Installation Guide- Full Height Panels

advertisement

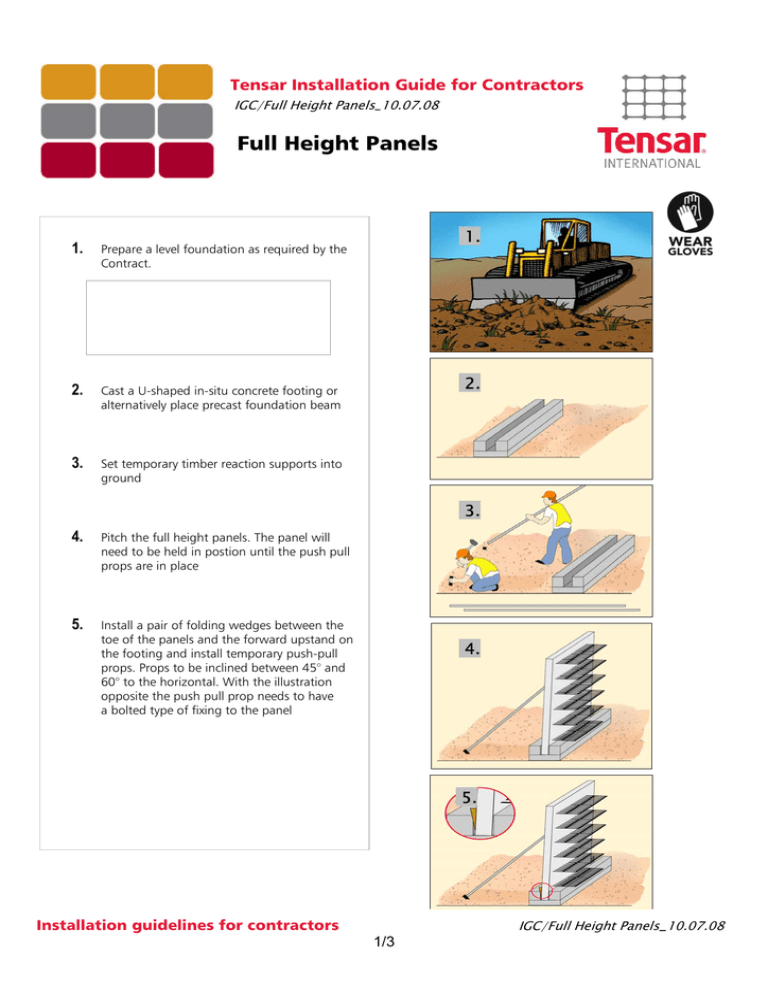

Tensar Installation Guide for Contractors IGC/Full Height Panels_10.07.08 Full Height Panels 1. Prepare a level foundation as required by the Contract. 2. Cast a U-shaped in-situ concrete footing or alternatively place precast foundation beam 3. Set temporary timber reaction supports into ground 1. 2. 3. 4. Pitch the full height panels. The panel will need to be held in postion until the push pull props are in place 5. Install a pair of folding wedges between the toe of the panels and the forward upstand on the footing and install temporary push-pull props. Props to be inclined between 45° and 60° to the horizontal. With the illustration opposite the push pull prop needs to have a bolted type of fixing to the panel 4. 5. Installation guidelines for contractors 1/3 IGC/Full Height Panels_10.07.08 6. Adjust facing panels to required batter 7. Connect adjacent panels by the use of a fish plate and then adjust horizontal alignment of these panels 8. Place drainage material (if required) behind units. Place and compact fill to Contract's specification up to the level of the lowest cast-in grid tail. Join the main geogrid to the starters using Tensar bodkin and lay out the geogrid over the fill 9. Fill should be placed by plant such as an excavator bucket or a dozer with an opening bucket which causes the fill to cascade onto the grids. A minimum of 150 mm thick cover of fill must be maintained between the tracks of any plant and the grid to avoid damage. Use plant with a total mass less than 1000 kg within 2 m of the face 7. 8. 9. 10. No traffic or site plant shall be permitted to travel directly on the grid 11. Use a vibrating plate compactor or a vibrating roller with a mass per metre width ≤ 1300 kg and a total mass ≤ 1000 kg within 2 m of the face 11. Installation guidelines for contractors 2/3 IGC/Full Height Panels_10.07.08 12. 13. 14. 12. Apply a load to the free end of the grid using a tensioning beam (see TN/SRREBeam) inserted through the apertures in the grid, until the slack is removed from the joint.Whilst maintaining tension, place a layer of fill on the grid, which is sufficient to restrain it in position when the load is released. Release the tension and remove the beam Folding and slack in the geogrid is not allowed. Continue construction up to approx. 1/3 of the full height of the wall. Remove the folding wedges from the toe of the wall 15. Continue construction up to approx. 2/3 of the full height of the wall. Remove props and make good the holes. 16. 17. Continue construction up to the top of the wall 13. The Contractor must fully asses the safety risk associated with working at height and where appropriate install any necessary temporary edge protection. 14. 15. The information in this document is of an illustrative nature and is supplied without charge. It does not form part of any contract or intended contract with the user. Final determination of the suitability of any information or material for the use contemplated and the manner of use is the sole responsibility of the user and the user must assume all risk and liability in connection therewith. Tensar is a registered trade mark Tensar International Limited Tel: +44 (0) 1254 262431 Fax: +44 (0) 1254 266867 E-mail: sales@tensar.co.uk www.tensar-international.com UK Head Office Cunningham Court Shadsworth Business Park Blackburn BB1 2QX United Kingdom Installation guidelines for contractors 3/3 IGC/Full Height Panels_10.07.08