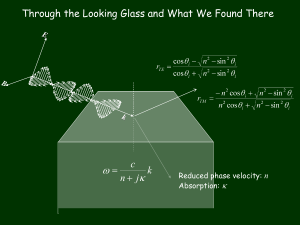

modeling of liquid crystal display and photonic devices

advertisement