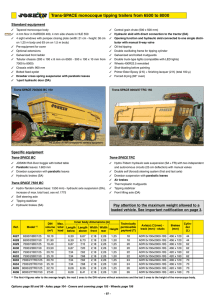

Strength of Experience!

advertisement