Series GRFS-4000 - UniControl Inc.

advertisement

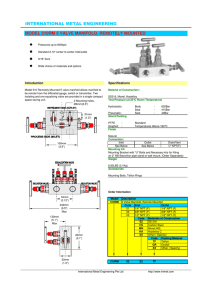

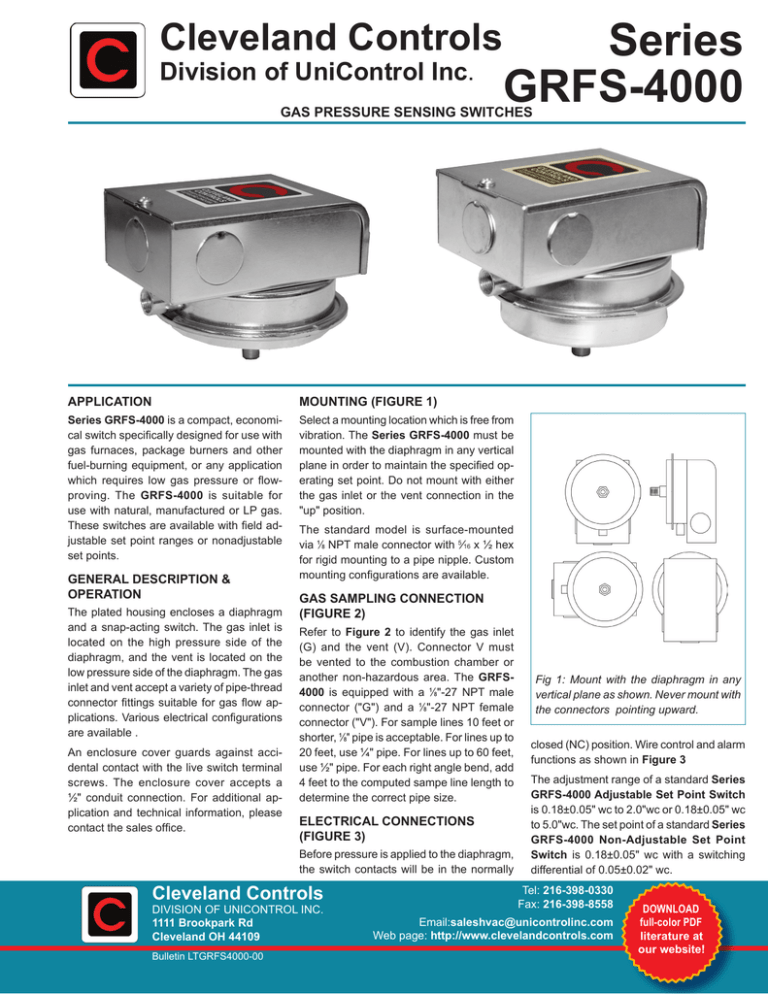

Cleveland Controls Division of UniControl Inc. Series GRFS-4000 GAS Pressure Sensing Switches Application Mounting (Figure 1) Series GRFS-4000 is a compact, economical switch specifically designed for use with gas furnaces, package burners and other fuel-burning equipment, or any application which requires low gas pressure or flowproving. The GRFS-4000 is suitable for use with natural, manufactured or LP gas. These switches are available with field adjustable set point ranges or nonadjustable set points. Select a mounting location which is free from vibration. The Series GRFS-4000 must be mounted with the diaphragm in any vertical plane in order to maintain the specified operating set point. Do not mount with either the gas inlet or the vent connection in the "up" position. General Description & Operation The plated housing encloses a diaphragm and a snap-acting switch. The gas inlet is located on the high pressure side of the diaphragm, and the vent is located on the low pressure side of the diaphragm. The gas inlet and vent accept a variety of pipe-thread connector fittings suitable for gas flow applications. Various electrical configurations are available . An enclosure cover guards against accidental contact with the live switch terminal screws. The enclosure cover accepts a ½" conduit connection. For additional application and technical information, please contact the sales office. The standard model is surface-mounted via ⅛ NPT male connector with 5⁄16 x ½ hex for rigid mounting to a pipe nipple. Custom mounting configurations are available. Gas Sampling Connection (Figure 2) Refer to Figure 2 to identify the gas inlet (G) and the vent (V). Connector V must be vented to the combustion chamber or another non-hazardous area. The GRFS4000 is equipped with a ⅛"-27 NPT male connector ("G") and a ⅛"-27 NPT female connector ("V"). For sample lines 10 feet or shorter, ⅛" pipe is acceptable. For lines up to 20 feet, use ¼" pipe. For lines up to 60 feet, use ½" pipe. For each right angle bend, add 4 feet to the computed sampe line length to determine the correct pipe size. Electrical Connections (Figure 3) Before pressure is applied to the diaphragm, the switch contacts will be in the normally Cleveland Controls Division of UniControl Inc. 1111 Brookpark Rd Cleveland OH 44109 Bulletin LTGRFS4000-00 Fig 1: Mount with the diaphragm in any vertical plane as shown. Never mount with the connectors pointing upward. closed (NC) position. Wire control and alarm functions as shown in Figure 3 The adjustment range of a standard Series GRFS-4000 Adjustable Set Point Switch is 0.18±0.05" wc to 2.0"wc or 0.18±0.05" wc to 5.0"wc. The set point of a standard Series GRFS-4000 Non-Adjustable Set Point Switch is 0.18±0.05" wc with a switching differential of 0.05±0.02" wc. Tel: 216-398-0330 Fax: 216-398-8558 Email:saleshvac@unicontrolinc.com Web page: http://www.clevelandcontrols.com DOWNLOAD full-color PDF literature at our website! Figure 2 Figure 3 specifications Series GRFS-4000 Gas Pressure Sensing Typical Reference Dimensions in Inches (Millimeters) Switches Mounting Position: Surface mount with the diaphragm in any vertical plane. Neither the gas nor the vent connection should point upward. Standard Set Point Ranges: • 0.18 ±0.05" wc to 2.0" wc. • 0.18 ±0.05" wc to 5.0" wc. Field Adjustable "Operate Ranges": • 0.23" wc to 2.0" wc. • 0.23" wc to 5.0". wc. Field Adjustable "Release Ranges": • 0.13" wc to 1.9" wc. • 0.13" wc to 4.7". wc. Approximate Switch Differentials: • For 2.0"wc set point range: progressive, increasing from 0.05±0.02" wc at minimum set point to approximately 0.1" wc at maximum set point. • For 5.0"wc set point range: progressive, increasing from 0.05±0.02" wc at minimum set point to approximately 0.3" wc at maximum set point. Measured Media: Air or natural, manufactured, LP, or other gas that will not degrade nitrile. Maximum Pressure: ½ psi (0.03 bar). Operating Temperature Range: 0 to 190F(–18.0 to 882C). Life: 100,000 cycles minimum at ½ psi maximum pressure each cycle and at maximum rated electrical load. Electrical Rating: 300 VA pilot duty at 115 to 277 VAC; 15 amp noninductive to 277 VAC, 60 Hz. Contact Arrangement: • SPST-NO. • SPST-NC. • SPDT. Electrical Connections: • Screw terminals with cup washers. Sample Line Connectors: • Externally threaded 7⁄16" -24 UNS 2A or 7⁄16" -20 UNF 2A thread with nuts and self-aligning ferrules. • ⅛" - 27 NPT male and female connectors. • ¼" - 18 female thread in combination with ⅛" - 27 NPT female connectors Approvals: UL & CUL. CSA pending. Shipping Weight: < 1 lb.