SUMMER 2005

E L E C T R I C

P O W E R

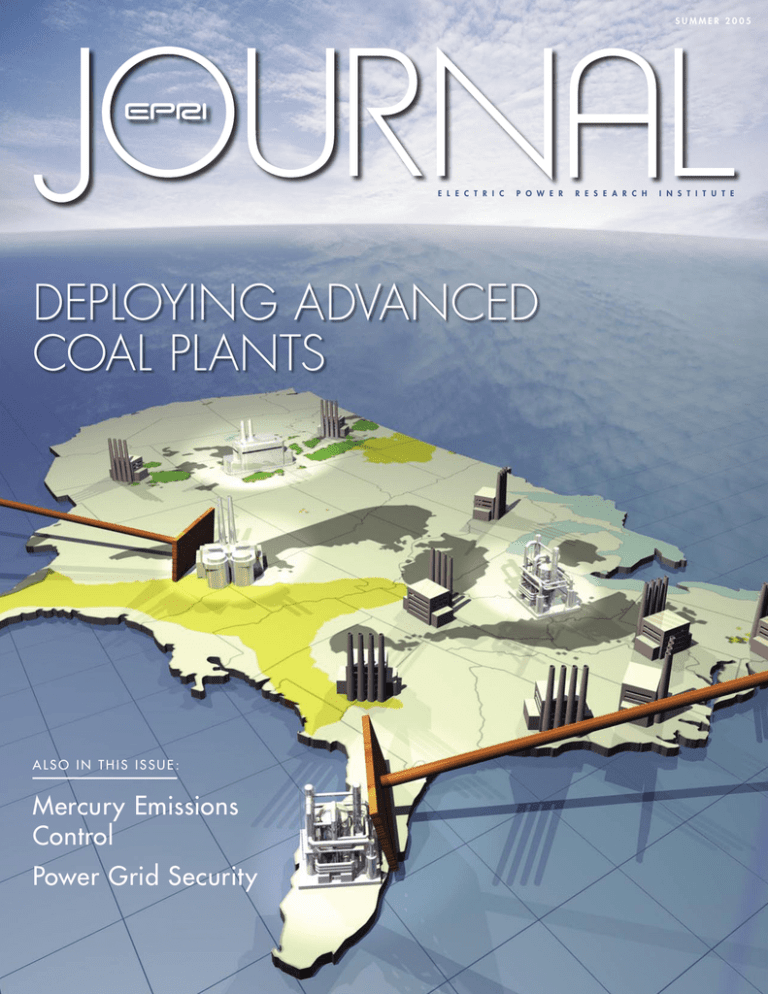

Deploying advanced

Coal Plants

A lso I n t h is I ssue :

Mercury Emissions

Control

Power Grid Security

R E S E A R C H

I N S T I T U T E

ELECTRIC POWER

RESEARCH INSTITUTE

The Electric Power Research Institute (EPRI), with major locations

in Palo Alto, California, and Charlotte, North Carolina, was

established in 1973 as an independent, nonprofit center for public

interest energy and environmental research. EPRI brings together

members, participants, the Institute’s scientists and engineers, and

other leading experts to work collaboratively on solutions to the

challenges of electric power. These solutions span nearly every

area of electricity generation, delivery, and use, including health,

safety, and environment. EPRI’s members represent over 90% of the

electricity generated in the United States. International participation

represents nearly 15% of EPRI’s total research, development, and

demonstration program.

Together. . . Shaping the Future of Electricity

Staff and Contributors

DAVID DIETRICH, Editor-in-Chief

JEANNINE HOWATT, Art Director

DEBRA MANEGOLD, Layout Designer/Production Manager

KEN COX, Illustrator/Photographer

MICHAEL ROHDE, Products Editor

CRAIG DISKOWSKI, Art Consultant

BRENT BARKER, Executive Director, Corporate Communications

KEVIN EVANS, Senior Vice President and Chief Business Officer

Address correspondence to:

Editor-in-Chief

EPRI Journal

P.O. Box 10412

Palo Allto, CA 94303-0813

The EPRI Journal is published quarterly. For information on subscriptions and permissions, call 650.855.2300 or fax 650.855.2900.

Please include the code number from your mailing label with

inquiries about your subscription.

Visit EPRI’s web site at www.epri.com.

For further information about EPRI, call the EPRI Customer

Assistance Center at 800.313.3774 or 650.855.2121 and

press 4, or email askepri@epri.com.

© 2005 Electric Power Research Institute (EPRI), Inc. All rights reserved. Electric

Power Research Institute, EPRI, and EPRI Journal are registered service marks of

the Electric Power Research Institute.

COVER: Commercial deployment of advanced clean coal power plants will allow the nation to

make use of its tremendous coal resources while meeting ever-tightening air qualtiy regulations.

(Art by Craig Diskowski/Edge Design)

SUMMER 2005

16

6

26

Editorial

F e at u r es

Depa r tme n t s

2 A Window Into EPRI

16 Mercury Control for Coal-Fired

Power Plants

3 Contributors

No commercial technologies yet exist

to fully control mercury emissions from

coal plants, but several approaches that

have shown good potential in full-scale

tests are now nearing market readiness.

4 Innovation

C ov e r S t o ry

6 Coal-Based Generation at the Crossroads

CoalFleet for Tomorrow—an industrydriven initiative—hopes to speed the

­deployment of advanced clean coal

power plants by reducing the technical

and cost barriers to market acceptance.

26 Grid Security in the 21st Century

A new, industrywide initiative focuses on

protecting electric power systems from

computer hackers and worse.

34 Technology at Work

LI S TIN G S

36 Technical Reports & Software

40 EPRI Events

Editorial

A Window Into EPRI

One of the great pleasures of my first year at EPRI

is to announce the relaunch of its flagship publication, the EPRI Journal. I very much enjoyed

reading the Journal while I was at GE. It was an

effective window into EPRI, providing an indepth understand­ing of the content and value of

EPRI’s programs and communicating the broader

business and social contexts of the industry’s most

pressing issues. The Journal also captures something that is easy to miss in a technical portfolio

as varied and rich as EPRI’s: the power and value

of pursuing com­prehensive, integrative approaches.

This highly ­coordinated route allows EPRI to

accomplish things that others cannot. It capitalizes

on the unique advantages of the collaborative

model—bringing people, ideas, perspective, money,

and expertise to bear on the truly difficult issues

we face now and for the future. It is important

that the Journal readers get this “big picture” of

what the Institute is doing.

One of the best examples of collaborative advantage is EPRI’s CoalFleet initiative, the topic of this

first issue’s cover story. Deployment and commercialization of advanced, clean coal generation

technologies carries all of the difficulties of transformational change: a wide and disparate slate

of stakeholders, hard technical challenges, cost

uncertainties, regulatory unknowns, and stubborn

market barriers. Yet we have here technologies that

clearly speak to the needs and constraints of the

coming decades. This is the kind of challenge that

will only yield to the collaborative approach.

Steven Specker

President and Chief Executive Officer

E P R I

J O U R N A L

And while CoalFleet is a key initiative for

electricity’s future, it is only a piece of the larger,

tougher question that I believe will define the

power industry over the coming decades: how will

we provide clean, affordable electricity in an

increasingly carbon-constrained world? There is

no silver bullet on this issue. We will solve the

problem only by thinking beyond individual

technologies, by considering a full complement of

options that together can satisfy our energy needs

in the new technical/environmental/­societal

context that we now see evolving across the globe.

Carbon constraints will require the broadest, most

innovative thinking we can muster. It will require

the ability to look beyond a seemingly endless

succession of difficult milestones and embrace a

goal that must and will be achieved. As with any

endeavor of this size and importance, our success

­depends on commitment, hard work, and strong

leadership—essentials that EPRI is well-equipped

and willing to provide.

I have much more to say about the challenges

facing our electricity system, present and future,

and I expect to do so in subsequent issues. For

now, I encourage you to read and enjoy the new

EPRI Journal. We have an exciting lineup of

articles planned for the coming year that I’m sure

will be both interesting and useful. And if you

have ideas about how we can use the magazine to

improve the service and value you derive from the

Institute, please let me know—it is a window into

EPRI that is designed to be open.

Contributors

Coal-Based Generation at the Crossroads

(page 6) was written by science writer Taylor Moore with

­technical assistance from Stu Dalton and Jack Parkes.

planetary sciences from MIT, an MS in atmospheric sciences

from the University of Washington, and a PhD in meteorology

from the University of Maryland.

director of EPRI’s Generation

Sector, came to the Institute in 1976, having

previously worked for Pacific Gas & Electric

and Babcock & Wilcox. From 1979 to 1994,

he headed EPRI’s SO2 control and integrated

emissions areas. For the last 10 years, he

has managed and developed strategy for broad areas of the

advanced coal and emissions control R&D portfolio. Dalton

holds a BS in chemical engineering from the University of

California at Berkeley.

a technical executive for

air emissions and coal combustion product

management, has been with EPRI since 1985.

He started the Institute’s program on mercury

control technology R&D in the late 1980s

and expanded it into the Integrated Environmental Control program several years ago. Offen coordinates

EPRI’s collaborations with DOE and EPA in air emission control technology. He holds BS and PhD degrees from Stanford

University in mechanical engineering and an MS from MIT in

the same field.

Stu Dalton,

has held senior management

posi­tions at EPRI, Bechtel, Ebasco, and GE

involving the design, reliability, and perform­

ance of coal-based power plants and sys­tems.

In his current EPRI position, area manager

for advanced generation, he directs the CoalFleet for Tomorrow Initiative. Parkes received a BS from The

Queens University of Belfast and an MS from Union College

in New York, both in mechanical engineering. He also earned

an MBA from the University of Santa Clara in California.

George Offen,

Jack Parkes

Mercury Control for Coal-Fired Power Plants

(page 16) was written by science writer Paul Haase with guidance from Leonard Levin and George Offen.

Grid Security in the 21st Century (page 26) was written by science writer John Douglas with technical information

from Robert Schainker.

is a technical executive in

EPRI’s Power Delivery and Markets Sector

with a current focus on electricity grid infrastructure security and power quality. Before

joining the Institute in 1978, he was with

Systems Control, Inc., of Palo Alto for 10

years, specializing in utility SCADA and energy management

systems. Schainker has a BS in mechanical engineering, an MS

in electrical engineering, and a PhD in applied mathematics,

all from Washington University in St. Louis.

Robert Schainker

is EPRI’s technical leader for

air toxics health and risk assessment, specializing in multimedia cycling and ­exposure,

chemical transport, and atmospheric physics.

Before coming to EPRI in 1986, he worked

for six years as a senior scientist at WoodwardClyde Consultants and earlier at Science Appli­cations International. Levin has a BS degree in earth, atmo­spheric, and

Leonard Levin

S U M M E R

2 0 0 5

Innovation

Largest Silicon Carbide

Switch Demonstrated

Widespread use of solid-state devices to

control power flow on utility networks

will require substantial reduction in

cost and improvement in availability

compared to the silicon-based controllers available today. Achieving such

performance enhancements will involve

replacing silicon in these devices with

­advanced semiconductors that can

switch larger currents at higher voltages and oper­ate at higher temperatures.

The most prom­ising near-term candidate is silicon carbide (SiC), and recent

­advances have brought SiC switches

much closer to commercial applications

in the power industry.

A key performance characteristic

of semiconductor materials is their

so-called “bandgap”—the amount

of energy needed to release

electrons bound in the

crystalline structure so

they can move freely

and thus conduct

electricity. Widebandgap semiconductors, such as SiC, are able

to withstand considerably

higher voltages and temperatures

before conduction begins, so power

controllers made from them can be

smaller and more robust, and not need

as much auxiliary cooling equipment.

This development could make large

solid-state devices, such as flexible ac

transmission system (FACTS) controllers, more competitive.

The main barrier to using wide-bandgap materials in electronic switches has

been crystal defects that limit their performance. Since 1996, EPRI has sponsored research aimed at improving the

E P R I

J O U R N A L

Emerging technologies and

cutting-edge engineering

quality of these materials, together with

finding better ways of fabricating useful

devices based on them. Last year, this

work paid off with a major achievement:

demonstration of the largest, fastest,

most powerful SiC switch ever made—a

1-cm2 device that could switch power

of 1750 volts and 250 amperes while

operating at 250°C. That’s twice as large

as any earlier SiC switch, with about 100

times greater current-carrying capacity,

and demonstrates the technology’s potential for use in large-scale devices.

This accomplishment brings commercialization of power control devices

based on wide-bandgap semiconductors much closer to reality, according to

project manager Ben Damsky. “Within

about five years, I believe we could

see silicon carbide used in devices

ranging from FACTS controllers

for power networks to power

conditioning equipment

for consumer electronics,” he says. “The

impact will probably be the greatest

in high-voltage utility

applications, where the

cost of FACTS devices could

potentially be reduced by about

one-third and availability increased

significantly.”

Maintaining high availability is

particularly critical in power system

applications, and today’s large solid-state

controllers have had difficulty achieving

availability factors greater than 96%.

The largest contributor to down time for

these installations is the auxiliary cooling

system, which is essential because siliconbased devices must be derated if they

reach 125°C. A SiC device operating at

250–300°C could have a much ­simpler

cooling system that would require

less maintenance. Eventually, a highly

­reliable passive cooling system with no

moving parts may become possible.

The next challenge will be to translate

the accomplishments achieved so far in

a laboratory setting into commercialscale production of SiC switches. Future

work is expected to focus particularly

on manufacturing and characterizing

SiC devices rated up to 5000 volts and

1000 amperes, while also testing their

performance under a variety of operating

conditions. Eventually, other wide-bandgap semiconductors may also be used in

high-power controllers, further reducing

their size and cost.

For further information, contact Ben

Damsky, bdamsky@epri.com.

Virtual Reality Simulation

to Reduce Nuclear

Construction Costs

Advanced visualization technology

promises to reduce the cost of building

nuclear power plants and other complex

industrial facilities by optimizing the

construction sequence, streamlining the

schedule, and identifying potential

problems before they are encountered

in the field. The technology represents

an extension of conventional 3-D

­computer-aided design by adding the

fourth “dimension” of time to the

modeling process so that engineers can

simulate the construction sequence in

unprecedented detail.

Developed through collaboration

between EPRI and Westinghouse, the

4-D visualization technology is being

integrated into the design process of

two Westinghouse advanced light water

reactors. For one of the reactors, more

than five months were removed from

alternative construction paths for large

plant modules, and simulated “con­

struction” of representative modules in

isolation. The technology can also be

used to prepare and train construction

crews, verify achievable construction

schedules, and enhance the confidence

of potential investors in the timing of

capital recovery.

“Our studies with Westinghouse

indicate that EPRI’s virtual reality construction technology should cut about

10% off construction times for the next

generation of nuclear plants, which will

help them to be more competitive,” says

project manager Layla Sandell. “Our

next step will be to extend the technology to nuclear plant designs from

­additional vendors.”

For further information, contact Layla

Sandell, lsandell@epri.com.

the projected construction schedule

without reducing the duration of any

­individual activity. Optimized sequencing of tasks also reduced the expected

on-site requirements for skilled craft

labor (e.g., concrete workers and pipe

fitters) by several months.

The detail and specificity of the

­animated modeling allows examination

of issues as varied as crane placement,

MagMolecules Selectively

Remove Contaminants From

Liquid Waste

Processing low-level waste (LLW) effluent streams from nuclear plants remains

a persistent challenge because the dissolved radioactive contaminants may be

present in only minute quantities so that

removing them from a large volume of

liquid is difficult and expensive. Evaporation, for example, leaves a solid waste

product in which the radionuclides may

represent only a small fraction of the

total material that must then be disposed

of. Ion exchange systems can remove

contaminants more selectively, but still

produces an unnecessarily large volume

of solid waste.

Now an innovative new approach

promises to greatly reduce radioactive

waste volume by using magnetic molecules that target specific radionuclides

dissolved in an LLW stream. Called

the MagMolecule process, for which

EPRI has filed a patent application, the

technology is also expected to be used

in other important applications, such as

removing heavy metals from industrial

effluents and groundwater.

“Laboratory results indicate that MagMolecule technology has the potential

for reducing waste volume by a factor of

up to 5000, compared to conventional

ion exchange treatment,” according to

project manager Sean Bushart. “The

­result would be significant cost savings for low-level waste management

in nuclear power plants, as well as for

applications in other industries.”

The concept is based on the use of

proteins called ferritins, which the body

uses to store iron, for example, in the

spleen and liver. Synthetically produced

and magnetically stronger “magnetoferritins” are used in the computer industry to manufacture data storage disks.

EPRI’s research has focused on modifying magneto-ferritins to bind selectively

to specific contaminants—initially strontium and cesium, and now cobalt—that

represent important radioactive constituents of LLW. The bound ferritincontaminant complex is then removed

from the effluent stream by a reusable

magnetic filter, which is backwashed to

collect the solid by-products.

Now that technical feasibility of the

MagMolecule process has been established in the laboratory, the next step

will be to scale up the technology for

pilot application in the field. Specifically,

by the end of this year, researchers hope

to test the process using actual nuclear

plant effluent, while also improving the

associated filtration and instrumentation

systems. Bushart says that commercialization of MagMolecule technology may

come in as little as two years.

For further information, contact Sean

Bushart, sbushart@epri.com.

S U M M E R

2 0 0 5

Coal-Based

generation

at the crossroads

by Taylor Moore

The Story

in Brief

Offering clean electricity

generation from an abundant

fuel, advanced coal technologies seem tailor-made for a

power industry facing evertighter environmental regulations. But committing to new

approaches—and the inevitably higher cost of first-of-a-kind

units—is always a difficult

business proposition. To help

break through the final barriers

to market acceptance, EPRI

is leading an industry-driven

initiative to speed the deployment of new clean coal plants

and support the development

of next-generation designs.

Wellhead Price of Natural Gas ($/million Btu)

ong the workhorse of electric generating systems around the world, coalbased power plants are increasingly

seen as one of the most economic choices

for meeting future growth in demand

for power. But while today’s units operate far more cleanly than when air-quality rules were ramped up in the 1970s,

coal-burning plants are still constantly

chasing tighter regulatory limits on emissions through the refinement of add-on

cleanup technologies. Now a new generation of advanced, clean coal power plants

that integrate emissions reduction into

their basic designs stands at the threshold

of commercial deployment. These plants

not only address the sulfur and nitrogen

oxides at the center of today’s air quality

regulations more efficiently, but also carry

advantages in removing carbon dioxide

(CO2), which may be regulated in the future because of its role as a greenhouse gas

associated with global climate change.

Such clean coal technologies have been

evolving for more than two decades; the

last major hurdle to reaching technological maturity and, in turn, economic

competitiveness with conventional coal

plants is the demonstration of their commercial viability and reliable operation at

full-scale by utilities and power generators. Expanded operating experience with

advanced coal generating systems is essential for convincing prospective investors

that the costs and risks are well understood and manageable. And getting more

such plants built and operating is critical

for the necessary engineering development that will take the technology from

first-of-a-kind plants to fully optimized,

“learned out” units with costs as low as

designers can eventually drive them.

To accelerate commercial deployment

of advanced clean coal power systems, the

electric utility industry is leading a broadbased collaborative program encompassing the development, demonstration, and

deployment of technologies including

integrated gasification combined-cycle

(IGCC), ultra-supercritical pulverized

coal (USC PC), and supercritical circulating fluidized-bed combustion (SC FBC).

Known as CoalFleet for Tomorrow, or

simply “CoalFleet,” the initiative aims to

tackle the technical, economic, and institutional challenges to making clean coal

6

5

4

3

2

1

0

1975

1980

1985

1990

1995

2000

2005

The low capital cost, quick construction, and relatively straightforward permitting of gas-fired power

plants made them by far the top choice for new generation capacity over the past decade. However,

a near tripling of the wellhead price of natural gas in recent years has changed the cost equation

substantially, making advanced coal generation options more attractive for strategic additions.

E P R I

J O U R N A L

power systems a prudent investment

­option for both the short run and the

long run. By collaborating across all sectors of the power industry, CoalFleet is

focused on breaking through the impasse

of the longstanding conundrum of advanced clean coal technologies: despite

wide agreement on their ultimate need

and value—and on the magnitude of investment and long lead time required to

reach commercial maturity—there is still

inadequate commitment of resources to

bring these advanced systems to fruition.

EPRI organized the CoalFleet initiative

with broad input from and on behalf of

the industry as a vehicle for mutual co­

operation in speeding the deployment of

advanced clean coal plants and in introducing next-generation designs.

Hank Courtright, EPRI’s vice president for generation, explains: “CoalFleet’s

goal is to preserve this abundant source of

fuel as a vital component in the electricity

generation mix. Work must begin now to

ensure that the advanced coal technologies can establish a solid track record—

before large numbers of coal plant replacements become necessary. We see the

need to get plants built and operating

soon in order to gain experience with

and reduce the cost of advanced coal

plant technology.”

In the near term, CoalFleet is focused

on incorporating user-defined requirements and lessons learned from existing

advanced plants into new designs that

will be developed for commercial orders

anticipated over the next decade. To accomplish this, the initiative has assembled

teams of engineers and other technical experts to advise and provide input to early

deployers of new advanced coal technologies and their technology suppliers. In

turn, the early deployers have agreed to

make general design basis and nonpro­

prietary engineering information available to all CoalFleet participants with the

aim of help­ing spur reductions in capital

costs and risks for subsequent orders as

well as improvements in plant availability

and performance.

Bituminous

Subbituminous

Lignite

Economic and engineering studies have shown that costs and performance for advanced coal technologies vary significantly with the type of coal

they use. Because there are substantial regional differences in coal type, several advanced technologies—IGCC, USC PC, and SC CFBC—must be

developed to fully utilize the nation’s tremendous coal reserves. (Source: USGS)

CoalFleet for Tomorrow is already gain­ing a high degree of visibility among the

utility and power generation technology industry. Over 40 organizations have

committed so far to support the initiative,

including energy companies representing

more than half of all presently installed

U.S. coal-fired generating capacity, major

coal-based European generators, leading

power equipment manufacturers, technology suppliers, and the U.S. Department of Energy (DOE).

Policymakers are taking notice as well.

Earlier this year, the U.S. Congress took

under consideration various possible financial incentives that may help close

the current gap in the levelized cost of

electricity (COE) between conventional

coal plants, which produce much of the

nation’s lowest-cost electricity, and the

15–20% higher COE expected for the

next several advanced coal plants that

may be built. EPRI provided valuable

data and insight as input for congressional

deliberations.

Changing Times

Turn the Tables

Despite the abundance and consistently

low cost of coal as a generating fuel, few

coal-fired power plants have been built

around the world for well over a decade,

except in Asia. Instead, the lower capital

costs, quicker construction, and more

straightforward permitting for natural

gas–fired plants led utilities and generating companies that needed additional capacity to favor these units, at least while

natural gas prices remained relatively low.

In the past seven years, over 200 GW of

gas-fired generating capacity have been

built in the United States, compared with

about 15 GW of coal-fired capacity. A similar preference was followed in Europe.

Today, far different economic conditions apply: oil and natural gas prices have

both set new record highs in recent years.

As a result, many gas-fired combinedcycle plants are being called on to gen­erate at only a fraction of their planned

capacity factor. The average capacity factor for such plants in 2003 was 32% and

continued to decline into 2004, making

many of the units poor performers as

­financial assets. Gas prices are forecast to

remain high as a result of supply and demand imbalances and transportation

bottlenecks. Increases in imports of oil

and liquefied natural gas, while potentially reducing the volatility of natural gas

prices, are also heightening concerns over

energy security and international trade

balance. Together, these factors are making the economics of coal power appear

more attractive to both power generators

and government agencies.

S U M M E R

2 0 0 5

Coal

Water

Oxygen

1

Gasifier

Exhaust Stack

3

4

Electricity

Water

Electricity

Clean Syngas

Steam

6

5

Sulfur

2

Ash

In IGCC plants, coal is not burned directly, but rather is processed with oxygen and water in a high-pressure gasifier (1) to form a synthesis gas.

Ash forms a slag (2) that is removed from the gasifier for disposal or commercial use. The syngas is cooled (3) and stripped of sulfur compounds

(4), which are converted to elemental sulfur that can also be sold commercially. The clean syngas is then combusted in a gas turbine/generator

(5), which generates most of the electricity the plant produces. The waste heat is recovered and used to produce steam that drives a smaller

turbine/generator (6) in a combined-cycle configuration to produce additional electricity.

Meanwhile, environmental advocates

and regulators are maintaining pressure

on coal plant operators to further reduce

emissions. As a result, new coal plants will

need to have substantially lower emissions, despite the industry’s impressive

achievements in reducing emissions from

the current fleet of plants. Future requirements for controls on CO2 emissions from

new plants under consideration today

could significantly influence decisions on

technology selection and design.

Conventional coal plant technologies

offer lower capital costs and lower projected costs of electricity than today’s

handful of advanced generating systems;

however, looming environmental restrictions that could lead to requirements to

retrofit emissions control equipment or to

purchase emission allowances creates uncertainty over which coal technologies

will actually be the most economical over

various design lifetimes. The answer is also

10

E P R I

J O U R N A L

influenced by location and the economics

of fuel supplies. Given the diversity of regional electricity markets and the variability in the properties of economical

coals among regions, a portfolio of advanced coal power systems—including

IGCC, USC PC, and SC CFBC—is

needed to comprehensively meet the needs

of the market.

IGCC systems combine the high efficiency and low emissions of gas turbines

with the ability to run on syngas, which

is coal-derived, or other low-cost solid

or heavy liquid fuels. But as Stu Dalton,

EPRI director for generation, told the

Senate Energy and Natural Resources

Committee’s Coal Conference last April,

“Electricity from initial IGCC plants

without CO2 capture and storage will

cost 15–20% more than electricity from

conventional coal power units with SO2

and NOx emission controls. Additional

experience with full-scale IGCC plants

will likely reduce or eliminate this cost

differential. Incentives will be needed

to deploy these initial IGCC plants in

order to overcome higher capital costs

and technology risks,” Dalton told the

conference.

IGCC’s relative competitiveness with

conventional, pulverized-coal plants firing bituminous coal improves if CO2 removal is required, but such a requirement

significantly reduces the power output

and increases the cost of both plant types.

Studies by EPRI, DOE, and others have

found that the incremental cost penalty

for removing CO2 from high-pressure

IGCC syngas is about 25% on a levelized

COE basis, whereas the cost penalty for

removing it from the flue gas of a conventional coal plant is about 70%. Additional costs for transporting and storing captured CO2 are not included in the

calculation, but would be comparable for

both plant types.

3500 psi

2400 psi

37

1000

1200

1400

Steam Temperature (°F)

Improvements in materials are allowing

pulverized coal plants to operate at higher

temperatures and pressures, which increases

plant efficiency and reduces the release of

CO2 and other emissions. Ultra-supercritical

plants are already in use in Europe and

Japan, with steam temperatures of 1120°F

and pressures of 4200 psi. Units with steam

temperatures up to 1400°F and pressures up

to 5000 psi are expected to be demonstrated

in the United States within 10–15 years.

The economics of IGCC technologies

demonstrated so far in the United States

are less favorable for lower-rank coals such

as subbituminous or lignite that predominate the resource in certain regions, as the

technologies currently work best using

the higher-rank bituminous coal typical

of many commercially mined coal deposits east of the Mississippi River. Design

changes or success with the advanced, dryfeed compact gasification systems now

under development by DOE and industry partners may eventually make IGCC

more economical for low-rank fuels.

For regions where low-rank fuels predominate, USC PC and SC CFBC may

be the most cost-effective advanced coal

options. For large-scale coal plants burning very low-grade fuels, new supercritical

CFBC designs are a high-performance,

cost-effective option. Meanwhile, worldwide advances in boiler and turbine materials that have greater strength at high

Strategy for Deploying

Advanced Coal Technologies

To provide technical input and advice to

a slate of task working groups and earlySC CFBC

Plants

USC PC &

IGCC Plants

Mercury

Capture

NOX Reduction

Pulverized Coal Plants

CO2 Capture

& Storage

SO2 Capture

Research

Development Demonstration

Deployment

Mature

plants

39

3500 psi

Next-generation

commercial plants

41

5000 psi

deployment project owners under the

CoalFleet for Tomorrow Initiative, EPRI

formed the CoalFleet World-Class Expert

Working Group, composed of key EPRI

personnel, independent industry experts

in advanced coal technologies, and utility

representatives with advanced coal plant

operating experience. The expert working group is developing a comprehensive

strategy for surmounting the so-called

“mountain of death” (high cost of market-entry units) that new technologies in

general and advanced coal technologies in

particular must overcome before reaching technological maturity and the lowest

achievable cost. According to Jack Parkes,

EPRI’s area manager for CoalFleet, “The

strategy is closely examining ways to remove barriers that have hindered the implementation of advanced coal systems,

including high capital and construction

costs, inadequate reliability, long project

schedules, lack of standardization, and

dif­ficult environmental permitting procedures. Optimizing, modularizing, and

standardizing plant designs for a range of

technologies, coal types, regional issues,

and types of owner/deployer organization are the keys to reducing the time,

Full-scale earlydeployment plants

43

1st demonstration

plants in service

45

Ultra-supercritical 5000 psi

Supercritical

Subcritical

5000 psi

Capital Cost per Unit of Capacity

Efficiency (%), High Heating Value

47

temperatures and less susceptibility to

thermal creep and fatigue have enabled

the emergence of reliable pulverized-coal

plants operating with main steam conditions in the ultra-supercritical range.

Such plants are already in operation in Japan and parts of Europe, where high fuel

prices place a premium on efficiency.

“Limits on CO2 emissions in the United States would have a comparable pricedriver effect on the cost of electricity from

conventional coal-fired plants,” explains

Dalton. “DOE, EPRI, and other organizations are working to develop long-lived,

reliable components for ultra-supercritical PC units with main steam temperatures up to 1400°F (760°C) and pressures

up to 5000 psi (340 bar). Plants operating at such steam conditions are expected

to achieve generating efficiencies topping

45% on a higher heating value basis and

to reduce CO2 and other emissions by

15–22% compared with current conventional plants.”

Mature Technology

Time

The difficult—and costly—process of bringing a new technology into the marketplace has been

called the “mountain of death.” Advanced coal technologies are nearing the crest of the curve,

but the high cost of first-of-a-kind plants can often stall a new technology in the demonstration

stage. The primary focus of the CoalFleet initiative is to get the first group of full-scale advanced

coal plants deployed as early as possible.

S U M M E R

2 0 0 5

11

Incentives for Advanced Coal Plant Deployment

The current estimated cost of electricity from initial IGCC plants is

about 15-20% more than that from a conventional pulverized-coal

plant when higher capital and fixed costs are accounted for and an

allowance is included for the risk of potential shortfalls in the IGCC

plant’s availability. In light of this, CoalFleet members expect that

financial incentives will be needed to spur initial plant deployment

and provide the design and operational experience necessary to

reduce cost and demonstrate reliable performance.

12

Tom Wilson, EPRI senior technical manager for climate change, who

conducted the analyses along with Charles Clark, an analyst working

with EPRI for the CoalFleet for Tomorrow Initiative, explored how various

combinations of incentives might work. In an article for Public Utilities

Fortnightly, the two noted, for example, that doubling the base-case investment tax credit from 10% to 20% and combining it with accelerated

depreciation would come close to closing the cost gap for IOUs and

IPPs. Alternatively, doubling the production tax credit to equal that cur-

EPRI and CoalFleet participants have analyzed financial incentives

rently available for wind energy facilities could actually make IGCC’s

that potentially could reduce the incremental cost gap of IGCC plants

COE less than that of conventional PC for taxable entities. A third pack-

for early deployers. In particular, the CoalFleet Incentives Task Work-

age of incentives—tripling the federal government’s cost-sharing to 30%

ing Group examined eight types of federal financial incentives: loan

without repayment and adding availability insurance—would provide

guarantees, direct federal loans, federal cost-sharing grants, investment

public power producers and cooperatives with sufficient cost-reduction

tax credits, production tax credits, tax-exempt financing, accelerated

to make IGCC attractive compared with conventional PC. The gap

depreciation, and the new concept of federal availability insurance.

would still not be closed for IOUs and IPPs, “but the difference is small

Their analysis considered three types of power producers—regulated

enough that other considerations might well determine their choice,”

investor-owned utilities (IOUs), independent power producers (IPPs) with

Wilson and Clark note.

contracts for their plants’ generating output, and public power produc-

“In the end, however, it must be remembered that any incentives

ers (cooperatives, municipal utilities, and federal and state entities)—

such as those just discussed are intended only to get IGCC ‘over the

and accounted for differences among them in borrowing costs and

hump’ of initial commercial deployment,” the analysts point out. “After

tax obligations. The findings were tabulated in terms of the effect of an

that, commercial attractiveness of this prototypical clean coal technol-

incentive on an IGCC plant’s levelized cost of electricity (COE).

ogy will depend on a variety of other factors. Foremost among these

No single type of fully evaluated incentive bridged the COE gap

will be resolution of the technical risks involved, specifically by showing

between IGCC and PC plants for all company types. Moreover, varia-

that IGCC plants can achieve sufficiently high availability to compete

tion in the value of different incentives to various types of power produc-

with conventional coal plants. Initial capital costs should also decline

ers was substantial. For example, public power producers receive no

with design and operational experience and as the infrastructure for

direct benefit from tax-based incentives, and loan guarantees provide

building, maintaining, and utilizing IGCC facilities develops. Additional

much greater benefit to IPPs than they do to other producer types. “As a

factors that may influence the long-term attractiveness of IGCC technol-

result, CoalFleet members have concluded that combinations of incen-

ogy include the potential need to capture and sequester CO2 to miti-

tives, or tailored packages of incentives, will be necessary to signifi-

gate global warming or to produce hydrogen for future fleets of fuel-cell

cantly lower the cost barrier to IGCC deployment and to give relatively

vehicles. Because of this potential, the ultimate value of IGCC may be

equal incentive to all power producers,” says EPRI’s Jack Parkes. “Par-

its importance as a hedging strategy—a way to keep using the nation’s

ticularly interesting with respect to the equitability aspect is the newly

most abundant energy resource while providing options to deal with

developed concept of availability insurance.” In this type of incentive,

long-term environmental hazards.”

the federal government would provide insurance for covered plants

EPRI is coordinating CoalFleet’s deployment incentives analyses

that are unable to meet a specified target for availability. Although

with DOE to ensure that the impact of incentives on federal budgets

analyses showed that availability insurance alone would not close the

is properly calculated. CoalFleet plans to update its incentives analy-

cost gap and make IGCC competitive with conventional pulverized

ses on the basis of peer review comments, evaluate additional types

coal, such an incentive may be valuable and effective in combination

of incentives, and extend the analysis to address a broader range of

with other incentives.

technology options.

E P R I

J O U R N A L

fits of standard, or reference, designs for

Supporting Early-Deployment

IGCC and other advanced coal plants.

Projects

As with the UDBS documents, CoalThe operating concept for CoalFleet is

Fleet’s goal is to create standard plant

“learning by doing,” with EPRI and the

independent experts participating direct- design guidelines for each major IGCC

ly in the site-specific engineering feasibil- gasifier technology and its applicable fuels

ity studies being conducted by the own- and for USC PC and SC CFBC technologies. These CoalFleet specifications, based

ers of three to five CoalFleet companies

that have pledged to build IGCC or other on the real-world experience of earlyadvanced coal plants. The early-deploy- deployment projects, should reduce the

time and cost for plant engineering conment project owners will benefit from the

siderably and result in plants with imknowledge, design, and operations and

maintenance experience in CoalFleet, proved performance and availability.

While IGCC is inherently very clean,

while the broader CoalFleet membership

will benefit from the rapid, real-life feed- obtaining environmental permits for an

IGCC plant is a critical-path item in the

back from the early-deployment projects.

project development process, and applicaThis symbiotic relationship will continue

as early-deployer companies select a sup- tions often must be submitted before frontend engineering is under way. The limited

plier and commit to the development of

experience of regulators with IGCC pera process design package and front-end

engineering design, followed by detailed mitting and a dearth of reference information from previous permits compound

design and construction.

As the early-deployment projects prog- the challenge. As a result, obtaining permits for a new IGCC plant can be highly

ress, CoalFleet will form teams for each

complex and pose a significant risk for

project that will translate project-specific,

nonproprietary information into a Coal- delays in plant construction. CoalFleet’s

Fleet Pre-Design Specification and a Ge- IGCC Permitting Task Working Group

neric Design Specification. The PreDesign Specifica100

Cost of CO2 sequestration

tion is essentially

Cost of CO2 capture

a generic version

80

of the project’s

feasibility study,

60

and the Generic

Design Specifica40

tion corre­sponds

to ap­proximately

the first 50% of

20

front-end

engineering design.

0

NGCC

IGCC

USC PC

Nonproprietar y

($5 NG)

costs and project

financial proformas for different

In comparisons of the 30-year levelized cost of electricity from new

orga niz ationa l

plants of similar capacity (500–600 MW), IGCC and USC PC compete

types will also be effectively with conventional natural gas–fired combined-cycle (NGCC)

derived, allowing plants when the price of natural gas reaches $5/million Btu—a level

CoalFleet partici- already exceeded today. And when the cost of capturing and

pants to see the sequestering CO2 becomes a factor, as many believe it will in the

anticipated bene- future, IGCC appears to have a clear economic advantage.

Cost of Electricity ($/MWh)

costs, and risks of building advanced coal

plants.”

To start the process, EPRI and the

CoalFleet world-class experts have assembled an Advanced Coal Technologies

Knowledge Base, the core of which presently comprises more than 50 design cases

from eight recent state-of-the-art studies

conducted by EPRI, DOE, utility companies, consultants, and technology supplier teams. Each case study details vital

characteristics in up to 450 defined fields.

CoalFleet will continue to add data as

they become available from new feasibility studies by members and from design

decisions made by companies undertaking early plant deployment projects. The

knowledge base will also include papers

from key conferences and lessons learned

from IGCC demonstration units at Cinergy Corp.’s Wabash River Generating

Station and Tampa Electric Co.’s Polk

Power Station.

“EPRI, the CoalFleet independent experts, and a CoalFleet participants’ task

working group are drawing on the knowledge base to assemble a clear and complete

User Design Basis Specification (UDBS)

for IGCC plant designers,” says Parkes.

CoalFleet’s initial version of the UDBS

will include three 600-MW bituminous

coal–fired IGCC plants, one for each of

the three commercial entrained-flow gasifiers (i.e., GE Energy, ConocoPhillips,

and Shell). For utilizing low-sulfur Powder River Basin (subbituminous) coal, the

UDBS will include an 800-MW IGCC

plant from Shell and a 600-MW transport-gasifier plant from Kellogg, Brown

& Root.

For each plant, the UDBS will estimate

availability with and without a spare gasifier and will specify three cooling options—wet tower, dry cooling, and parallel wet-dry. Also included are heat rate

targets, back-up fuel considerations, timeto-build targets, emission limits for startup and off-design operation, and expected

supplier performance guarantees. Subsequent CoalFleet UDBS documents will

cover USC PC and SC CFBC plants.

S U M M E R

2 0 0 5

13

Two demonstration projects supported by DOE and the industry have paved the way for the

deployment of IGCC technology. Cinergy was host to a 262-MW IGCC repowering demonstration

at its Wabash River Generating Station near Terra Haute, Indiana, in 1995. Tampa Electric’s 250MW Polk County IGCC demo is a green-field unit that began operation in 1996.

is attempting to significantly reduce the

time to permit an IGCC plant through

identification of the critical technical,

regulatory, and procedural issues that

must be addressed up-front and through

the plant design and equipment selection

process. The group’s findings will guide

the development of design recommendations for enhancing and streamlining the

permitting process.

Columbus-based American Electric

Power Co. announced in 2004 that it

plans to build a large-scale, commercial

600-MW IGCC plant. The company

contracted with GE Energy and Bechtel

Corp. for a scoping study of the param­

eters of an IGCC facility at one of

three sites in Ohio, Kentucky, and West

Virginia.

“Continuing significant environmental investments in our current fleet and

building a commercial-scale IGCC plant

are the right steps going forward to ensure that we can continue to burn coal

economically while reducing our emissions,” says Michael G. Morris, AEP’s

chairman, president, and chief executive

officer. “AEP is taking significant steps to

keep coal in the picture as a low-cost, low-

14

E P R I

J O U R N A L

emissions energy source. We must be able

to rely on our vast coal resources to generate electricity if America and the world are

to continue to have growing economies.”

Adds Robert Powers, AEP’s executive

vice president for generation, “The CoalFleet initiative is important to the industry’s ability to help resolve many of the

new environmental issues and challenges

we face in a cost-effective manner. We’re

at a crossroads. After the demonstrations

of IGCC in the 1990s, we’re now working

to answer how the technology will perform at large scale and whether it can

compete as new baseload capacity. Achieving the low capital cost and low cost of

electricity demanded by today’s customers will be an exciting challenge. CoalFleet reflects the recognition by EPRI’s

membership that it’s time to make something happen and to move ahead with

advanced coal power systems.”

Meanwhile, Cincinnati-based Cinergy

Corp., under an agreement with GE Energy and Bechtel, is studying the feasibility of building a commercial 500- to

600-MW IGCC generating station at one

of several possible sites, including the 50year-old coal-fired station of its subsidiary

Public Service of Indiana at Edwards­

port, Indiana. PSI earlier was host and

cosponsor with DOE of a $417 million

IGCC repowering demonstration at PSI’s

Wabash River Generating Station near

Terre Haute. The project’s new 262-MW

IGCC plant successfully demonstrated

40% efficiency and plant availability as

high as 79% from 1995 to 1999. Akronbased FirstEnergy Corporation has also

announced interest in the development

and commercial deployment of IGCC

technology within the next several years.

And a team led by Southern Company

was selected for a DOE Clean Coal Power

Initiative (CCPI) Round 2 award to build

a 285-MW transport-gasifier IGCC plant

in Orlando, Florida.

“We face the need for additional generation in Indiana, and as the demand

for electricity increases in the future, we

will need to build more power plants,”

says James E. Rogers, Cinergy’s president,

chief executive officer, and chairman.

“Coal is our most practical, economical option. But the key to building more

coal plants will be to develop zero-emission, clean coal technologies. Our central challenge is to find ways to use an

abundant energy resource—of which our

country has a more than 250-year supply

in reserve—in an economic and environmentally clean way,” adds Rogers. “Coal

gasification has proven to be efficient,

and there is no cleaner coal generating

technology. It is critical for our country

to commercialize IGCC, from the standpoint of greater energy independence and

from that of the international balance of

payments. We need to get to work now

deploying and optimizing the current

generation of commercial IGCC so that

even more economical generations of the

technology will be available over the next

10 to 15 years.”

Linking R&D and Deployment

to Reduce Costs

CoalFleet participants believe that collaborative research, development, and

demonstration among power industry

stakeholders can both hasten the deployment of current state-of-the-art advanced

coal plants and spur the development of

technical and operational improvements.

Such advances promise to boost availability or lower heat rate and emissions in

the near term and ultimately lead to the

commercial introduction of next-generation plant designs that are approximately

20–25% lower in capital cost.

The initiative’s strategy simultaneously

addresses the RD&D needs for three

­major timeframes:

• Near-term refinements or evolutionary technologies for IGCC, USC PC,

and SC CFBC plants coming on-line

around 2010–2012—the early-deployment projects.

• Mid-term R&D requiring demonstrations that will conclude after the earliest commercial projects are built; this

work will produce technologies that

can be readily incorporated in plants

coming on-line around 2012–2015.

• Longer-term R&D on advanced concepts for IGCC, USC PC, and SC

CFBC plants—including integration

of CO2 capture systems—for plants

coming on-line after 2015–2020.

DOE is currently supporting fundamental materials research, coal plant–

related RD&D, and new coal technology

plant demonstrations through the CCPI.

FutureGen, a large IGCC demonstration

project initiative of the DOE, will involve approximately $1 billion when

fully funded. These efforts represent a

substantial contribution to the development of advanced coal systems. EPRI is

actively participating in many of these

programs to help ensure the suitability and transferability of results to users.

Technology from DOE’s RD&D programs, along with CoalFleet results and

industry RD&D, must be incorporated

and proven in both early-deployment and

next-generation units. Coordination with

relevant programs in other countries will

also help CoalFleet accelerate advanced

coal plant deployment, especially for USC

PC units.

Railroad Co. (1)

Federal Agency (1)

Federal Power Co. (1)

Eng/Proc/Const Co. (2)

IOU (15)

State Utility (2)

Muni (2)

Int'l Utility (3)

IPP (3)

Supplier (8)

Co-op (4)

The CoalFleet for Tomorrow Initiative is supported by an extremely broad range of stakeholders.

At the time of publication, 42 participants were on-board, representing more than 50% of the

coal-fired generation in the United States.

In 2005, CoalFleet is creating an industry-focused RD&D plan with projects that augment and accelerate current

RD&D activities; the initial emphasis is

on technology that could be ready for inclusion in early-deployment plants. Some

needs are well understood, and plans are

already being developed for collaborative

RD&D projects that address longer gasifier feed nozzle and refractory life and

reliability improvements for syngas-fed

combustion turbines. Other projects will

explore heat rate improvement and ­lowercost CO2 separation and capture processes. Human performance capability

enhancement projects will also be developed, including efforts involving training

simulators, instrumentation and control

systems, and operation and maintenance

guidelines. Private and public partners

will be identified to help launch high-priority projects over the next year.

Pushing Forward to a

New Generation

CoalFleet has attracted a great deal of

industry support, and for good reason.

“CoalFleet for Tomorrow is an extremely

important initiative for our energy and

environmental future, considering that

our nation generates half of its electricity

from coal, which is really the only generating fuel we have in ample, long-term

supply,” notes Barry Pulskamp, Cinergy’s

vice president for power operations. “The

CoalFleet initiative is bringing all the

players in advanced coal systems technology into the fray to reduce the cost of

these systems for producing electricity.

We’ve seen tremendous improvement in

the reliability of IGCC technology and

the resolution of many technical issues

over the past decade. Now the industry

must take advanced clean coal technologies to the next generation and further

drive costs down through plant standardization. Chevrolet has improved its V-8

engine enormously over 50 years, and the

company has produced around 100 million units. I would hope that our industry

could achieve the same degree of improvement in advanced coal systems in terms of

cost efficiency and emissions. I’m excited

about our prospects for the future.”

Background information for this article was

pro-vided by Stu Dalton (sdalton@epri.com),

Jack Parkes (jparkes@epri.com), Neville

Holt (nholt@epri.com), and Tom Wilson

(twilson@epri.com).

S U M M E R

2 0 0 5

15

MERCURY

CONTROL

for Coal-fired

power plants

by Paul Haase

The Story in Brief

After some 15 years of study, the U.S. Environmental Protection Agency issued final rules

on March 15, 2005, for regulating mercury

emissions from coal-fired power plants. The

new ­regulations require a reduction of mercury

emissions by 70%, phased in over the coming 12 years. No commercial technologies yet

exist for fully controlling mercury emissions from

coal plants, but several approaches show good

potential in full-scale tests and some are nearing market readiness. EPRI, working closely with

DOE and the power industry, has conducted

­extensive mercury control research and developed some of the most promising technologies.

s late as the 1950s, mercury perme­­­ated American life. Parents

annu­ally administered mercurous chloride, or calomel, to children as a

laxative and dewormer. Mercury-bearing

calamine lotion soothed itches; mercurochrome sterilized wounds; mercuro-organic wonder-compounds preserved seeds

and wood. Mercury even helped smooth

the ride of luxury cars—one Studebaker

model employed some 40 pounds of it.

Although the risk of mercury vapor as a

human neurotoxin was not unknown—

the U.S. Public Health Service banned

mercury from felt-making in 1941—few

concerned themselves with mercury waste

when children sought out spilled blobs of

mercury to play with. Factories discharged

mercury directly into rivers and lakes,

hospitals and laboratories discarded broken mercury thermometers with the trash,

incinerators and power plants sent mercury skyward.

side-down. The U.S. Environmental Protection Agency (EPA) named mercury as

a potentially hazardous air pollutant in

1971, and the Safe Drinking Water Act

in 1974 established limits on mercury in

public water systems. The 1976 Resource

Conservation and Recovery Act identi­fied mercury as a hazardous material and

man­dated safe management and disposal

(in­clud­ing for emissions from combustion). Regulators have since refined and

expanded pollution laws to eliminate mer­

cury in batteries and paint, reduce emissions from municipal incinerators and

­industry, and control most other sources.

Today, domestic use of mercury has

dropped to well below one-fifth of its

1964 peak, according to EPA estimates.

The worst human health problem, discharging mercury-containing waste into

water where it can contaminate food fish,

has been virtually eliminated in the

­United States.

Mercury emissions to the air were the

last to be regulated, with initial rules

focus­­ing on two of the most obvious

­sources—medical waste incineration and

the burning of municipal waste. As a ­

Mercury Emissions (tons per year)

Quick Change for Quicksilver

By the 1960s, recognition of mercury as a

toxin and environmental danger turned

the public attitude toward mercury up-

250

200

63.56

72.76

150

49.73

40.47

100

56.73

50

0

31.78

58.21

1.6

4.9

51.05

51.25

47.91

1990

1996

1999

Utility Coal Boilers

Medical Waste Incinerators

Municipal Waste Combustors

Other (gold mines, institutional boilers, chlorine

production, hazardous waste incineration, etc.)

U.S. mercury air emissions have been substantially reduced over the last 15 years, in part through

regulation of medical waste incineration and municipal waste combustion. EPA’s Clean Air

Mercury Rule, issued earlier this year, will put limits on emissions from the nation’s 600 or so large

coal-fired power plants.

18

E P R I

J O U R N A L

result, U.S. mercury air emissions have

fallen by half since 1990, to about 115

tons per year, and continue to decline.

This progress has focused attention on a

third substantial source of mercury air

emissions: the nation’s 600 or so large

coal-fired power plants. Mercury from

these plants accounts for 45–50 tons of

domestic mercury air pollution annually.

And while the releases have remained

steady at this level for the past 15 years, as

other mercury emissions have fallen, coal

plants have come to represent a greater

and greater fraction—now about 40% —

of total domestic emissions. In a global

accounting, mercury emissions from U.S.

coal plants represent less than 1% of natural and human-caused sources.

The Clean Air Mercury Rule

EPA began studying coal plants as the last

significant source of mercury emissions

in 1997 and, after some controversy (see

sidebar, p. 24), formally issued its Clean

Air Mercury Rule, or CAMR, to regu­late

coal plant emissions on March 15, 2005.

This two-phased rule creates performance

standards and establishes permanent, declining caps on mercury emissions from

coal plants. The Clean Air Mercury Rule

marks the first time EPA has regulated

mercury emissions from coal-fired power

plants and makes the United States the

first country in the world to regulate

these emissions.

The mercury rule is intended to work

in tandem with EPA’s new Clean Air In­ter­

state Rule, or CAIR, which tightens ex­ist­

ing regulations on two other coal plant

emis­sions: sulfur dioxide (SO2), which con­

tributes to acid rain and fine particulates,

and nitrogen oxides (NOx), a precursor of

ozone (sometimes referred to as smog) and

also of fine particulates. The aim is that by

2018, these two rules will reduce coal plant

emissions of mercury by about 70%, to 15

tons per year nationwide. Reductions will

be achieved through a market-based “capand-trade” pro­gram similar to that of EPA’s

highly successful Acid Rain Program,

which in the 1990s delivered its environ-

Polishing Filter

(TOXECONTM)

Coal

Additives

Sorbent Injection

Combustion

Modifications

Scrubber

Coal Cleaning

Coal Blending

ESP/Fabric

Filter

Boiler

Stack

FGD

Additives

SCR

Catalysts

Fixed Adsorption Structures

A number of approaches are being investigated for controlling mercury emissions from coal-fired power plants. Potentially beneficial modifications

of the fuel or combustion process include coal cleaning, coal blending, and control of the mixing of air and coal during combustion. Options

to increase the removal of mercury by scrubbers, which are already on the system to control SO2 emissions, include adding an SCR (which also

reduces NOx emissions) or catalysts and additives designed specifically to convert the mercury to a scrubbable form. Finally, several mercury-specific

approaches are being developed—injection of activated carbon or other sorbent material into the flue gas, sorbent-based polishing filters, and fixed

adsorption structures.

mental improvements faster and much

more inexpensively than anticipated.

Under the cap-and-trade program for

mercury, EPA will assign individual states

(and two Native American tribes with

coal-fired power plants on their lands) an

emissions budget for mercury. Each state

will determine how to regulate its coal

plants to meet this emissions budget.

During the phase-in period, plants that

meet emissions limits ahead of time can

bank these credits for use later or can sell

them to those that will not be able to meet

their limits on time. After the 2010 Phase

1 compliance date and the 2018 Phase 2

compliance date, companies whose plants

in aggregate control mercury emissions

below their allocated limit will be able to

sell the “over-control” amount to companies whose plants cannot achieve their

­a llocated limits cost effectively.

The Capture Challenge

Now that EPA has ruled, coal plant owners and operators will need the means to

better capture mercury emissions. Some

improvements can be achieved by modifying existing SO2 or NOx control devices,

but new approaches will be required to

meet the final 2018 emission limits. As

yet, no technology designed specifically

to control mercury in coal plants is in use

anywhere in the world, or has even under­

gone long-term testing.

To develop and demonstrate such technologies, EPRI is working with the U.S.

power industry and government organi­

za­tions in a broad program of research

and field testing at power plants. The

large-scale mercury field testing in the

United States was made feasible through

signifi­cant funding and technical management by the U.S. DOE’s National

Energy Technology Laboratory (NETL).

Important col­laborators are the host sites,

the developers of the control technologies

themselves, and the engineering firms

conducting the tests. The overall effort

builds on 15 years of EPRI mercury control research.

This important work could not be done

without the contributions of the many

power companies that offer their plants

for field testing. “With federal regula-

S U M M E R

2 0 0 5

19

The DOE-NETL field test program, which

benefits from 15 years of EPRI mercury

research, is exploring the effectiveness of a

dozen mercury control strategies at over 30

utility plants. The extensive test program is

scheduled to continue through 2007.

(Photos courtesy URS Corp.)

tion now in place, full-scale testing at the

power plant is a critical step in the development of potential technologies,” says

EPRI President and CEO Steve Specker.

“We cannot simulate these conditions

in the laboratory and need to determine

whether performance in the field can be

sustained over a period of time without

interfering with the plant’s operation.”

The commitment of the field-test utilities

20

E P R I

J O U R N A L

is of tremendous value, considering that a

typical coal plant generates tens of thousands of dollars worth of electricity each

hour—electricity and revenue that are

lost if the plant is shut down to install or

tend experimental equipment.

Most emission control strategies for

mercury focus on boosting the mercurycapture effectiveness of the standard pollution control equipment already installed

at existing coal-fired power plants. This

equipment includes flue gas catalysts to

control NOx, scrubbers and spray dryers

to capture SO2, and particulate filters to

catch fly ash. These existing technologies capture about 35% of the mercury

in flue gases, on average, but performance

varies widely from plant to plant. Of the

approximately 75 tons of mercury found

in the tens of millions of tons of coal

delivered to power plants each year, about

25–30 tons are captured in existing pollution controls and 45–50 tons are emitted

to the air.

Key to capturing emissions is the chem­

ical form of the mercury—elemental or

ionic—as it passes through each pollution

control device. Ionic mercury, which is

soluble in water, is absorbed in scrubbers,

whereas elemental mercury is not. Thus,

the mercury-control challenge in a coal

plant is primarily one of chemistry. For

plants with existing or impending SO2

controls, the objective is to increase the

proportion of ionic mercury—either during combustion of the coal or in the flue

gas itself—by some kind of oxidation process. Those without SO2 controls may need

to install mercury-specific technology.

The choice is neither simple nor obvious. Chemistry and economics dictate

that most coal plants will employ one

mercury control approach rather than a

combination, and the choice must be determined plant by plant because of the

wide difference in coal plant designs, the

pollution equipment they have, and the

coal types they burn. “For any given regulation, we must have options for all the

combinations of coals and existing air

pollution controls used by the industry,”

says George Offen, EPRI’s technical

­executive for air emissions. “It’s no ‘onesize-fits-all’ situation.”

Modifying Coal and

Combustion

Mercury control starts with the source,

coal. This presents the first difficulty, because coal is a sedimentary rock that has

no fixed composition. In coal, as in many

similar sediments, mercury occurs as a

trace element at about one part per million. Although coals come in a great variety—the chemistry and characteris­tics

varying with the amount of heat and pressure a coal has experienced over its long

history—most U.S. power plants burn one

of two broad types, according to which is

regionally available. In the East, plants

generally fire harder bituminous coal,

Sunflower Electric’s Holcomb Station near Garden City, Kansas, was host to a full-scale field test

of sorbent injection for mercury capture under the DOE-NETL program. Conventional sorbents

injected into the flue gas duct (far left) before the plant’s spray dryer unit achieved only modest

results in removing mercury. However, use of a new, chemically enhanced sorbent removed 90%

of the mercury at low-to-moderate injection rates. The sorbent is collected by the plant’s fabric

filter, and the cleaned flue gas exits the stack at right. (Photo courtesy ADA-ES)

and in the West, softer subbituminous or

lignite coals are the typical choice. The

behavior of these coal types varies significantly with regard to mercury emissions:

most—more than 60% —of the mercury

released from the combustion of eastern

coal is in the soluble and more easily captured ionic form, whereas only 20–30%

of mercury released from western coal is

ionic. Thus, even though eastern coals

typically contain one-third more mercury

than western types, plants firing western

coal generally will require more aggressive

approaches to control mercury emissions.

Precombustion cleaning increases the

mercury difference between coal types,

because eastern coal can be cleaned prior

to use whereas western types generally

cannot. Cleaning removes noncombustible materials and, for eastern coals,

­reduces mercury content by about onethird on average. For western coals, various dewatering treatments have been ex-

plored to improve combustion properties;

such dewatering appears to also remove

mercury—up to 70% in tests—and may

become commercial in the future.

Cleaned or not, once coal reaches a

power plant, several mercury control strat­

e­gies are possible. First, the combustion

process can be modified to increase the

yield of unburned carbon in the fly ash,

which can adsorb mercury emissions;

the additional carbon may also increase

the percentage of ionic mercury. These

changes may be accomplished by staging

the flow of air or coal in the boiler or by

adding halide salts or other treatments to

the coal or directly in the boiler.

“Several of our research projects have

shown that adding a little halogen to

promote oxidation significantly improves

short-term mercury capture on western

coals,” says Ramsay Chang, EPRI’s technical leader for air emissions. DOE-NETL

is following up on these results in 2005

S U M M E R

2 0 0 5

21

by cofunding longer-term tests of halogen

additives at two power plants burning

western coals.

Increased yield of ionic mercury or

adsorbent carbon ash can also be accomplished by blending different types of coal.

In short-term tests at Sunflower Electric’s

360-MW Holcomb Station, located near

Garden City, Kansas, EPRI researchers

found that mixing modest amounts of

bituminous coal with the subbituminous

Powder River Basin (PRB) coal fired at

the plant reduced mercury emissions by

up to 80% without any other changes.

“The emissions control equipment at

Sunflower’s Holcomb Station is typical

of many power plants in the West,” says

EPRI’s Specker. “It has exactly the same

configuration as most of the new plants

being planned that will burn PRB coal.

This makes the results particularly significant.” Indeed, EPRI recently honored

Sunflower Electric with its 2005 Technology Achievement Award for Rural Electric Cooperatives for hosting this work.

Tests at Holcomb Station are part of

EPRI’s work with DOE-NETL to perform extensive longer-term mercury control technology testing for coal plants in

the 2004–2007 timeframe. EPRI is coordinating with the power industry to shape

the design and content of the DOE-NETL

tests. It’s a big job: in addition to government agencies and host Sunflower Electric,

the Holcomb test alone involved ADA-ES,

Inc., NORIT Americas, Arch Coal, Western Fuels Association, Kansas City Board

of Public Utilities, Westar Energy, Empire

District Electric Company, Nebraska Public Power District, Kansas City Power and

Light, Tri-State Generation & Transmission, Missouri Basin Power Project, Wisconsin Public Service, Associated Electric,

Southern Minnesota Municipal Power

Agency, the City of Sikeston, TransAlta

Utilities, and TransAlta Energy.

Co-Benefit Approaches

The mercury-control potential of com­

bustion modifications at many plants may

be limited by the chemistry governing

22

E P R I

J O U R N A L

plant efficiencies, by boiler corrosion

from ­halide salts, or by the economics of

coal transport. But “co-benefit” modifications are possible that can boost mercury

capture in equipment already installed to

control SO2 and NOx emissions.

SO2 is captured by routing flue gas

through large liquid-filter flue gas desulfurization (FGD) scrubbers or through

spray dryers that work with an injected

slurry of a calcium compound. Such SO2

controls capture nearly all of the ionic

mercury emissions but almost no elemental mercury. Consequently, mercury control based on SO2 controls and combustion modifications work best at plants