Measuring power with

a Fluke ScopeMeter®

190 Series

Application Note

Although many electrical test tools are available to measure

voltage, few can measure current, and even fewer are

equipped to measure electrical power directly. Moreover,

there is always the question of how to measure power in

electronic systems that are not operating at mains frequencies. The Fluke ScopeMeter 190 Series has the answer.

Power measurements

The prime parameter specified

for any electrical system is operating voltage. But that voltage in

itself has little meaning if, once

applied, it doesn’t result in

power to, for example, exert a

force, drive a machine or run a

lighting system. Accurate measurement of electrical power is

therefore crucial for understanding a system’s behaviour.

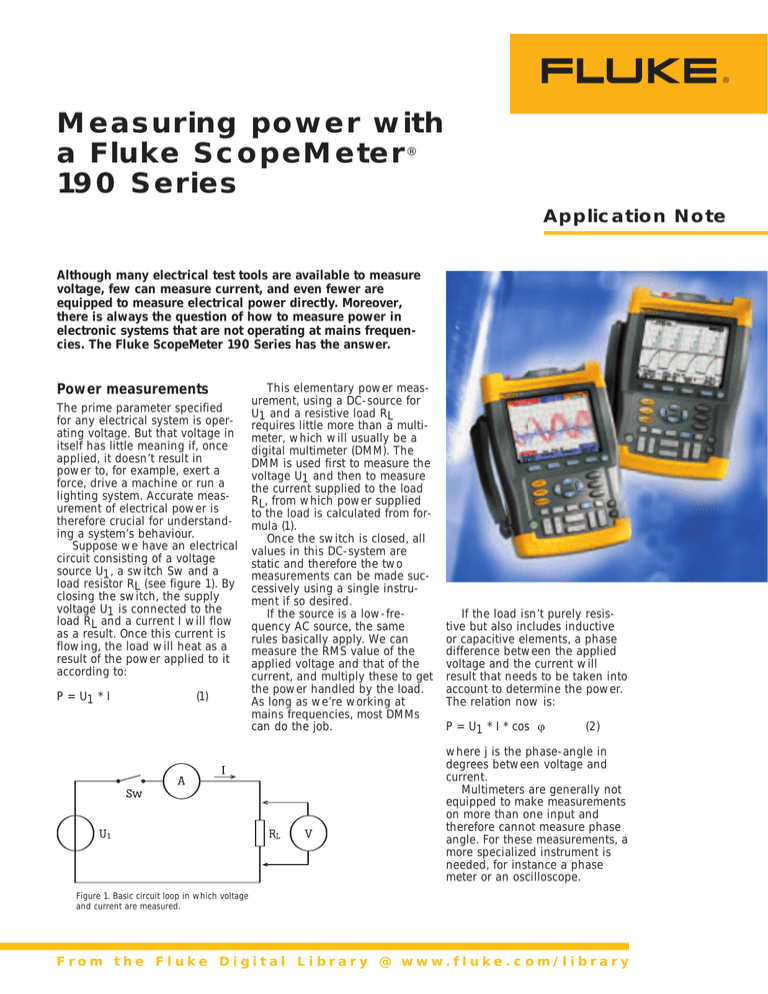

Suppose we have an electrical

circuit consisting of a voltage

source U1, a switch Sw and a

load resistor RL (see figure 1). By

closing the switch, the supply

voltage U1 is connected to the

load RL and a current I will flow

as a result. Once this current is

flowing, the load will heat as a

result of the power applied to it

according to:

P = U1 * I

(1)

This elementary power measurement, using a DC-source for

U1 and a resistive load RL

requires little more than a multimeter, which will usually be a

digital multimeter (DMM). The

DMM is used first to measure the

voltage U1 and then to measure

the current supplied to the load

RL, from which power supplied

to the load is calculated from formula (1).

Once the switch is closed, all

values in this DC-system are

static and therefore the two

measurements can be made successively using a single instrument if so desired.

If the source is a low-frequency AC source, the same

rules basically apply. We can

measure the RMS value of the

applied voltage and that of the

current, and multiply these to get

the power handled by the load.

As long as we’re working at

mains frequencies, most DMMs

can do the job.

If the load isn’t purely resistive but also includes inductive

or capacitive elements, a phase

difference between the applied

voltage and the current will

result that needs to be taken into

account to determine the power.

The relation now is:

P = U1 * I * cos ϕ

(2)

where j is the phase-angle in

degrees between voltage and

current.

Multimeters are generally not

equipped to make measurements

on more than one input and

therefore cannot measure phase

angle. For these measurements, a

more specialized instrument is

needed, for instance a phase

meter or an oscilloscope.

Figure 1. Basic circuit loop in which voltage

and current are measured.

From the Fluke Digital Library @ www.fluke.com/library

If power measurements are

made more frequently, a power

meter like the Fluke 43B Power

Quality Analyzer would be the

most appropriate test tool. This

instrument measures both voltage and current simultaneously

and automatically takes the

phase angle into account. For the

occasional user, however, this

may be an expensive option and

a more generic tool like the

ScopeMeter would be preferred.

Use of the Fluke

ScopeMeter

All Fluke ScopeMeters have two

input channels and can measure

voltage and current at the same

time, whilst also measuring and

displaying the phase angle

between them. See also the section “practical set-up hints” near

the end of this publication for

further details.

If the voltage is non-sinusoidal or if the load isn’t purely

resistive, power measurements

become too complex to be performed on a DMM. The best way

to determine power under these

conditions is to take a large

number of current and voltage

measurements over each cycle of

the supply voltage. The measurements need to be made simultaneously on both signals. Each set

of simultaneous measurements

can then be multiplied to produce a corresponding set of data

points from which a curve can be

constructed of the power handling at successive moments in

time.

The Fluke 190 Series

ScopeMeter is capable of performing this specific function for

you!

Included in the functionality of

the Fluke ScopeMeter 190 Series

is the ability to multiply individual curves (waveforms) to create

a resultant curve. With this function, sets of samples from channels A and B are multiplied to

create a resultant curve labeled

M. In other words, every time a

sample for channel A and a sample for channel B is taken and

written on screen, these are also

multiplied and displayed to create the resultant waveform M on

screen. From this waveform, the

2 Fluke Corporation

(instantaneous) power can be

read off, at every point in time,

for instance using the cursors of

the Fluke 190 Series.

Example of a light

dimmer

As an example, we’ve applied

the mains voltage to a so-called

“light dimmer”. This is a thyristor-based power control device

in which current is allowed to

flow only during a selected part

of the mains cycle. The effective

output voltage to the load (the

lights) can be controlled by

changing the phase angle. The

measured voltage (see figure 2,

trace A) shows that the output is

active during approximately twothirds of the time, or about 120

degrees during each half-cycle.

During one-third of the time, the

dimmer is ‘off’ and no output

voltage is supplied to the lights.

If we change this phase angle,

the lights will brighten or dim.

Figure 3. Menu tree for setting up the waveform multiplication.

scaling can be modified. After

pressing softkey F3 we can also

change the vertical position of

the resultant trace M.

Figure 4. Voltage, Current and Power curves

on the Fluke 190 Series ScopeMeter.

Figure 2. Output voltage and current of a

dimmer driving a string of lights.

In figure 2 we can also see

the resulting current through the

light-bulbs (channel B, blue

curve). We can now set up the

ScopeMeter to calculate the

power applied to the lights (see

figures 3 and 4).

To do this select:

SCOPE,

then F4 (= Waveform Options),

next Mathematics, and Enter,

then A * B, and Enter.

Next we select a scaling that

we expect will keep the power

curve on screen; this may also be

changed later. The two input

waveforms and the resultant (M)

will now be visible. If the resultant is too small or too large, the

Measuring power with a Fluke ScopeMeter® 190 Series

Figure 4 shows the voltage

(waveform A, in red), the current

(B, in blue) and the multiplied

curve (M, in green), representing

the power supplied to the lights.

On the Fluke ScopeMeter 190

Series, the cursors can be used to

measure the power at any point

in time, as shown in figure 5.

Figure 5. The ScopeMeter’s cursor is used for

power measurement at a specific point in time.

Here, the cursor is set at about

the maximum peak of the power

curve, and the reading tells us

that the lights are handling a

peak of approximately 1.7 kW at

that instant in time.

Power measurement in a

switched-mode power

supply (SMPS)

In electronic systems, the frequencies of the signals are often

much higher and the waveforms

much more diverse than those in

above example.

As an example, consider some

waveforms from a switchedmode power supply (figure 6). In

this system, the mains voltage is

rectified and filtered, resulting in

a DC voltage of about 350 V. This

is then applied to a switching

transistor that drives a stepdown transformer.

Figure 7. Voltage and current waveforms are

used to create the power-curve.

From the curves in figure 6,

we calculate the power that the

transistor is handling by multiplying the two graphs, as in figure 7. Here also the

timebase-setting has been

changed to see the part of the

waveform that is of particular

interest in more detail.

On these curves, we can use

the cursors of the Fluke 190

Series to measure the peak in

power handling, as is done in

figure 8.

Figure 6. Voltage and current handled by the

switcher component in a SMPS.

In figure 6 we can see the

voltage across the switching

transistor (curve A, in red) and

the current through the transistor

(curve B, in blue). The voltage

reaches peak values of over

400 V (see the 4 divisions of

amplitude at 100 V/div) and the

current has a peak-value of over

200 mA. A single cycle of this

converter’s signal takes approximately 26 µs, which means the

operating frequency is around

36 kHz. Note, however, that for a

given SMPS, the frequency may

vary with changes in the line

voltage and loading.

3 Fluke Corporation

Figure 8. Cursor used to measure the peak of

the power, handled by the transistor.

From this we see that the

switching transistor is handling a

peak power of 123 W. During

design of the SMPS, one has to

be aware that such power peaks

may occur and the components

need to be selected with this in

mind.

Instrument set-up

The ScopeMeter is unique in that

its inputs are fully insulated from

one another, allowing direct connection to electrical wiring, even

if this is at mains potential. Most

standard oscilloscopes have a

common ‘ground’ connection on

the inputs which has to be used

as a common reference point for

Measuring power with a Fluke ScopeMeter® 190 Series

all input signals (and which is

connected to the mains’ safety

ground). In contrast, the

ScopeMeter 190 Series has independently floating inputs. This

allows for voltage measurements

at voltage test-points as well as

across current-sensing resistors,

which may be at different voltage levels. See the ScopeMeter’s

technical specification for full

details.

When used with current

clamps or with current sensing

resistors in the network, the

ScopeMeter inputs can be set-up

to read amplitudes in amps

directly.

To do so, select the input

channel key (e.g.: “B”) and then

softkey F3 (“Probe channel B”). A

selection can then be made if the

input signal represents a voltage

or a current, or even a temperature. What’s more, the sensitivity

of the current clamp or the circuit’s sensing resistor can be

selected from a selection table,

indicated in mV/mA (equivalent

to V/A or simply Ω).

If we have connected a 1 Ω

current sensing resistor in our

network and want to measure

the voltage across it, the current

sensitivity would be set at 1 V/A.

If we include a 0.1 Ω resistor in

our network to sense the current,

then the sensitivity would be set

at 100 mV/A. If the voltage

across that resistor is measured

using the standard (10:1) voltage

probe, the overall sensitivity

would be 10 mV/A. By selecting

this sensitivity from the menu,

the current that we read on the

ScopeMeter screen directly indicates the true value.

Total energy

The total energy handled over

time can be calculated by multiplying the continuous power and

the time the system is active:

W=P*t

(3)

The result is expressed in

watt-seconds (Ws), also known

as joules (J). The value in joules

can be rescaled into kWh,

whereby

1 kWh = 1000 Wh =

1000 * 3600 Ws = 3.6 * 106 Ws

Some ScopeMeter models also

contain a function for calculating

the total power accumulated over

a period of time, which is then

selected using the cursors. Power

over time equals energy, and we

can read this on the ScopeMeter

as watt-seconds directly.

Figure 9. Power curve and energy

measurement.

Looking at figure 9, we can

see that between the two cursors, i.e. within a single cycle of

the mains voltage, an energy of

10.09 Ws is delivered to the

lights. A cycle of the mains in

this case takes 20 ms.

Per second this leads to a

power consumption of:

10.09 Ws / 20ms =

10.09 * 50 W*s/s = 505 W

And over a time-span of one

hour, this equals a total energy

consumption of:

505 W * 1 h = 505 Wh =

0.505 kWh = 1.8 MWs

Practical set-up hints

The best way to measure a current in a circuit loop is with a

current clamp. These are commercially available for AC and for

DC+AC measurements, and for

various current ranges. The Fluke

80i-100s, for instance, measures

DC and AC currents from 0.1 to

100A; the Fluke i1010 can even

be used up to1000A AC and/or

DC.

These clamps eliminate the

need to open up the circuit loop

when making measurements and

provide good isolation between

any ‘live’ wiring and the test

instrument. When working on

power circuits, this is definitely

the safest way to measure the

current.

If a current clamp is used for

measuring small currents and the

sensitivity of the clamp in insufficient, the effective sensitivity can

be increased by feeding multiple

turns of the wire through the

clamp. The actual current is now

the measured current divided by

the number of turns.

Sometimes, however, it’s not

so simple to cut the wiring of an

existing circuit loop in order to

include a current meter, for

example when all wiring is part

of a printed circuit board. A possible way to bring the current

meter into the loop of a lowpower circuit would then be to

set up the DMM for current

measurement and select the

highest current-range provided.

Now connect the meter over the

contacts of the on/off-switch. If

the switch is left open, the meter

will close the loop and read the

current, while no wiring needs to

be interrupted or modified.

If no switch is provided, or if

the DMM has no current-measuring capability, we may also add

a current sensing resistor of a

known value Rs to the circuit,

which needs to be small in value

compared with the load-resistance RL (see figure 10). We can

now measure the voltage across

this sensing resistor and calculate the current from Ohms’ law.

Adding the resistor is a one-time

modification, which is more convenient than repeatedly opening

up the circuit loop.

If Rs is more than 10 times

smaller in value than the load

RL, less than a percent of the

energy will be handled by the

series resistance, and thus the

error in the power measurement

that results from adding the

resistor will be less than 1%.

Conclusion

Power measurements on low-frequency linear systems can be

performed using a DMM. The

measurement of power in electronic systems where waveforms

are more complex and frequencies often much higher than the

mains frequency requires more

sophisticated tools. The Fluke

190 Series of ScopeMeters are

well equipped to make these

measurements, and can even

make fast peak-power measurements to determine the power

handling of fast electronic components, for instance in

switched-mode power supplies.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

Figure 10. Adding a current sensing resistor to

the circuitry to allow current measurement.

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

In Canada (800) 36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2004 Fluke Corporation. All rights reserved.

Printed in U.S.A. 3/2004 2140127 A-ENG-N Rev A

4 Fluke Corporation

Measuring power with a Fluke ScopeMeter 190 Series

®