pdf - Progress in Science and Engineering Research

advertisement

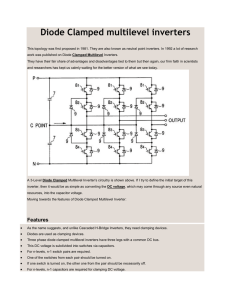

Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) FIELD ORIENTED CONTROL OF MULTILEVEL FED INDUCTION MOTOR FOR DIFFERENT SPEED Sandeep Kumar1, Ishtiyaque Ahamad2, Vinay Bhardwaj3, Neha Choudhary4 1,3.4 PG Student, 2Assistant Professor, Department of Electrical and Electronic Engineering, Dehradun Institute of Technology, Dehradun Abstract: This paper presents Induction Motor fed independently thus to increase its transient response. In through Neutral Point Clamped (NPC) or Diode Clamped the rotating frame of reference the frame of reference in Multilevel Inverter using Field Oriented Control. Field regard to the phase A is named the d-axis (for direct Oriented Control technique is used as it allows torque and axis) and the other axis is named the q-axis (for speed to be nearly controlled. Field Oriented Control quadrature axis). explains Induction Motor in relative simple term by using dq variable. Induction Motor when driven by Field Oriented Controller, behaves as separately excited DC Motor to control torque and flux independently and also to generate pulses for Multilevel Inverter. Multilevel Inverter is advantageous then conventional Inverter as it synthesized waveform near about sinusoidal waveform to reduce harmonic distortion. This paper shows Fig.1: Two reference model for rotating machine IMPLEMENTATION and SIMULATION when Induction Motor are driven at different speed. When induction motors are controlled by a vector drive, control computation is often done in the synchronous Index Terms: Multilevel Inverter, Field Oriented Control, Modulation Technique, D-Q transformation frame. Since actual stator variables either to be generated or to be measured are all in stationary a-b-c I. INTRODUCTION frame, frame transform should be executed in the Field Oriented Control or Vector Control explains control. The most popular transform is between Induction Motor in relative simple term by using d-q stationary a-b-c frame quantities to synchronously variable. Three-phase induction motor can be modeled rotating d-q quantities. in an arbitrary two axis (d & q-axis) rotating reference frame. It will be shown that when we choose a synchronous reference frame in which rotor flux lies on the d-axis, this model can estimate the stator current along the direction of two-reference axis as shown in fig.1 along D & Q axis. Induction Motor when driven by Field Oriented Controller, behaves as separately excited DC Motor to control torque and flux Corresponding Author: Mr. Sandeep Kumar, PG Student, Department of Electrical and Electronic Engineering, Dehradun Institute of Technology, Dehradun Email Id: sandeep.om.nain@gmail.com Fig.2 Rotor Flux Oriented control scheme Diode Clamped Multilevel is used in this paper. In conventional Inverter technology output waveform is of two values (level) include increase harmonic distortion, © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) ripple factor, higher voltage derivative, torque pulsation purpose of speed control. In this paper induction motor in induction motor. Multilevel Inverter is considered as has been modeled by MATLAB program. a state of art power conversion from DC to AC for high power and power quality demanding applications. Some of the other features of Multi level Inverter are as fallow II. MULTILEVEL INVERTER Voltage source inverter produces an output voltage or current with two levels. Two levels inverter have some limitation in operating due to harmonic content and 1- The output generated voltage is of extremely low distortion and lower voltage derivative 2- The switching frequency on which they are operated are of lower order 3- Reduce the stress in motor bearing by generating smaller common mode voltage 4- Produce voltage with reduce harmonic content and near sinusoidal waveform switching losses. Now it is easy to produce a high power, high voltage inverter with multilevel structure increasing the number of voltage or current level at output terminals. Various PWM strategies are to be applied on multilevel inverter to obtain quality output voltage or current. The general purpose of multilevel inverter is to synthesize a near sinusoidal voltage and to reduce harmonic content and ripple factor. The number of level of inverter can be defined as the number of The term Multilevel was first introduced by Nable el al; as number of levels increase in inverter the output voltage has more steps generating a staircase waveform with a reduced harmonic distortion but a higher number increase the control complexity. PWM, SVM, SHE, DTC etc are the modulation and control strategies developed for multilevel inverter. steps or constant voltage that is generated by inverter at output terminal. Minimum three different voltage levels have to be generated at output terminal to be called as multilevel inverter. This is the basic difference between two level inverter and multilevel inverter. Multilevel inverter has an array of power semiconductor and capacitor voltage sources thus generate output with stepped waveform when proper switching is performed. It eliminates the use of step up transformer. With this phenomenon KV rating can be extended and it is suitable for high voltage high current application. There are three type of Multilevel Inverter named as Diode Clamped Multilevel Inverter, Capacitor Clamped Multilevel Inverter and Cascade Multilevel Inverter. Diode Clamped Multilevel Inverter have same major Fig 3. (a) Two levels, (b) three levels, (c) n levels advantage then other topology in a manner that is does not require separate DC source as in Cascade Multilevel This paper emphasizes on the fact that when induction motor are fed with Multilevel Inverter it torque Inverter also does not require charging of capacitor as in Capacitor Clamped Multilevel inverter. pulsation are reduced and motor run smoothly. In this manner efficiency of induction motor are also increase In fig. three levels and five levels Multilevel Inverter and losses are reduced. The dynamic model of the are shown. N is the neutral point . Vdc is the input and induction motor is necessary for understanding and C1 and C2 are the two capacitor voltage connected to analyzing the three-phase inductor motor for the this input. For three level the output voltage Van has © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) three states: Vdc/2 , 0, and –Vdc/2 . For voltage level above control technique are use to reduce harmonic Vdc/2 , switches S1 and S2 need to be turned on; for – content by giving proper pulses to multilevel inverter. Vdc/2 , switches S1’ and S need to be turned on; and for There is inherent additional complexity of having more the 0 level,S2 and S1’ need to be turned on. Diode power electronic device but it create possibility to take clamped inverter have some advantage over other type advantage of the extra degree of freedom with the help of multilevel inverter such as when number of level are of these modulation and control technique. A very high enough harmonic content are low enough. Inverter popular method is the classic carrier based sinusoidal efficiency is high and control method is low. It has PWM which use phase shifting technique to reduce the some major drawback also like excessive clamping harmonic. Another alternative is SVM, SHE, DTC etc. diode are required when the number of level are high also its difficult to control real power flow of the individual converter in multi converter system Current control PWM, as is used, because both flux and torque are directly related to the current. Fig.5 Modulation technique for multilevel inverter IV.FIELD ORIENTED CONTROL Field Oriented Control allows torque and speed to be nearly controlled. Scalar Control is simple to implement but have instability because of coupling effect which indicate that if torque is changed flux change and vice versa. This coupling effect must be decoupled to get better performance. In Vector Control, Rotor Flux Orientation gives natural decoupling control whereas Stator Flux Orientation gives a coupling effect which has to be compensated by decoupling compensation current. Voltage modal flux estimation is better at Fig.4 Diode clamped multilevel inverter circuit (a) three level (b) five level higher speed whereas current modal is made at any speed. It is also possible to have hybrid modal where III. MODULATION AND CONTROL STRATEGIES voltage modal is effective at higher speed and current Switching state of a converter is a set of signal used to explains Induction Motor in relative simple term by control each switching device of power circuit. The using d-q variable. Vector Control Induction Motor modal at lower speed range. Field Oriented Control © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) operates as separately excited DC Motor to get better Where ids response. current, ψdr and ψqr are the d-axis and q-axis rotor flux The three-phase induction is modeled into a two-phase and iqs are the d-axis and q-axis stator linkage. Rr is the rotor resistance, Lr and Lm is the rotar model. We can look at the motor as a 2-phase machine. inductance and mutual inductance respectively. Utilizing of the 2-phase motor model reduces the the slip frequency. Torque can be expressed in terms of number of equations and simplifies the control design. stator currents and rotor flux linkages as Such a model is valid for any instantaneous variation of T= ( ) Lm/Lr (ψdrsiqss – ψqrsidss) voltage and current, and adequately describes the performance of the machine under both steady-state and is Motor Parameter transient operations. Vector control methods of the induction motor permit independent control of the torque and flux by decoupling the stator current into two orthogonal component, a torque producing Motor Type- Squirrel Cage, nominal power- 50*746, voltage-460, frequency-60, stator resistance-0.087, stator inductance- 0.8, rotar resistance- 0.228, rotar inductance- 0.8, mutual inductance- 34.7 component iqs and a flux producing component ids. The goal is to transform the three phase stationary reference frame variable into two phase stationary reference frame variable and then transform these to synchronously rotating reference frame. PI Controller Parameter Kp-550, Ki- 150, Torque Limit- 350 V.SIMULATION MODAL AND RESULTS Transformation of three phase axes to two phase stationary axes For the validation of previously discussed approach, [ inverter fed induction motor controlled by Field ] simulation on three level diode clamped multilevel Oriented Controller, is carried out using MATLAB = [ ][ ] Simulink. Transformation of stationary axes to synchronously rotating axes Vqs = Vqss - Vdss Vds = Vqss + Vdss Flux is expressed as © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) [6]. J Rodriguez, J.S. Lai and F.Z. Peng, “Multilevel Inverter: A survey of topologies, controls and applications,” IEEE Trans. Ind. Electron., vol 49, pp. 724-738, aug. 2002 [7]. Dr.Rama Reddy and G.Pandian, “Implementation of Multilevel inverter fed Induction motor Drive,” Journal of Industrial Technology, vol 24, no. 1, April 2008. [8]. Nikolaus P. Schibli, T. Nguyen, and Alfred C. Rufer, “A Three-Phase Multilevel Converter for High - Power Induction Motors,” IEEE Trans on Power Electronics, vol.13, no.5, Sept 1998. [9]. N.Celanovic and D.Boroyevich, “ A Comprehensive study of neutral-pointvoltage balancing problem in three-level neutral – point clamped voltage source PWM inverters,” IEEE Trans on Power Electronics, vol.15, no. 2, pp. 242 – 249, March 2000 [10]. T. A. Meynard and H. Foch, “Multi-level choppers for high voltage applications,” Eur. Power Electron. Drives J., vol. 2, no. 1, p. 41, Mar. 1992. [11]. P. Hammond, “A new approach to enhance power quality for medium voltage ac drives,” IEEE Trans. Ind. Applicat., vol. 33, pp. 202–208, Jan./Feb. 1997. Fig.6. Layout & Output waveform VI. CONCLUSION [12]. E. Cengelci, S. U. Sulistijo, B. O. Woom, P. Enjeti, R. Teodorescu, and F. Blaabjerge, “A new medium voltage PWM inverter topology for adjustable speed drives,” in Conf. Rec. IEEE-IAS Annu. Meeting, St. Louis, MO, Oct. 1998, pp. 1416– Multilevel Inverter fed Induction Motor,controlled by Field Oriented Controller, run smother due to reduce in harmonic content. Torque and Flux can be control independtly to make speed controll easier and for fast response. 1423. [13]. R. H. Baker and L. H. Bannister, “Electric power converter,” U.S. Patent 3 867 643, Feb. 1975. [14]. J. Rodríguez, P. Correa, and L. Morán, “A vector control technique for medium voltage multilevel inverters,” in Proc. IEEE APEC, Anaheim, CA, Mar. 2001, pp. 173–178. [15]. L. Li, D. Czarkowski, Y. Liu, and P. Pillay, “Multilevel REFERENCES [1]. J. S. Lai and F. Z. Peng, “Multilevel converters–A new breed of power converters,” IEEE Trans. Ind. Applicat., vol. 32, pp. 509–517, May/June 1996. [2]. L. Tolbert, F.-Z. Peng, and T. Habetler, “Multilevel converters for large electric drives,” IEEE Trans. Ind. Applicat., vol. 35, pp. 36–44, Jan./Feb. 1999. [3]. R. Teodorescu, F. Beaabjerg, J. k. Pedersen, E. Cengelci, S. Sulistijo, B. Woo, and P. Enjeti, “Multilevel converters — A survey,” in Proc.European Power Electronics Conf. (EPE’99), Lausanne, Switzerland, 1999, CD-ROM. [4]. Jose Rodriguez, Samir Kouro, Ramon C. Portillo and Marcelo A. Perez “Multilevel converter: enabling technology for HighPower Application” 2009 IEEE [5]. A. Nabae, I. Takahashi, and H. Akagi, “A new neutral-point clamped PWM inverter,” IEEE Trans. Ind. Applicat., vol. IA17, pp. 518–523, Sept./Oct. 1981. selective harmonic elimination PWM technique in seriesconnected voltage inverters,” in Conf. Rec. IEEE-IAS Annu. Meeting, Oct. 1998, pp.1454–1461. [16]. Novotny, D.W., and Lipo, T.A.: ‘Vector control and dynamics of AC drives’, (Clarendon Press, Oxford, 1996) [17]. Bose, B.K.: ‘Modern power electronics and AC drives’ (Prentice Hall PTR, New Jersey, 2002) [18]. Vas, P., and Alakula, M.: ‘Field-oriented control of saturated induction machines’, IEEE Trans. Energy Convers., 1990, 15, (1), pp. 218–224 [19]. Lin, F.J., and Liaw, C.M.: ‘Reference model selection and adaptive control for induction motor drives’, IEEE. Trans. Autom. Control, 1993, 38, (10), pp. 1594–1600 [20]. Choi, J.W., and Sul, S.K.: ‘Fast current controller in threephase AC/ DC boost converter using d-q axis crosscoupling’, IEEE. Trans. Power Electron., 1998, 13, (1), pp. 179–185 [21]. Liaw, C.M.: ‘System parameter estimation from sampled data’,Control Dyn. Syst., 1994, 63, pp. 161–195 © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080 Progress In Science and Engineering Research Journal ISSN 2347-6680 (E) [22]. M. Dspsnbmclg ’Direct self oontrol of inverter-fed induction machines,” IEEE Transactions on Power Electronic 1988, “013, pp. 420429. [23]. J.HolR “Sensorless oontrol of induction motor drives,” Proceedings of 1he IEEE Vol. 90, No. 8, Aug. 2002 [24]. G. R. Slemon, “Modelling of induction machines for electric drives,” IEEE Transactions on Industry Applications, vol. 25, no. 6, pp. 1126– 1131, Nov./Dec. 1989. [25]. S. Williamson, A. Smith, M. Begg, and J. Smith, “General techniques for the analysis of induction machines using finite elements,” in Proc. Of International Conference on Evolution and Modern Aspect of Induction Motors, Turin, Italy, July 8– 11 1986, pp. 389–395. © 2014 PISER Journal http://.piserjournal.org/ PISER 14, Vol.02, Issue: 04/06 July-August; Bimonthly International Journal Page(s) 075-080