Determinants of Production and Sales in Automotive Industry

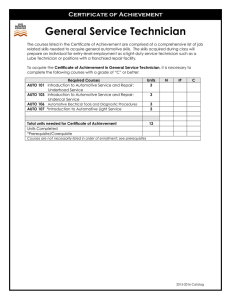

advertisement

Charles University in Prague

Faculty of Social Sciences

Institute of Economic Studies

Ondřej Sezemský

Determinants of Production and

Sales in Automotive Industry:

Evidence from ŠKODA AUTO

MASTER THESIS

Prague 2014

Author: Ondřej Sezemský

Supervisor: PhDr. Petr Teplý, Ph.D.

Academic Year: 2013/2014

Bibliography Reference

SEZEMSKÝ, Ondřej: "Determinants of Production and Sales in Automotive Industry: Evidence from ŠKODA AUTO." Prague, 2014, 82 p. Master Thesis (Mgr.) Charles University,

Faculty of Social Sciences, Institute of Economic Studies. Supervisor: PhDr. Petr Teplý,

Ph.D.

Abstract

Automobiles can be today considered as cultural icons which indicate the level of development of a particular state. This thesis provides analysis of the automotive industry in

general from the point of view of globalization, linkages, value chains and macroeconomic

environment. We will stress crucial challenges that face global original equipment manufacturers, depict situations on most important emerging markets and forecast development

that we can expect there. In the context of these information we will develop econometric

analysis which will widen current findings from microeconomic and macroeconomic perspective of a car manufacturer. ŠKODA AUTO represents the most important enterprise

in the Czech Republic and at the same time is a part of the biggest automobile concern in

the world. We will use internal data from the company for our research and give overall

recommendations. Central questions in this study are the following: What are the forecasted needs of the customers on emerging markets? How sensitive are companys’ costs

on the output? And finally, which role do the macroeconomic indicators play in delivering

of automobiles to end customers?

Key Words: automotive industry, costs, deliveries, emerging markets, suppliers, linkages

JEL Classification: C22, C32, C52, L22, L62, O11, O14

Extent of the Thesis: 126,855 characters (with spaces)

Bibliografický záznam

SEZEMSKÝ, Ondřej: "Determinanty produkce a prodeje v automobilovém průmyslu: případová studie ŠKODY AUTO." Praha 2014. 82 s. Diplomová práce. Univerzita Karlova v

Praze, Fakulta sociálních věd, Institut ekonomických studií. Vedoucí práce: PhDr. Petr

Teplý, Ph.D.

Abstrakt

Automobily jsou dnes považovány za symboly a kulturní ikony, které vypovídají o stupni

vývoje daného státu. V této diplomové práci analyzujeme automobilový průmysl z pohledu

globalizace, vazeb mezi výrobci a dodavateli, hodnotových řetězců a makroekonomického

prostředí. Budeme diskutovat základní výzvy, kterým čelí globální výrobci, popíšeme situaci

na nejdůležitějších růstových trzích a budeme se snažit předpovědět tamější vývoj v budoucnosti. V tomto kontextu vytvoříme ekonometrickou analýzu, která rozšíří současné poznatky z mikroekonomického a makroekonomického pohledu výrobců aut. ŠKODA AUTO

představuje nejdůležitější podnik v České Republice a zároveň je součástí největšího automobilového koncernu na světě. Pro náš výzkum použijeme interní data ze společnosti

a poskytneme patřičná doporučení. Hlavní otázky této práce jsou: Jaké jsou předpokládané potřeby zákazníků na růstových trzích? Jak jsou senzitivní náklady společnosti na

počet vyrobených aut? A konečně, jakou roli hrají makroekonomické indikátory v celkových

prodejích?

Klíčová slova: automobilový průmysl, náklady, dodávky zákazníkům, růstové trhy, dodavatelé, vazby

JEL klasifikace: C22, C32, C52, L22, L62, O11, O14

Rozsah práce: 126.855 znaků (včetně mezer)

Declaration

I hereby declare that I compiled this thesis independently, using only the listed resources

and literature.

I declare that this thesis was not used to acquire degree from any other institution.

I grant to Charles University permission to reproduce and to distribute copies of this thesis

document in whole or in part.

Prague, July 30, 2014

Signature

Acknowledgments

I would like to thank to my supervisor PhDr. Petr Teplý, Ph.D. for valuable suggestions

and support. I am also grateful to Ing. Jan Ryšavý from the ŠKODA AUTO for mediation

of interesting meetings with specialists from the company and provision of the required

company’s internal information. Apart from that I would like to thank my family, girlfriend

and friends for their support and encouragement.

Acronyms

ADF

Augmented Dickey-Fuller

AIC

Akaike Criterion

BIC

Bayesian Criterion

CEE

Central and Eastern Europe

CFR

Cost and Freight

CIF

Cost Insurance and Freight

CIS

Commonwealth of Independent States

CKD

Completely knocked down.

CZK

Czech Crown

DF

Dickey-Fuller

ECM

Error Correction Model

EU

European Union

EUR

Euro

FDI

Foreign Direct Investment

GDP

Gross Domestic Product

GPS

Global Positioning System

GVC

Global Value Chain

HQC

Hannan-Quinn criterion

IMF

International Monetary Fund

KPSS

Kwiatkowski–Phillips–Schmidt–Shin

MKD

Medium knocked down

NASDAQ National Association of Securities Dealers Automated Quotations

NYSE

New York Stock Exchange

vi

OEM

Original Equipment Manufacturers

OLS

Ordinary Least Squares

R&D

Research & Development

S&P

Standard & Poor’s

SAIC

Shanghai Automotive Industry Corporation

SAIPL

ŠKODA AUTO India Private Ltd.

SKD

Semi knocked down

SUV

Sport Utility Vehicle

TPCA

Toyota, Peugeot and Citroën Automobile joint venture

US

United states

USA

United States of America

VAR

Vector Autoreggression

VECM

Vector Error Correction Model

WTO

World Trade Organization

vii

Master Thesis Proposal

Student:

Ondřej Sezemský

Specialization:

Finance, Financial Markets and Banking

Supervisor:

PhDr. Petr Teplý, Ph.D.

Determinants of Production and Sales in Automotive

Industry: Evidence from ŠKODA AUTO

Topic Characteristics

We analyze global automotive industry and selected emerging markets and introduce reader

to the basic information about ŠKODA AUTO. We employ econometric methodology to

examine microeconomic and macroeconomic indicators on the performance of the company.

We decided to apply cointegration analysis and Error Correction Models. This concept

enables us to measure non-stationary time series. For estimating our models we use internal

company’s data and then data from Czech National Bank, Index Mundi database or IMF

World Economic Outlook Database.

Outline

• Analysis of Automotive Market

◦ Globalization

◦ Trends in Automotive Industry

◦ Development on important ŠKODA AUTO markets

• ŠKODA AUTO

◦ Brief History

◦ Organization

◦ Structure of the Costs

◦ SWOT Analysis

• Time Series Methodology

◦ Hypotheses

◦ Descrption of the Data

◦ Time Series Analysis

◦ Cointegration Analysis

viii

• Model of Production

◦ Data Set and Definitions

◦ Sensitivity Analysis on Input Variables

◦ Unit Root and Cointegration Testing

◦ Error Correction Model

• Model of Sales

◦ Data Set and Definitions

◦ Sensitivity Analysis on Input Variables

◦ Unit Root and Cointegration Testing

◦ Error Correction Model

Core Bibliography

Cipra, Tomáš (2008): "Finanční Ekonometrie." Praha: Ekopress, s. r. o.

Engle, Robert F. and Granger, Clive W.J. (1987): "Cointegration and error correction:

representation, estimation and testing."

Green, William H. (2002): ”Econometric Analysis.”

Johansen, Soren (1988): "Statistical Analysis of Cointegrating Vectors." Journal of Economic Dynamics and Control, Vol. 12.

Richet, Xavier (2002): "Restructuring and Competition in the Car Industry in Russia:

Conglomerate Control vs. Cooperation with Foreign Firms." Journal of Economics and

Business, Vol. 6.

Russo, Bill; Tse, Edward and Ke, Tao (2009): "The Path to Globalization of China’s

Automotive Industry."

Sturgeon, T. J.; Memedovic, O., Biesebroeck, J. V. and Gereffi, G. (2009): "Globalization

of the automotive industry: main features and trends." Int. J. Technological Learning,

Innovation and Development, Vol. 2.

ix

Contents

1 Introduction

1

2 The

2.1

2.2

2.3

2.4

Automotive Industry

Globalization in Automotive Industry . . . . . . . . . . . . . . .

Trends in Automotive Industry . . . . . . . . . . . . . . . . . . .

Global Value Chains in Automotive Industry . . . . . . . . . . . .

Macroeconomic Development . . . . . . . . . . . . . . . . . . .

2.4.1 Financial Crisis . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Macroeconomic Forecast for Main Car Markets of ŠKODA

2.5 Development of the Markets with ŠKODA AUTO Branded Cars .

2.5.1 China . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 India . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Russia . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

3

5

7

8

10

11

12

12

16

20

24

28

.

.

.

.

.

.

.

.

.

29

29

30

31

32

33

33

33

33

36

4 Methodology

4.1 Hypotheses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Description of the Data . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Time Series Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

37

37

38

3 ŠKODA AUTO

3.1 Brief History . . . . . . . .

3.2 Basic Information . . . . .

3.3 Organization . . . . . . . .

3.4 Structure of the Costs . . .

3.4.1 Material Costs . . .

3.4.2 Personnel Costs . .

3.4.3 Overheads . . . . .

3.5 SWOT Analysis . . . . . .

3.6 Motivation for the Research

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

x

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . .

. . . .

. . . .

. . . .

. . . .

AUTO

. . . .

. . . .

. . . .

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Contents

4.4

Cointegration Analysis . . . . . . . . .

4.4.1 Error Correction Model . . . .

4.4.2 Vector Autoregressive Model . .

4.4.3 Vector Error Correction Model .

5 The

5.1

5.2

5.3

Model of Production

Data Set and Definitions . . . . . . .

Sensitivity Analysis on Input Variables

Unit Root Testing . . . . . . . . . .

5.3.1 ADF Test . . . . . . . . . .

5.3.2 KPSS Test . . . . . . . . . .

5.4 Cointegration Testing . . . . . . . .

5.4.1 Engle-Granger Test . . . . .

5.4.2 Johansen Test . . . . . . . .

5.5 Vector Error Correction Model . . . .

6 The

6.1

6.2

6.3

Model of Sales

Data Set and Definitions . . . . . . .

Sensitivity Analysis on Input Variables

Unit Root Testing . . . . . . . . . .

6.3.1 ADF Test . . . . . . . . . .

6.3.2 KPSS Test . . . . . . . . . .

6.4 Cointegration Testing . . . . . . . .

6.4.1 Engle-Granger Test . . . . .

6.4.2 Johansen Test . . . . . . . .

6.5 Vector Error Correction Model . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

39

40

41

42

.

.

.

.

.

.

.

.

.

43

43

44

45

46

47

48

48

49

50

.

.

.

.

.

.

.

.

.

52

52

53

54

54

55

56

57

57

58

7 Conclusion

59

8 References

61

Appendix

i

xi

List of Figures

2.5.1 ŠKODA AUTO Deliveries to Customers in Emerging Markets . . . . . . .

2.5.2 ŠKODA AUTO Deliveries Percentage Change in Emerging Markets (y-o-y

percent growth) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 GDP development and Car Sales Growth Rates in China (y-o-y growth) . .

15

18

5.2.1 Logarithms of Variables . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

6.2.1 Logarithms of Variables, LIBOR and Inflation . . . . . . . . . . . . . . . .

54

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.10

i

i

i

ii

ii

ii

iii

iii

iii

iv

Production Model - Information Criteria .

Production Model - OLS Residuals . . .

Production Model - Johansen Test . . .

Production Model - VECM Summary . .

Production Model - VECM Coefficients .

Sales Model - Information Criteria . . . .

Sales Model - OLS Residuals . . . . . .

Sales Model - Johansen Test . . . . . . .

Sales Model - VECM Summary . . . . .

Sales Model - VECM Coefficients . . . .

xii

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

15

List of Tables

2.1

2.2

2.3

Light Vehicle Density in 2012 . . . . . . . . . . . . . . . . . . . . . . . .

Car Markets Development (y-o-y growth) . . . . . . . . . . . . . . . . . .

ŠKODA AUTO Deliveries to Customers – Largest Markets and by Region .

3

13

14

5.1

5.2

5.3

5.4

5.5

Summary of Variable Production

ADF Test . . . . . . . . . . . . .

KPSS Test . . . . . . . . . . . .

Johansen Test . . . . . . . . . .

Estimated Coefficients . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

44

46

47

49

50

6.1

6.2

6.3

6.4

6.5

Summary of the Variables (rounded to 2 decimal places)

ADF Test . . . . . . . . . . . . . . . . . . . . . . . . .

KPSS Test . . . . . . . . . . . . . . . . . . . . . . . .

Johansen Test . . . . . . . . . . . . . . . . . . . . . .

Estimated Coefficients . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

53

55

56

57

58

.

.

.

.

.

.

.

.

.

.

xiii

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1 Introduction

The automotive industry began 120 years ago and vast changes have taken place in

automobile manufacturing plants since that time. Car factories around the world have cut

costs per car and reduced man-hours, while offering many possibilities for consumers to

customize their cars. Today, more than ever, the design, comfort and purposefulness are

important. Car manufacturers and their suppliers are cooperating in revolutionizing the

entire production process. Vehicle manufacturers are the world leaders in research and

development (“R&D“) and spend many billions of Euros every year on R&D in order to

further improve existing concepts and to develop hybrids or alternative fuel vehicles using

natural gas, bio fuels, hydrogen and others.

The car industry is one of the most important economic sectors by revenue in the world

and is considered to be highly capital and labor intensive. Top managers have to precisely

estimate future needs of customers, profile the key products, streamline the operations of

the company and discover new emerging markets. The environment of turbulent automotive markets is highly competitive with more than 50 vehicle manufacturing groups around

the world. The the situation of car manufactures is even more complicated, because the

automotive industry is extremely sensitive to macroeconomic situation, especially on financial and banking crises. Bankruptcies at General Motors and Chrysler in 2009 enabled these

firms to shed debt, cut employees and dramatically reduce operating costs.

Despite recent slumps of car deliveries, future demand for vehicles will far outstrip former peaks, creating immense business opportunities. Globalization, the tendency of world

investment and businesses to move from national and domestic markets to a worldwide

environment, is a huge factor affecting the automotive market. The incomes are rising

in developing economies and the car makers want to introduce their low-cost options for

buyers in China or India. Eisenstein (2010) suggests, that one of every three global car

sales will be soon only in so-called ”BRIC” countries. Competing in Brazil, China, India

and Russia won’t be easy, but car makers trying to compete in only the major industrialized

markets will find increasing difficulties to survive.

The objective of this thesis is to analyze current automotive market and examine factors

influencing production and total deliveries to customers. We will begin with an analysis

of the global automotive market and value chains in automotive industry and then we will

1

1 Introduction

describe the main ŠKODA AUTO markets. We will employ econometrics methodology for

non-stationary time series data which helps us to study the sensitivity of the most relevant

factors influencing company’s performance on production and sales. We chose for our

analysis ŠKODA AUTO as the steadily largest Czech company by sales. We will determine

the root sources of company’s performance, their relative importance and then we will

summarize these findings and suggest possible improvements.

The motivation and the main arguments for this innovative research are the widening

of current findings, to be able to forecast development on automotive markets more effectively and to offer some possibilities for further research. It is important to know, which are

the essential challenges on automotive market, how to observe and measure variables that

influence performance of the company externally and how to manage internal processes to

reduce costs and make the production more efficient. We will analyze influence of macroeconomic indicators, the financial crises, changes in price of mineral resources, sensitivity

of particular internal costs or impacts of major events in the company. We believe that

these determinants will have a significant role in determining the structure and volume of

ŠKODA AUTO production and sales.

This thesis is structured as follows. The next Chapter provides review of current research and introduces worldwide automotive industry. We will focus on globalization, global

macroeconomics and main automotive markets of ŠKODA AUTO. Chapter 3 introduces

ŠKODA AUTO and provides general data about the company as well as the brief overview

of its long history. We will also describe the organization of ŠKODA AUTO for better

understanding of the company’s functioning and structure of the costs. In Chapter 4 we

state hypotheses to be tested, briefly describe the data and introduce methodology we use

in analyzing the collected data. The last two Chapters introduce the concrete data sets,

describe our variables, set and test the empirical models and discuss our results.

2

2 The Automotive Industry

In last decades, the car culture has spread over the entire planet. Automobiles have

influenced not only the global economy but also lifestyles of billions of people. Plunkett

Research (2013) claims that there were about 1 billion cars and light trucks on the road in

2013 around the world and this number is growing by roughly 40 million yearly.

The leading car original equipment manufacturers ("OEM") have to take into consideration vast number of opportunities and threats today. They are implementing technological

changes in order to enhance their fuel efficiency and are developing smaller, highly efficient

vehicles (hybrids, electric vehicles, etc.). Customers keenly demand high quality and fine

after sales service. European OEMs are facing challenges with high costs of production,

tough labor laws or daunting government regulations which finally led to slowdown in domestic sales in last years. On the other hand, there have arisen new emerging markets

with a huge potential. The low car density in these countries, improving infrastructure and

permanently rising level of education and income means that these markets are nowadays

the most attractive for car manufacturers.

Table 2.1: Light Vehicle Density in 2012

Population Light vehicle fleet Vehicle density

Country

million

million

per 1,000 people

United States

315.31

202.23

641

Germany

81.89

43.56

532

France

63.61

31.74

499

United Kingdom

63.24

31.55

499

Poland

38.32

18.17

474

Czech Republic

10.51

4.63

442

South Korea

48.59

14.61

301

Russia

143.00

37.22

260

Ukraine

44.94

8.04

179

Brazil

198.36

24.93

126

China

1,353.38

69.83

52

India

1,258.35

21.51

17

Source: Ernst & Young survey (2013)

The future will not develop in the same way in every country or type of car. The main

3

2 The Automotive Industry

growth will come from emerging markets and, to a lesser extent, the US, while Europe,

Japan, and South Korea will be stagnant in terms of profit growth. Analysts from McKinsey

stresses in their study from 2013 four key challenges for automakers in medium-term future

to be able to get a piece of future potential profitability:

• Complexity and cost pressure - Car makers will have to develop new technologies

for low-emission vehicles without knowing what will be the prevailing technology in

the future. At the same time, prices in established markets are likely to be flat and

governments will introduce new regulations with respect to environmental and safety

standards. These challenges will require significant investments. To reduce costs,

there will be more platform sharing systems to rise complexity.

• Diverging markets - Share of global sales and profits in emerging markets will rise

by 10 percent till 2020. Car manufacturers need to have sufficient local production,

supply base, after sales market and will have to have balanced product portfolio to

meet local demand.

• Digital demands - Digital channels are for today’s consumers the main source of

information when they want to buy a car. Online purchasing can mean an opportunity

but also puts a pressure on the existing dealership structure. Main requirements of

the customers are active safety and ease of use of the web page.

• Shifting industry landscape - Since car manufacturers will have to enhance their

facilities in emerging markets, they have to be sure if local suppliers are able to match

future market demands and their own production plans. Suppliers will also likely add

more value to the car. The car manufacturers in Europe will have to restructure their

business and deal with emerging Chinese players entering new segments and markets.

These challenges can rise future risk to automotive profit but the overall perspectives

for automotive markets are good. All leading institutions forecast sharp increase in sales in

following decades because people will have sufficient income to acquire the cars. Some of

them are talking even about 3 billion cars in year 2050. New traffic and safety measures may

smooth traffic flow, new technologies in highly efficient cars will strongly reduce air pollution

and fuel consumption. However, many questions reduce excessive enthusiasm: Will that

many consumers find automobile ownership to be desirable? Will public transportation, car

sharing systems, commuter trains and other alternatives to individual car ownership reduce

demand for personal automobiles? Will fuel, whether gasoline, hydrogen or electricity, be

affordable and readily available? Will roads, parking and other traffic infrastructure be

adequate to support car ownership on this scale?

4

2 The Automotive Industry

2.1 Globalization in Automotive Industry

One of the most important strategic topics in automotive industry is a globalization. This

term was first used in the 1980s, but the concept is known for decades, even centuries, if you

count the trading empires built by Britain, Netherlands, Portugal and Spain. Globalization

is an economic phenomenon, involving the increasing interaction, or integration, of national

economic systems through the growth in international trade, investment and capital flows.

Globalization has influenced every aspect of human life and it offers certain opportunities

and threats to each aspect of business. For better understanding of world automotive

industry functioning, it is needed to outline linkages between lead automakers and their

suppliers. We recognize three kinds of linkages:

• Rational – Design engineers from automotive company and its supplier company

works closely together to develop parts that will be used for competition of the whole

vehicle.

• Market – Engineers from automotive company develop all the vehicle parts alone and

then put the parts out for bids.

• Captive – Engineers from automotive company develop all the vehicle parts alone

and then put the parts out for bids and some specific investments from suppliers are

required (which they often are).

Market linkages allow the manufacturers to easily switch their suppliers, while relational and

captive linkages make supplier switching more difficult. Understanding of these linkages is

crucial to developing precise concept of today’s automotive industry.

Since the late 1980s, foreign direct investment ("FDI"), global production and crossborder trade have accelerated dramatically in many industries including automotive. New

World Trade Organizations’ liberal agreements have facilitated trade and investments in

countries with huge surplus of low-cost but skilled labour force and high potential market

growth such as China, India or Brazil. Outsourcing and bundling of more chain activities in

supplier firms is next feature of globalized industries. Sturgeon and Lester (2004) suggest

that the largest suppliers based in developed countries have become global suppliers with

multinational operations and an ability to provide goods and services to a wide range of

lead firms thus they increased their own involvement in FDI and trade. Globalization is of

course also great chance for suppliers from developing countries that have new vast opportunities to trade and to increase their capabilities. These features are similar also for other

industries like apparel or electronics.

The automotive industry is distinctive from other industries because of extremely concentrated firm structure which was enhanced by a wave of mergers and acquisitions in the

5

2 The Automotive Industry

1990s. Eleven lead firms from the three countries (Germany, Japan and USA) dominate

production in main markets. The next distinctive globalization feature of automotive industry is that final vehicle assembly has been kept close to the final markets. Companies from

developed countries invest great amounts in regions with future potential growth and try

to build strong position to maximize future profits and sales. On the other hand, car manufacturers also develop strong regional-scale patterns of integration in their base countries.

The next distinctive feature is that there are not a lot of fully generic parts or subsystems

that can be used in a wide variety of end products without extensive customization. This

feature can be problematic for suppliers of leading firms because parts and subsystems tend

to be specific to particular vehicle models. The leading car manufacturers have been trying

to unify some parts that can be used for more types of vehicle as so called “platforms”.

Platforms can be shared only across the brands owned by a specific lead firm and usually

should not be visible to avoid having the same product design among several models. They

include mainly rolling chassis but sometimes also braking systems, suspension parts, engines or transmissions. Since there are few standardized parts in the automotive industry,

specifications must be developed for every part of each vehicle model. This raises costs

of suppliers that serve multiple customers, limits economies of scale, economies of scope,

even more ties them to lead firms and often creates captive character of linkages between

them and lead firms.

Krkoska and Spencer (2008) suggest that when global automotive market grew, OEMs

started to increase their production capacity. They chose the plant location according

to local network of suppliers, infrastructure or labour. A new efficient plant has to then

satisfy their business strategy for local markets and the location should be also suitable for

exporting to other markets. All of these features have resulted in the “nested” geographic

and organizational structure of the automotive industry:

• Local clusters – Activities tend to be concentrated within clusters of specialized activity, such as design or development, which are concentrated in, or near, the headquarters of the firms. Next example of local clusters can be assembly of new vehicles

that can be located for example in target market.

• National production systems – Domestic production of cars is still very strong and

still dominates many national markets.

• Regional production systems – Intra-regional finished vehicle and part flows are the

dominant operational pattern in auto industry.

• A global industry – Auto markets and global suppliers from buyer-supplier relationships

on a global scale. Intra-regional vehicle and parts trade is substantial but restricted

by political and operational considerations.

6

2 The Automotive Industry

2.2 Trends in Automotive Industry

Global automotive industry has shown many specific trends during last decades which we

should summarize in the beginning of our study. Sturgeon et. al. (2009) suggest following:

The boom in vehicle production in the 1990s and 2000s

According to OICA, the global vehicle production has more than tripled since 1970. There

were produced 29 million cars and commercial vehicles in 1970 and 87 million in 2013.

The world vehicle production grew till 1990s on average rate of around 2 percent and from

this time it raised to around 3 percent. The main driver of this growth in last 20 years is

opening of new markets in Asia as China and India. The huge population and low level

of motorization resulted in large increase in investments in these countries and in rapid

production growth. The production shares of traditional leader producers as EU, Japan and

USA in total world production have lost in last years but still belong among the biggest car

manufacturers.

The continuing importance of core markets

As we already said, the leading car manufacturers has tried to expand their activities to

new emerging markets in last 15 years. Nevertheless, for many companies the home market

remains important. According to OICA, production and sales by the leading manufacturers

in Europe and North America remained concentrated in their home regions. The exceptions

are Japanese producers, which experienced the largest fall in concentration in the home

market.

Regional integration of production

Concentration of vehicles and vehicle parts production to particular regions in North and

South America, Europe, Asia and Southern Africa is in last decades the dominant trend

in automotive industry. The main reason is to lower transaction and operating costs.

There are several reasons that contribute to the importance of regional production. The

automotive industry is highly visible, high cost and powerful local manufacturers or parts

suppliers employ a lot of people. This can provoke strong backlash of population if they see

that imported vehicles account for too large share of vehicles sold and when local producers

are threatened by imports. This explains why automakers choose voluntarily to invest in

foreign regions (even in regions like USA where the employee expenses are much higher

than for example in Mexico) and do not strengthen the home production even the tariffs or

some other local content rules are not present or are scheduled to decline under WTO rules.

Next reasons to build vehicles and major heavyweight subsystems close to end markets can

7

2 The Automotive Industry

be high transportation costs of new vehicles to target market because the final product

is heavy and "fragile" or implementations of "lean" production techniques and increasing

product and module variety.

National and local elements

The regional integration of automotive industry is nowadays the most dominating trend

in automotive industry but we have to also discuss some national and local elements.

Consumer tastes and purchasing power, driving conditions, labour markets regulations,

standard requirements and public policy (incentives and taxation) can vary widely by country

(and even within countries). Consumer preferences reflect climate, characteristics of the

society or high & low income countries. In developed world customers demand more specific

features and on the other hand in developing countries we will find frequently fuel and roads

of poorer quality, so the most important is to adapt vehicle to local conditions (strengthening

the body, suspension, steering, etc.). Each country has also its own set of environmental

regulations (water regulations, air emissions, waste management, noise control, etc.) and

taxation policies, which can create demand for particular type of car.

2.3 Global Value Chains in Automotive Industry

To develop our context of automotive industry in more detail and to outline challenges

within this industry we use Global Value Chain ("GVC") analysis. In GVC analysis of

automotive industry we will recognize two broad types of firms: automakers and suppliers.

Automakers decide about product strategy, place orders, take financial responsibility for final

goods production, carry out most aspects of product design, produce most of the engines

and transmissions and assembly nearly all vehicle within their own facilities. They are large

employers, traders and innovators. They have substantial coordination and buying power

in the chain. But as we already mentioned, outsourcing has led to the creation of large

global suppliers since 1990s, which have taken on more responsibility in the field of design,

production and foreign investment. Memedovic (2007) described a simple automotive value

chain as follows:

1. Raw materials - Rubber, glass, plastics, steel and aluminum. Their costs have increased significantly, mostly due to oil and natural rubber price increases. Aluminum

and plastics increasingly replace steel to make automobiles lighter and more fuel

efficient.

2. Design and product development - These areas are mostly kept near the headquarters

of the automobile manufacturers. Design process has been significantly shortened by

8

2 The Automotive Industry

using computers. The designers are today factual chiefs most of the car companies.

3. OEM parts - Include bodies, electronic and mechanical components, tire and rubber

hoses, seats, windshields, air bags, lighting, batteries, engines, transmissions and

replacement parts.

4. OEM assembly - Today’s trend is using fewer parts in each vehicle component to

reduce industrial waste and pollution, and having parts delivered just-in-time, or lean

supply.

5. Marketing - OEM individual dealers work together to create national, regional and

local marketing strategies.

6. Distribution and sales - Work with automakers on vehicle strategies. May offer incentives to increase sales and collect customer feedback.

7. After sales service

These features are related and affect each other. From raw materials and product development we get OEM parts, product development and design have to cooperate with sales and

marketing to meet customers’ needs, production of parts is important part of also after sales

service etc. Only if everything cooperates perfectly, then the car makers can be globally

competitive.

Globalization of automotive industry has also meant globalization of suppliers. Today we

distinguish two classes of suppliers in car industry: global and local. The most of the top

suppliers now serve to the European, Japanese and US manufacturers. They have to have

global strategy, be able to offer platforms, be flexible, be able to follow automakers’ strategic

decisions and supply the same part with the same quality and price in every location in the

world. It often means immense investments to new facility in areas to which the customer

is expanding. However, building of a new facility is not required at each location. They can

concentrate production of some parts in one region and then ship them to customer’s final

assembly plants. This concentrated industry structure, vast requirements for engineering

hours for developing a new product and huge initial investment to become a global supplier

gives power to a few giant firms and is a big limit for smaller firms to enter the chain.

Value chain linkages between automakers and suppliers in the automotive industry are

typical with huge amount of power of automakers in the chain (even if the suppliers are

global). As Herrigel (2004) shows, the US lead firms (General Motors and Ford) had historically great tensions between them and their main suppliers. They had aggressive buying

practices to lower input costs as much as possible, did not often paid for whole services and

they switched suppliers with little advance notice. Result was oscillation between rational

9

2 The Automotive Industry

and market linkages. In Japan applied more captive linkages with suppliers based on trust

and long-term cooperation. As a result none of the major suppliers of Japanese automotive

companies have bankrupted in last 15 years in contrast to the suppliers of US automakers.

Japanese assemblers are the most loyal in the world, followed by Europeans on the other

hand Americans are the least loyal.

2.4 Macroeconomic Development

The more is the automotive industry global industry, the more is sensitive to fluctuations

of global economy. The review of main economic trends from last years is described in this

section.

The world GDP grows dynamically (with the exception of year 2009) for several decades.

This growth is strongly supported by Asian economics in last years. The world economy

grew more slowly in 2007 than in the previous years, mainly due to the slowdown in the USA

economy and beginning of housing bubble on the local market. To the global dynamics

then more and more increasingly contribute Asian economies, especially China and India.

Rising oil prices and the ongoing political instability in the Middle East in 2007 led to higher

prices of synthetic materials. The increase in consumption of raw materials in 2007 caused

a further increase in steel prices. The world economy in 2008 significantly slowed its growth

and in the end of the year experienced a decline. The main reason was the onset of a deep

financial crisis with all its negative impacts - the bankruptcy of a number of investment

banks (Lehman Brothers), uncertainty in the financial markets and the slowdown in many

world economies. To the global dynamics contributed more Asian countries, especially

China and India. EU economies slowed growth, some of them, such as Ireland, Spain and

Germany, have fallen into recession (they recorded two consecutive quarters of negative GDP

growth). The Global Financial and Economic Crisis influenced of course the all significant

industries such as the automotive industry. Besides the direct impact - financial market

instability - the most dramatic impact of the crisis was for the automotive industry large

slump in a demand. The vast majority of the world’s manufacturers had to face a significant

decline in sales which had to be necessarily reflected in the results of their operations. This

development logically resulted in the further slowdown in the global economy. In 2009 the

global economy was fully affected by the Global Financial Crisis. The problems of banks

resulted in a significant decline in world GDP after long time.

The Global Economic Crisis had a harmful effect on the automotive industry. All the

major brands had to face double-digit declines in sales which resulted in the reduction of

earnings and redundancies with subsequent effect on suppliers. After a significant decline in

2009, in 2010 the global economy recorded a recovery. Most countries returned to growth

10

2 The Automotive Industry

in GDP. Economic recovery and rising demand led to an increase in prices of precious metals

and steel in this year. The main consequences of the crisis, which influenced the automotive

industry, were following:

• Debt crisis in various countries

• High volatility on financial markets

• High volatility in exchange rates

• High prices of raw materials

2.4.1 Financial Crisis

In this thesis we will discuss impacts of financial crisis on car deliveries in global automotive market. Thus it is important to define financial crisis for our purposes and find the

most important drivers. Current literature appears to be unclear in specification of financial

crisis definition. There are several major directions. The first, represented by monetarists

(e.g. Schwartz, 1987), sees the true reason of financial crises only in the banking panics,

since they believe those are the ones causing severe downturns in aggregate economy. The

other definition is quite broad. As e.g. Kindelberger and Aliber (2011) and Minsky (1970)

suggest, the financial crisis includes substantial decline in asset prices, deflation, defaults of

financial and non-financial companies, disturbances in exchange markets, disinflation, or its

combinations. Mishkin (1992) defines entirely different approach. He uses the asymmetric

information assumption, which says that in financial transactions one party usually has a

superior information set than the other. Based on this assumption, the author derives that

a financial crisis is a situation, when the adverse selection and moral hazard phenomena

become much worse, which results in inefficient channeling of funds through the financial

system.

Reinhart and Rogoff (2010) identify three different types of financial crisis in another

study:

• Banking crisis - Situation when the bank is no longer solvent or is not able to maintain

liquidity (the trust of public declines and people start withdrawing their deposits, a

bank invests to a particular industry in a higher than optimal proportion and the

industry performance decreases).

• Currency crisis - Defined as a rapid exchange rate depreciation (at least 15 percent

per annum). Periods of high inflation (more than 20 percent per annum) are also

included in this type of crisis, because a currency depreciation and high inflation often

go hand in hand (based on empirical evidence).

11

2 The Automotive Industry

• Debt crisis - Failures to meet debt obligations incurred in a foreign country, repudiations, or the restructuring of debt into worse terms to the creditors (external debt

crisis is usually much more noticeable than a domestic one).

2.4.2 Macroeconomic Forecast for Main Car Markets of ŠKODA

AUTO

Global economic projection of GDP growth is approximately 3 percent and inflation 5

percent. According to International Labour Organization (2013), the global unemployment

will slightly rise up to 6.5 percent (from today’s 5.9 percent unemployment rate) in next 5

years, because of an uncertain economic outlook, which has weakened aggregate demand,

holds back investment and hiring employees. The situation of youth unemployment is

expected to improve slightly in developed economies over the next 5 years, but it is expected

to rise in emerging economies in Eastern Europe, East and South-East Asia and the Middle

East.

In advanced economies we can see stagnation of GDP or slight growth; inflation will be

probably low and under 2 percent. The expected GDP growth for China for the next 5 years

is according to both International Monetary Fund and World Bank (2014) around 7 percent

and inflation around 3 percent. Russia is showing slight positive results of GDP growth but

inflation outlook is relatively high - over 5 percent in next years. The expected GDP growth

for India for the next 5 years is little bit losing to previous year’s growth but will surely remain

over 4 percent with relatively high inflation around 6.5 percent. Unemployment rate in India

are in average 7.6 percent and decreased from all time maximum 9.4 percent in 2010 to

3.8 percent in 2011. The unemployment is supposed to even more decline to around 1.2

percent in 2015. However there is unstable economic and monetary situation with high

interest rates around 8 percent in last years. These high interest rates are also predicted

for near future.

2.5 Development of the Markets with ŠKODA AUTO

Branded Cars

The global car markets steadily grew from late 1990s till the Financial Crisis in 2008. The

impacts of the Crisis on the banking markets led to the restraint on automotive markets.

The decline was also amplified by rising prices of raw materials and energies. Above-average

declines in sales recorded particularly regions of North America and Western Europe. On

the other hand the positive development continued in the markets of Central and Eastern

Europe and also in Asia but with significantly reduced growth rate. In 2009 the sharp

12

2 The Automotive Industry

decline in sales was recorded mainly in regions of North America, Central and Eastern

Europe. In contrast, the positive trend continued in Asia. The sales in 2010 were strongly

influenced by the ending of scrappage program which was implemented as an economic

stimulus to increase market demand in the industrial sector during the global recession that

began in 2008. Significant increase in sales was recorded mainly in Eastern Europe and also

in Asian markets. The recovery that had begun in 2010 on the global automobile markets

continued also in 2011 and 2012. This trend was mainly driven by the positive developments

in markets as India, China and the Russia and total global automobile sales increased by

4.5 percent and 6.3 percent year-on-year respectively. In 2013 grew the markets of China,

North America and Middle East. Earlier dynamically growing markets in Russia and India

recorded a decline in demand in 2013. In following Table is the summary of year-on-year

global car market development in most important ŠKODA AUTO car markets.

Table 2.2: Car Markets Development (y-o-y growth)

2007

2008

2009

2010

2011

World

+4.2%

-5.8%

-6.1% +11.4% +4.5%

Central Europe

+8.5%

+4.7% -16.5%

-3.5%

-3.3%

Western Europe +0.2%

-8.4%

+0.5%

-5.1%

-1.4%

Eastern Europe

+36%

11.4%

-52.5% +2.3% +35.2%

China

+22.3% +7.8% +53.9% +35.1% +8.1%

India

+16%

+2.1% +17.8% +29.8% +5.6%

Russia

+37.5% +15.4% -50.3% +27.9% +39.8%

Source: Scotiabank (2014) and ŠKODA AUTO Annual Reports

2012

+6.3%

-2.1%

-8.2%

+7.7%

+9.3%

+11.1%

+10.9%

2013

+4.6%

+1.1%

-1.9%

-4.9%

+17%

-6.7%

-5.7%

We can see deliveries to customers on 12 biggest markets of ŠKODA AUTO and in each

of four regions in the table below. China and Russia are from year 2010 the first and

third biggest markets of ŠKODA AUTO respectively and together with India represent the

markets with biggest future potential. Germany, United Kingdom, Czech Republic, Poland,

France, Austria, Switzerland, Belgium and Slovakia belong among very important markets

for the company with relatively stable results. Central Europe region has stable markets

and evinces slight growth, while Western Europe is more sensitive on economic recessions

and its performance vary. Eastern Europe and Overseas/Asia regions with their growing

Russian, Chinese and Indian markets play an important role in the ŠKODA growth strategy

and steadily grow. Therefore we will focus on them further.

13

2 The Automotive Industry

Table 2.3: ŠKODA AUTO Deliveries to Customers –

2008

2009

2010

China

59,284

122,556 180,515

Germany

112,504 162,328 113,323

Russia

50,733

33,002

45,577

United Kingdom 37,072

36,012

41,632

Czech Republic

58,001

56,504

58,033

Poland

33,986

38,305

37,918

India

16,051

14,535

20,019

France

19,480

20,313

20,394

Austria

16,700

17,500

18,803

Switzerland

n.a.

n.a.

14,320

Belgium

14,130

12,358

15,756

Slovakia

17,809

14,613

13,650

Central Europe

131,084 119,923 121,063

Western Europe 315,571 345,185 333,261

Eastern Europe 123,630

60,464

73,747

Overseas/Asia

104,245 158,654 234,529

Total

674,530 684,226 762,600

Source: ŠKODA AUTO Annual Reports

Largest Markets and by Region

2011

2012

2013

220,089 235,674 226,971

128,011 132,580 136,415

74,074

99,062

87,456

45,282

53,249

66,029

58,202

59,674

60,042

38,116

36,307

38,710

30,005

34,265

22,563

22,536

22,022

20,400

21,208

22,300

20,073

16,298

17,830

16,984

18,900

17,530

15,482

15,182

15,902

14,827

123,156 124,012 126,481

361,777 358,439 369,598

108,423 137,057 125,359

285,828 319,694 299,312

879,184 939,202 920,750

On the figure below, we can see that since 2006 the ŠKODA AUTO deliveries to customers have been increasing year by year for China, Russia and India as well with exception

of the year 2013. Although Russia experienced a major decline due to the financial crises

in 2009, it has recover quickly and ŠKODA AUTO delivered almost 10 percent of the total

production on local market in 2013.

14

2 The Automotive Industry

Figure 2.5.1: ŠKODA AUTO Deliveries to Customers in Emerging Markets

Source: ŠKODA AUTO Annual Reports, own calculations

The figure below depicts the percentage change over the past years of deliveries to

customers in emerging markets plotted into the total world deliveries. We can see, with

exception of the year 2009 and 2013, that the growth of deliveries in the emerging markets

is above the ŠKODA AUTO worldwide average.

Figure 2.5.2: ŠKODA AUTO Deliveries Percentage Change in Emerging Markets (y-o-y

percent growth)

Source: ŠKODA AUTO Annual Reports, own calculations

15

2 The Automotive Industry

In the year 2013 slight decline in deliveries to customers was recorded. In 2013, ŠKODA

AUTO sold 920,750 vehicles worldwide (year 2012: 939,202; -2.0 percent). Deliveries to

customers have been affected by changes in production due to the comprehensive model

renewal. With eight new or completely revised models, 2013 is ŠKODA AUTO’s year

dedicated to the biggest model offensive in corporate history. The Czech automaker could

not also fully escape the weak market environment. But in September 2013 ŠKODA

AUTO recorded an increase of 3.3 percent over the same month in 2012, further increased

its market share in Europe and growing trend lasted till the end of the year. Also current

incoming orders are developing very positively. The model campaign is finally paying off

and on the basis of these indicators, ŠKODA AUTO expects similar progress in the future.

In next Subsections we will look closely to the main emerging ŠKODA AUTO’s markets.

2.5.1 China

China’s Economy

After the collapse of the Republic of China and formation of the People’s Republic of

China in 1949 came into power Communist party of China and they started to transform the

country into a modern and powerful socialist nation. In economic terms, these objectives

meant industrialization, improvement of living standards, narrowing of income differences

and production of modern military equipment. The reforms that mostly influenced the

boom of automotive production were so-called Chinese economic reforms starting in 1978.

The Party decided that the centrally planned economy had failed to produce efficient economic growth and started to shift a centrally planned to a socialist market economy. They

reduced the government planning and direct control and added market mechanisms in the

system thus this economic model is based on dominance of the state-owned sector and an

open-market economy. China experienced rapid economic, industrial and social development after these reforms. This boom was also enhanced by China’s entry into the World

Trade Organization in 2001.

The socialist market economy of China with a population of 1.3 billion became recently

the world’s second-largest economy and is increasingly playing an important and influential

role in the global economy. It is the world’s fastest growing economy, with growth rates

averaging 10 percent over the past 30 years and fastest growing consumer market. China is

also the largest manufacturing economy, the largest exporter and second largest importer of

goods in the world. Coastal regions of China tend to be more industrialized, while regions in

the hinterland are less developed. The predictions for China are continuing strong economic

growth and high inflation in next years. However, China still remains developing country

because its per capita income is still very low and almost 100 million people live below

16

2 The Automotive Industry

the national poverty line. There is high inequality in the country, the market reforms are

incomplete, they challenge environmental sustainability, rapid urbanization and external

imbalances. According to Accenture (2013) report, there are 14 modern metropolises with

population of more than 10 million and 150+ cities with populations of more than one

million. The percentage of population living in urban areas is still supposed to rise from

51 percent in 2011 to 60 percent in 2020 and also the income of households is going

to rise greatly. Significant policy adjustments are required in order for China’s growth to

be sustainable. According to World Bank (2014), the last Five-Year Plan (2011-2015)

highlights development of services, settings targets to reduce pollution, to improves access

to education and healthcare, addresses environmental and social imbalances and expands

social protection. The quality of infrastructure has improved significantly in last years

while expansion of road systems is going to continue. The target growth is 7 percent and

predicted inflation is relatively low.

China’s Car Industry and Market

China’s passenger cars and commercial vehicles manufacturing industry has become the

number one automaker in the world in 2009 with an annual production of more than 22

million units in 2013. Russo et al. (2008) suggest in their report that most of the cars

manufactured in China are sold within China. Even if Chinese firms have learned very quickly

how to assemble cars and develop supply chains, they are very inexperienced at the vehicle

development and synthesis process. They often draw inspiration from foreign brands and

their ability to compete on foreign markets is insufficient. As a result, exports reached only

977,300 units in 2013. Native player’s share of the passenger car market in China was 40

percent in 2013 and the rest were produced by joint ventures with foreign car makers. The

production plant in China’s industrial metropolis of Shanghai was inaugurated in 1984 as a

joint venture of Volkswagen and the Chinese firm Shanghai Automotive Industry Corporation

("SAIC"). In 2005, the production of the plant expanded also by ŠKODA AUTO models;

Octavia was the first, later followed also the Fabia and Superb. ŠKODA AUTO further

produces Rapid in plant in Yizheng.

Chinese automotive market has been largest single-country market in the world since 2010

and is also supposed to be the market with the biggest potential for ŠKODA AUTO cars.

In 1975 only 139,800 automobiles were produced annually, but as a result of the reforms

from 1978, by 1985 production had reached 443,377, then jumped to nearly 1.1 million

by 1992 and during the next 10 years reached 2.3 million and has continued growing. We

can see sustainable growth of sales in Table 2.2. In 2008, dynamics of growth significantly

slowed down, particularly because of increased fuel prices and implementing of measures

to control inflationary tendencies. The growth of China’s car market is undeniable but has

17

2 The Automotive Industry

experienced great volatility of growth rate in last 20 years. Year-on-year car sales growth

rate ranged from 0 to 70 percent (see following Figure) which can be one of the challenges

for car makers on China’s market.

Figure 2.5.3: GDP development and Car Sales Growth Rates in China (y-o-y growth)

Source: IHS Automotive Insight (2013) and IMF (2014)

In 2011, number of registered automobiles in China exceeded 100 millions. Cars account

for almost half of the demand of motor vehicles (automobiles, motorcycles, and others).

The dominant player on Chinese market is Volkswagen but other brands (like Chery, Greely,

SAIC or Toyota) are strongly catching up. According to China Auto Web (2013) ShanghaiVolkswagen was with more than 1.5 million sold cars a close second on China’s passenger

car market behind Shanghai-General Motors in 2013.

There are several consumer segments according to Accenture (2013). First tend to buy

domestic brands either because of the loyalty to the local brands and country or because their

low income is insufficient to afford foreign cars. Other customer segments are interested

in foreign brands. The wealthier of them keen on exclusivity and high-end products, other

aspire to buy trendier and more sophisticated brands or brands with long tradition on

Chinese market.

Customers in China predominantly rely on four factors when they decide which car to

buy: advice from family members, opinions shared via social media, recommendations from

friends and colleagues and they also often look on manufacturer websites. Social media

nowadays have significant role on Chinese consumers’ purchasing behaviors. They use

social media to learn about companies’ products and services, share positive or negative

comments or communicate with companies about their product or customer service. The

digital marketing can strengthen relationships and brand loyalty. Chinese customers want

18

2 The Automotive Industry

more access to carmakers’ products (e.g. mobile-enabled websites), more content and

digital features (clearer pricing, online customization or online chat with a dealer) and a

digital experience that is simple to navigate.

A Perspective on the China’s Car Market

China’s automotive market grew at a compound average rate of 24 percent a year between

2005 and 2011 and is expected that the growth will continue. Chinese customers are more

sophisticated now and their tastes are evolving so automakers just need to understand their

needs and which segments will be most important. They need to translate those consumer

insights into quick action. Prices of cars are falling and this trend is expected to continue

over the next five to ten years. China is a huge country and the tastes of the customers

may also vary depending on the region where they live. Fundamental drivers for demand

growth are increasing urbanization, rising household income, low car penetration rates and

infrastructure improvements. Wang et al. (2012) mention in their paper following trends

on Chinese auto market in the next 10 years which will drive growth:

• Going bigger - Consumers in China are going to buy bigger cars. Sedans will remain

the largest segment but sales of sport utility vehicles ("SUVs") will triple. Wealthy

customers will consider SUV more likely as an upgrade from sedan and they will

show off heir personal tastes and needs by some big car. But despite high growth

in this segment, the share of sedans in 2020 will be still only 20 percent and sedans

will command 70 percent. But even among sedans the customers will likely choose

bigger cars as long as they can afford it. However, in segment of small cars is also

great potential. Chinese market development will be likely consistent with US and

European markets, where a lot of families in urban areas buy second cars just for

commuting.

• Trading up - The segment middle-priced cars (80,000 to 250,000 CNY) will remain

the dominant price segment with 60 percent of the market in 2020. Rising demand

for small and medium-sized cars will support as well as rising household income will

underpin demand in this price segment. But customer will be more likely to buy

high-priced cars (250,000 to 800,000 CNY) because there will be more second-time

buyers and aggressive marketing strategies of leading car companies will strongly

influence a selection of a new car. There are also more and more environmentally

conscious customers which will look for cars with green technologies, alternative fuels

and fuel-economy engines. Additional in-vehicle technologies, like Wi-Fi connectivity,

GPS or access to real-time traffic data, will also generate added revenue per car sold.

19

2 The Automotive Industry

In last 20 years, the automotive market in China has had to face some unfavorable developments that can influence further market growth. Wang et al. (2012) mention in their

paper following:

• Global economic uncertainties will likely have negative impact on rate of urbanization

and thus on number of jobs.

• Governments could introduce policies that might restrict car use in more than 20 big

cities in order to reduce air pollution.

• Emerging alternatives to new car ownership as used car market, improved public

transportation or cheap car rental.

• Next challenges are to satisfy evolving customers’ tastes and reduce disruption of the

landscape.

Despite these uncertainties, the new car sales in China are forecast to contribute 35 percent

of the world’s car market growth between 2011 and 2020. The China auto market growth

is expected to slow but it will still be in average 7 to 8 percent a year in next 10 years but

the volatility observed in last twenty years as likely to continue. Regional importance of

the sales is going to be crucial because increase in sales in next 8 years in smaller cities is

around 60 percent. Automakers should invest in order to understand local customers needs,

select effective marketing strategy in particular region and have to understand, in which

regions are customers more sensitive on price or rather on design. But crucial for sales will

be still big cities which will have major share of newly sold cars.

Chinese people appreciate German quality of vehicles and ŠKODA AUTO benefits from

it. The growth of ŠKODA AUTO’s cars have been steadily above the growth of the market

and this growth is expected to continue. The ŠKODA AUTO’s goal on Chinese market is

to deliver 500,000 vehicles to the customers around year 2020 to accomplish the company’s

growth strategy.

2.5.2 India

Indian Economy

The reforms that have had the biggest impact on car market in India in last decades

were established in 1991. The period from 1947-1991 is called Pre-liberalisation period

and is characterized by the protectionism, with a strong emphasis on import substitution,

industrialization, economic interventionism, a large public sector, business regulation, and

central planning inspired by Soviet Union, while trade and foreign investment policies were

relatively liberal. In 1991 the new government initiated economic liberalization. The reforms

20

2 The Automotive Industry

reduced tariffs and interest rates and then brought foreign competition in Indian market, led

to the privatization of certain public sector industries, improved infrastructure and ended

many public monopolies, allowing automatic approval of foreign direct investment in many

sectors. According to IMF (2014), the GDP of India has then risen rapidly since 1991

growing on rates 4-10 percent per year with a peak in 2010. By the turn of the 21st

century, India had progressed towards a free-market economy, with a substantial reduction

in state control of the economy and increased financial liberalization.

India is the largest democracy in the world with 1.2 billion people and steadily growing

middle class. The Indian economy is fourth-largest economy in the world according to

purchasing power parity. India is nowadays the 3rd largest investor in the world and rapidly

invests to infrastructure. The country will soon have the largest and youngest workforce in

the world and now is in the midst of a massive wave of urbanization. To create jobs, housing

and infrastructure, massive investments are needed. According to ACMA (2013), the total

planned infrastructure investments from 2007-2012 were $500 billion and infrastructural

spend is targeted to double to $1 trillion for 2012-2017.

The great problem in India are social inequalities. Poverty rates are especially in some

regions incredibly large. The level of education is still not enough to to compete in today’s

changing job market, despite primary education has largely been generalized. The forecast

for Indian economy is continuing strong economic growth but high inflation in next years.

India now has a great opportunity to lay the foundations for a truly prosperous future and

to improve the quality of life of its citizens.

Indian Car Industry and Market

The automotive industry in India is economically and demographically considered as

well-positioned for growth and for satisfaction of domestic demand and also export. It is

one of the key drivers of India’s economy, accounting for around 4 percent of India’s GDP

and over 200,000 jobs. India’s automobile exports are expected to cross $12 billion by 2014.

India’s passenger cars and commercial vehicles manufacturing industry is the sixth largest

in the world, with an annual production of almost 3.9 million units in 2013. The majority

of India’s car manufacturing industry is based around three clusters in the south (Chennai), west (Mumbai and Pune) and north (National Capital Region). In 2011, there were

10 Indian automotive companies and more than 30 foreign automotive companies which

produced their vehicles in 3,695 factories across India. ŠKODA AUTO produces its cars