River Water Remediation Using Electrohydraulic Discharges or

advertisement

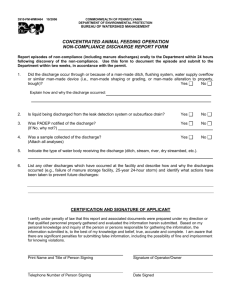

IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 39, NO. 3, MARCH 2011 953 River Water Remediation Using Electrohydraulic Discharges or Ozonation T. Izdebski, M. Dors, and J. Mizeraczyk Abstract—River water cleaning from microorganisms using electrohydraulic discharges and ozonation was investigated. The processed water was highly polluted with the total number of microorganisms (70 400 cfu/mL) and total Escherichia coli bacteria (280 cfu/mL). The processing was conducted in a tube reactor with a hollow needle-rod electrode configuration. A 400-mL sample of river water was treated at different flow rates. Ozonation was performed in a washing bottle with an ozone concentration of 20 g/m3 . The corona discharge treatment showed a steady decrease of bacteria and microorganisms but did not kill them completely. Spark discharge killed the bacteria and microorganisms completely; however, its energy efficiency was much lower than that of ozonation. The ozone treatment decreased the concentration of microorganisms and coli bacteria down to 785 and 10 cfu/mL, respectively, in 45 s which resulted in higher energy efficiency than processing using corona and spark discharges. The NPOC analysis of the treated samples showed its concentration of 5 ± 0, 4 ppm in all samples. Index Terms—Disinfection, ozonation. electrohydraulic discharges, I. I NTRODUCTION T HE MOST frequent reason of epidemic formation is the pollution of the surface and drinking water by wastewater bacteria. The largest part of this pathogenic microorganisms are fecal bacteria, for example, Escherichia coli (E. coli). The wastewater treatment plants reduce the amount of fecal bacteria by one to three orders of magnitude, depending on the initial number of bacteria, which can be 104 −106 colony-forming units (cfu) in 1 mL [1]. To enhance efficiency of bacteria inactivation in the wastewater and drinking water, various methods are tested, like electrochemical [2] and photocatalytic [3] disinfections, chlorination, ozonation [4], Fenton reaction [5]– [7], UV irradiation [8], [9] and electrohydraulic discharges, i.e., electrical discharges in water, such as, pulsed arc between needle electrodes [10]–[12], pulsed corona between wire and plate [13], and pulsed corona with the addition of gas as bubbles [14] and without added gas [15], [16]. In spite of extensive investigations in many laboratories, there is a lack of data on waste and drinking water purification by electrohydraulic discharges. Analysis of the literature Manuscript received August 9, 2010; revised November 2, 2010; accepted December 2, 2010. Date of publication January 20, 2011; date of current version March 9, 2011. This work was supported by the Ministry of Science and Higher Education, Poland, under Grant PB 3547/B/T02/2009/36. The authors are with the Centre for Plasma and Laser Engineering, The Szewalski Institute of Fluid-Flow Machinery, Polish Academy of Sciences, 80-952 Gdañsk, Poland (e-mail: mdors@imp.gda.pl). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TPS.2010.2098889 allows determining the influence of electrohydraulic discharges in deionised or distilled water on several organic compounds such as phenols, trichloroethylene, polychlorinated biphenyl, perchloroethylene and pentachlorophenol, acetophenone, organic dyes (such as methylene blue), aniline, anthraquinone, monochlorophenols, methyl tert-butyl ether, benzene, toluene, ethyl benzene, and 2, 4, 6-trinitrotoluene, 4-chlorophenol, and 3,4-dichloroaniline [17], [18]–[26]. The electrohydraulic discharges in the water also cause the destruction and inactivation of viruses, yeast, and bacteria. It is generally assumed that a mechanism of microorganism killing by the electrohydraulic discharges involves an electric field, shock wave, UV radiation, and radical reactions. The destruction of microorganism depends on the microorganism cell structure. It is different for each bacterial species and depends also on the mode of electrohydraulic discharge [17], [27]. In the case of corona discharge, E. coli bacteria cells are destroyed mainly due to reactions with oxidizing radicals, namely, OH and H2 O2 , with compounds forming the bacterial cell wall [13], [15], whereas in the spark and arc discharges, they are mainly damaged by shock waves and UV radiation [11], [12]. Unfortunately, detailed mechanisms of microorganism inactivation are still not clarified. In the case of bacteria, including E. coli, strong oxidants cause destruction of bacterial membrane through alteration of glycoproteins or glycolipids [28] and certain amino acids such as tryptophan [29]. There is also disruption of enzymatic activity of bacteria by acting on the sulfhydryl groups of certain enzymes [31] as well as affection of both purines and pyrimidines in nucleic acids resulting in inhibited replication of DNA [28]. The last kind of changes in DNA is also caused by UV in the range 240–280 nm emitted by electrohydraulic discharges. However, it must be noted that, under certain conditions, some organisms are capable of repairing damaged DNA and reverting back to an active state in which reproduction is again possible [30]. Typically, photoreactivation occurs as a consequence of the catalyzing effects of sunlight at visible wavelengths outside of the effective disinfecting range. The extent of reactivation varies among organisms. Coli bacteria and some bacterial pathogens such as Shigella have exhibited the photoreactivation mechanism; however, viruses (except when they have infected a host cell that is itself photoreactive) and other types of bacteria cannot photoreactivate [32]. In the case of viruses, strong oxidants cause modification in the viral capsid sites that the virion uses to fix on the cell surfaces. High concentrations of ozone dissociate the capsid completely [30]. In most investigations concerning the application of electrohydraulic discharges for water purification, the deionised water with additives regulating conductivity was used. There 0093-3813/$26.00 © 2011 IEEE 954 IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 39, NO. 3, MARCH 2011 Fig. 1. Corona and spark discharge reactor with water pumping/cooling system and pulsed power system (C1 = 2 nF, C2 = 22 nF, R = 10 kΩ). are few studies on the influence of electrohydraulic discharges on chemical pollutants and microorganism present in drinking water as well as in surface water, i.e., rivers and lakes [33]. In this paper, we observed the influence of selected electrohydraulic discharges, i.e., corona and spark discharges, in the water, as well as conventional ozonation of water on inactivation of all kinds of microorganisms, total coli, and E. coli. Water samples were taken from the Strzyża river, in the Gdańsk region. Strzyża is a type-IV sanitary class river, so it has a total coli number of over 3000 cfu in 100 mL. Due to this fact, it cannot be used to supply region inhabitants with drinking water. This would be possible only after complete removal of coli bacteria, e.g., by plasma processing. II. E XPERIMENTAL S ETUP The processing of the river water samples was conducted in a glass tube reactor (inner diameter of 22.5 mm) equipped with water pumping and cooling systems (Fig. 1). Every sample had a volume of 400 mL. Water samples were being pumped once through the reactor tube at different flow rates and discharge voltages. A pulsed positive discharge was generated between a high-voltage stainless steel hollow needle electrode and a grounded brass rod electrode (10 mm in diameter), both immersed in the water. The inner and outer diameter of the hollow needle were 1.4 and 1.6 mm, respectively. The discharge was generated at the edge of the hollow needle, whereas the rest of the needle was covered with an insulator. Corona discharge was generated when the needle-rod spacing was 45 mm, whereas the spark discharge was formed in the spacing of 9 mm. Part of the river water samples underwent ozonation process in a washing bottle. The O3 concentration in the inlet gas was 20 g/m3 . The ozone was created in DBD reactor from pure oxygen, at a flow rate of 1 L/min. The ozonator was operating at 15 W. The processed water was taken from the Strzyża river in February 2010. The water initial characteristics were as follows: temperature 18 ◦ C, pH = 7.4, conductivity 376 μS, total number of coli bacteria 11 750 cfu/mL, number of E. coli 280 cfu/mL, and the total number of microorganisms at 36 ◦ C and 22 ◦ C were 30 500 and 74 500 cfu/mL, respectively. Fig. 2. Photographic image of the corona discharge. Positive high-voltage pulses were applied to the hollow needle electrode from a discharge capacitor C1 (2 nF)—Fig. 1. The capacitor was charged from a dc power supply through a resistor R (10 kΩ) and a capacitor C2 (22 nF). The pulse repetition rate of 50 Hz was fixed by the rotation velocity of a rotating spark gap switch. The amplitudes of the voltage and current corona pulses were measured using a TEKTRONIX P6015A high-voltage probe and a PEARSON 2878 current monitor (Rogowski coil), respectively. The waveforms were observed and recorded on a TEKTRONIX TDS 3052B oscilloscope after being averaged over up to 256 acquisitions to eliminate a random noise. The first set of polluted water samples was processed by corona discharge at three different flow rates: 36, 69, and 175 mL/min. Second set of samples was treated by a spark discharge at a flow rate of 38 and 71 mL/min. Third set of samples was treated by ozonation for 45, 91, 152, and 212 s. Every treated sample had a 400-mL volume for comparison purposes and was tested for microbiological markers such as the following: number of microorganisms after 24 h of growing in 36 ◦ C, number of microorganisms after 72 h of growing in 22 ◦ C, total number of coli bacteria, and the number of E. coli bacteria. In all samples, the concentration of the total organic carbon (TOC) was determined using Sievers InovOx TOC analyzer. III. R ESULTS A photographic image of the electrohydraulic corona discharge is shown in Fig. 2. This type of electrohydraulic discharge is named “corona” or “corona-like” due to the similar shape as in streamer corona in gaseous phase [17]. For the same reason, electrohydraulic discharge generated just after bridging electrodes is named “spark.” However, one should remember that development mechanisms of such electrohydraulic discharges are quite different than corona and spark discharges in gases and still not well understood. The amplitudes of the voltage and current corona pulses were up to 40 kV and 35 A, respectively, with a full width at half maximum (FWHM) of 3.8 μs. The amplitudes of the voltage and current spark pulses were up to 27 kV and 30 A, IZDEBSKI et al.: REMEDIATION USING ELECTROHYDRAULIC DISCHARGES OR OZONATION Fig. 3. Typical voltage pulses of corona and spark discharges. respectively, with an FWHM of 1.4 μs. These current and voltage pulses are shown in Figs. 3 and 4. In Fig. 4, a zoom of current waveform in the range of 0–3 μs is shown. In contrast to the current waveform recorded by Ceccato et al. [34], we did not observe streamer propagation phase separated from the initiation one. This is probably caused by the geometry of active electrode, which is a hollow needle in our experiment, whereas Ceccato et al. [34] used a simple needle with conical tip. The hollow needle electrode has a ring edge acting as a multipoint electrode. Thus, the probability of simultaneous propagation of several streamers is much higher than for simple needle, which is more like a single-point electrode. As can be seen in Fig. 4, initiation phase of the streamer is overlapped by the stray capacitive current and its ripples at the beginning of the current 955 Fig. 4. Typical current pulses of corona and spark discharges. waveform. This “stray” current superimposed with the initiation current is LC ringing obtained when applying voltage, with L from the power supply and the reactor circuit and C from the interelectrode capacitance [34]. Thus, even these current ripples are taken into account when calculating the pulse energy of the discharge (Ep ) by the integration of the pulse voltage times the current over the pulse duration Ep q = U (t)I(t)d(t). (1) pulse Since the current pulse is shorter than the voltage one, the Ep calculation ends with the current pulse. The integration was carried out for five oscillograms and then averaged. For 956 Fig. 5. Concentration of microorganisms grown in 36 ◦ C river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 39, NO. 3, MARCH 2011 Fig. 7. Concentration of the total number of coli bacteria in river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. Fig. 8. Concentration of E. coli bacteria in river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. Fig. 6. Concentration of microorganisms grown in 22 ◦ C river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. the corona and spark discharges, the resulted pulse energy was 0.42 ± 0.02 J and 0.17 ± 0.01 J, respectively. A comparison of bacteriological results of the total number of microorganisms and coli bacteria concentrations in river water samples treated by corona discharge, spark discharge, and ozonation is shown in Figs. 5–8. Energy efficiencies of various treatments are shown in Figs. 9–12. The energy efficiency η was calculated using the following formulas: 1) for the ozonation η= P O · tp (C − C0 ) · VS (2) where Po is the discharge power used in the ozonator (15 W), tp is a processing time in seconds, C and C0 are the initial and final number of microorganisms in IZDEBSKI et al.: REMEDIATION USING ELECTROHYDRAULIC DISCHARGES OR OZONATION 957 Fig. 9. Energy efficiency of inactivation of microorganisms grown in 36 ◦ C river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. Fig. 11. Energy efficiency of inactivation of the total number of coli bacteria in river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. Fig. 10. Energy efficiency of inactivation of microorganisms grown in 22 ◦ C river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. Fig. 12. Energy efficiency of inactivation of E. coli bacteria in river water samples as a function of processing time using ozonation, spark discharge, and corona discharge. colony-forming unit per milliliter, respectively, and Vs is a sample volume (400 mL); 2) for the corona and spark discharges η= Ep · f · t p (C − C0 ) · VS (3) where Ep is the pulse energy calculated from (1) and f is a pulse repetition rate (60 Hz). Other symbols have the same meaning as in (2). Processing time tp is calculated from the following formula: tp = VS Q (4) where Q is a water flow rate (mL/s). It is seen that processing by corona discharge caused significant reduction in the concentrations of microorganisms and bacteria but did not kill them completely. The lower the 958 flow rate, the more energy efficient it was. Comparing to the EU regulations for drinking water, i.e., 0 cfu/100 mL for coli and E. coli bacteria and 100 and 20 cfu/mL for the number of microorganisms grown in 22 ◦ C and 36 ◦ C, respectively [35], microbial quality of water processed by corona discharge is far from satisfactory. The spark discharge was much more effective than the corona, causing a 100% decrease in the number of microorganisms and bacteria after 622 s of processing, except for the total number of microorganisms in 36 ◦ C, which survived in the number of 36 cfu/mL. This number is only slightly higher than the regulation, and we believe that it can be improved. As seen in Figs. 9–12, the energy efficiency of spark discharge was three times higher than the corona but still much below that of ozonation. The ozonation process caused a fast decrease of the total bacteria concentrations with increasing treatment time. After 45 s of processing, the total coli number dropped from initial 11 750 to 10 cfu/mL and E. coli number from 280 to 1 cfu/mL. Processing time of 152 s resulted in killing all of the coli bacteria and microorganisms. The energy efficiency was a magnitude higher than that of the electrohydraulic discharges. The reason for the higher efficiency of ozonation against corona and spark discharges is the saturation of all water volume with ozone and sustaining this saturation to the end of the ozonation process by ozone excess. In the case of corona and spark electrohydraulic discharges, water flowing through the reactor cannot be saturated with oxidizing radicals due to their short lifetime. Thus, their action is limited to plasma vicinity. UV generated by discharges is strongly absorbed by the water, so it is harmful also for microorganism in the region close to plasma, whereas pressure waves are relatively strong only in the case of spark discharge, however not intense enough to inactivate all microorganisms. The TOC concentrations measured in every water sample are similar, i.e., 5 ± 0.4 ppm. It is seen that TOC concentrations were not affected by the treatment in this experiment. It shows that neither electrohydraulic discharges nor ozonation oxidized organic compounds to CO2 . Thus, their action was limited to inactivation of microorganisms, possibly with the destruction of their structure and to the oxidation of one organic compound into another. Due to the fact that real river water contains different kinds of microorganisms, i.e., bacteria, viruses, fungi, and protozoa, mechanisms of disinfection in our experiment probably involves all known processes induced by oxidizing agents, pressure wave, and UV irradiation [30]. It is known that ozone and OH radicals cause destruction of bacterial membrane through alteration of glycoproteins or glycolipids [28], conversion of certain amino acids such as tryptophan in bacterial cells [29], disruption of enzymatic activity of bacteria by acting on the sulfhydryl groups of certain enzymes [31], affection of both purines and pyrimidines in nucleic acids [28], and modification of the viral capsid sites that the virion uses to fix on the cell surfaces (high concentrations of ozone dissociate the capsid completely) [30]. Pressure waves can mechanically damage microorganism structure, whereas UV irradiation, in particular, in the range of 240–280 nm, is able to alter nucleic acids [30]. IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 39, NO. 3, MARCH 2011 Destruction of microorganism cells means that their contents, inter alia, nucleic acids, contaminated the water. This process may be an explanation for the observed increase in conductivity from initial 376 μS to 657–680 μS in all samples. Presence of organic acids, both nucleic and other formed through the oxidation of organic compounds [17], [19] should result in increased pH. However, measurements of pH showed that there were no changes of this parameter. This may be caused by possible presence of phosphorous fertilizers, which very often contaminate, which act as chemical buffers sustaining pH at the same level. IV. C ONCLUSION Our experiment has demonstrated that ozonation is the most efficient method of water disinfection comparing to pulsed spark and pulsed corona discharges. The pulsed spark discharge in the water is capable to kill all microorganisms similarly to ozonation, however with much lower energetic efficiency. The pulsed corona discharge turned to be the less effective method of water disinfection. However, further studies using other electrode configurations and materials, e.g., using porous ceramics increasing the number of discharge channels [36], as well as reactor geometry, e.g., asymmetric shape prohibiting subtraction of pressure waves reflected from the reactor opposite walls, may improve energy efficiency of spark and/or corona discharge and make them competitive to ozonation. R EFERENCES [1] Waste-Water Treatment Technologies: A General Review, United Nations, New York, 2003. [Online]. Available: http://www.escwa.un.org/ information/publications/edit/upload/sdpd-03-6.pdf [2] M. I. Kerwick, S. M. Reddy, A. H. L. Chamberlain, and D. M. Holt, “Electrochemical disinfection, an environmentally acceptable method of drinking water disinfection,” Electrochim. Acta, vol. 50, no. 25/26, pp. 5270– 5277, Sep. 2005. [3] P. S. M. Dunlop, J. A. Byrne, N. Manga, and B. R. Eggins, “The photocatalytic removal of bacterial pollutants from drinking water,” J. Photochem. Photobiol. A: Chem., vol. 148, no. 1–3, pp. 355–363, May 2002. [4] T. A. Ternesa, J. Stüber, N. Herrmanna, D. McDowell, A. Ried, M. Kampmann, and B. Teiser, “Ozonation: A tool for removal of pharmaceuticals, contrast media and musk fragrances from wastewater?” Water Res., vol. 37, no. 8, pp. 1976–1982, Apr. 2003. [5] H. F. Diao, X. Y. Li, J. D. Gu, H. C. Shi, and Z. M. Xie, “Electron microscopic investigation of the bactericidal action of electrochemical disinfection in comparison with chlorination, ozonation and Fenton reaction,” Process Biochem., vol. 39, no. 11, pp. 1421–1426, Jul. 2004. [6] J. C. Joret, V. Mennecart, C. Robert, B. Compagnon, and P. Cervantes, “Inactivation of indigenous bacteria in water by ozone and chlorine,” Water Sci. Technol., vol. 35, no. 11/12, pp. 81–86, 1997. [7] M. Sato, T. Soutome, S. Mii, T. Ohshima, and Y. Yamada, “Decomposition of phenol in water using water surface plasma in wetted-wall reactor,” Int. J. Plasma Environ. Sci. Technol., vol. 1, no. 1, pp. 71–75, Mar. 2007. [8] J. Koivunen and H. Heinonen-Tanski, “Inactivation of enteric microorganisms with chemical disinfectants, UV irradiation and combined chemical/UV treatments,” Water Res., vol. 39, no. 8, pp. 1519–1526, Apr. 2005. [9] V. Lazarova, P. Savoye, M. L. Janex, E. R. Blatchley, and M. Pommepuy, “Advanced wastewater disinfection technologies: State of the art and perspectives,” Water Sci. Technol., vol. 40, no. 4/5, pp. 203–213, 1999. [10] R. d’Agostino, P. Favia, Y. Kawai, H. Ikegami, N. Sato, and F. Arefi-Khonsari, Advanced Plasma Technology. Weinheim, Germany: WILEY-VCH Verlag GmbH & Co. KGaA, 2008, ch. 24, pp. 421–432. [11] M. B. Emelko, A. J. Arnold, C. A. Santillan, S. E. Dickson, and J. S. Chang, “Treatment of drinking water with pulsed arc electrohydraulic discharge: Promising outcomes and future challenges,” in Proc. IZDEBSKI et al.: REMEDIATION USING ELECTROHYDRAULIC DISCHARGES OR OZONATION [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] Asia-Pacific Int. Symp. Air Water Treatments Green Oxidation/Reduction Technol.—Catalyst, Plasma and Hybrid Systems, Dalian, China, 2006. W.-K. Ching, A. J. Colussi, H. J. Sun, K. H. Nealson, and M. R. Hoffman, “Escherichia coli disinfection by electrohydraulic discharges,” Environ. Sci. Technol., vol. 35, no. 20, pp. 4139–4144, Oct. 2001. A. Abou-Ghazala, S. Katsuki, K. H. Schoenbach, F. C. Dobbs, and K. R. Moreira, “Bacterial decontamination of water by means of pulsedcorona discharges,” IEEE Trans. Plasma Sci., vol. 30, no. 4, pp. 1449– 1453, Aug. 2002. K. Yasuoka and K. Sato, “Development of repetitive pulsed plasmas in gas bubbles for water treatment,” Int. J. Plasma Environ. Sci. Technol., vol. 3, no. 1, pp. 22–27, 2009. M. Sato, T. Ohgiyama, and J. S. Clements, “Formation of chemical species and their effects on microorganisms using a pulsed high-voltage discharge in water,” IEEE Trans. Ind. Appl., vol. 32, no. 1, pp. 106–112, Jan./Feb. 1996. M. Dors, E. Metel, J. Mizeraczyk, and E. Marotta, “Coli bacteria inactivation by pulsed corona discharge in water,” Int. J. Plasma Environ. Sci. Technol., vol. 2, no. 1, pp. 34–37, 2008. B. R. Locke, M. Sato, P. Sunka, M. R. Hoffmann, and J.-S. Chang, “Electrohydraulic discharge and nonthermal plasma for water treatment,” Ind. Eng. Chem. Res., vol. 45, no. 3, pp. 882–905, Feb. 2006. B. Sun, M. Sato, and J. S. Clements, “Use of a pulsed high-voltage discharge for removal of organic compounds in aqueous solution,” J. Phys. D, Appl. Phys., vol. 32, no. 15, pp. 1908–1915, Aug. 1999. D. R. Grymonpré, W. C. Finney, R. J. Clark, and B. C. Locke, “Hybrid gas-liquid electrical discharge reactors for organic compound degradation,” Ind. Eng. Chem. Res., vol. 43, no. 9, pp. 1975–1989, Apr. 2004. C. M. Miller, R. L. Valentine, M. E. Roehl, and P. J. J. Alvarez, “Chemical and microbiological assessment of pendimethalin-contaminated soil after treatment with Fenton’s reagent,” Water Res., vol. 30, no. 11, pp. 2579– 2586, Nov. 1996. K. H. Chan and W. Chu, “The dose and ratio effects of Fe(II) and H2 O2 in Fenton’s process on the removal of atrazine,” Environ. Technol., vol. 24, no. 6, pp. 703–710, Jun. 2003. A. L. Barros, T. M. Pizzolato, E. Carissimi, and I. A. H. Schneider, “Decolorizing dye wastewater from the agate industry with Fenton oxidation process,” Minerals Eng., vol. 19, no. 1, pp. 87–90, Jan. 2006. N. Kang, D. S. Lee, and J. Yoon, “Kinetic modeling of Fenton oxidation of phenol and monochlorophenols,” Chemosphere, vol. 47, no. 9, pp. 915– 924, Jun. 2002. M. Pera-Titusa, V. Garcia-Molina, M. A. Baños, J. Giménez, and S. Esplugas, “Degradation of chlorophenols by means of advanced oxidation processes: A general review,” Appl. Catal. B: Environ., vol. 47, no. 4, pp. 219–256, Feb. 2004. 959 [25] J. S. Chang, “Thermal plasma solid waste and water treatments: A critical review,” Int. J. Plasma Environ. Sci. Technol., vol. 3, no. 2, pp. 67–84, 2009. [26] M. Sato, “Degradation of organic contaminants in water by plasma,” Int. J. Plasma Environ. Sci. Technol., vol. 3, no. 1, pp. 8–14, 2009. [27] A. Mizuno, “Recent progress and applications of non-thermal plasma,” Int. J. Plasma Environ. Sci. Technol., vol. 3, no. 1, pp. 1–7, 2009. [28] D. B. M. Scott and E. C. Lesher, “Effect of ozone on survival and permeability of Escherichia coli,” J. Bacteriol., vol. 85, no. 3, pp. 567–576, Mar. 1963. [29] B. D. Goldstein and E. M. McDonagh, “Effect of ozone on cell membrane protein fluorescence I. In vitro studies utilizing the red cell membrane,” Environ. Res., vol. 9, no. 2, pp. 179–186, Apr. 1975. [30] Alternative Disinfectants and Oxidants Guidance Manual, U.S. Environ. Protection Agency, Cincinnati, OH, Apr. 1999. EPA 815-R-99-014 [31] A. C. Giese and E. Christensen, “Effects of ozone on organisms,” Physiol. Zool., vol. 27, no. 2, pp. 101–115, 1954. [32] Hazen and Sawyer, Disinfection Alternatives for Safe Drinking Water. New York: Van Nostrand Reinhold, 1992. [33] T. Vykouk, M. Clupek, and P. Lukes, “Inactivation of Escherichia coli by pulsed corona discharge in water,” in Proc. 10th Int. Symp. High Pressure Low Temp. Plasma Chem., Saga, Japan, 2006, pp. 229–233. [34] P. H. Ceccato, O. Guaitella, M. Rabec Le Gloahec, and A. Rousseau, “Time-resolved nanosecond imaging of the propagation of a corona-like plasma discharge in water at positive applied voltage polarity,” J. Phys. D, Appl. Phys., vol. 43, no. 17, p. 175 202, May 2010. [35] Council Directive 98/83/EC, “On the quality of water intended for human consumption,” Official J. of the European Communities1998. [36] P. Lukes, M. Clupek, V. Babicky, and P. Sunka, “Pulsed electrical discharge in water generated using porous-ceramic-coated electrodes,” IEEE Trans. Plasma Sci., vol. 36, no. 4, pp. 1146–1147, Aug. 2008. T. Izdebski, photograph and biography not available at the time of publication. M. Dors, photograph and biography not available at the time of publication. J. Mizeraczyk, photograph and biography not available at the time of publication.