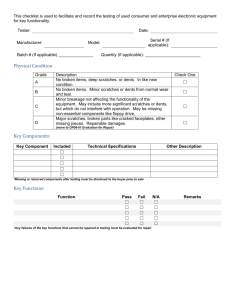

Exterior Cosmetic

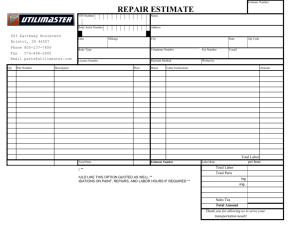

advertisement

Exterior Cosmetic Last Update: March 12, 2003 Part 3: Wholesale Certification Minimum Standards Exterior Sheet Metal and Paint Standards Acceptable Damage Damage that would be considered normal wear and tear, does not make the panel or component objectionable, and is not easily seen. Examples include minor parking lot damage, scratches that do not break the paint, palm dents associated with normal closing of the hood and deck lids (etc.), and less than one half-hour metal repair labor. Other examples are minor nicks, cuts, and scuffs. Damage to the bumpers should be viewed objectively. Unacceptable Damage All small dents above normal wear and tear, abuse, poorly repaired paint and metal, a scratch or multiple scratches that break the paint making a panel objectionable due to quantity or length, are to be considered unacceptable. Condition of Paint The condition of the vehicles overall finish must not detract from the vehicles appearance. Faded, cracked or substandard paint repairs are not acceptable. An increase in the orange peel or poor color match of the finish is the most noticeable effect when a panel has been repaired. If the finish of the vehicle has been compromised by being excessively chipped or scratched it is unacceptable. Prior Repairs Standard: Prior repair does not automatically exclude vehicles eligibility in the program. The number of panels having been repaired and more importantly the quality of the repairs are the items to be evaluated. A proper repair will not only include removing the damage completely, but also matching paint color and texture. It is important to realize that when a panel has sustained sheet metal damage, the finish of the vehicle has also been altered from its original condition. Substandard body and paint repairs are not acceptable. Recommended Test Procedure: The vehicle must undergo an extensive visual inspection to determine if it has had prior repairs. The repairs must be of a quality that requires trained personal recognition. If there are any apparent signs of structural alteration or damage, the vehicle must meet the NAAA Structural Guidelines. Standard: Prior repair does not automatically exclude vehicles’ eligibility in the program. The number of panels having been repaired and more importantly the quality of the repairs are the items to be evaluated. A proper repair will not only include removing the damage completely, but also matching paint color and texture. It is important to realize that when a panel has sustained sheet metal damage, the finish of the vehicle has also been altered from its original condition. Substandard body and paint repairs are not acceptable. Recommended Test Procedure: The vehicle must undergo an extensive visual inspection to determine if it has had prior repairs. The repairs must be of a quality that requires trained personal recognition. If there are any apparent signs of structural alteration or damage, the vehicle must meet the NAAA Structural Guidelines. Bumpers Standard: Acceptable Damage Small nicks and scratches Minor dents Proper alignment of bumper Unacceptable Damage Severe bends, twists, tears, or punctures Bent, twisted, or gouged moldings/guards Bent or broken metal Severe sandblasting of paint, excessive chips, large scratches and/or gouges Peeling of painted surfaces Damaged/broken filler panels or shields Cracks in paint or bumper Peeling chrome Misaligned bumpers Recommended Test Procedure: Bumpers are subject to considerable wear. It is important to view bumpers carefully. Excessively damaged bumpers may require replacement. View each end of the bumper carefully to ensure the bumper is aligned properly with body panels. This could be a possible indicator of further damage due to previous repairs. Grille/Header Panels Standard: Acceptable Damage Minor chips or scuffs Small scratches Unacceptable Damage Bent, cracked or broken grilles Severe sandblasting Peeling paint/chrome Recommended Test Procedure: The grille area is susceptible to serious damage. Grilles that are painted or have bright metal must be inspected carefully. Moldings/Trim/Ornamentation Standard: Acceptable Damage Minor chips Small dents Nicks or scratches Unacceptable Damage Missing items Broken or dented Gouged, scratched, or torn Permanent stains Peeling paint Recommended Test Procedure: Visually inspect for damage to these items. They may be minor enough to be brought back to an acceptable level by normal appearance reconditioning. Glass Standard: Acceptable Damage Minor windshield chips without legs Minor chips not in the line of drivers sight Unacceptable Damage Glass must have no apparent substandard repairs Apparent cracks Chips that have legs Stars or bulls eyes Deep scratches Windshield wiper scoring Sandblasting that affects visibility Recommended Test Procedure: The glass must be visually inspected for cracks, stars, bulls eyes, or heavy scratches. The glass should be visually inspected for substandard repairs. Always inspect the glass carefully. The number, severity and location of damage will be the criteria used to determine if the glass damage is acceptable or unacceptable. Fuel Door Openings Minor scratches, paint chips or minor dents at or around the fuel door opening are considered normal wear and tear. These items are acceptable. However, fuel doors that have been sprung or have signs of abuse are considered unacceptable damage. Gas Cap Standard: The gas cap must meet OEM standards and have no cracks or splits on the gasket. The gas cap must be fully tightened. Recommended Test Procedure: It must be verified that the cap meets OEM standards. Then it must be inspected to ensure there are no cracks or splits in the gasket. The cap must be fully tightened to guarantee that proper pressure will be held in the gas tank. Improper pressure will cause the MIL (malfunction indicator lamp) to illuminate.v Vinyl Roofs Standard: Acceptable Damage Minor scuffing Unacceptable Damage Tears Seam separations Distortions in the vinyl due to rust on the underside Recommended Test Procedure: A thorough visual inspection of the top should be performed to look for telltale signs of unacceptable problems. Convertible Top Standard: The The The The top must be aesthetically pleasing. motor must be fully operational. The top must be completely functional. top must retract and go up easily with no binding conditions. rear window glass (or plastic) should be clear and have no objectionable defects. Recommended Test Procedure: A visual inspection should be performed on the top to look for any significant defects. The top should be lowered to position and all attachments should be present and in working order. The rear window glass should be clear and transparent. It should not be scratched or have any other objectionable defects. If equipped the boot should be present, presentable, and functional. There should be no binding conditions present in the full range of motion of the top. There should be no gaps between the weather-stripping and the glass that would create leaks or wind noises. The top should be easily secured to its mounting points and all of the locking safety features should be credible. All weather-stripping must be present and in good condition. Wheel Covers, Trim Rings and Center Caps Standard: Acceptable Damage Minor scratches and gouges Unacceptable Damage Dented, cracked, or broken Excessive scratches or gouges Repairs to wheel covers are unacceptable Recommended Test Procedure: These components will have some normal wear and tear related to their location on the vehicle. All items must be appropriately matched sets. If the unit has wheel covers requiring wrenches, these must be with the unit. Wheels Standard: Matched set Good valve stem condition No major defects or gouges in rim or hubcap Recommended Test Procedure: Visually determine if all of the wheels are the same type and free of all major defects. Also check the rim for any bent conditions. Severe gouges and scratches to the wheel are unacceptable. If it has sustained damage, which may affect the tire, it must be repaired or replaced. Ensure the valve stem has no cuts of damage. The wheels must be appropriately matched if they are aftermarket and be appropriate for that model vehicle. The wheel rim is considered a safety item. Luggage Compartment Standard: The trunk release must be operational. The weather-stripping must be present and in good condition. There should be no moisture in the spare tire compartment. The cargo area trim and tool kit must be present and properly secured. The carpet and mats should be present and in good condition. The tire cover should not be broken, or have any major cracks, and be in good condition. The wheel lock key must be present and in good condition. The jack and lug wrench must be present and properly secured. The spare tire must be present, in good condition, and inflated to the specifications listed on the spare tire. The spare tire tread depth must be acceptable. Recommended Test Procedure: Find the trunk release cable or depress the automatic trunk release button to ensure functionality. A visual inspection must be performed on the trunk to ensure all of the cargo area trim and tools are properly secured and in good condition. The spare cover will have to be removed to check tire inflation and security of the mounting of the spare and other equipment. The tread depth must be checked to ensure the tread is in good condition. Now, the tire pressure can be checked and inflated to specification if required. The wheel lock key (if equipped) must be found, inspected for integrity, and must match the lug nuts. It must then be placed in its appropriate position.