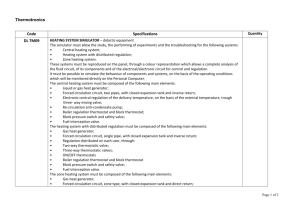

Installation and Service Instructions VITOCROSSAL 300

advertisement