2-Component Combination Motor Controller

advertisement

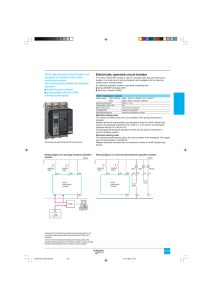

2-Component Combination Motor Controller solutions for North America M 3~ The complete range of contactors, efficient motor-starters and variable speed drives for the motor circuit. New simple to install solutions based on clever communication. Technical Paper Dipl.-Ing. Wolfgang Esser Contactors DIL Reliably and safely controlling, switching and managing power. In industry, in buildings and in machine construction. Innovative protection concepts. With built-in diagnostics and communication functions. Housed in modern switchboard systems. Circuit-breakers NZM For Moeller Electric Sales and Support call KMparts.com (866) 595-9616 2-Component Combination Motor Controller solutions for North America – fuseless motor starters without separately mounted overload relay – Differing styles of motor starters Everyone would agree that motors are by far the most important pieces of equipment in the machine tool and panel building industry. This paper will deal mainly with modern aspects of switching and protecting asynchronous or squirrel-cage motors, still the primary workhorses of the industry. There are essentially 2 traditional approaches involved in switching and protecting such motors. One uses fuses as the primary overcurrent protective device. The other is fuseless, and relies on motor protective switches or circuit breakers as the core protective element. Both versions feature a separately mounted overload relay as a means to protect the motor against running overloads, and both are typically combined with motor switching and HP rated motor contactors to provide longer life and remote control operational capabilities for the motor starter. Fuseless solutions have the advantage that they are inherently independent of local fusing styles and conditions, which can vary greatly from market to market, and they also would permit, in most cases, a relatively quick resetting of the circuit without exchange of components once the cause for the fault had been eliminated. An additional safety related consideration of significant importance would be that the fuseless protective device would operate to open all 3 poles simultaneously in the event of a fault, whereas fuses operate independently and are thus more prone to allow single phasing conditions to develop in a circuit. The combination of a motor protective device, or a circuit breaker, and a motor switching contactor also lends itself well to different levels of component protective co-ordination testing, such as been popularized for years in the IEC/ EN 60 947 standard, and of late as well in the recently introduced and comparable North American UL 60 947 industrial control standard. Co-ordination levels are indicators of the protection afforded to the circuit and a determination as to whether or not, in the event of fault, welding and inoperability of the contactor are permissible outcomes. In the IEC world, the choice between a motor protective switch or a circuit breaker can often be made simply based on the size and rated current of the motor. In North America, both types of components fall under markedly different product standards (UL 508 resp. UL 489, or CSA-C22.2 No.14 resp. CSA-C22.2 No. 5-02), which ultimately also impacts the application range of both components when they are used as protective devices in branch circuits. Typically, the equipment would be subject to different construction requirements as well, such as the need for circuit breakers to feature the larger electrical clearances of distribution equipment. In the IEC world, the situation is different, with many manufacturers of motor protective switches more apt to commonly refer to their equipment as circuit breakers, making the line between both types decidedly more blurry. Motor protective switches represent a particularly significant product grouping within Moeller, both from a technical and manufacturing volume point of view. Moeller actually prefers to use the more precise term „Motor Protective Switch“ for their own devices, since they are optimally designed for motor protection and generally available in relatively low current ranges, i.e. up to appr. 65A, to cover the large majority of industrial motors. These components are also phase failure sensitive per the requirements of IEC/EN 60 947, which is considered a premium feature for motor protection applications. Moeller is justifiably considered a pioneer in the field of motor protective switch design, to the point where the PKZM brand reference in the electrical industry is often used as an eponym or generic term to refer to products from all makes in this category. The IEC product standard pertaining to a molded case circuit breaker, IEC/ EN 60 947 Part 2, does not contain any specific testing provisions for motor protection. One needs to combine certain test requirements from an additional product standard, IEC/ EN 60 947-4-1 for contactors, overload relays and motor starters, in order to legitimize the device as a „Motor Protective Circuit Breaker“, or large motor protective switch. A similar situation exists in North America, whereby the applicable product standards for molded case circuit breakers and switches, i.e. UL 489 in the US, and CSA-C22.2 No. 5-02 in Canada, also do not include any testing provisions to specifically verify the circuit breaker’s performance as a motor protective device. In order to establish the circuit breaker as a motor protective device, the breaker must first be listed under the UL 489 product standard, and then pass additional calibration testing per the industrial control standard, UL 508 [1]. In Canada, the same situation would apply, with additional motor overload testing required per their equivalent standard for industrial control equipment, CSA-C22.2 No.14. It can thus be said that, world-wide, a molded case circuit breaker requires additional calibration per the product standards for contactors and motor starters in order to verify its performance as a motor overload protective switch. In the IEC world, as well as in North America, one would typically add a motor switching contactor to a circuit breaker in order to provide motors with the added capability of remote switching, as well as a higher switching frequency and a longer electrical life for the motor starter. In the IEC world, these motor starters would predominently consist of two components, i.e. a circuit breaker or motor protective 2 For Moeller Electric Sales and Support call KMparts.com (866) 595-9616 switch for motor overload and shortcircuit protection, and a motor contactor for direct switching purposes. In North America, on the other hand, combination motor starters are still overwhelmingly made up of at least three power circuit components in the motor branch circuit. North American combination motor starters are mainly 3 component assemblies Whereas it is common to find circuit breakers additionally calibrated for motor overload protection in global regions dominated by IEC standards, in North America circuit breakers are still commonly combined with separately mounted overload relay protective devices conforming to UL 508 and CSA-C22.2 No.14 in motor starter circuits. Thus, the prevalent combination motor starter configuration in the US and Canada consists of at least three power circuit components, a number not unlike the combination of fuses, contactor and motor overload relay still very commonly encountered in the IEC world for motor circuits. In both cases, the circuit breaker or fuse fulfills the role of branch circuit protective device (BCPD) for the branch circuit. A typical IEC motor protective device, e.g. a Moeller PKZM0, is referred to as a motor protective switch or manual motor controller in North America. Manual motor controllers certified per UL 508 and CSA-C22.2 No.14 standards are not suitable as branch circuit protective devices (BCPD) per the electrical codes. In a motor branch circuit, they would require the additional presence of a BCPD such as a circuit breaker or fuse [2]. They can fulfill the role of a BCPD for individual motor branch circuits if they are additionally evaluated as Type E selfprotected controllers, in which case they would also require the provision of an additional terminal block on their UL 489 Inverse Time Circuit Breaker, with adjustable or, more commonly encountered, fixed overload response trips. (UL 508 Table 76.2, Construction Type C) incoming supply side to achieve the necessary electrical clearances. In that capacity they can also be combined with conventional magnetic contactors for certification as Type F combination motor controllers. Two common types of combination starters encountered in North America include a circuit breaker as the overcurrent protective device along with a motor switching contactor and a separately mounted overload relay. The first, and most common, features an Instantaneous-Only Trip circuit breaker as the protective device and accounts for the great majority of circuit breaker type combination motor starters in the North American industrial sector. The other form of circuit breaker type combination starter would feature an inverse time circuit breaker, most likely with a fixed overload response setting (Figure 1). Circuit breakers with a fixed overload response capability are very seldom UL 489 Motor Protective Circuit Breaker, with adjustable overload trip, with UL 508 calibration, without separate overload relay I> UL 489 Instantaneous Trip Circuit Breaker, without overload trips (UL 508 Table 76.2, Construction Type D) b NZM..-ME..-NA M 3~ M 3~ new! I> I> a M 3~ M 3~ c Figure 1: In North America, combination motor starters still predominently consist of at least 3 main power circuit components. The new motor protective circuit breaker Type NZM..2-ME..-NA allows for a 2 component combination motor starter solution consisting of the circuit breaker and a motor switching HP rated contactor. 3 For Moeller Electric Sales and Support call KMparts.com (866) 595-9616 have been tested and certified together as a motor starter assembly. The main disadvantages of a 3 component motor starter solution from an IEC point of view, include an obvious greater need for volume to house the assembly, as well as more elaborate mounting and wiring considerations. In the case of an inverse time breaker, there is the additional aspect that the breaker and the motor overload relay would now double the heat produced in the enclosed housing space through normal component power losses. The advantages of a 2 component combination motor starter solution FIgure 2: Modern design 2 component combination motor starter solutions for the North American market: UL 508 Type F – Combination Motor Starters, consisting of a PKZM0 manual Type E self-protected combination motor controller combined with a DIL M motor switching contactor. The pictured starters are mounted on busbar adapters directly fed from a busbar system. As a Type E device, the PKZM0 is also equipped with an incoming supply terminal (circled in red) featuring the larger electrical distribution clearances. encountered in the IEC world, and are mostly found in Asia or in the residential market. The need for a circuit breaker with fixed response settings would more likely arise in non-motor load applications and would probably tend to feature larger currents and long cable lines, for which a closer match of the load ampacity to the breaker’s fixed setting would be useful in keeping down material costs, such as copper content. A circuit breaker with an adjustable overload or long time response, on the other hand, would always have to be connected to a conductor whose ampacity would be equal to, or greater than, the circuit breaker’s maximum adjustable current setting, and could thus potentially lead to higher overall installation costs. In the IEC world, instantaneous-only trip circuit breakers are occasionally used for motors with unusually long starting times, and combined with a separately provided electronic motor overload relay on which various trip class settings can be selected to better match the load. Instantaneous Trip-only circuit breakers are certified in North America as Recognized Components only. This type of certification is by definition restrictive, and subject to additional conditions of acceptability in order to meet the requirements of the North American electrical codes. In the case of these circuit breakers, this would primarily involve the need to always apply them with a dedicated motor contactor and overload relay which Figure 3: The motor protective circuit breaker NZM2-ME-NA, listed per UL 489 and certified per CSA-C22.2 No. 5-02, has additionally been evaluated per the motor overload calibration requirements of UL 508 and CSA-C22.2 No. 14. In addition to the adjustable overload and instantaneous short circuit trip adjustments, the device has a motor inrush trip class selection feature similar to the ones available in premium design overload relays. Moeller offers 2 component combination motor starters in the form of UL 508 listed Type F combination controllers for current ranges up to 52A. They are especially popular since they can also be mounted and wired in arrays on modern space saving busbar adpaters for control panel applications (Figure 2) [2, 3]. Moeller has introduced a new molded case circuit breaker, Type NZM..2-ME...-NA, with a built-in motor overload protective function (Motor Protective Circuit Breaker) for motor full load currents in the range of 45...200A. The circuit breaker is also certified and was developed at the same time as the North American standards and testing requirements for this type of protective device were being formulated. The breaker is „UL-Listed“ and „CSA-Certified“. In Moeller’s line it’s a size 2 frame construction breaker, and it is equipped with an electronic trip unit. These larger NZM..2-ME…-NA „motor protective switches“ also feature a much broader, and overlapping, adjustable setting range (Figure 3). Only three separate devices are required to cover the entire 45A to 200A motor full load current setting range (Table 1). The current values correspond to North American motor HP ratings from 60 through 150HP @ 460/480VAC. The instantaneous short circuit trips are adjustable and can be set in a broad range between 2 ... 14 x In in order to accommodate typical motor inrush currents and prevent nuisance tripping. A special feature of this breaker is its 4 For Moeller Electric Sales and Support call KMparts.com (866) 595-9616 Motor Protective Circuit Breakers for North America (Inverse Time Circuit Breakers) Circuit Breakers with adjustable electronic trips for motor overload and short circuit protection. Listed to UL 489 und certified to CSA -C22.2 No. 5-02, also IEC rated and CE marked. Motor overload trip calibration per UL 508 and CSA C22.2 No.14 Additional time delay setting, incremental between 2 and 20 seconds, to adjust for motor inrush at 6 x Ir UL/CSA 100 % rated circuit breakers Setting Range Overload Trip* Instantaneous short circuit trip Projected Max. HP Ratings 460 V 480 V HP Breaker with Normal Interrupting rating Type Breaker with High Interrupting rating Type SCCR SCCR 575 V 85 kA 240 V 600 V 35 kA 480 V 25 kA 600/347 V HP Suitable motor switching contactor Type 150 kA 240 V 100 kA 480 V 50 kA 600/347 V In = Iu [A] Ir [A] Ii [A] Ii 90 45-90 901260 2 ... 14 x In 60 75 NZMN2-ME90-NA NZMH2-ME90-NA DILM80 DILM95 140 70-140 1401960 2 ... 14 x In 100 125 NZMN2-ME140-NA NZMH2-ME140-NA DILM115 DILM150 200 100200 2002800 2 ... 14 x In 150 200 NZMN2-ME200-NA NZMH2-ME200-NA DILM185 DILM225 Ratings in the latest Moeller main catalog are binding! Table 1: Circuit breakers with adjustable overload and short circuit trips, and additional evaluation per the motor overload calibration requirements of the industrial control standards UL 508 and CSA-C22.2 No.14, are destined to become in North America the larger versions of popular motor protective switches. These breakers will be typically combined with remotely operable electro-magnetic motor switching contactors for long life combiantion motor starter applications. The circuit breakers are also 100% rated, so that the full range of their adjustability can be utilized. 100% rating. Conventional circuit breakers in North America are normally rated at 80%, which means that a circuit breaker serving a continuous load can only be operated up to 80% of its current rating. 100 % rated Circuit Breakers, on the other hand, can be set to up their maximum rating, which in the case of this motor protective circuit breaker would correspond to the motor’s full load current. Circuit breakers which have been certified for 100% rating in North America are all marked accordingly, whereas standard 80% breakers do not have to carry a marking to this effect. These motor protective circuit breakers represent a significant improvement in Moeller’s range of molded case circuit breakers for the North American market and constitute an important step in the effort to achieve world market rated assemblies, such as control panels for global applications, which would share identical layouts and bills of material. Per the North American electrical codes, circuit breakers are able to also fulfill the function of motor controller. However, it is much more typical and useful to combine them with motor switching contactors in motor starter applications in order to provide the starter with both a remote operational capability and a much longer electrical lifespan. The circuit breaker is better suited as the main disconnect and protective device in these applications. Of course, motor reversing applications can also be easily accommodated with the use of an additional contactor to configure a reversing combination motor starter assembly. Thus, the availability of 2 component combination motor starters for motor rated currents up to 200A easily covers the very large majority of motors encountered in today’s modern industrial environment. The motor protective breaker and contactor combinations have been listed as „Combination Motor Starters“ with two levels of Short Circuit Current Ratings (SCCR) to provide a broader and more flexible range of values for industrial control panel applications. Motors with full load rated currents extending beyond 200A are encountered much less frequently than small motors so that, relatively speaking, 3 component combination motor starters can still be applied for larger motors without too great of an additional cost burden for the installation. The new motor protective circuit breakers also carry IEC ratings and bear the important CE mark for applications within the European Union. They are thus equally suitable as motor protective devices in countries subject to compliance with IEC standards. IEC compliant circuit breakers for motor protection are, in fact, available for motor rated currents up to 1400A. Acknowledgment: With grateful acknowledgment of the support from: Mr. Andre R. Fortin, BA Phys. Manager – Codes & Standards International Corporate Advisor – Power Products Moeller Electric Corporation, Millbury, Massachusetts, USA and Mr. Dieter Reiß, Dipl.-Ing. Approvals, Institute for International Product Safety GmbH, Bonn 5 For Moeller Electric Sales and Support call KMparts.com (866) 595-9616 Bibliography: [1] „Schaltgeräte und Schaltanlagen für den Weltmarkt und für den Export nach Nordamerika“ VKF0211-563D Article No. 110188 „Components and Systems suitable for World Markets and Export to North America“ VKF0211-563GB Article No. 110189 Moeller GmbH, Bonn, 2007 [2] Wolfgang Esser „Besondere Bedingungen für den Einsatz von Motorschutzschaltern und Motorstartern in Nordamerika“ VER1210+1280-928D Article No. 267951 „Special considerations governing the application of Manual Motor Controllers and Motor Starters in North America“ VER1210+1280-928GB Article No. 267952 Moeller GmbH, Bonn, 2003 [3] Wolfgang Esser „Sammelschienenadapter für die rationelle Motorstartermontage – jetzt auch für Nordamerika –“ VER4300-960D Article No. 110774 „Busbar Component Adapters for modern industrial control panels“ VER4300-960GB Article No. 110775 Moeller GmbH, Bonn, 2007 [4] Wolfgang Esser „Leistungsschalter für den Einsatz in Nordamerika“ VER1230-939D Article No. 285780 “Molded Case Circuit Breakers, for applications in North America” VER1230-939EN Article No. xxxxx Moeller GmbH, Bonn, 04/2008 Moeller addresses worldwide: www.moeller.net/address E-Mail: info@moeller.net Internet: www.moeller.net www.eaton.com Issued by Moeller GmbH Hein-Moeller-Str. 7-11 D-53115 Bonn © 2008 by Moeller GmbH Subject to alterations VER1200+2100-967en ip 07/08 Printed in Germany (07/08) Article No.: 118983 Eaton’s electrical business is a global leader in electrical control, power distribution, uninterruptible power supply and industrial automation products and services. Eaton’s global electrical brands, including Cutler-Hammer®, Powerware®, Holec®, MEM®, Santak® and Moeller®, provide customer-driven PowerChain™ Management solutions to serve the power system needs of the industrial, institutional, government, utility, commercial, residential, IT, mission critical and OEM markets worldwide. Eaton Corporation is a diversified industrial manufacturer with 2007 sales of $13.0 billion. Eaton is a global leader in electrical systems and components for power quality, distribution and control; hydraulics components, systems and services for industrial and mobile equipment; hydraulics, fuel and pneumatic systems for commercial and military aircraft; intelligent truck drivetrain systems for safety and fuel economy; and automotive engine air management systems, powertrain solutions and specialty controls for performance, fuel economy and safety. Eaton has 79,000 employees and sells products to customers in more than 150 countries. For more information, visit www.eaton.com. For Moeller Electric Sales and Support call KMparts.com (866) 595-9616