Real pulling force.

advertisement

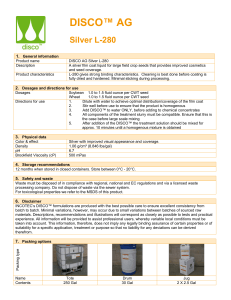

DISCO Trailed disc mowers Real pulling force. Systematic forage harvesting. In forage harvesting, every minute counts. What you need is a partner who can offer much more than just robust machinery. Outstanding product quality and excellent customer service are required, for example. And an continuous forage harvesting chain which precisely integrates every process from mowing to tedding and swathing through to collection. Thanks to our expertise and experience, we are today one of the leading providers of systems involving forage harvesting. But we have always kept our feet on the ground. Whether you are farming 10, 100 or 1,000 hectares, you will always find the right solution for you in our product range. And our solution will guarantee you forage of the highest quality. 3 Be part of the Action! Contents. P-CUT SAFETYLINK Bar technology Drive, bar protection Knife changing system Conditioner Crop spreading device Trailed mowers with side drawbar DISCO 3050 TC DISCO 3050 TRC DISCO 3050 TC FLAPGROUPER DISCO 3050 AS/TRC AS Trailed mowers with central drawbar ACTIVE FLOAT DISCO 3100 TC/3500 TC DISCO 3100 TRC/3500 TRC FIRST CLAAS SERVICE® Specifications 06 10 12 14 16 18 20 22 28 30 32 34 36 42 44 46 48 50 5 P-CUT - reasons that will convince you. Continuous lea made of 5 mm Quick blade change, hardened blade bolts Wolfram Carbid wear seam Dirt remover Indentation with tunnel effect 6 SAFETY mod af spring special steel Satellite gearbox 24 mm strong gearwheels Automotive bearing Bolted bar; 6 mm strong housing cover Hardox steel inserts Y LINK dule 7 P for professional. P for perfect cut. The same cutterbar technology for all, regardless of working width. You'll find the P-CUT cutterbar in the large-scale machine range, for example the COUGAR, which is the biggest self-propelled mower in the world, or the largearea mowers, but you'll also find it in the smaller DISCO models for small and medium-sized farms. P-CUT - professional technology for top class forage harvest quality. A small recess produces a big effect. The tunnel effect produced by an indentation on the underside of the cutterbar causes dirt firstly to empty out directly, and secondly, to be thoroughly brushed away from the cutterbar by the stationary stubble. No clumps of dirt are left behind, nor does mowing produce a striped effect – the cut is perfect. The broad overlap of the discs ahead of the cutterbar ensures a clean, uniform cut. All of the housing bolts in the cutting zone are recessed. 8 P-CUT. With CLAAS, the word "professional" applies right down to 2.6 m working width. P-CUT Bar technology 9 P for power drive. Smooth running, low-wear power transmission and a long lifecycle thanks to: • Slow-turning, large-diameter main gearwheels with a consequently large number of rounded gearteeth meshing together for a low level of wear. • Separate drive for each cutting disc via an upstream pinion which only has to transmit a fraction of the total power. • 24 mm forged gearwheels in high quality spring steel. • Gearing is able to absorb significant shocks effectively. P for patented solution – SAFETYLINK. With our unique SAFETYLINK safety module featured on the P-CUT cutterbar head, safety for both man and machine remains a priority for us. • Defined shear points on every cutting disc reliably and effectively prevent cutterbar damage in the event of severe impact with an obstruction. • The satellite pinion gear and the bearing or even the complete module, can be replaced in no time at all. • Minimum downtime during harvest. Safety for everyone. If the SAFETYLINK is activated after a large obstacle has been hit, the cutting disc stays firmly in place. The hexagon bolt located in the pinion shaft prevents the cutting disc from flying off. Minimising the risk of further damage. 10 P-CUT. Permanent reliability. Stable bearing. The cutting discs of the P-CUT bar are mounted in a high-strength double angular contact bearing, such as is also used in automotive applications. • Very high level of durability under all load conditions. • Absorption of extremely high axial forces, e.g. initiated by foreign bodies. • Innovative, reliable bearing seal against dirt and water during cleaning for longer service life and complete operational reliability. Individual bearings or, if necessary, the entire SAFETYLINK unit can be changed quickly. P-CUT SAFETYLINK 11 P-CUT. Work like a professional – it's not a question of working width, but of expectation. Wear skids for operation on sandy or stony ground or in the case of area output to protect the cutterbar skids (available as an option). 12 P for premium housing. The heavy-duty gear housing is another guarantee for high-grade, long-life CLAAS technology. • Scrapers which are positioned lower than the leaf springs and reach as far as the bearing flange protect the leaf springs along their entire length. • Extra-depth mowing bar for added protection of the bar and cutting discs. Maximum cutterbar flexural strength and sturdiness through: • Bar tray made of high-strength, fine-grained structural steel. • Extra-strong cover plate. • Small service openings. • Large depth of the cutterbar. CLAAS features like these make sure that your harvest chain doesn't come to a standstill. P for permanent wear resistance. • Robust cutterbar skids underneath. • Extra-hard Hardox inserts welded in at the front between the skids. • The service life of the leading edge of the hardened leaf springs is extended even further through the additional hard coating of tungsten carbide. P-CUT Bar technology 13 Smart power transfer. • Direct input drive via a maintenance-free universal joint located in the feed drum. • The universal joint effectively cancels torsional forces and vibrations. • No additional drive mechanisms with input drive openings. • No storage area surfaces on which cuttings can collect. Active feed drums. • Extra fast-conveying, cylindrical mowing drums for a constant forage flow and a cleanly delineated swath in all operating conditions. • Screw-on wear parts on the conveyor slats for easy, quick and cost-effective replacement. Fast-conveying mowing drums on the right and left quickly remove the crop to the rear, thus blades can always rotate freely to produce a clean cut. 14 P-CUT. External values count as well. P for progressive following for all applications. Every region and every type of terrain makes its own special demands on the equipment supplied by technology. • Adaptation to local circumstances through the use of additional equipment: – Wear skids on sandy or stony ground or in the case of a high area output to protect the cutterbar skids. – Increase in cutting height of 30 mm using high-cut skids ,for example for field crops. P-CUT drive Bar protection 15 P-CUT. Blade replacement at the double. P for practical – Knife changing system as standard. With the knife changing system, CLAAS provides an effective combination of sophisticated technology and convenient handling. • Easy blade change: the fixing lever is placed around the blade bolt, the leaf spring pushed downward and the old blade swapped for a new one. Well organised. • Rainproof blade box mounted where it is easy to access, with two separate compartments for right and left-hand side blades. • The part numbers of the blades are also displayed on the lid of the blade box. 16 Safety first. • The hardened steel blade bolt is welded firmly to the leaf spring. • The leaf spring pushes the blade bolt from below firmly into the disc. • The blades rotate freely around the bolt without any impact. This prevents damage to the blades. • A 7 mm overlap and the mushroom-shape of the blade bolt keep the blade firmly in place, even in the toughest of conditions. • The blade can only be changed if the blade attachment is directly above the cavity. This prevents the blade from coming free by mistake. Original CLAAS cutting blades. • Cutting blades made of high-grade spring steel. • Ground blades. • Clean cut to encourage rapid growth. P-CUT Quick blade change 17 Only the best. Whatever the weather. Regardless of which mower you opt for, the conditioning system, which has proved itself time and again in largescale operations, is featured on all CLAAS mowers. CLAAS refuses to compromise on conditioning quality or on service life. As with everything CLAAS produces, the conditioners on the DISCO mower are tough, reliable and powerful. They help you to work even more efficiently and exploit the available harvesting window to the full. Now you can outsmart the weather. Tried-and-tested technology. • Stable and robust power transfer. • V-shaped offset tines comprising two single elements and made of hardened steel for efficient operation over several years. • You can match the conditioning intensity to the harvest conditions by adjusting the baffle plate, without the need of tools. • The swathing plates are adjustable for the right swath width. Dry matter With conditioner Without conditioner Time The steel tines are flexibly mounted which allows them to simply give way if they hit against stones, thereby avoiding damage. 18 DISCO with conditioner – for faster drying and wilting. Efficient operation. Precision adjustment. • Loose swath accelerates the drying and wilting process considerably. • Time saved through fewer working operations. The level of conditioning can be set from aggressive to gentle by altering the intake as well as the ability to turn the asymmetric steel tines. Securely mounted. • The conditioner rotor is mounted on highly stable block bearings. • The bearings are fitted outside the crop flow so they are well protected from dirt and harmful crop fluids. • Easy removal and replacement of the rotor for maintenance purposes. Conditioner 19 Mowing and spreading. Less work, faster operation. To make work even more effective in good drying conditions or when processing wet silage, CLAAS now supplies the DISCO mower units 2650 C, 3050 C, 2700 C CONTOUR, 3100 C CONTOUR, 3500 C CONTOUR, 3050 TC, 3050 AS, 3100 TC, 3500 TC, 3050 FC, 8550 C, 9300 C DUO as an option and DISCO 3100 FC PROFIL, 8550 AS and COUGAR 1400 C as standard with a crop spreader. This is a more cost-effective approach to grass mowing. • The crop is conditioned and then distributed evenly across the entire width of the mower – all in one go. • The adjustable vanes generate an even and loose swath. • Set up of the desired swath shape without using tools. • Minimises the requirement to ted. 20 Crops spread wide are already half dried. The adjustable vanes on the DISCO crop spreader distribute the crop behind the conditioning rotor over the entire working width. Crop spreader 21 22 A cut above the rest. 23 Trailed mowing with side draw bar – pure power on two wheels. As wide as you need. The DISCO 3050 TC doesn't waste an inch of working width. These disc mowers can be adjusted to handle any width of tractor. Whether operating on its owned or in combination with a front mower, whether a straightforward DISCO 3050 TC as standard or as a version with roller conditioner, with an automatic swather unit with baffle plates or conveyors – these mowers are designed for a maximum work rate. Its precise tracking is thanks to the wide profile tyres. Unrestricted attachment. • Free-moving bracket for attachment to the lower linkage for maximum flexibility during cultivation. All trailed DISCO, regardless of their equipment, have a travel speed of up to 40 km/h - depending on country regulations. 24 40 The drive: robust and well-designed. The tractor's power is transferred to the mower via a highly robust and reliable swivelling drive head. • Drive shaft resistant to bending even in the tightest of corners. • Minimum mechanical wear when negotiating corners. As standard, the mower is driven at 1000 rpm. If required, you can quite easily simply turn the input transmission around and, using the appropriate drive shaft, convert the unit to a speed of 540 rpm. Easy adjustment to all track widths. • The highly stable side drawbar can be set to 4 different positions. Steady flow. • Optimised crop flow around the mower thanks to its straight edges and rounded corners. • Side protection panels with straight outer edges for maximum elasticity of the protective covers. • Rounded hood for a clean swath and a smooth crop flow. Trailed DISCO with side drawbar 25 Don't wait, just mow. When time is the key factor, it's often the details that make all the difference during operation or maintenance. • Convenient adjustment of the discharging springs by means of cranks. • Simple cutting height crank adjustment between 30 mm and 70 mm indicated on a scale. • Foldable, securely hinged protectors with a reliable locking mechanism to ensure optimum maintenance conditions and easy access to the belt pulleys. • Safety frame acts as a bumper to prevent damage to the protective covers. • Stable jack with practical locking device. • 250 hour lubrication interval for the drive shaft. 26 The DISCO TC range with side drawbar – Focusing on comfort. Blade change in a flash. Takes obstacles in its stride. • The weatherproof blade box, fixing lever and cutting blades are always at hand. • Save time by changing the blades on the spot. • Minimum downtime for maintenance and maximum safety are guaranteed. If the DISCO 3050 TC hits a stone, for example, the entire mower and conditioner unit automatically swings up and back and is guided safely over the danger point. The mower then resumes its normal position automatically. Parallel suspension. The springs are easily adjusted via cranks. Because the ground pressure can be matched to harvesting conditions, adaptation to ground contours is optimised and mechanical wear is kept to a minimum. Trailed DISCO with side drawbar 27 DISCO 3050 TC The one with the fast tines. More efficient conditioning. Trailed CLAAS mowers are attractive because of their very high efficiency, which is achieved not least thanks to the extremely robust and reliable conditioner. The conditioner goes to work on the waxy layer of the plants so that the sap surfaces and dries more rapidly. In addition, the swath is mixed thoroughly and is discharged on to the stubble, which also accelerates the drying process. This saves time and effort, and allows you to exploit the short harvesting time to the full. A crop spreader hood is optionally available for all mowers with tine conditioners, ensuring an extra-wide swath deposit over the entire width of the mower. Wide tyres are available for smooth driveability and large contact areas while remaining gentle on the ground. 28 Faster with a tine conditioner. Adjustable swath plates. • Fast and even drying of the forage, thus minimising the risk posed by bad weather. • Setting of the conditioning level by means of baffle plate adjustment, which is positioned close to the conditioner. • Large number of tines aligned on the robust conditioning shaft for highly intensive conditioning of the forage. • Continuously rounded housing to ensure smooth forage flow. • Swath widths adjustable between 1.30 and 2 metres. • By adjusting the swath width to the tractor's track width, driving over the crop can be avoided. • The width and density of the crop can be used to influence the drying process. Rugged know-how. • The asymmetrical rubber-mounted, spring-steel tines allow for two different levels of conditioning: – The rounded side of each tine provides gentle conditioning. – Straight, factory-fitted side for more aggresive crop conditioner. DISCO 3050 TC 29 The mower for special situations. Smooth operator. There are situations when it's not appropriate to condition the crop intensively during mowing. Crops like alfalfa and clover have a lot of leaves and appreciate very gentle treatment. The DISCO 3050 TRC with its special gentle roller conditioner is the perfect solution. • Easy, wear-resistant and maintenance-free conditioner drive: the lower roller is driven via a drive shaft and the upper roller runs along with it. • The tension and the spacing between the rollers can be adapted to the harvesting conditions. • Protection from foreign objects with the spring loaded upper roller. Gentle and fast. • Conditioner with two helical, meshed rubber rollers. • The hard stalks are squashed whilst the sensitive, nutritious leaves are treated gently. 30 DISCO 3050 TRC For gentle conditioning. The conditioning rollers are positioned closely to the bar. They pick up the crop without loss and ensures optimum crop flow. DISCO 3050 TRC 31 DISCO 3050 TC PLUS with FLAP GROUPER. The alternative. The trailed DISCO 3050 TC PLUS with FLAP GROUPER is another extremely efficient and cost-effective alternative designed to exploit the potential of big trailing machines to the full. Narrow double swath. • Two narrow swaths are packed next to each other and made into one unit. • Moving the drawbar as far as the stop position makes very close driving possible without driving over the first swath, with enough space between the swaths for the tractor's wheels, thus ensuring a clean crop. • No additional hydraulic connections are needed since both swath plates are altered using hydraulic cylinders which are coupled with the swivel cylinder of the drawbar. • The approx. 3 metre-wide swath can be processed in one pass by a self-propelled JAGUAR with a 3.80 metre pick-up. 32 The driver sets the required swath width from the tractor cab. The two swath plates swivel left and right hydraulically to lay the crop together. DISCO 3050 TC PLUS with FLAPGROUPER 33 Two become one. Adjustable throwing distance. You can choose to use the DISCO 3050 AS with or without swathing. This trailed machine offers outstanding flexibility, surface output and a smooth crop flow, even when handling high volumes of forage. • The crop can be deposited accurately on the existing swath from the conveyor belt. Reaching new heights. Whatever the crop. For those types of crop which are richer in leaves, such as alfalfa or clover and which require softer conditioning, the mower is also available with a roller conditioner. The meshed rubber rollers of the DISCO 3050 TRC AS squash the stalks and, at the same time, save the more tender leaves from damage. Powerful drive. • Cross conveyor driven independently of the tractor hydraulic by a separate on-board hydraulic system. • Conveyor speed set using a continuously adjustable oil flow regulator. 34 • Conveyor can be adjusted to three different positions from flat to steep, depending on the forage properties. • Extremely wide and long cross conveyor (900 mm x 2200 mm) for optimum crop flow and maximum surface output. • Angled arrangement of the adjustable folding plate for accurate crop guidance on the conveyor. • Extremely wide tyres for gentle field travel and even greater clearance height. • Optimum transport conditions thanks to the rigid position of the conveyor over the arm. DISCO 3050 AS / 3050 TRC AS Top-level conveyer efficiency. Variable adjustment. The speed of the 220 centimetre long and around 90 cm wide cross conveyor can be infinitely adjusted. Whenever the belt is no longer needed, it can be folded up and disengaged automatically. One mower or two. The aim is to deposit the thickest possible swath while maintining an extremely high-output forage harvesting. The DISCO 3050 AS and DISCO 3050 TRC AS create optimum swaths for collection by the JAGUAR pick-up. • A DISCO 3050 AS or 3050 TRC AS in a double pass cycle: mow first with a normal, centrally deposited swath without the cross conveyor, then mow with side discharge via the cross conveyor and place the forage on the first swath. • Combination with the DISCO 3050 FC / 3100 FC PROFIL / 3100 FRC PROFIL: deposit one compact swath from six metres of working width in one single pass. The reversing valve switches on the belt automatically during lowering. Operating errors are thus excluded. DISCO 3050 AS DISCO 3050 TRC AS 35 Well engineered. 36 37 NEW The trailed DISCO with central drawbar – Back and forth, as you wish. The new generation. Hitching made easy. The new trailed DISCO 3100 and 3500 TC/TRC with central drawbar are the perfect choice to mow large fields. The option of simply swivelling the mower to the left and right side of the tractor with the double-acting control device allows you to mow in rows or circles. As flexibly as you wish and as the surface permits. It's your choice: whether 3.00 m or 3.40 m working width, whether tine or roller conditioners - the perfect machine to suit any conditions. • Inverted U-frame for simple fitting and detaching of the machine. • Parking supports for hydraulic hoses and drive shaft. • Stable and comfortable stand. Mowing strategy. Close mowing will save you a lot of precious time. The drying process is much more even. In addition, you can make a contribution to protecting the game; mowing the crops from one side will create appropriate escape routes for the game. When mowing on slopes, the central drawbar connection creates the necessary stability. 38 Excellent in all areas. Only available at CLAAS: mowers with trailed central hitching in combination with ACTIVE FLOAT hydropneumatic mower's suspension. Perfect ground following even in difficult conditions as the mower is trailed across uneven ground – it literally slides across the surface. • Solid frame design. • Trailed central hitching of the mowing unit for best ground following and cutting quality. • 10° perpendicular oscillation through central hitching for accurate adaptation to all uneven grounds. • ACTIVE FLOAT hydro-pneumatic mower suspension. • If an obstruction is hit, the mower swivels up and back through the trailed rhomboid design. Trailed DISCO with central drawbar 39 NEW DISCO 3100 TC / TRC DISCO 3500 TC / TRC The green mean. A recipe for versatility. The combination of two single-acting cylinders allows the mower to be swivelled to both sides via the central drawbar. During the swivelling process, one cylinder is extended on one side while the other cylinder, which is retracted on the other side, acts as a stop. This creates reliable stability the connection between drawbar and mowing unit. With four plug-in positions for each swivel cylinder, it is easy to adjust the mower to different track widths, so you can use the entire working width to the left and right. Mowing as you wish, in rows or in circles - ultimate flexibility in all circumstances. 40 40 All trailed DISCO, regardless of their equipment, have a travel speed of up to 40 km/h - depending on country regulations. Sophisticated drive. From the front swivelling drive head, an external drive line leads to a second swivelling head installed directly at the mower. • Swivelling drive heads of a sturdy and reliably design. • Steady position of the drive shaft on the tractor's side for smooth running, even when cutting very tight corners. • Efficient power transmission. • Maximum flexibility and manoeuvrability during operations. • Convenient access to the drive line during servicing. The DISCO with central bar will always serve you well. • Large ground clearance of 500 mm during transport. • Large 350/50-16 12PR tyres as standard for high transport stability, good guidance even when driving on slopes, as well as minimum soil compaction. And comfortable, too. • Hydro-pneumatic suspension of the mowing unit ACTIVE FLOAT adjustable from the tractor seat; the adjusted ground pressure is saved during uncoupling. • Simple cutting height adjustment via a crank. • Folding protective covers for optimum maintenance. • 250 h lubrication intervals on the drive shaft's universal joints. • Quick blade change as standard. Trailed DISCO with central drawbar 41 Grass isn't just grass. No crop is consistent. Wet patches or dry raised areas – it is now possible to react to these quickly and simply using the hydro-pneumatic cutterbar suspension provided by ACTIVE FLOAT. You can regulate the mower's suspension at any time from the driver's seat, even while travelling. The currently selected ground pressure can be read from the cab's pressure gauge. Set the value you want. The principle: as much suspension as possible with as little loading as necessary. The result: • Effortless adaptation to ground contours providing forage quality. • Less crop contamination, highest quality forage. • Mechanical wear is kept to an absolute minimum. • Reduced power requirement and fuel consumption. The balancing pressure is adjusted with a single-acting control device via the nitrogen pressure container. The current value can be read from the pressure gauge in the cab. 42 ACTIVE FLOAT – a licence to float. Two-fold strategy. • Adjust the balancing pressure to the changing ground conditions quickly, easily and continuously via the single-acting tractor hydraulic connection. You can do this at any time without descending from the cab, even during mowing. • If conditions are constant, set the balancing pressure once before you start and you can begin mowing straight away. The tap of the single-acting hydraulic hose can be closed and the hose stored in the holder on the mower. The pressure is maintained. This means that the trailed DISCO can be operated either with a dual-acting or with just a single-acting control valve. rougher drier smoother softer and damper As an additional application, the ACTIVE FLOAT can also be set for an edge mowing function by fully suspending the cutterbar. It "hovers" over the uneven ground at the edges, as it were. 100 bar Basic setting under "normal conditions" "Headland Function" Release pressure ACTIVE FLOAT 43 A rapid and efficient harvest. Thinking and working economically and making the most of the short harvesting periods is essential when it comes to crop harvesting. The new DISCO 3100 TC and 3500 TC are also fitted with the tried-and-tested CLAAS tine conditioner which spans the entire working width. As these mowers are tough when it comes to conditioning the crop, they work efficiently in the shortest timeframes. The drying process is accelerated significantly, saving time and effort. 44 • Rugged tine conditioner. • Removal of the wax coating from the crop and deposit of a loose, well-ventilated swath. • Reliable and powerful V-belt drive. • Adjustable conditioning intensity: – Adjusting the distance between the tines and the baffle plate. – Two different conditioning speeds can be achieved by changing the V-belt pulleys. – The asymmetrical rubber-mounted spring steel tines are reversible, with a smooth side for gentle conditioning and a straight side for more aggressive crop conditioning. • Adjustable swathing plates allow a free choice of widths from narrow – to avoid driving over the crop – to distribution over the full working width – to produce a low swath which dries more quickly. • A crop spreader hood is optionally available ensuring an extra-wide swath deposit and faster drying of the forage. NEW DISCO 3100 TC and 3500 TC Conditioning with professional technology. DISCO 3100 TC DISCO 3500 TC 45 NEW DISCO 3100 TRC and 3500 TRC * A knack for legumes. * Not available in the UK 46 The keepers of nutrients. Leafy crops, for example, clover or alfalfa, require particular care during the harvest. Gentle conditioning to protect the soft, nutritious leaves while sufficiently crushing the stalks place high demands on both mower. • Conditioner with helical, meshed rubber-coated rollers with V-profile for crushing the hard stalks and for protecting the delicate, nutritious leaves. • Tension and spacing between the rollers, and hence conditioning intensity, can be adjusted to the particular harvest conditions. • Perfect crop flow thanks to the optimum position of the rollers close to the cutterbar. • Swathing plates with can be adjusted simply and without tools for a neatly formed and delineated swath. DISCO 3100 TRC* DISCO 3500 TRC* 47 We are there for you, wherever you are. We provide the service. Rest assured that we can supply your business with the necessary spare parts at any time. Our central spare parts warehouse delivers all ORIGINAL CLAAS parts quickly and reliably all over the world. The many partners of CLAAS guarantee that they reach their destination as soon as possible – wherever you may be. The FIRST CLAAS SERVICE® teams can be counted on for professionalism and reliability in every minute of use. Round the clock, CLAAS importers and sales partners ensure optimum spare parts supply and reliable customer service worldwide. We are speaking the same language. CLAAS sales partners are some of the world’s most efficient agricultural machinery companies. Not only are they perfectly trained and equipped with specialist tools, but they also have intimate knowledge of the workings of your farm and your expectations regarding competence and reliability. 48 Good partners never leave you in the lurch. However late it may be. FIRST CLAAS SERVICE® 49 DISCO Side drawbar DISCO 3050 TC DISCO 3050 TRC* DISCO 3050 AS/3050 TRC AS trailed II 3,00 3,00 6,20 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 trailed II 3,00 3,00 6,20 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 trailed II 3,00 3,00 6,20 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 DISCO 3050 TC* FLAPGROUPER Mounting position Mounting Working width Travel width Travel length Permissible travel speed PTO shaft speed Discs Blades per disc Blade dimensions Quick blade change PLUS Cutting height Adjustment range with additional runners Swath width(1) with conditioner with joined swaths Dimensions of cross conveyor Conditioner engine speed Tyres Weight with conditioner Hydraulic control devices category m (DIN) m m km/h rpm Quantity Quantity mm mm, approx. mm, approx. mm, approx. mm, approx. mm, approx. mm, approx. rpm kg, approx. trailed II 3,00 3,00 6,20 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 1300–2000 1400–1800 1400–1800 1600–2200 – 1600–2500 1600–2500 3100 – 900 x 2200 900 x 2200 – 900 or 770 1033 1033 1033 11,5/80–15,3 8 PR 11,5/80–15,3 8 PR 350/50–16 12 PR 11,5/80–15,3 8 PR or 350/50 –16 12 PR 1750 1900 2050/2150 1900 1 x single-acting 1 x single-acting 2 x single-acting 1 x single-acting + 1 x double-acting + 1 x double-acting + 1 x double-acting + 1 x double-acting Options: Crop spreader High-cut skids Wear skids Reversing valve 왌 왌 왌 – – 왌 왌 – 왌/– 왌 왌 왌 (1 x single-acting + 1 x double-acting) 쐌 standard 왌 option The specified swath widths will depend on prevailing crop conditions. * Not available in the UK (1) CLAAS continually strives to adapt its products to meet practical requirements. Thus, all products are subject to changes. All descriptions and specifications in this brochure should be considered as approximate and may include optional equipment that is not part of the standard specifications. This brochure is designed for worldwide use. Please refer to your nearest CLAAS dealer and their price list for local specification details. Some protective panels may have been removed for photographic purposes in order to present the function clearly. Never remove these protective panels yourself, to avoid any risk of danger. In this respect, please refer to the relevant instructions in the operator's manual. 50 – 왌 왌 – Central drawbar DISCO 3100 TC DISCO 3100 TRC* DISCO 3500 TC DISCO 3500 TRC* trailed II 3,00 3,00 7,34 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 trailed II 3,00 3,00 7,34 40 1000 7 2 115 x 48 x 4 쐌 40 30–70 + 30 trailed II 3,40 3,40 8,34 40 1000 8 2 115 x 48 x 4 쐌 40 30–70 + 30 trailed II 3,40 3,40 8,34 40 1000 8 2 115 x 48 x 4 쐌 40 30–70 + 30 1300–2000 – – 1080/900 350/50-16 12 PR 1300–2000 – – 1050 350/50-16 12 PR 1700–2400 – – 1080/900 350/50-16 12 PR 1700–2400 – – 1050 350/50-16 12 PR 2220 2320 2290 2390 1 x single-acting 1 x single-acting 1 x single-acting 1 x single-acting + 1 x double-acting + 1 x double-acting + 1 x double-acting + 1 x double-acting (+ 1 x single-acting) (+ 1 x single-acting) (+ 1 x single-acting) (+ 1 x single-acting) 왌 왌 왌 – – 왌 왌 – 왌 왌 왌 – – 왌 왌 – DISCO Rear mowers Front mowers DISCO Large-scale mowers Front mowers The cut is everything. In the brochure "The cut is everything.", you will find the DISCO 2650, 3050, 3450, 2650 C, 3050 C and 2650 RC rear mowers, which are installed on the side, the DISCO 2700, 3100, 3500, 3900, 2700 C, 3100 C, 3100 RC and 3500 C CONTOUR, which are suspended from the centre, as well as the DISCO 3100 F PROFIL, 3050 FC, 3100 FC PROFIL and 3100 FRC PROFIL front mowers. Full width mowing quality. In the brochure "Full width mowing quality.", you'll find the DISCO 8550 C, 8550 AS large-scale mowers, the new DISCO 8400 and 9100 CONTOUR, as well as the DISCO 9300 C DUO, the DISCO 3100 F PROFIL front mowers, 3050 FC and 3100 FC PROFIL, as well as the COUGAR 1400 self-propelled mower. Specifications 51 CLAAS KGaA mbH Postfach 1163 33426 Harsewinkel Deutschland Tel. +49 (0)52 47 12-0 claas.com 09/08 (Be) englisch 20/000 256 134.1