The CN Tower

The world’s tallest freestanding

structure is a functional landmark in

concrete

C

onstructing a single facility adequate for all of To ro nto’s radio and TV requirements dictated the great

height of the CN Communications Tower. An elevation of

1100 feet was needed to clear all Toronto area obstacles

for microwave re c e i ve r s. Above that height a 350-foot

separation was required between the receivers and the

UHF/VHF and FM antennas, which in turn had to be

spread out over a 335-foot antenna mast. These and other design considerations led to a slender, tapering beauty in concrete, and a record height for a freestanding

structure—1815 feet 5 inches. The record was previously

held by the 1761.89-foot Ostankino Tower for radio and

STATISTICS

Height: 1815 feet 5 inches

Dimension at base: 167 feet (side of triangle)

Variation of concrete from plumb: 1.1 inches

Sky pod diameter: 100 to 140 feet

height: 7 levels

floor space: 70,000 square feet

Total weight: 130,000 tons

Concrete: 53,000 cubic yards

Post-tensioned steel: 80 miles

Reinforcing steel: 5000 tons

Estimated sway resistance in 120-mph winds with

200-mph gusts: antenna—31⁄2 feet from center

space deck—11⁄2 feet from center

skypod—9 inches from center

Broadcast facility”* current users:

6 television broadcasters

8 FM broadcasters

7 microwave users

* Includes UHF, VHF and cable television, FM radio, microwave telecommunications, and local point-to-point and

mobile systems

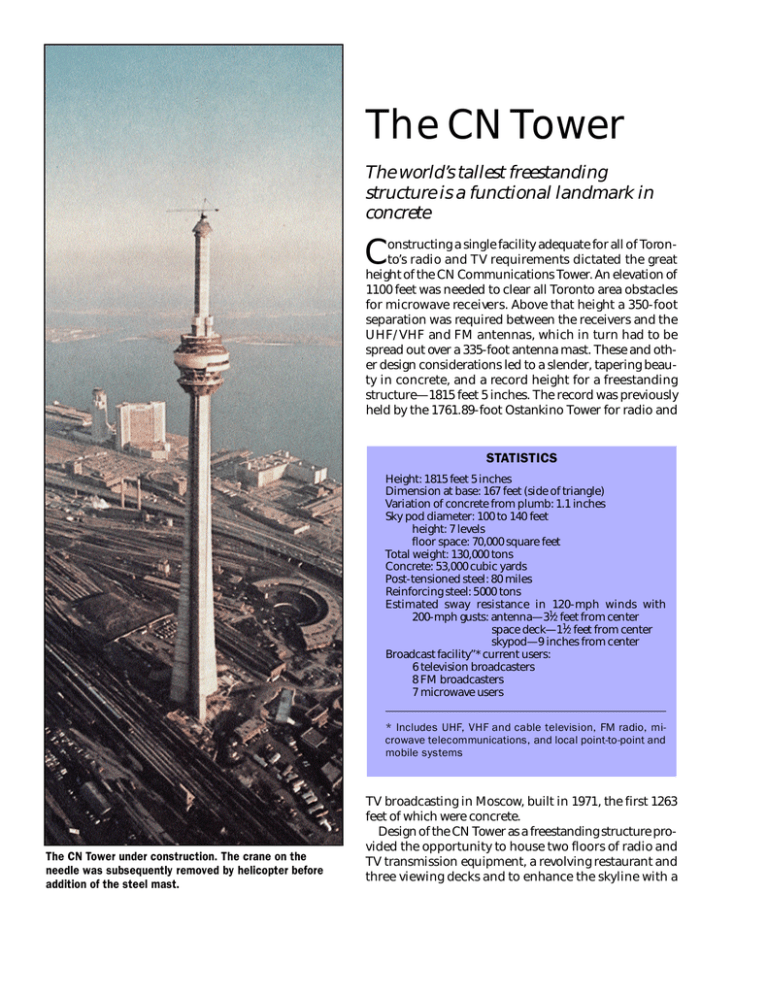

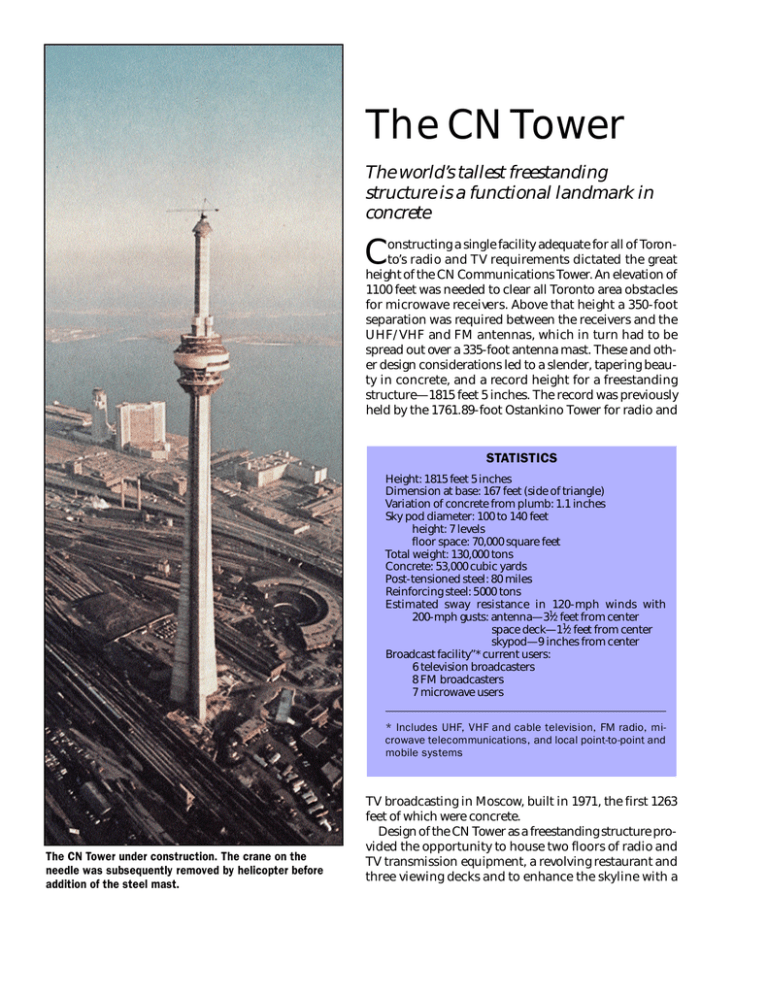

The CN Tower under construction. The crane on the

needle was subsequently removed by helicopter before

addition of the steel mast.

TV broadcasting in Moscow, built in 1971, the first 1263

feet of which were concrete.

Design of the CN Tower as a freestanding structure provided the opportunity to house two floors of radio and

TV transmission equipment, a revolving restaurant and

three viewing decks and to enhance the skyline with a

striking monument and navigational aid. From the top

deck, on a clear day, one can view the landscape as far

as 100 miles away.

Foundation

Findings from numerous pictures and test samples

taken as deep as 100 feet in four 30-foot-diameter holes

led to design of a Y-shaped foundation resting on shale

at a depth of about 50 feet and capable of both supporting the tower weight and resisting the great pre s s u re s

induced by wind. Since the water table was only 19 feet

down, the area had to be dewatered before excavation

and during construction of the foundation. Post-tensioning cables crisscrossing the Y prevent cracking. Nine

caverns within the foundation provided sheltered work

space and means of anchoring the vertical tendons of

the tower when post-tensioned.

Slipforming

A Y-shaped slipform accommodated the full dimensions of the base of the concrete tower. As the slipform

rose the end portions were jacked steadily inward and

the protruding ends of the sides were periodically cut

off. The tendency of the deck to rotate in response to the

e a rt h’s rotation was monitored every 2 hours by optical

plumb instruments on the slipform wings and the twisting was overcome by adjustment of three cables anchored to points on the walls below. A 250-pound steel

bob suspended from the slipform deck down through

the tower core into an oil bath provided readings for adjusting the plumb. Curing in winter was provided by a

heater deck below the finishing deck, followed by an insulated skirt, and by hot air within the core.

Concrete testing

With the monumental tower rising 20 feet per working

day, the builders were not comfortable to wait 1 to 4

weeks to assure themselves that 7- or 28-day concrete

strengths had been met. For the first time on a project of

any magnitude they boldly adopted a relatively new accelerated strength test based on autogenous curing. Using Type I and Type IV portland cements, singly or in

combination as required by weather, they achieved excellent strength control with 2-day tests. Cores taken at

ages greater than 28 days showed strengths between

6000 and 8000 psi.

Post-tensioning the tower

CN Tower configuration shows space deck at top of

slipformed concrete, 1465 feet above base. Top of antenna

mast at 1815 feet makes this the world’s tallest

freestanding structure.

Selection of a fully post-tensioned construction instead of reinforced or partially post-tensioned concrete

was made early in the design process. The fully post-tensioned structure will remain essentially uncracked at all

loads. This is important for a tower which will be exposed to great changes in temperature and humidity as

well as chemically aggressive air. Post-tensioning also

contributed to economy of materials, reducing the foundation requirements and permitting the walls of the

hexagonal core to be only about 24 inches thick.

Principal post-tensioning consists of 144 cables of various lengths. From the terminal heights of the post-tensioning ducts at 180, 560, 1122, 1255, 1370, and 1480 feet,

the high-strength 270,000-psi prestressing steel tendons

were fed from the slipform deck. When any duct became

unusable from plugging, damage to tendons or other

cause, one of the small number of spare ducts installed

for such exigencies was utilized. The longest tendons

stretched 9 feet 2 inches during tensioning. Cold weather precluded grouting of ducts containing tendons posttensioned in the winter. Corrosion of these tendons was

prevented by steadily blowing oil-free dry air up through

the ducts until summer.

Pod

The seven-level pod beginning at a height of about

1100 feet was built with six formwork sections of steel

box trusses, wood forms and reinforcing steel. These

were raised, after slipforming had been completed, by

open-faced climbing jacks located on a temporary structural steel frame at the top of the tower. With this formwork were cast 12 triangular concrete brackets that support the pod as well as the floor and wall concrete work

of the pod itself. The concrete floor cast just above the

brackets includes a ring beam that is a 12-sided polygon,

post-tensioned circumferentially to resist radial loads.

Antenna mast

A light tower crane was used to assemble the slipform,

then was lifted along with the slipform and handled materials on the slipform deck. After the remnants of the

slipform, which had diminished in size as it rose, were

dismantled and lowered, the crane remained in place to

raise the forms and concrete for casting in place the 16foot-high beam that supports the antenna mast. The

crane finally lifted the 12-foot-high steel base section of

the steel antenna mast before being taken down in eight

sections by a helicopter.

The helicopter then lifted the 39 mast sections into

place. A total of 55 helicopter construction flights were

made in 31⁄2 weeks, saving about 5 months construction

time. The mast sections, pentagonal cans varying from

31⁄2 to 20 feet high, were assembled by bolting. Inside the

mast are specially designed hula-hoop dampers tuned

to different frequencies to counter motion of the mast

from wind. Over the surface of the mast are mounted the

many antennas that serve the Toronto area.

A tower to be proud of

As the most unusual element of the skyline, the CN

Tower must inevitably become associated with Toronto

in people’s minds. Designed to resist the projected 1000year-frequency wind of 130 miles an hour with a factor

of safety of 2, it should long serve its purpose. As to serving the originally conceived purpose, Toronto and a

great surrounding area now enjoy what is probably the

best broadcast reception in the world.

Credits

Owner: CN Tower Ltd., Toronto

Architects: John Andrews International/Roger Du Toit; The

Webb Zerafa Menkes Housden Partnership, Toronto

Structural Consultants: Nicolet Carrier Dressel and Associates Ltd., Montreal

Manager Contractor: Foundation Company of Canada,

Toronto

PUBLICATION #C830125

Copyright © 1983, The Aberdeen Group

All rights reserved