REEVolution

advertisement

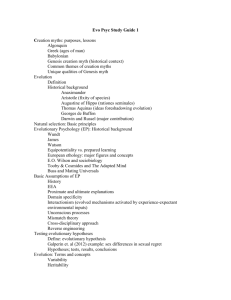

REEVolution REEVolution - Evolution of REEV Technologies Building a UK Supply Base LCV 2012 5th September 2012 Ashfaq Hussain– Jaguar Land Rover 2 REEVolution Overview REEVolution is an accelerated development and integration programme of new technologies, from concept through to validated components and systems. It is intended to produce robust technology demonstrator vehicles whilst strengthening and developing the UK supply base. The aims have been to:• Deliver and demonstrate high performance Range Extended Electric Vehicles (REEV) and Ultra Low Carbon Plug-in Hybrid Electric Vehicles (PHEV) • Develop capabilities for major REEV/EV/PHEV commodities and bring key UK suppliers towards tier 1 capability • Position UK manufacturers and suppliers to exploit the global market potential for low carbon vehicle technologies 3 REEVolution The Consortium The REEVolution consortium, led by Jaguar Land Rover, consists of three UK based suppliers: • Axeon Technologies Limited • EVO Electric Limited • Xtrac Limited And engineering teams from three UK based vehicle manufacturers: • Jaguar Land Rover • Nissan (Nissan Technical Centre, Europe) • Lotus Cars (Lotus Engineering) 4 REEVolution Project Structure Jaguar Land Rover (Project Lead) Nissan (NTCE) Lotus Cars EVO Electric PHEV Development 3 XJ_e Xtrac Axeon REEV Development 2 Infiniti EMERG-E 1 Lotus Evora 414e 5 REEVolution The project has successfully developed key UK technology suppliers with novel Ultra Low Carbon (ULC) technologies towards tier 1 capability by working with three major UK vehicle manufacturers. Laying the foundations for a robust and globally competitive UK supply base, drawing on the product development experience of the vehicle manufacturers. • Robust design and development processes (System Engineering) • Automotive Requirement RFQ’s & DVP’s • Optimisation of design for cost, package and weight • Project Management • Support with developing key collaboration and alliances with other Tier 1 suppliers 6 REEVolution The project has successfully delivered several high performance Range Extended Electric Vehicles (REEV) and Plugin Hybrids Electric Vehicles (PHEV) as outlined below, also being showcased on stand C78 and demonstrated on the track. • INFINITI EMERG-E The INFINTI EMERG_E is series hybrid REEV design capable of accelerating from 0-60mph in just four seconds - and from zero to 130mph in a single, seamless 30 second burst. CO2 55g/km (NEDC cycle) with a target EV Range 30 miles, combined range 300 miles. • Lotus Evora 414E The Evora 414E is series hybrid REEV design capable of accelerating from 0-60mph in just four seconds, with a target EV Range of 30 miles and a target combined range of 300 miles. • Jaguar XJ_e The XJ_e is an advanced parallel plug-in hybrid design that delivers reductions in CO2 emissions of over 70 per cent, without compromising vehicle performance, EV Range 25 miles, combined range 679 miles on a full tank of fuel. 7 REEVolution In addition to consortium partners project contributions the project has :• Developed an additional UK based battery supplier • Used over 100 tier 1 UK based suppliers • Used at least another 32 tier 2 UK based suppliers • Spent over £10m with UK tier 1 and tier 2 suppliers (including consortium partners) 8 REEVolution EVO Electric Ltd Since mid-2011 Nissan, Lotus and EVO Electric Ltd (EVO) have been working closely together to ensure that EVO successfully delivers to the project a motor-inverter sub-system capable of delivering a functioning, driveable vehicle, capable of achieving the performance targets identified by the project at the outset. For EVO this led to a greater amount of system integration activities in conjunction with Lotus. Nissan has provided additional technical input and assistance from an OEM perspective regarding key Safety Case and Performance requirements. EVO’s direct involvement with Lotus and Nissan has expedited EVO’s understanding of the Automotive OEMs EV related standards and requirements In addition EVO has appreciated and benefited from JLR being REEVolution Project Lead 9 REEVolution EVO Electric Ltd EVO Electric Ltd’s involvement switched from the supplier of drivetrain parts only to complete subsystem supplier. EVO Electric has designed and supplied their new Ø300 mm Axial Flux machines to Lotus which required thorough testing and evaluation of the drivetrain sub-systems to ensure the required technical requirements were met and validate certain key individual components. EVO thereby has: An improved relationship with the REEV Project OEMs especially with Lotus and Nissan Via thorough DVP testing, validated the new Ø300 mm Axial Flux machines in conjunction with their respective inverter(s) Developed a better understanding of the OEMs Safety Requirements From capturing the Lessons Learned during DVP testing made machine design improvements 10 REEVolution Axeon Technologies Limited Axeon’s involvement was Battery supplier for the PHEV (XJ_e) Concept, key challenges and outcomes are outlined below:• Ensuring that the battery fitted into minimal space in the existing XJ car boot; this required tailor-made casing and precision design • Managing the impact of the liquid cooling and heating system on the vehicle’s performance; the tighter control through the thermal microgen software for cold and hot use is a new concept • Maximising the learning for both the customer and Axeon through a collaborative project, particularly on system knowledge of hybrid and EV technologies • Gaining a greater understanding through working effectively with the Vehicle Manufacturers and other collaboration and Tier 1 suppliers 11 REEVolution Axeon Technologies Limited • Greater understanding of OEM development processes e.g. GTDS and how to integrate these into our own processes • How OEMs are structured: R&D vs. Prototype vehicle builds vs. Production. This understanding enables us to pitch more effectively for future business • The desire for the OEM to 'learn early' stretched us to deliver something novel 12 REEVolution Xtrac Limited Xtrac’s involvement was around the design, development, manufacture, test and refinement of a transmission system for the REEVolution programme. It provided an opportunity for Xtrac to develop a dedicated EV gearbox that is suitable for multiple vehicle applications with little or no modification for future applications The main innovative aspect of the design is the independent gear trains for the twin electric motors, which allow each drive output to be individually monitored and regulated. The gearbox incorporates the use of an integrated park brake that is potentially relevant to a wide range of electric vehicles. This project has assisted Xtrac in further expanding its UK supply base. Xtrac has utilised 13 local suppliers for the manufacture of components for the gearboxes. 13 REEVolution Xtrac Limited The REEVolution project has provided an excellent opportunity for high level collaboration with 3 automotive OEMS and to further develop, validate and commercialise the twin electric motor drivetrain (2EV). Working with the 3 vehicle manufacturers has added further credibility to Xtrac’s automotive & engineering business development and marketing efforts to promote its transmission capabilities by leveraging OEM exploitation activity. With further development by working the 3 OEMs to optimise and industrialise the design, the REEVolution product will be one of Xtrac’s core offerings to the EV market. Developed a better understanding of the Vehicle Manufacturers systems and processes. 14 REEVolution Conclusions • REEVolution is an important collaborative project bringing major UK-based vehicle manufacturers together with innovative suppliers to build three ground-breaking demonstrator concepts and build up the UK tier 1 capabilities • The UK’s Technology Strategy Board was the platform upon which, with the help of UK government funding, the consortium was formed • The Technology Strategy Board represents an important mechanism for highlighting the capabilities of UK based firms and driving innovation faster towards production reality 15