1 series soft-starter is used for controlling motor automatically. It adopts intelligentized digital control mode and use SCMC(single chip Microcomputer) techniques as the core to control silicon controlled module. It is suitable for all kind of load drived by squirrel cage asynchronous motor.NJR1 can make motor start softly in any conditions, protect the drive system, cut down the damage to the power line caused by start current and ensure the motor start-up stably. The motor will shut down smoothly and the extra-inertia impact to the drive system can be eliminated. The perfect system protection function must prolong the system's life, make the system cost down and enhance the system reliability. It includes all kinds of starting device function, therefore, it become the new generation and most ideal product to replace the traditional Y-△ starter and couple starter. 2. Type Designation N J R 1-□ / □ Installation(G-Switchgear type, Blank-Wall hanging type) Power of Control Motor(kW) Design number Soft Starter AC Motor Company Code 3. Technical Data Supply voltage: three phase AC400V±15%, 50Hz±2% Initial current: start current limited from 1~4.5 times Ramp up time : 1~240s Ramp down time: 1~120s Min. voltage for soft starter: 25%Ue~75%Ue Kick start-up time: 0-10(×0.1) (0 denotes no jump start) Start-up frequency: average interval 10 times every hour Environment condition: Temperature is -25℃~+55℃, relative humidity is 90% max(T=20℃), altitude below 2000m, vibration less than 0.5G, placing in the room where is fine ventilation, no conductive dust, no corrosive gas. .16. 4. Overall and Mounting dimensions Diagram 1(wall hanging type) B E A 软起 软停 急停 D C 设置 复位 Diagram 2(switchgear type) H B E C D F A F H-17 Model Rated current (A) Power of control motor(kW) NJR1-7.5 15 7.5 NJR1-11 22 11 NJR1-15 29 15 NJR1-18.5 36 18.5 NJR1-22 42 22 NJR1-30 57 30 NJR1-37 70 37 NJR1-45 84 45 NJR1-55 103 55 NJR1-75 140 75 NJR1-7.5/G 15 7.5 NJR1-11/G 22 11 NJR1-15/G 29 15 NJR1-18.5/G 36 18.5 NJR1-22/G 42 22 NJR1-30/G 57 30 NJR1-37/G 70 37 NJR1-45/G 84 45 NJR1-55/G 103 55 NJR1-75/G 140 75 NJR1-90/G 167 90 NJR1-110/G 207 110 NJR1-115/G 210 115 NJR1-132/G 248 132 NJR1-150/G 280 150 NJR1-160/G 300 160 NJR1-185/G 349 185 NJR1-220/G 404 220 NJR1-250/G 459 250 NJR1-280/G 514 280 NJR1-315/G 579 315 NJR1-400/G 720 400 NJR1-500/G 900 500 Overall Dimensions(mm) B×E×D Mounting dimensions(mm) A×C 240×205×430 190×415 325×205×490 290×465 330×235×555 265×525 600×370×1600 500×300 700×600×1800 540×540 800×800×2280 640×740 .18. Soft Starter 5. Wiring 5.1 Description of control circuit terminal and secondary wiring About Terminal Lable Terminal Lable Terminal Function Description Input signal Soft-start signal(continuity signal) X1 X2 X3 X4 Input signal Soft-stop(pulse signal) X5 X6 Input signal Reset signal (pulse signal) Stop-immediately X16 X17 Output signal Event signal (Protect event, Fault event, Warning event) X19 X20 Output signal Running signal 01 Output signal By-pass relay NO 02 Output signal By-pass relay NC 03 Output signal By-pass relay public point 5.2 Standard wiring Diagram 5 L 1 ,L2 ,L3 ,N R TA2 110 N T FU1 FU2 207 QF R ,S ,T SB6 SB5 235 Power off QF U RQ W RQ 03 01 215 KA1 213 211 RQ 03 02 217 KA1 219 221 KA2 HY SB3 KA2 227 Running lamp HR1 RQ 1. Descripticon of control terminal: M ~ HR2 X, X2--Soft-start signal X, X4--Soft-stop signal RQ X5, X6--Reset signal (Stop-immediately) X16, X17--Event signal(Protect, Fault, Warning) X19 X1 223 X16 TA1 Stop lamp Fault lamp KA1 225 U,V ,W Start lamp SB1 231 X17 PV V HG SB2 SB4 A PA E KA1 Event signal X20 X2 KA2 Event signal X4 KA1 X19, X20--Running signal 2. Remote control point in broken-line box X3 233 KA1 Diagram 6 N R L 1 ,L2 ,L3 ,N FU1 RQ 03 01 213 RQ 03 02 215 RQ X16 X17 217 TA2 HR1 Stop lamp 211 110 HG Running lamp A PA E QF HR2 Fault lamp R ,S ,T SB2 RQ SB1 219 KA1 Soft-start control SB3 221 KA2 Soft-stop control SB6 223 KA3 Reset Control /Stop-immediately W PV V TA1 M ~ SB5 1. Descripticon of control terminal: X1, X2--Soft-start signal X3, X4--Soft-stop signal RQ X5, X6--Reset signal (Stop-immediately) X19 X1 X20 X2 KA1 KA2 X5 X6 X16, X17--Event signal(Protect, Fault, Warning) X19, X20--Running signal 2. Remote control point in broken-line box X3 X4 .19. U U,V ,W SB4 KA3 6. Functions 6.1 Digital, type SCM control; 6.2 Advanced soft start mode; a. Voltage start-up mode b. Current limiting start mode 6.3 With several optional protection functions such as peak over current protection, Input/Output phase failure protection, overload protection, current limiting overtime protection, over-voltage protection, overheat protection of radiator, inlet phase sequence protection etc. 6.4 Communication between operator and machine; 6.5 With the function of indicating operation current and supply voltage; 6.6 With the function of fault display and memory 6.7 Natural air cooling, save space; 6.8 After the side of input power being added the isolation switch, it can be hung on the wall to use seperatedly ( Display panel operation) 7. Ordering Information ( Refer to Overall and Installation dimensions) Example 1: The power of control motor is 45kW,by-pass AC contactor shall be assembled in the soft starter, wall hanging type installation is adopted. Model: NJR1-45 Example: The power of control motor is 45kW, the complete device is adopted the cabinet type installation. Model: NJR1-45/G Special order: It can be customized according to user's technical requirements. .20. Soft Starter NJR1D soft starter (Control Unit) 1. General NJR1D soft starter device adopts 16 bits MPU as the core to control high power controllable silicon module, and to realize soft starting and soft stopping of three-phase AC asynchronous motor(Squirrel cage motor), In addition, it supplies a few optional protection function like overload protection, phase-failure protection, over current of process protection, under current of process protection, over-voltage, under-voltage. The product is usually assembled with complete control switchgear, and it must be connected with by-pass contactor with the corresp-onding specification. The product is arailable for the protection of motors ranging from 7.5kW to 500kW. It is widely applied in the fields of metallurgy, petrol, fire control, mine, petrochemical, It is a new generation of product Y-△ starter and coupling starter. 2. Type Designation N J R 1 D -□ Power of Control Motor(kW) Device Core Design No. Soft Starter AC Motor Company code 3. Technical Data Supply voltage: three phase AC400V±15%,50Hz±2% Initial current: 1~4.5 In Ramp up time: 1~240s Ramp down time: 1~120s Min. Voltage for soft starter: 25%Ue~75%Ue Kick start-up time: 0-10(×0.1) (0: without kick start-up) Start-up frequency: (average interval) 10 times every hour Environment as condition: Temperature is -25℃~+55℃, relative humidity is 90% max ( T=20℃), altitude below 2000m, vibration less than 0.5G, placing in the room where is fine ventilation, no conductive dust, no corrosive gas. 4. Overall and Installation dimensions Diagram 1 B Diagram 2 B A C D C D E A 软 起 设 置 软 停 复 位 急 停 软起 设置 软停 复位 急停 E .21. Model Overall Dimensions(mm) A B C D E Rated current Power of control (A) motor(kW) NJR1D-7.5 15 7.5 NJR1D-11 22 11 NJR1D-15 29 15 NJR1D-18.5 36 18.5 NJR1D-22 42 22 NJR1D-30 57 30 NJR1D-37 70 37 NJR1D-45 84 45 NJR1D-55 103 55 NJR1D-75 140 75 NJR1D-90 167 90 NJR1D-110 207 110 NJR1D-115 210 115 NJR1D-132 248 132 NJR1D-150 280 150 NJR1D-160 300 160 NJR1D-185 349 185 NJR1D-220 404 220 NJR1D-250 459 250 NJR1D-280 514 280 NJR1D-315 579 315 NJR1D-400 720 400 NJR1D-500 900 500 Weight (kg) Remark 8 212 233 340 364 170 9 Diagram 1 10 12 230 258 378 530 205 20 Diagram 2 250 288 455 590 220 25 Diagram 2 5. Wiring 5.1 Primary electric diagram Diagram 3 L1 L2 L3 QF RST U1 V1 W1 KM NJR1D U V W KH Note: The circuit breaker (QF), AC contactor (KM) and the thermal overload relay(KH) is supplied by M ~ user. .22. Soft Starter 5.2 Description of control circuit terminal and secondary connection principle About Terminal Lable Terminal Function Description X1 X2 Input signal Soft-start signal(continuity signal) X3 X4 Input signal Soft-stop(pulse signal) Terminal Lable X5 X6 Remark Input signal Reset signal (pulse signal) Stop-immediately X16 X17 Output signal Event signal (Protect event, Fault event, Warning event) AC240V/5A X19 X20 Output signal Running signal AC240V/5A X22 X23 Output signal Top of ramp signal(AC240V/10A) AC240V/10A 5.3 Control circuit diagram Diagram 4 L1 L2 L3 N QF KM KH FU RQ X22 R S U1 V1 W1 KM HD X23 1.SB1、SB2、SB3The wire do not more than 1.5m. T 2.X1 connect to X19 and X2 connect to RQ Emereacy Stop/reset U X6 V W X5 Soft stop X4 SB3 KH X20.(refer to the diagram) Soft start X3 X2 SB2 X1 X19 A2 A A 3.The softstarter has over-load function, though KH(thermal relay) is unnecessarily. SB1 4.To operate from panel, SB3(button) is Push button box A1 X20 unnecessarily. 5. A2(amperometer ) for monitor current TA used to user or remote monitor. 3~ M Diagram 5 N L1 L2 L3 KA3 RQ X16 X17 SB3 KA2 SB1 KA2 QF KA3 KA1 SB2 KA1 KM 1.The softstarter has over-load function,though KH FU KH HD RQ (thermal relay) is unnecessarily. X22 X23 2.X1 connect to X19 and X2 connect to X20.(refer to R U1 V1 W1 KM S T the diagram) RQ Emereacy Stop/reset Soft stop U X6 V W KA2 KH Push button box TA 3~ M .23. X5 A1 A2 A A X4 KA1 3.To operate from panel, To connect X5 and X6 from Soft start X3 X2 X1 KA1 X19 X20 KA2 is unnecessarily. 4.To used this connection, The panel of starter is unavailability . 5.A2(amperometer ) for monitor current used to user or remote monitor. Diagram 6 N L1 L2 L3 KA2 RQ X16 X17 SB1 KA2 QF KA1 SB2 KA1 FU KH KM HD RQ X22 X23 R S U1 V1 W1 KM T RQ U 1.To used this connection, X1 and X2 short for start, X2 V W X1 contrarily for stop. 2.The softstarter has over-load function,though KH KA1 KH (thermal relay) is unnecessarily. 机旁按钮箱 A1 A2 A A 3.A2(amperometer ) for monitor current used to user TA or remote monitor. 3 ~ M Diagram 7 N L1 L2 L3 KA3 SB3 KA2 SB2 KA1 QF SB1 KM KH FU X22 R U1 V1 W1 S HD RQ X23 T 1.X1 connect to X19 and X2 connect to X20.(refer to RQ 急停、复位 KM U X6 V W X5 KA3 KH 机旁按钮箱 TA A1 A2 A A 软停 X4 软起 X3 KA2 X2 X1 KA1 X19 X20 the diagram) 2.The softstarter has over-load function,though KH (thermal relay) is unnecessarily. 3.To operate from panel, To connect KA3(AC Contactor) is unnecessarily. 4.A2(amperometer ) for monitor current used to user or 3 ~ M remote monitor. 6. Functions 6.1 Digital, type SCM control; 6.2 Advanced soft start mode; a. Voltage start-up mode b. Current limiting start mode 6.3 With several optional protection functions such as peak over current protection, input/output phase failure protection, overload protection, current limiting overtime protection, over-voltage protection, overheat protection of radiator, inlet phase sequence protection etc. 6.4 LED display and operation keyboard assembled, to realize the communication of operator and machine, set kinds of parameter and programming. 6.5 Display operating current and supply voltage; 6.6 With the function of fault display and memory 6.7 Natural air cooling, space saving; 6.8 Supply output of running relay, ramp to top relay and fault relay, it is for external interlock; 6.9 One soft starter start multi motors. 7. Order Information Example 1: Power of controlled motor is 45kW, it is installed and used mating with soft start cabinet or distribution cabinet. Model: NJR1D-45 Example 2: Power of controlled motor is 90kW, it is installed and used mating with soft start cabinet or distribution cabinet. Model: NJR1D-90 .24. Soft Starter NJR1 Soft Start Control Switchgear (One soft starter starts multi motors) 1. General NJR1 soft start control switchgear (one soft starter starts multi motors) is designed and produced for lowering production cost, device investment, and etticient utilization of the space. It is designed on side of controlled device or in the switching room, to realize field control or remote control. One soft starter starts multi motors with the same power or approxim ate. The interval time for motor starting is more than 5mins best. The inner core part of this product is NJR1D series soft start device standard: IEC/EN 60947-4-2. 2. Type Designation N J R 1-□/□ Pcs of Controlled Motor:2(one starts two), 3(one starts three)or 4(one starts four) Power of Control Motor(kW) Design No. Soft Start AC Motor Company Code 3. Technical Data Supply voltage: three phase AC400V±15%, 50Hz±2% Initial current: start current limited from 1~4.5 times Ramp up time : 1~240s Ramp down time: 1~120s Min. voltage for soft starter: 25%Ue~75%Ue Kick start-up time: 0-10(×0.1) (0 denotes no jump start) Start-up frequency: average interval 10 times every hour Environment condition: Temperature is -25℃~+55℃, relative humidity is 90% max(T=20℃), altitude below 2000m, vibration less than 0.5G, placing in the room where is fine ventilation, no conductive dust, no corrosive gas. 4. Overall and Installation dimensions Diagram 1 D B E .25. Power of control motor(kW) Model NJR1 (One soft starter starts two motors) NJR1 (One soft starter starting three motors) Mounting dimensions(mm) A×C Overall Dimensions(mm) Length(B) Height(D) Width(E) 7.5~45 700 600 1800 55~75 800 600 2200 650×546 90~280 1000 600 2200 850×546 550×546 315 1000 800 2200 850×746 7.5~45 800 600 2200 650×546 55~75 1000 600 2200 850×546 90~280 1200 600 2200 1050×546 315 1200 800 2200 1050×746 5. Wiring diagram 5.1 Wiring diagram (One soft starter starts two motors) Diagram 2 N L1 L2 L3 N L12 N L13 FU2 FU3 1 23 KH1 3 5 KH2 25 SB1 SB4 QF2 SB3 KM1 L12 L11 SB8 KM2 KM1 L13 19 KM3 11 KM2 KM3 KM4 31 KM2 17 SB7 KA1 9 QF3 SB6 29 KA1 QF1 SB5 27 SB2 7 21 39 KM3 41 KM4 33 KM4 43 KM1 R S T 37 15 NJR1 Soft Starter(Core) HR1 RQ KM2 KM4 KH1 KH2 KM1 HG1 HY1 Stop KM2 Running Start HR2 HY2 Stop KM3 HG2 Start KM4 Running U V W N L11 FU1 KM1 69 KM3 RQ 101 TA1 X22 PA1 102 A E TA2 RQ PA1 A KM1 E 71 67 3~ M1 3~ M2 1# 2# KM3 X1 X23 KA1 KA2 X2 KA2 .26. Soft Starter 5.2 Wiring diagram (One soft starter starts three motors) Diagram 3 N L1 L2 L3 N N L12 L13 FU3 FU2 23 1 KH2 KH1 3 5 25 SB1 27 SB2 SB4 SB3 KM1 SB8 KM2 KA1 L11 QF2 QF3 L12 KM1 QF4 L13 L14 19 11 KM2 SB7 13 39 21 KM3 41 KM4 T HR1 KM1 KM5 37 Stop NJR1 Soft Starter(Core) RQ U V KM1 HG1 HY1 KM2 KM4 KM6 KH1 KH2 KH3 W KM2 Running Start N 43 35 KM5 S KM4 KM4 33 15 R KM3 KA1 KM3 KM2 17 SB6 31 9 QF1 SB5 29 7 HR2 HY2 Stop KM3 HG2 KM4 Running Start L14 FU4 N L11 FU1 KH3 45 47 KM1 SB9 69 49 51 SB10 RQ KM3 SB12 SB11 KM5 KM6 KA1 X22 53 KM5 KM5 61 63 KM1 KM6 55 KM6 65 X23 KM1 TA1 102 A PA1 E 103 A TA2 PA2 PA3 HR3 E 3~ M1 3~ M2 3~ M3 1# 2# 3# RQ 67 KA2 59 A TA3 E KM5 X1 KM3 101 KM3 71 57 HY3 KM5 HG3 KM6 KA1 Stop Start KA2 X2 Running 6. Functions 6.1 Digital, type SCM control; 6.2 Advanced soft start mode; a. Voltage start mode b. Current limiting start mode 6.3 With several optional protection functions such as peak over current protection, input/output phase failure protection, overload protection, current limiting overtime protection, over-voltage protection, overheat protection of radiator, inlet phase sequence protection etc. 6.4 Communication between operator and machine; 6.5 With the function of fault display and memory 6.6 Natural air cooling, save space; 6.7 With the function of local control and remote control; 6.8 Can start any motor at any time. 7. Ordering Information Example 1: Power of control motor is 45kW, there are two motors, choose one as oft starting to control. Model: NJR1-45/2(One soft starter starts two motors) Example 1: Power of control motor is 90kW, there are three motors, choose one as soft starting to control. Model: NJR1-45/3(One soft starter starting three motors) Note: All soft start controllers (One soft starter starts multi motors) are stated (One soft starter how many motors) in back when user orders. .27. Soft Starter NJR1 Soft Start Control Switchgear of Motor (One motor operation, the other back up) 1. General NJR1 Soft start control switchgear of motor (one motor operation, the other reserve) is applied to the occasion that one motor is running, another motor is reserved (The reserve motor isoptional), when fault occurs on chy device that cause stopping operation, the other reserved will run automatically, so it can make sure the reserve device can work under the special condition. To guarantee reliable operation of the device automatic switching device can be supplied for selection when user orders. The core part of this product is NJR1D soft start device. 2. Type Designation N J R 1-□/1-1(One motor operation, the other back up) Rated Voltage Code(3 phase AC400V) Power of Control Motor(kW) Design No. Soft Starter AC Motor Company Code 3. Technical Data Supply voltage: three phase AC400V±15%, 50Hz±2% Initial current: start current limited from 1~4.5 times Ramp up time : 1~240s Ramp down time: 1~120s Min. voltage for soft starter: 25%Ue~75%Ue Kick start-up time: 0-10(×0.1) (0 denotes no jump start) Start-up frequency: average interval 10 times every hour Environment condition: Temperature is -25℃~+55℃, relative humidity is 90% max(T=20℃), altitude below 2000m, vibration less than 0.5G, placing in the room where is fine ventilation, no conductive dust, no corrosive gas. 4. Overall and Mounting dimensions Diagram 1 D B E .28. Soft Starter NJR1 (One motor operation, the other reserve) Mounting dimensions(mm) A×C Overall Dimensions(mm) Length(B) Height(D) Width(E) Power of control motor(kW) Model 7.5~75 700 600 1800 90~185 1000 600 2200 850×546 220~315 1000 800 2200 850×746 550×546 5. Wiring diagram Diagram 2 L1 L2 L3 N 1R N FU1 N FU2 HG1 KM1 QF1 2R KM2 HG2 KM2 HR3 KA3 HR4 RQ2 KM2 1 Running 2 Running HR1 KM1 1 Stop KA1 HR2 RQ1 KM1 2 Stop 1 Failure QF2 QF3 X22 X23 RQ1 R S T U1 V1 W1 RQ1 R S T KM1 U V W X16 U1 V1 W1 RQ2 TA2 1 2 3 4 5 6 M ~ 2 TA1 TA2 PA2 A 2 Failure output 7 8 9 10 11 12 KA4 KA1 1 号起停控制 Start/stop contral KA2 KA4 2 Start/stop contral 2# 2 1 2 SA 1-2 3-4 5-6 7-8 9-10 11-12 PA1 A KA2 KA3 X17 SB3 SB4 SA KA4 2 By-pass running X23 RQ2 KA3 1# 1 X16 KA2 1 M ~ X22 1 Failure output SB1 SB2 SA KA3 TA1 1 By-pass running KA1 X17 KA1 KM2 U V W 2 Failure KA2 KA4 RQ1 RQ2 X1 X2 X1 X2 Manual 1 In use 2 In use E 6. Functions 6.1 Digital, type SCM control; 6.2 Advanced soft start mode; a. Voltage start mode b. Current limiting start mode c. Time-delay start model(0~240s) 6.3 With several optional protection functions such as peak over current protection, input/output phase failure protection, overload protection, current limiting overtime protection, over-voltage protection, overheat protection of radiator, inlet phase sequence protection etc. 6.4 Communication between operator and machine; 6.5 With the function of indicating operation current and supply voltage; 6.6 With the function of fault display and memory 6.7 Reserve for each other; 6.8 Optional for manual or auto operation. 7. Ordering Information Example 1: The power of control motor is 45 kW,thus, a motor needs be reserved. Model: NJR1-45/1-1(One motor operation, the other reserve) Example 2: The power of control motor is 90 kW,thus, a motor needs be reserved. Model: NJR1-90/1-1(One motor operation, the other reserve) .29. Soft Starter NJR1 Soft Start Control Switchgear of Motor (Two motors operation, another back up) 1. General NJR1 Soft start control switchgear of motor is applied in the occasion that two motors are running, another motor is back up(The reserve motor can be chosen), when any one device occurs fault that causes stopping operating, another reserved will run automatically, so it can make sure the reserve device can work in time under the special condition. To guarantee the device reliable operation, double power auto switching can be supplied for selection when user orders. The inner core part of this product is NJR1-Z fully digital soft start device. 2. Type Designation N J R 1-□/2-1 2-1(Two motors operation, another back up) Power of Control Motor(kW) Design No. Soft Starter AC Motor Company Code 3. Technical Data Supply voltage: three phase AC400V±15%, 50Hz±2% Initial current: start current limited from 1~4.5 times Ramp up time : 1~240s Ramp down time: 1~120s Min. voltage for soft starter: 25%Ue~75%Ue Kick start-up time: 0-10(×0.1) (0 denotes no jump start) Start-up frequency: average interval 10 times every hour Environment condition: Temperature is -25℃~+55℃, relative humidity is 90% max(T=20℃), altitude below 2000m, vibration less than 0.5G, placing in the room where is fine ventilation, no conductive dust, no corrosive gas. 4. Overall and Mounting dimensions Model NJR1 (Two motors operation, another reserve) Power of control motor(kW) Overall Dimensions(mm) Length(B) Height(D) Width(E) Mounting dimensions(mm) A×C 7.5~75 800 600 2200 90~280 1200 600 2200 1050×546 315 1200 800 2200 1050×746 650×546 .30. Soft Starter Diagram 1 D B E 5. Wiring Diagram Diagram 2 L1 L2 L3 N 1R N FU1 QF1 KM1 HG1 KM1 HR1 2R N FU2 KM2 HG2 KM2 HR3 1 running indication KA1 HR2 KA3 RQ1 R S T R S T U1 V1 W1 KM1 RQ2 U V W U1 V1 W1 X16 KM2 RQ3 U V W HR6 3 stop indication 3 failure indication RQ2 1 bypass operation X23 RQ2 1 failure out put X17 KM2 RQ3 2 bypass operation X22 X23 KA1 X22 2 failure out put X16 X17 X16 KM3 3 bypass operation X23 RQ3 KA3 KA5 3 failure out put X17 KM3 KA5 SB5 KA3 SB3 TA3 SB2 SA 1 2 3 4 SA KA2 KA2 KA3 1 KA5 U V W TA2 M ~ HR5 3 running indication HR4 KA1 TA1 KM3 2 failure indication KM1 RQ1 RQ1 U1 V1 W1 HG3 QF4 X22 R S T KM3 2 stop indication 1 failure indication QF3 FU3 2 running indication 1 stop indication QF2 N 3R M ~ M ~ 2 3 6 7 8 SA 9 KA4 KA1 1 satrt/stop KA5 SB4 5 KA5 SB6 KA6 10 KA1 KA4 11 2 satrt/stop 12 KA3 KA6 3 satrt/stop SA 1-2 3-4 TA1 TA2 TA3 PA1 A PA2 A PA3 A 5-6 KA2 KA4 KA6 RQ1 RQ2 RQ3 7-8 9-10 X1 X2 X1 X2 X1 X2 11-12 Stop Naual 3# 2# 4# Back up Back up Back up E 6. Tunctions 6.1 Digital, type SCM control; 6.2 Advanced soft start mode; a. Voltage start mode b. Current limiting start mode 6.3 With several optional protection functions such as peak over current protection, input/output phase failure protection, overload protection, current limiting overtime protection, over-voltage protection, overheat protection of radiator, inlet phase sequence protection etc. 6.4 Communication of operator and machine; 6.5 With the function of indicating operation current and supply voltage; 6.6 With the function of fault display and memory 6.7 Reserve for each other; 6.8 Optional for manual or stop operation 6.9 Simple circuit, convenient maintenance. 7. Ordering Information Example 1: The power of control motor is 45 kW,there are three motors, one of them needs be reserved. Model: NJR1-45/2-1(Two motors operation, another reserve) Example 2: The power of control motor is 90 kW,there are three motors, one of them needs be reserved. Model: NJR1-90/2-1(Two motors operation, another reserve) .31.