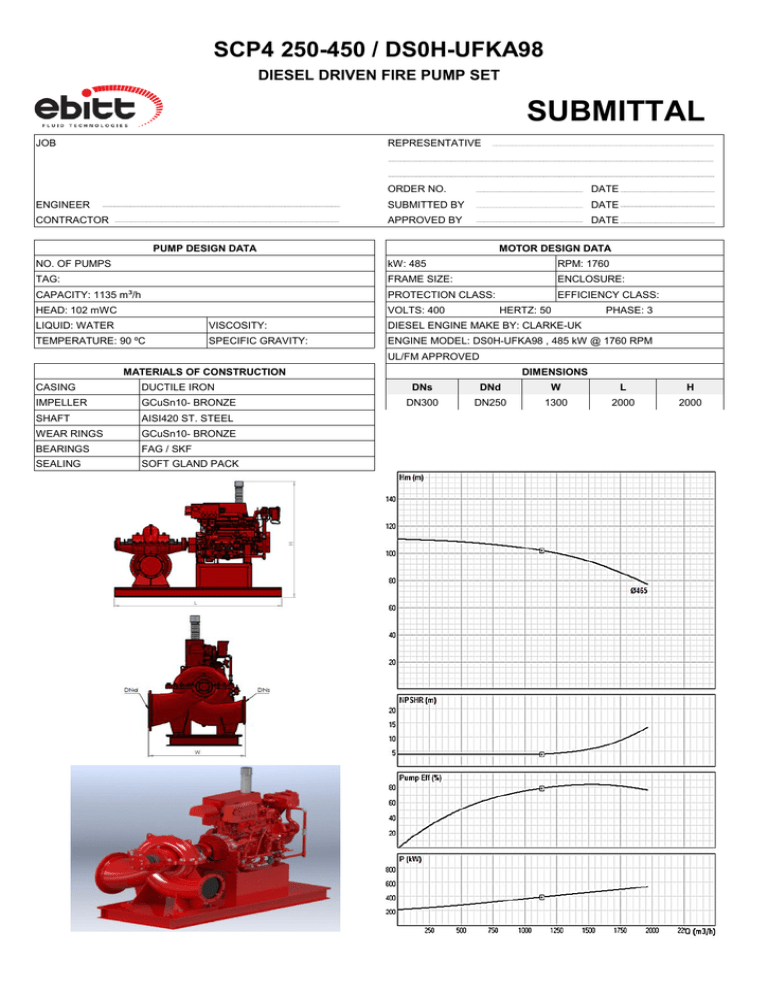

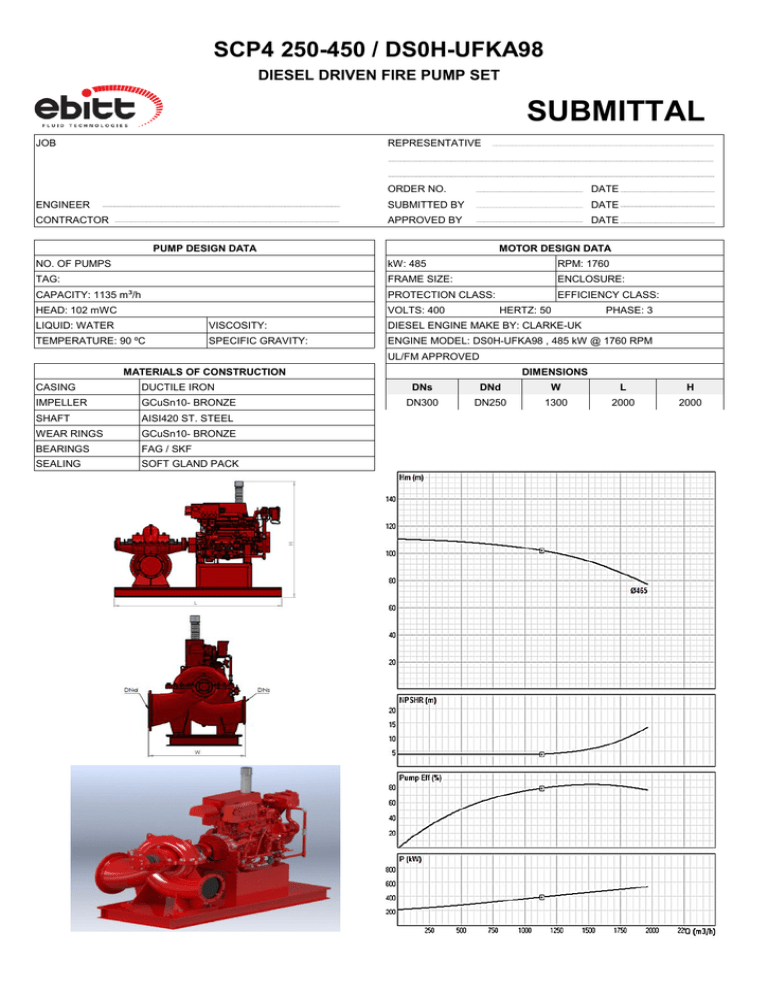

SCP4 250-450 / DS0H-UFKA98

DIESEL DRIVEN FIRE PUMP SET

SUBMITTAL

JOB

REPRESENTATIVE

ORDER NO.

DATE

ENGINEER

SUBMITTED BY

DATE

CONTRACTOR

APPROVED BY

DATE

PUMP DESIGN DATA

MOTOR DESIGN DATA

NO. OF PUMPS

kW: 485

RPM: 1760

TAG:

FRAME SIZE:

ENCLOSURE:

CAPACITY: 1135 m³/h

PROTECTION CLASS:

HEAD: 102 mWC

VOLTS: 400

EFFICIENCY CLASS:

HERTZ: 50

PHASE: 3

LIQUID: WATER

VISCOSITY:

DIESEL ENGINE MAKE BY: CLARKE-UK

TEMPERATURE: 90 ºC

SPECIFIC GRAVITY:

ENGINE MODEL: DS0H-UFKA98 , 485 kW @ 1760 RPM

UL/FM APPROVED

MATERIALS OF CONSTRUCTION

CASING

DUCTILE IRON

IMPELLER

GCuSn10- BRONZE

SHAFT

AISI420 ST. STEEL

WEAR RINGS

GCuSn10- BRONZE

BEARINGS

FAG / SKF

SEALING

SOFT GLAND PACK

DIMENSIONS

DNs

DNd

W

L

H

DN300

DN250

1300

2000

2000

SCP4 250-450 / DS0H-UFKA98

Capacity

1135,0 m³/h Impeller diameter

465 mm

Head

102,0 mWC Efficiency

78,7%

Density

1,00 g/cm³

400,4 kW

Shut-off head

110,5 mWC Motor power

485 kW

NPSH required

4,4 mWC

1760 rpm

Power required

Speed

MODELS

®

DS0H-UFKAN0

DS0H-UFKA68

FIRE PUMP ENGINES

DS0H-UFKA60 DS0H-UFKA92

DS0H-UFKA98 DS0H-UFKAM0

FM-UL-cUL APPROVED RATINGS kW/BHP

DS0H

MODEL

RATED SPEED

1470

DS0H-UFKAN0

DS0H-UFKA68

389.5

522

1760

404

542

438

587

650

485

520

388

DS0H UFKA60

DS0H-UFKA60

DS0H-UFKA98

DS0H-UFKA92

DS0H-UFKAM0

2100

2350

429

575

458

614

722

538.5

530

395

452

606

All Models are available for Export

= Non-Emissionized

SPECIFICATIONS

DS0H MODELS

UFKAN0

ITEM

UFKA68

UFKA60

Number of Cylinders

UFKA98

UFKAM0

10

Aspiration

TRWA

Rotation*

CW

Overall Dimensions – mm (in.)

1947 (76.7) H x 1568 (61.7) L x 1369 (53.9) W

Crankshaft Centerline Height – mm ( in.)

597 (23.5)

Weight – kg (lb)

1450 (3200)

Compression Ratio

14.6:1

Displacement – l (cu. in.)

18.3 (1115)

g Type

yp

Engine

4 Cycle,

y , 2 Valves p

per Cylinder,

y

, Vee

Bore & Stroke – mm (in.)

128 x 142 (5.04 x 5.59)

Installation Drawing

D665

Wiring Diagram AC

C07651

Wiring Diagram DC

C071842

Speed Interpolation

None

Abbreviations:

UFKA92

CW – Clockwise TRWA – Turbocharged with Raw Water Aftercooling

L – Length

W – Width

H - Height

*Rotation viewed from Heat Exchanger / Front of engine

CERTIFIED POWER RATING

ENGINE RATINGS BASELINES

• Each engine is factory tested to verify power and performance.

• Engines are to be used for stationary emergency standby fire pump service only. Engines

are to be tested in accordance with NFPA 25.

• Engines are rated at standard SAE conditions of 29.61 in. (752.1 mm) Hg barometer and

77°F (25°C) inlet air temperature [approximates 300 ft. (91.4 m) above sea level] by the

testing laboratory (see SAE Standard J 1349).

1349)

• A deduction of 3 percent from engine horsepower rating at standard SAE conditions shall

be made for diesel engines for each 1000 ft. (305 m) altitude above 300 ft. (91.4 m)

FM

• A deduction of 1 percent from engine horsepower rating as corrected to standard SAE

conditions shall be made for diesel engines for every 10°F (5.6°C) above 77°F (25°C)

ambient temperature.

Page 1 of 9

MODELS

®

DS0H-UFKAN0

DS0H-UFKA68

FIRE PUMP ENGINES

DS0H-UFKA60 DS0H-UFKA92

DS0H-UFKA98 DS0H-UFKAM0

ENGINE EQUIPMENT

EQUIPMENT

STANDARD

OPTIONAL

Air Cleaner

Direct Mounted, Washable, Indoor Service with Drip Shield

Disposable, Drip Proof, Indoor Service Outdoor Type, Single or

Two Stage (Cyclonic)

Alarms

Overspeed Alarm & Shutdown, Low Oil Pressure, Low & High

Coolant Termperature, High Raw Water Flow, High Raw Water

Temperature

Low Coolant Level, Low Oil Level, Oil Filter Differential Pressure,

Fuel Filter Differential Pressure, Air Filter Restriction

Alternator

24V-DC, 45 Amps with Dual (2) V-Belt Drive with Guard

Coupling

Bare Flywheel

Non-Listed SC2160A Driveshaft; Vertical Turbine Drivedisc

E i Heater

Engine

H

230V AC 2500

230V-AC,

2 00 Watt

W

11 V AC 2500

115V-AC,

2 00 Watt

W

Exhaust Flex Connection

SS Flex, 150# Flange Connection, 5”

SS Flex, 150# Flange Connection, 6”

Exhaust Protection

Blankets

Flywheel Housing

SAE #1

Flywheel Power Take Off

14.0” Industrial Flywheel Connection

Fuel Connections

Fire Resistant, Flexible, USA Coast Guard Approved, Supply and

Return Lines

Fuel Filter

Primary and Secondary

Fuel Injection System

Direct Injection,

Injection Inline Pump

Fuel Solenoid

24V-DC Energized to Stop

Governor, Speed

Variable Speed, Mechanical

Heat Exchanger

Tube and Shell Type, 60 PSI (4 BAR), NPT(F) Connections – Sea

Water Compatible

Instrument Panel

Tachometer, Hourmeter, Water Temperature, Oil Pressure and

Two (2) Voltmeters, Front Opening

Junction Box

Integral with Instrument Panel; For DC Wiring Interconnection to

Engine

g Controller

Lube Oil Cooler

Engine Water Cooled, Plate Type

Lube Oil Filter

Full Flow with By-Pass Valve

Lube Oil Pump

Gear Driven, Gear Type

Manual Start Control

On Instrument Panel with Control Position Warning Light

Overspeed Control

Electronic with Reset and Test on Instrument Panel

Raw Water Cooling Loop – w/

Alarms

Galvanized

Sea Water, All 316 SS, High Pressure

Raw Water Cooling Loop

Solenoid Operation

Automatic from Fire Pump Controller and from Engine Instrument

Panel (for Horizontal Fire Pump Applications)

Not Supplied (for Vertical Turbine Fire Pump Applications)

Run – Stop Control

On Instrument Panel with Control Position Warning Light

Starters

One (1) 24V-DC with Two (2) Start Contactors

Throttle Control

Adjustable Speed Control, Tamper Proof

Water Pump

Centrifugal Type, Dual (2) V-Belt Drive with Guard

Abbreviations:

DC – Direct Current, AC – Alternating Current, SAE – Society of Automotive Engineers, NPT(F) – National Pipe Tapered Thread (Female), SS – Stainless Steel

®

UK, Ltd.

Grange Works, Lomond Rd., Coatbridge, ML5-2NN

United Kingdom

Tel +44-1236-429946

Fax +44-1236-427274

www.clarkefire.com

U131536 revE

3JUN15

Fire Protection Products, Inc.

100 Progress Place, Cincinnati, Ohio 45246

United States of America

Tel +1-513-475-(FIRE)3473 Fax +1-513-771-8930

www.clarkefire.com

Specifications and information contained in this brochure subject to change without notice.

Page 2 of 9

.

FIRE PUMP MODEL: DS0H-UFKA98

Heat Exchanger Cooled/Turbocharged

Raw Water Charge Cooling

18.3 Liter

486.5

486

485.5

485

485

484.5

484

Non Emissionized

Ref: Engine Emission Label

483.5

1758.5

1759

1759.5

RESTRICTED:

1760

1760.5

ENGINE SPEED - RPM

1761

1761.5

USE ONLY FOR STAND-BY FIRE PUMP APPLICATIONS

ENGINE PERFORMANCE:

STANDARD CONDITIONS: (SAE J1349, ISO 3046)

77°F (25°C) AIR INLET TEMPERATURE

29.61 IN. (751.1MM) HG BAROMETRIC PRESSURE

#2 DIESEL FUEL (SEE C13940)

KEVIN KUNKLER 28AUG13

NAMEPLATE kW (MAXIMUM PUMP LOAD)

THIS DRAWING AND THE INFORMATION HEREIN ARE OUR

PROPERTY AND MAY BE USED BY

OTHER ONLY AS AUTHORIZED BY

US. UNPUBLISHED -- ALL RIGHTS

RESERVED UNDER THE

COPYRIGHT LAWS.

Page 3 of 9

CREATED

DATE CREATED

08/28/13

ENGINE MODEL DS0H-UFKA98

DRAWING NO.

U131591

REV

A

DS0H-UFKA98

INSTALLATION & OPERATION DATA (I&O Data)

UK Produced

Basic Engine Description

Engine Manufacturer

Ignition Type

Number of Cylinders

Bore and Stroke - mm (in)

Displacement - L (in³)

Compression Ratio

Valves per cylinder

Intake

Exhaust

Combustion System

Engine Type

Fuel Management Control

Firing Order (CW Rotation)

Aspiration

Charge Air Cooling Type

Rotation, viewed from front of engine, Clockwise (CW)

Engine Crankcase Vent System

Installation Drawing

Weight - kg (lb)

180 Series

Compression (Diesel)

10

128 (5.04) X 142 (5.59)

18.3 (1115)

14.6:1

1

1

Direct Injection

Vee, 4 stroke cycle

Mechanical, Inline Pump

1-6-5-10-2-7-8-3-4-9

Twin Turbocharged

Raw Water Cooled

Standard

Closed

D665

1450 (3200)

Power Rating

Nameplate Power - kW (HP)

1760

485 (650)

Cooling System - [C051529]

Engine Coolant Heat - kW (Btu/sec)

Engine Radiated Heat - kW (Btu/sec)

Heat Exchanger Minimum Flow

15°C (60°F) Raw H20 - L/min (gal/min)

37°C (100°F) Raw H20 - L/min (gal/min)

Heat Exchanger Maximum Cooling Raw Water

Inlet Pressure - bar (psi)

Flow - L/min (gal/min)

Typical Engine H20 Operating Temp - °C (°F)[1]

Thermostat

Start to Open - °C (°F)

Fully Opened - °C (°F)

Engine Coolant Capacity - L (qt)

Coolant Pressure Cap - kPa (lb/in²)

Maximum Engine Coolant Temperature - °C (°F)

Minimum Engine Coolant Temperature - °C (°F)

High Coolant Temp Alarm Switch - °C (°F)

1760

260 (246)

72.8 (69)

94.6 (25)

114 (30)

4.1 (60)

303 (80)

76.7 (170) - 93.3 (200)

71.1 (160)

85 (185)

31.2 (33)

48.3 (7)

96.1 (205)

71.1 (160)

96.1 (205)

Electric System - DC

System Voltage (Nominal)

Battery Capacity for Ambients Above 32°F (0°C)

Voltage (Nominal)

Qty. Per Battery Bank

SAE size per J537

CCA @ 0°F (-18°C)

Reserve Capacity - Minutes

Battery Cable Circuit, Max Resistance - ohm

Battery Cable Minimum Size

0-3.1m Circuit Length [2]

3.1m-4.1m Circuit Length [2]

4.1m-5.1m Circuit Length [2]

Charging Alternator Maximum Output - Amp,

Starter Cranking Amps, Rolling - @60°F (15°C)

Standard

24

12

2

8D

1400

430

0.0012

00

000

0000

45

315

[C07633]

[65.26101-7153C]

[65.26201-7074D]

NOTE: This engine is intended for indoor installation or in a weatherproof enclosure. 1Engine H2O temperature is

dependent on raw water temperature and flow. 2Positive and Negative Cables Combined Length.

Page 4 of 9

Page 1 of 2

DS0H-UFKA98

INSTALLATION & OPERATION DATA (I&O Data)

UK Produced

Exhaust System (dual exhaust outlets)

Exhaust Flow - m³/min (ft.³/min)[3]

Exhaust Temperature - °C (°F)

Maximum Allowable Back Pressure - kPa (in H20)

Minimum Exhaust Pipe Dia. - mm (in) [4] (quantity 2)

1760

86.9 (3069)

518 (964)

10 (40)

127 (5)

Fuel System

1760

Fuel Consumption - L/hr (gal/hr)

115 (30.3)

Fuel Pressure - kPa (lb/in²)

117 (17) - 179 (26)

Minimum Line Size - Supply - in.

.75 Schedule 40 Steel Pipe

Pipe Outer Diameter - mm (in)

26.7 (1.05)

Minimum Line Size - Return - in.

.50 Schedule 40 Steel Pipe

Pipe Outer Diameter - mm (in)

21.5 (0.848)

Maximum Allowable Fuel Pump Suction Lift

with clean Filter - mH20 (in H20)

1.4 (54)

Maximum Allowable Fuel Head above Fuel pump, Supply or Return - m (ft) 4.9 (16)

Fuel Filter Micron Size

5

Heater System

Engine Coolant Heater

Wattage (Nominal)

Voltage - AC, 1 Phase

Part Number

Air System

Combustion Air Flow - m³/min (ft.³/min)

Air Cleaner

Part Number

Type

Cleaning method

Air Intake Restriction Maximum Limit

Dirty Air Cleaner - kPa (in H20)

Clean Air Cleaner - kPa (in H20)

Maximum Allowable Temperature (Air To Engine Inlet) - °C (°F)[5]

Standard

Optional

2500

230 (+5%, -10%)

[C122194]

2500

115 (+5%, -10%)

[C122190]

1760

53.3 (1882)

Standard

[C03244 Qty (2)]

Indoor Service Only,

with Shield

Washable

Optional

[C03330 Qty 2]

Canister,

Single-Stage

Disposable

3.5 (14)

1.7 (7)

54.4 (130)

Lubrication System

Oil Pressure - normal - kPa (lb/in²)

Low Oil Pressure Alarm Switch - kPa (lb/in²)

In Pan Oil Temperature - °C (°F)

Total Oil Capacity with Filter - L (qt)

365 (53) - 614 (89)

78.6 (11.4)

68.9 (156) - 110 (230)

35 (37)

Lube Oil Heater

Wattage (Nominal)

Voltage

Part Number

Optional

300

120V (+5%, -10%)

C04559

3.5 (14)

1.7 (7)

Optional

300

240V (+5%, -10%)

C04560

Performance

1760

BMEP - kPa (lb/in²)

1810 (262)

Piston Speed - m/min (ft/min)

500 (1640)

Mechanical Noise - dB(A) @ 1m

Consult Factory

Power Curve

U131591

3Engine has dual exhaust outlets. Combined total exhaust flow from both outlets is given. 4Based on Nominal System. Back pressure flow

analysis must be done to assure maximum allowable back pressure is not exceeded. (Note: minimum exhaust Pipe diameter is based on: 15 feet of

pipe, one 90° elbow, and a silencer pressure drop no greater than one half of the maximum allowable back pressure.) 5Review for horsepower

derate if ambient air entering engine exceeds 77°F (25°C). [ ] indicates component reference part number.

Page 2 of 2

U131592 Rev D

DP 25MAR15

Page 5 of 9

CLARKE

Fire Protection Products

DR8 & DS0

ENGINE MATERIALS AND CONSTRUCTION

Air Cleaner

Type………………………….

Indoor Usage Only

Oiled Fabric Pleats

Material……..…..…….………. Surgical Cotton

Aluminum Mesh

Air Cleaner - Optional

Type………………………….

Canister

Material……………………… Pleated Paper

Housing………………..……… Enclosed

Camshaft

Material…………...….……..… Chromium Molybdenum Steel

Nitride Hardening

Location…………...….……..… In Block

Drive……………….………..… Gear

Type of Cam…………..…......…Ground

Charge Air Cooler

Type………………………….. Raw Water Cooled - All

Materials (in contact with raw water)

Tubes………………………….. 90/10 CU/NI

Tube Header Plate…………… Brass (ASTM C4621)

Inlet/Outlet Covers………………

Bronze (BC6)

Plumbing…………………………Galvanized Steel Pipe

ISO 15540 Hose (Standard)

Other Materials (Optional)

Coolant Pump

Type……… .…………………… Centrifugal

Drive……… ……………………. Belt

Coolant Thermostat

Type………………………………Full Blocking

3

Qty…………………………………

Cooling Loop (Galvanized)

Tees, Elbows, Pipe………………

Galvanized Steel

Ball Valves………………………Brass ASTM B 124

Solenoid Valve………………… Brass

Bronze

Pressure Regulator………………

Strainer……………………………Cast Iron (1/2"- 1" Loops)

or Bronze (1.25" - 2" Loops)

Cooling Loop (Sea Water)

Tees, Elbows, Pipe………………

316 Stainless Steel

Ball Valves………………………316 Stainless Steel

Solenoid Valve………………… 316 Stainless Steel

Pressure Regulator/Strainer……Cast Brass ASTM B176 C87800

Cooling Loop (Sea Water)

Tees, Elbows, Pipe………………

316 Stainless Steel

Ball Valves………………………316 Stainless Steel

Solenoid Valve………………… 316 Stainless Steel

Pressure Regulator/Strainer……316 Stainless Steel

Connecting Rod

Type………………………………One Piece, Diagonally Split

Material……………………………

Die Forged Steel

Crank Pin Bearings

Type………………………………One Piece

Material………………………… Steel backed, Lead Bronze

Crankshaft

Material………………………… Forged Steel

Type of Balance…………………Dynamical, Screwed on Balanced

Weights

Cylinder Block

Type………………………………One Piece w/ Non-Siamese Cyl.

Material………………………… Cast Iron

Cylinder Head

Type……..

………………… Individual, 2 Valve

Material……………………… Cast Iron

Cylinder Liners

Type…………..………………Centrifugal Cast, Wet Liner

Material…………………….…Alloy Iron Plateau, Honed

(Effective Dec 2013)

Heat Exchanger - Standard (Sea Water Compatible)

Type…………………………

Tube & Shell

Materials (in contact with raw water)

Tubes…...…………………. Copper

Shell……………………….. Copper

Headers………….………… Copper

Electrode…………………… Zinc

Injection Pump

Type…………………………

Drive…………………………

In Line

Gear

Lubrication Cooler

Type…………………………

Plate

Lubrication Pump

Type…………………………

Drive…………………………

Gear

Gear

Main Bearings

Type..……………………….

Material……………………..

Precision Half Shells

Steel Backed, Lead Bronze

Piston

Type and Material………….

Cooling………………………

Aluminum Alloy with Reinforced/Top Groove

Oil Jet Spray

Piston Pin

Type ……………………….

Full Floating

Piston Rings

Number/Piston……………..

Top…………………………..

Second ……………………

Third…………………………

3

Keystone Barrel FacedHard Chrome Coated

Tapered Cast Iron

Hard Chrome Coated

Double Rail Type

with Expander Spring

C134774 revC

Page 6 of 9

Page 7 of 9

Page 8 of 9

Page 9 of 9

DIESEL Engine Fire Pump Controllers

Features

FD120 Diesel Engine Controllers

Engine Run Relay

An external computer can be communicate with

the Diesel Plus controller via Ethernet. An

embedded web page will display the controller's

current status, as well as display all current

readings, set points and history.

The Power I/O Board houses a 10 Amp engine run

relay which is used for alarm purposes, or to power

external louvers.

The Diesel Plus fire pump controllers

communicate to systems using the Regular

level of Modbus (includes both RTU and ASCII

transmission modes). Communication settings

are user configurable through the Diesel Plus

configuration menu.

Product Description

Field Connections

The DIESEL Plus Fire Pump Controllers from

Eaton Corporation are designed to control

and monitor 12 or 24 volt, diesel fire pump

engines and are among the most technically

advanced diesel engine controllers available.

Inputs

The use of an embedded web page for

retrieving diagnostics and history reports,

along with USB and Ethernet communication

ports for downloading data, make the Diesel

Plus Series of controllers easy to

troubleshoot and maintain. As well, critical

information can be easily accessed and used

for report generation and analysis, which aids

in providing effective, reliable fire protection.

Product Features

Communication

Embedded Web Page

The embedded web pages allow the user to

view the current status of the controller as

well as all amperage readings, set points,

diagnostics and history. An external computer

connected via the Ethernet port is used to

access the pages. The specific data required

can be downloaded for reference purposes.

Communication Types

Canbus

The controller can communicate with the

diesel engine electronic control module

(ECM) and log key engine data via the

Canbus (SAE J1939) engine port.

March 2010

Ethernet

Modbus

They are an enhanced version of the original

microprocessor-based, FD100 Series of

diesel engine controllers. Programming is

straightforward due to the use of the core

firmware and menu structure utilized in the

LMR Plus Series of electric controllers.

1-1

Standard Inputs

·

Deluge Valve

·

Low Suction

·

Interlock On

·

Pump Start

·

Low Fuel

·

Programmable Inputs (10)

Common Alarm Relay

The FD120 controller has a common alarm relay

which energizes whenever there are any alarm

conditions present. This relay is energized under

normal conditions and has LED status indication.

Alarm Relay Rating

All alarm relays are rated 10 amps, 220Vac, 1/3HP

resistive load only.

Programmable Outputs

Up to 10 additional, programmable outputs (two

standard; eight via optional output boards) can be

programmed to indicate up to 45 output conditions.

They can be programmed for fail safe and latch

until reset by the user. All optional inputs, outputs

and LED's can be linked, as required. They can

also be programmed with time delay functions. As

well, six optional alarm LED's can be programmed

for up to 28 alarm conditions.

Programmable Inputs

Up to 10 additional, programmable inputs can

be programmed to indicate up to 13 different

types of inputs. They can be programmed to

energize the common alarm output, link to

relays and optional LED's and latch until reset

by the user.

All optional inputs, outputs and LED's can be

linked, as required. They can also be

programmed with time delay functions.

4-20mA Analog Input

External devices that provide a 4-20mA input

can be installed in the Diesel Plus controller.

These may include flow meters or a second

transducer that can be used as for monitoring

functions such as low suction, or for backup

purposes.

Outputs

Standard Output Relays

All standard output relays are 8 amp, DPDT.

·

Future # 1

·

Future # 2

·

Low Fuel

·

Auto Mode

·

Common Alarm

Optional Output Relays

There is provision to add up to eight additional

relay outputs, via four optional relay output

boards which mount in a snap-on configuration.

Each board contains a maximum of 2 additional

relays.

USB

The USB port is used to download the

controller message history, statistics,

diagnostics, status and configuration data to

a USB disk drive. The USB port can also be

used to upload custom messages, additional

languages, and update the microprocessor

firmware.

Power / Voltage

Universal Voltage Supply

The controller can be powered with supply voltages

from 90Vac to 240Vac by connecting to the three

input terminals L,N,G located on the bottom left of

the engine board.

Dual Output

12 or 24Vdc output is selectable via a DIP Switch

located on the battery chargers.

Note: Each controller is factory set for 12Vdc. If

24Vdc is required from the factory, it should be

noted on the ordering information.

Line Filter

A line filter incorporated onto the engine board, is

used to reduce/eliminate external incoming voltage

transients.

AC Power Disconnect

A breaker located inside the controller on the

Engine Board, is used to switch on and off AC

power to the unit. It will illuminate when energized.

DC Power Disconnect

The engine board houses two on-board circuit

breakers used to switch on or off DC power from

the batteries.

Each breaker has an LED mounted on the engine

board that illuminates when the breaker is

energized.

For more information visit: www.chfire.com

BR05805067K/C

1-2

DIESEL Engine Fire Pump Controllers

Features

FD120 Diesel Engine Controllers

Alarm and Status Indication

Accessibility

All alarm and status LED's as well as the

LCD Display and programming buttons are

accessible from the front of the controller

through a panel cutout.

March 2010

Diagnostics

Up to ten diagnostic points are recorded that

can be used to help in troubleshooting issues

with the controller. The diagnostics can be

viewed on the main display, saved to a USB

disk drive, or viewed on the embedded

webpage.

Message History

LCD Display

The Controller Display Board contains a 4

Line by 40 Characters wide, backlit, LCD

display which is capable of generating

multiple languages. The display will show the

current system pressure, time and date,

charger output voltage and any custom

messages, alarms or timer values.

Alarm & Status LED's

Status LED's

The controller is supplied with ten (10) green

status LED's for the following:

ENGINE RUN

REMOTE START

INTERLOCK ON

DELUGE VALVE

Six Programmable LED's - (numbered 1

through 6)

Up to10k alarm/status messages can be stored

in the controller memory. They can be viewed

on the main display, saved to a USB disk drive,

or viewed on the embedded webpage.

DC Fail

A visual indication and audible alarm is provided

to indicate DC power loss due to one or both

batteries being disconnected from the controller.

This indication will also be provided if the

controller is not operating due to an electronic

board failure.

Technical Specifications

Supply Voltage: 90-240Vac

Output Voltage: 12-24Vdc

Hertz: 50/60 Hz

Enclosure: Standard NEMA 2

Optional NEMA 3R, 4, 4X, 12

Temperature: 4 to +40 deg. C; 39 to +104 deg. F

Alarm Relays: 24Vdc, DPDT 8amp

Engine Run Relay: 24Vdc, DPDT 10amp

Crank / Fuel Stop Relays: 24Vdc, SPDT

Pressure Transducer: 600psi

Immunity Compliance: Environment A

Emission Compliance: Environment B

Battery Chargers

·

Mode: Switching

·

Dual 10 Amp

·

Communication to Power I/O Board

·

Diagnostics Recording

·

Lead Acid or NiCad

·

Three Step Charge

·

Internal Temperature Monitoring

·

Universal Voltage Input

·

Selectable Dual Voltage Output

Programmable Features

Alarm LED's

The controller is supplied with fourteen (14)

red alarm LED's for the following:

BATTERY #1 FAILURE

CHARGER # 1 FAILURE

BATTERY #2 FAILURE

CHARGER # 2 FAILURE

LOW PRESSURE

SYSTEM OVER PRESSURE

LOW SUCTION PRESSURE

LOW FUEL

FAIL TO START

HIGH ENGINE TEMP

LOW OIL PRESSURE

ENGINE OVER SPEED

ECM SELECTOR IN ALT POSITION

FUEL INJECTION MALFUNCTION

Statistics

Up to 27 of statistical points are recorded to

provide a quick review of how the system

has been operating. The statistics can be

viewed on the main display, saved to a USB

disk drive, or viewed on the embedded

webpage.

BR05805067K/C

·

Languages

(English, French, Spanish Standard.

Other languages are available. Consult

factory.)

·

Date and Time

·

Pressure Start and Stop Points

·

Low and High Pressure Alarms

·

Stop Mode

·

Low Suction Shutdown

·

Pressure Recording Parameters

·

Run Period Timer

·

Weekly Test Timer

·

Sequential Start Timer

·

AC Failure Alarm

·

AC Fail to Start

Enclosures

Standards & Certification

The FD120 Diesel Engine Fire Pump Controllers

meet or exceed the requirements of Underwriters

Laboratories (UL 218), Underwriters Laboratories

of Canada, Factory Mutual (FM1321 / 1323), the

Canadian Standards Association, New York City

building code, are built to NFPA 20 standards and

meet CE mark requirements.

Ratings

All FD120 controllers come standard with

NEMA 2 enclosures unless otherwise ordered.

Available options include: NEMA 3R, 4, 4X, 12.

Reduced Size

A streamlined internal design has allowed the

overall size of the DIESEL Plus controllers to be

reduced from previous models. See

dimensional drawings in this document.

For more information visit: www.chfire.com

N. Y. C.

APPROVED

Diesel Engine Controllers

Main Display

Main Display - Diesel Plus Engine Controller

Main Display

ENGINE RUN

REMOTE START

DELUGE VALVE

INTERLOCK ON

SPEED SWITCH FAULT

ECM SELECTOR IN ALT POSITION

LOW PRESSURE

FAIL TO START

FUEL INJECTION MALFUNCTION

LOW FUEL

CHARGER # 1 FAILURE

CHARGER # 2 FAILURE

SILENCE

ALARM

BATTERY # 1 FAILURE

BATTERY # 2 FAILURE

DieselLUS

P

LOW SUCTION PRESSURE

LOW OIL PRESSURE

ENGINE OVERSPEED

HIGH ENGINE TEMPERATURE

ENGINE

TEST

DATA

PRINT

MENU

LAMP

TEST

RESET

SAVE/EXIT

ACK.

4A55737H01

NOTES:

1. Refer to the DIESEL Plus technical manual for details and

setup information, as well as programming and custom

labeling for the Programmable LED’s # 1 through # 6.

N. Y. C.

APPROVED

MD05805151K

For more information visit: www.chfire.com

Diesel Engine Fire Pump Controllers

Electrical Wiring Schematic

March 2010

FD120 Diesel Plus Engine Controllers

Electrical Wiring Schematic

INPUT #10

INPUT #9

INPUT #8

INPUT #7

INPUT #6

INPUT #5

INPUT #4

INPUT #3

INPUT #2

INPUT #1

INTERLOCK ON

LOW FUEL

LOW SUCTION

PUMP START

DELUGE VALVE (1)

REMOTE START

NOTES:

1. DELUGE VALVE INPUT NORMALLY CLOSED.

REMOVE JUMPER IF USED.

2. ALL RELAY CONTACTS ARE SHOWN IN NO POWER

CONDITION.

3. ALARM CONTACTS RATED FOR 8A/250VAC. ENGINE

RUN CONTACTS RATED 10A/250VAC.

CUSTOMER INPUTS

OPTION RELAY #1

(2 SETS FORM-C)

ENGINE RUN

OPTION RELAY #2

(2 SETS FORM-C)

ENGINE RUN

FUTURE #1

OPTION RELAY #3

(2 SETS FORM-C)

FUTURE #1

OPTION RELAY #4

(2 SETS FORM-C)

ALARM CONTACTS

FUTURE #2

FUTURE #2

LOW FUEL

LOW FUEL

OPTION RELAY #5

(2 SETS FORM-C)

OPTION RELAY #6

(2 SETS FORM-C)

OPTION RELAY #7

AUTO MODE

(2 SETS FORM-C)

AUTO MODE

OPTION RELAY #8

(2 SETS FORM-C)

COMMON ALARM

(NORMALLY ENERGIZED)

AUX. ANALOG INPUT (4-20MA)

COMMON ALARM

(NORMALLY ENERGIZED)

90-240VAC

POWER

BATTERY #1 INPUT(+)

BATTERY #2 INPUT(+)

BATTERY #1 CRANK

BATTERY #2 CRANK

BATTERIES (-)

BATTERIES (-)

ENGINE CONNECTIONS

FUEL & WATER SOLENOID VALVE

ENGINE RUN SW.

OVERSPEED SW.

OIL PRESSURE SW.

ENGINE WATER TEMP. SW.

FUEL SOLENOID

ECM IN ALTERNATE

FUEL INJECTOR FAIL

N. Y. C.

APPROVED

ES05805162K

For more information visit: www.chfire.com

Diesel Engine Fire Pump Controllers

Field Connections

FD120 Diesel Plus Engine Controllers

Field Connections

Inputs

Engine Board Terminal Blocks

90-240VAC

POWER

FUEL & WATER SOLENOID VALVE

ENGINE RUN SW.

OVERSPEED SW.

OIL PRESSURE SW.

ENGINE WATER TEMP. SW.

BATTERY #1 INPUT(+)

BATTERY #2 INPUT(+)

BATTERY #1 CRANK

BATTERY #2 CRANK

BATTERIES (-)

BATTERIES (-)

FUEL SOLENOID

ECM IN ALTERNATE

FUEL INJECTOR FAIL

Outputs

ENGINE RUN

LOW FUEL

ENGINE RUN

LOW FUEL

FUTURE #1

AUTO MODE

FUTURE #1

AUTO MODE

FUTURE #2

COMMON ALARM

(NORMALLY ENERGIZED)

FUTURE #2

COMMON ALARM

(NORMALLY ENERGIZED)

Technical Data and Specifications

Line Terminals (Incoming Cables)

Recommended Wire Size

Terminal Number

Distance

I/O Board

Stranded # 14

(1.63 mm)

11, 34-49, 60-95

N. A.

Stranded # 14

(1.63 mm)

Option Board Terminals

N. A.

1-5, 9, 10, 12, 301, 302, L, N, G

N. A.

Engine Board

Stranded # 14

(1.63 mm)

Battery Wire

Stranded # 10

Stranded # 8

(2.59 mm)

(3.26 mm)

6, 8, 11

0 feet to 25 feet (7.62m)

6, 8, 11

25 feet to 50 feet (7.62 - 15.24m)

N. Y. C.

APPROVED

ES05805164K

For more information visit: www.chfire.com

March 2010

Fire Pump Controllers

Technical Data & Specifications

LMR

S

PLU

DieselLUS

P

March 2010

Wire & Cable Conversion Tables

Technical Data and Specifications - LMR Plus Electric Controllers

Line Terminals on Main Isolation Switch (Incoming Cables)

Qty. & Cable Sizes

American Wire Gauge

(AWG / MCM)

Diameter

(mm)

(1)#14-1/0 PER Ø (CU/AL)

(1.63 - 8.25 mm)

(1)#4-1/0 PER Ø (CU)

(5.19 - 11.68 mm)

(1)#3-350MCM PER Ø (CU/AL)

(5.83 - 15.03 mm)

(2)3/0-250MCM PER Ø (CU/AL)

(10.40 - 12.70 mm)

(2)250-350MCM PER Ø (CU/AL)

(12.70 - 15.03 mm)

Service Entrance Ground Lug - Qty. & Cable

American Wire Gauge

(AWG / MCM)

Diameter

(1)#14-2/0 (CU/AL)

(1.63 - 9.27 mm)

(1)#14-2/0 (CU/AL)

(1.63 - 9.27 mm)

(1)#4-350MCM (CU/AL)

(5.19 - 15.03 mm)

(2)#4-350MCM (CU/AL)

(5.19 - 15.03 mm)

(2)#2-600MCM (CU/AL)

(6.54 - 19.67 mm)

(mm)

Load Terminals (To Motor)

Qty. & Cable Sizes

American Wire Gauge

(AWG / MCM)

Diameter

(1)#14-#3 PER Ø (CU)

(1.63 - 5.83 mm)

(1)#4-1/0 PER Ø (CU/AL)

(1.63 - 8.25 mm)

(1)#6-250MCM PER Ø (CU/AL)

(4.11 - 12.70 mm)

(2)1/0-250MCM PER Ø (CU/AL)

(8.25 - 12.70 mm)

(2)2/0-500MCM PER Ø (CU/AL)

(9.27 - 17.96 mm)

(mm)

For Proper Cable Size Refer to National Electrical Code NFPA-70.

Technical Data and Specifications - DIESEL Plus Diesel Engine Controllers

Line Terminals (Incoming Cables)

Recommended Wire Size

Terminal Number

Distance

I/O Board

Stranded # 14

(1.63 mm)

11, 34-49, 60-95

N. A.

Stranded # 14

(1.63 mm)

Option Board Terminals

N. A.

(1.63 mm)

1-5, 9, 10, 12, 301, 302, L, N, G

N. A.

Engine Board

Stranded # 14

Battery Wire

Stranded # 10

(2.59 mm)

6, 8, 11

0 feet to 25 feet (7.62m)

Stranded # 8

(3.26 mm)

6, 8, 11

25 feet to 50 feet (7.62 - 15.24m)

For more information visit: www.chfire.com

SA05805005K

Diesel Engine Fire Pump Controllers

Dimensions

August 2009

FD120 Diesel Plus Engine Controller

Dimensions

Standard Enclosure - Type NEMA 2, 3R, (*4, 4X), 12

19.19 [487]

15.00 [381]

26.72 [679]

7.00 [178]

13.11 [333]

2.00 [51]

34.98 [888]

32.98 [838]

52.98 [1346]

18.00 [457]

10.56 [268]

1 - DIESEL PLUS MEMBRANE

2 - LOCKABLE HANDLE

3 - HAND OFF AUTO SELECTOR SWITCH

4 - STOP BUTTON

5 - CRANK BUTTONS

6 - AUDIBLE ALARM

7 - DC FAIL LIGHT

8 - DISCHARGE 1/4" NPT - FEMALE

9 - SENSING LINE 1/2" NPT - FEMALE

3.42 [87]

5.32 [135]

1.23 [31]

5.75 [146] 8.48 [215]

8.00 [203]

4.85 [123]

1.37 [35]

1.14 [29]

10.29 [261]

3.32 [84]

Dimensions in Inches and [millimeters].

Approx. Weight

Lbs. (Kg)

NOTES:

1. All enclosures finished in FirePump red.

2. Cable Entrance bottom only.

3. Standard Enclosure type NEMA 2, 12

4. Enclosure made from #14 Gauge (0.75) HR Steel.

5. Feet are removable.

105

(48)

* NEMA 4, 4X enclosures are supplied:

With 1/4 Turn latches instead of 3 point handle.

N. Y. C.

APPROVED

MD05805148K/B

For more information visit: www.chfire.com

Diesel Engine Fire Pump Controllers

Dimensions

Fuel Level Switch - FD120 Diesel Plus Engine Controller

December 2009

Fuel Level Switches

3A14119-G01: 16 inch unit

3A14119-G02: 45 inch unit

Dimensions in Inches.

MD05805159K

For more information visit: www.chfire.com

Fire Pump Controllers

Features

1-1

February 2009

Diesel Plus Fire Pump Controllers

Typical Specifications

1. Approvals

A. The Fire Pump Controller shall meet the requirements of the latest edition of NFPA 20 as well as

meeting CE mark requirements. It shall be listed

by [Underwriters Laboratories (UL)] [Underwriters

Laboratories of Canada (ULC)] and approved by

[Factory Mutual Research (FM)] [Canadian Standards Association (CSA)] [New York Department

of Buildings (NYSB)] for fire pump service.

B. The controller shall be [12 volt / 24 volt] negative

ground, for use with Diesel Engine, Model manufactured by _______________.

2. Construction

A. All internal components shall be front mounted

and wired for ease of inspection and maintenance. All relays shall be of the plug-in type,

complete with visual indication to show that the

relays are energized. The controller shall include

an LCD display to indicate battery voltage and

amperes as well as system pressure, in PSI or

Bars.

B. The controller shall have twin battery chargers

meeting NFPA 20 requirements. The battery

chargers shall have reverse polarity protection/

indication and be capable of recharging a completely discharged battery within 24 hours. The

chargers shall auto detect the input voltage of either 120VAC or 220VAC and shall be able to be

programmed for either 12VDC or 24VDC output.

C. The controller shall come standard with a breaker

disconnect on the AC line and for both battery

connections.

3. Pressure Transducer

A. A 4-20mA, solid state pressure transducer shall

be installed in the enclosure bottom to ensure all

plumbing connections are made external to the controller. The controller piping and pressure system

shall be rated for operation in system pressures up to

600 PSI (42.25 kg/cm2) within +/- 1.5% accuracy.

4. Output Relays

A. Two (2) sets of alarm contacts (Form-C) rated at

8A, 220VAC/32VDC, shall be provided for remote

indication of:

1. ENGINE RUN (10A)

2. LOW FUEL

3. AUTO MODE

4. COMMON ALARM

B. Two (2) ‘FUTURE’ relays, each containing two

sets of alarm contacts (Form-C) shall be provided. Relays can be be factory set to indicate a

specific alarm and shall be field programmable /

adjustable to meet future site requirements:

C. The Common Alarm relay shall be energized

under normal conditions.

5. Enclosure

A.

B.

The controller shall be housed in a NEMA Type 2

(IEC IP11) drip-proof, powder baked finish, freestanding enclosure.

Optional Enclosures:

1. NEMA 3R (IEC IP14) rain-tight enclosure.

2. NEMA 4 (IEC IP56) watertight enclosure.

3. NEMA 4X (IEC IP56) watertight 304

stainless steel enclosure.

4. NEMA 4X (IEC IP56) watertight 316

stainless steel enclosure.

5. NEMA 4X (IEC IP56) watertight corrosion

resistant enclosure.

6. NEMA 12 (IEC IP52) dust-tight enclosure.

6. Microprocessor Control

A.

The following parameters shall be programmable

and included as standard:

1. START and STOP PSI points

2. High and Low Pressure Alarm Setpoints

3. STOP MODE: Manual or Auto

4. RUN PERIOD TIMER: 0-60 min

5. AC POWER FAILURE: Enable or Disable

6. SEQUENTIAL START TIMER: 0-300 sec.

7. WEEKLY TEST TIMER

8. PRESSURE DEVIATION: 1-99 PSI

9. LANGUAGE: English/French/Spanish/Other

B. The following visual and audible alarms shall be

provided:

FAIL TO START

HIGH ENGINE TEMP.

LOW OIL PRESSURE

ENGINE RUN

ENGINE OVERSPEED

LOW FUEL

BATTERY #1 FAILURE CHGR #1 FAILURE

BATTERY #2 FAILURE CHGR #2 FAILURE

REMOTE START

DELUGE VALVE

LOW PRESSURE

INTERLOCK ON

SPEED SWITCH FAULT LOW SUCTION

ECM SELECTOR IN ALT POSITION

FUEL INJECTOR MALFUNCTION

STARTER #1 FAILURE

STARTER #2 FAILURE

TRANSDUCER FAILURE

DATA CABLE DISCONNECT

DC FAIL

C. The controller shall have a 4 line by 40 character

LCD display mounted on a panel opening in the

front door. The LCD display shall indicate the following:

1. Main screen displaying system pressure,

Battery #1/#2 voltage and amperage, operation mode, shutdown mode, custom messages, alarms, timers, date, and time.

2. Set point review screen displaying the programmed pressure start and stop points, and

weekly test time.

3. Controller statistics screen, including:

a. Powered Time

For more information visit: www.chfire.com

PS05805003K/F

Fire Pump Controllers

Features

1-2

February 2009

Diesel Plus Fire Pump Controllers

b. Engine Run Time

c. Number of Calls to Start

d. Number of Starts

e. Last Engine Motor Start Time

f. Last Engine Motor Run Time

g. Last Low Pressure Start

h. Minimum Battery #1 Voltage

i.

Maximum Battery #1 Voltage

j. Minimum Battery #2 Voltage

k. Maximum Battery #2 Voltage

l. Minimum System Pressure

m. Maximum System Pressure

n. Last System Startup

o. Last Engine Test

p. Last Low Oil Pressure

q. Last High Engine Temp

r. Last Overspeed

s. Last Fail To Start

t. Last Low Fuel

u. Last Charger Failure

v. Last Battery Failure

w. Last ECM Alarm

4. Controller diagnostics screen, including:

a. Date & Time

b. Firmware Version

c. Shop Order Number

d. Customer Order Number

e. Battery Voltage

f. Internal Board Voltage

g. Transformer Output Voltage

h. Current Transformer Outputs

i. Pressure Transducer Calibrated

Settings

j.

Input Status

k. Relay Status

5. Display last messages screen that will display at least the last 10,000 alarms / messages stored in the controllers' memory.

6. Display up to ten (10) custom messages of

up to 100 characters each, which will continually scroll across the fourth line of the display.

7. Remaining time left on active timers.

D. The controller shall be supplied with eleven (11)

green status LED’s for the following:

1. Engine Run

2. Remote Start

3. Low Pressure

4. Interlock On

5. Deluge Valve

6. Six Programmable LED’s

(numbered 1 through 6)

E. The controller shall be supplied with thirteen (13)

red alarm LED’s to indicate the following:

1. BATTERY #1 FAILURE

2. BATTERY #2 FAILURE

3. CHARGER #1 FAILURE

4. CHARGER #2 FAILURE

5. SPEED SWITCH FAULT

6. ECM SELECTOR IN ALT POSITION

7. FUEL INJECTION MALFUNCTION

8. LOW SUCTION PRESSURE

9. FAIL TO START

10. HIGH ENGINE TEMP.

11. LOW OIL PRESSURE

12. ENGINE OVERSPEED

13. LOW FUEL

F. The microprocessor logic board shall be

equipped with:

1. A J1939 Engine Communication port.

2. A USB port for transference of message history, controller status, diagnostics, and statistics and the ability to update firmware.

3. An Ethernet port for direct connection to a

computer for data transfer.

4. An RS485/RS422 Modbus communication

terminals.

5. RS232 Serial Port

G. The controller shall come complete with an embedded web page which allows viewing of the

controllers' current status, data values, programmed set points, and downloadable history.

H. A Fail-to-Start alarm shall occur if the engine

does not start after the crank cycle.

I. A sequential start timer, weekly test timer and AC

Failure Start timer shall be provided as standard.

J. The controller shall be supplied with interlock and

shutdown circuits as standard. A flashing green

LED shall indicate an interlock on condition.

K. Where shutdown of the pump(s) due to low suction pressure is required, it shall be accomplished

without the addition of a separate panel or enclosure. The LCD display shall indicate low suction

shutdown. Resetting of the condition shall be

automatic or manual as selected by the user.

L. Means shall be provided to test the operation of

all LED’s to ensure their functionality.

7. Programming Menu

A.

The programming menu shall have the ability to

enable an entry password.

B. The programming menu shall be limited to two

(2) levels of password protection.

C. The controller shall have three (3) languages as

a standard, English, French, and Spanish, with

the ability to add a fourth language.

D. The programming menu shall be grouped into 5

main menu headings as follows:

1. Regional Settings

2. Pressure Settings

3. Timer Values

4. Input/Output Menu

5. System Configuration (password protected)

8. Custom Inputs/Outputs

For more information visit: www.chfire.com

PS05805003K/F

Fire Pump Controllers

Features

1-3

February 2009

Diesel Plus Fire Pump Controllers

A.

9.

The controller shall come standard with ten (10)

future inputs, six (6) future LED indicators, and

two (2) future outputs, with the ability to add up to

another 8 outputs via optional relay boards.

B. The user shall be able to program the future inputs/outputs and optional relays through the main

programming menu.

C. The inputs shall be selectable based on the following criteria:

1. User selected message or twenty four (24)

predetermined messages.

2. Energize the common alarm relay when the

input is received.

3. Link to a future relay and/or LED indicator.

4. Alarm latched until reset.

5. Normally open or closed input.

6. On-delay timer.

7. Energize the buzzer when the input is received.

D. The LED indicators shall be selectable based on

the following criteria:

1. Indication based on a minimum of fourteen

(14) predetermined alarms or a custom input.

E. The future relays shall be selectable based on

the following criteria:

1. Output based on a minimum of forty (40)

predetermined alarms, controller status or a

custom input.

2. Latched until reset.

3. Energized under normal conditions.

4. On or off delay timer on the output.

Manufacturer

A. The controller shall be microprocessor based

as manufactured by Eaton Corporation.

For more information visit: www.chfire.com

PS05805003K/F