Preprints, 8th

8th IFAC

IFAC International

International Symposium

Symposium on

on

Preprints,

Preprints,

8th

IFAC

International

Symposium on

Advances

in

Control

Preprints,

IFAC

International

on

Advances 8th

in Automotive

Automotive

Control Symposium

Preprints,

8th

IFAC

International

Symposium

on

Advances

Automotive

Control

June

19-23,in

2016.

Norrköping,

Sweden

Available

online at www.sciencedirect.com

Advances

in

Automotive

Control

June

19-23,

2016.

Norrköping,

Sweden

Advances

in2016.

Automotive

Control

June

19-23,

Norrköping,

Sweden

June

June 19-23,

19-23, 2016.

2016. Norrköping,

Norrköping, Sweden

Sweden

ScienceDirect

IFAC-PapersOnLine 49-11 (2016) 657–664

Cycle

Beating

-- An

Analysis

of

the

Cycle

Beating

An

Analysis

of

Cycle

Beating

An

Analysis

of

the

Cycle Beating

- An Vehicle

AnalysisTesting

of the

the

Boundaries

During

Boundaries

During

Vehicle

Testing

Boundaries

During

Vehicle

Testing

Boundaries

During Vehicle

Testing

∗

∗

Kristoffer Ekberg

Ekberg ∗∗ ,, Lars

Lars Eriksson

Eriksson ∗∗ and

and Martin

Martin Sivertsson

Sivertsson ∗∗∗

Kristoffer

∗ , Lars Eriksson ∗ and Martin Sivertsson ∗

Kristoffer

Ekberg

∗ , Lars Eriksson ∗ and Martin Sivertsson ∗

Kristoffer

Ekberg

Kristoffer Ekberg , Lars Eriksson and Martin Sivertsson

∗

∗ Vehicular Systems, Dept. of Electrical Engineering, Linköping

∗ Vehicular Systems, Dept. of Electrical Engineering, Linköping

∗ Vehicular Systems, Dept. of Electrical Engineering, Linköping

∗ University,

Vehicular

Dept.

of

Engineering,

Linköping

SE-581

83

Linköping,

Sweden,

{kristoffer.ekberg,

University,

SE-581

83

Linköping,

Sweden,

{kristoffer.ekberg,

Vehicular Systems,

Systems,

Dept.

of Electrical

Electrical

Engineering,

Linköping

University,

SE-581

83

Linköping,

Sweden,

{kristoffer.ekberg,

University,

SE-581

83

Linköping,

Sweden,

{kristoffer.ekberg,

lars.eriksson}@liu.se,

sivertsson.martin@gmail.com

lars.eriksson}@liu.se,

sivertsson.martin@gmail.com

University,

SE-581

83

Linköping,

Sweden,

{kristoffer.ekberg,

lars.eriksson}@liu.se, sivertsson.martin@gmail.com

sivertsson.martin@gmail.com

lars.eriksson}@liu.se,

lars.eriksson}@liu.se, sivertsson.martin@gmail.com

Abstract: Todays

Todays vehicle

vehicle industry

industry is

is strictly

strictly controlled

controlled by

by environmental

environmental legislations.

legislations. The

The

Abstract:

Abstract:

Todays

vehicle

industry

is

strictly

controlled

by

environmental

legislations.

The

Abstract:

Todays

vehicle

industry

is

strictly

controlled

by

environmental

legislations.

The

vehicle

industry

is

spending

much

money

on

reducing

the

fuel

consumption

and

fulfilling

the

vehicle

industry

is

spending

much

money

on

reducing

the

fuel

consumption

and

fulfilling

the

Abstract:

Todays

vehicle

industry

is

strictly

controlled

by

environmental

legislations.

The

vehicle

industry

is

spending

much

money

on

reducing

the

fuel

consumption

and

fulfilling

the

vehicle

industry

is

spending

much

money

on

reducing

the

fuel

consumption

and

fulfilling

the

emission

requirements

to

make

sales

possible

in

different

regions

in

the

world.

Before

introducing

emission

requirements

to

make

sales

possible

in

different

regions

in

the

world.

Before

introducing

vehicle

industry

is

spending

much

money

on

reducing

the

fuel

consumption

and

fulfilling

the

emission

requirements

toitmake

sales

possible

in

different

regions

in

thecycles

world.

Before

introducing

emission

requirements

sales

possible

regions

in

world.

a

vehicle

on

the

market,

is

tested

according

to

standardized

driving

to

specify

the

vehicle

a vehicle

vehicle on

on

the market,

market,to

itmake

is tested

tested

according

to different

standardized

driving

cycles

toBefore

specifyintroducing

the vehicle

vehicle

emission

requirements

toit

make

salesaccording

possible in

in

different

regions

in the

thecycles

world.

Before

introducing

a

the

is

to

standardized

driving

to

specify

apollutant

vehicle on

on

the market,

market,

it

is tested

tested

according

to standardized

standardized

driving

cycles to

to from

specify

the

vehicle

pollutant

emissions

and it

fuel

consumption.

These

cycles allow

allowdriving

some deviation

deviation

from

thethe

reference

emissions

and

fuel

consumption.

These

cycles

some

the

reference

a

vehicle

the

is

according

to

cycles

specify

the

vehicle

pollutant

emissions

and

fuel

consumption.

These

cycles

allow

some

deviation

from

the

reference

pollutant

emissions

fuel

consumption.

These

cycles

deviation

reference

vehicle

speed

during

tests,

e.g.

NEDC

allows

deviations

of

±2

km/h

and

±1

s.

This

paper

vehicle speed

speed

duringand

tests,

e.g.

NEDC allows

allows

deviations

of some

±2 km/h

km/h

and from

±1 s.

s.the

This

paper

pollutant

emissions

and

fuel e.g.

consumption.

Thesedeviations

cycles allow

allow

some

deviation

from

the

reference

vehicle

during

tests,

NEDC

of

±2

and

±1

This

paper

vehicle

speed

during

tests,

e.g.

NEDC

allows

deviations

of

±2

km/h

and

±1

s.

This

paper

uses

dynamic

programming

to

find

fuel

optimal

velocity

profiles,

given

the

allowed

deviations

uses

dynamic

programming

to

find

fuel

optimal

velocity

profiles,

given

the

allowed

deviations

vehicle

speed

during

tests,

e.g.

NEDC

allows

deviations

of

±2

km/h

and

±1

s.

This

paper

uses

dynamic

programming

to

find fuel

optimal

velocity

profiles,

given

the

allowed

deviations

uses

programming

to

optimal

velocity

profiles,

the

deviations

of

±2

km/h

and

±1

from

reference

speed

during

drive

cycle

test.

By

taking

advantage

of

of ±2

±2dynamic

km/h and

and

±1 sss from

from reference

reference

speed

during

drive cycle

cycle

test.given

By taking

taking

advantage

of the

the

uses

dynamic

programming

to find

find fuel

fuel

optimal

velocity

profiles,

given

the allowed

allowed

deviations

of

km/h

±1

speed

during

drive

test.

By

advantage

of

of

±2 km/h

km/h

and ±1

±1

s from

from

reference speed

speed

during

drive cycle

cycle

test.

By taking

taking

advantage

of the

the

allowed

deviation,

the

fuel consumption

consumption

canduring

be reduced

reduced

by up

uptest.

to 16.56

16.56

% according

according

to model

model

allowed

deviation,

the

fuel

can

be

by

to

%

to

of

±2

and

s

reference

drive

By

advantage

of

the

allowed

deviation,

the

fuel

consumption

can

be

reduced

by

up

to

16.56

%

according

to

model

allowed

deviation,

the

consumption

can

reduced

up

to

%

to

results,

NEDC

if

gear

selections

are

unrestricted

(i.e.

using

automatic

gearbox),

and

results, running

running

NEDC

if

gear

selections

are be

unrestricted

(i.e.

using

automatic

gearbox),

and

allowed

deviation,

the fuel

fuel

consumption

can

be

reduced by

by(i.e.

up using

to 16.56

16.56

% according

according

to model

model

results,

running

NEDC

if

gear

selections

are

unrestricted

automatic

gearbox),

and

results,

running

NEDC

if

gear

selections

are

unrestricted

(i.e.

using

automatic

gearbox),

and

up

to

5.90

%

if

changing

gears

according

to

the

specifications

in

the

drive

cycle.

Two

different

up

to

5.90

%

if

changing

gears

according

to

the

specifications

in

the

drive

cycle.

Two

different

results,

running

NEDC

if

gear

selections

are

unrestricted

(i.e.

using

automatic

gearbox),

and

up

to

5.90 %

if

changing

gears

according

to

the

specifications

in

the

drive

cycle.

Two

different

up

to

if

gears

to

specifications

in

drive

optimization

goals

are

investigated,

minimum

amount

of

mass

fuel

consumed

and

best

mileage.

optimization

goals

are investigated,

investigated,

minimum

amount

of mass

mass fuel

fuel

consumed

and Two

best different

mileage.

up

to 5.90

5.90 %

% goals

if changing

changing

gears according

according

to the

the

specifications

in the

the

drive cycle.

cycle.

Two

different

optimization

are

minimum

amount

of

consumed

and

best

optimization goals

goals are

are investigated,

investigated, minimum

minimum amount

amount of

of mass

mass fuel

fuel consumed

consumed and

and best

best mileage.

mileage.

optimization

mileage.

© 2016, IFAC (International Federation of Automatic Control) Hosting by Elsevier Ltd. All rights reserved.

Keywords:

Keywords: Dynamic

Dynamic Programming,

Programming, Cycle

Cycle Beating.

Beating.

Keywords:

Dynamic

Programming,

Cycle

Beating.

Keywords:

Dynamic

Programming,

Cycle

Keywords: Dynamic Programming, Cycle Beating.

Beating.

1.

E/ECE/TRANS/505/Rev.1/Add.82/Rev.5

1. INTRODUCTION

INTRODUCTION

E/ECE/TRANS/505/Rev.1/Add.82/Rev.5 (2015),

(2015), the

the drdr1.

INTRODUCTION

E/ECE/TRANS/505/Rev.1/Add.82/Rev.5

(2015),

the

dr1.

E/ECE/TRANS/505/Rev.1/Add.82/Rev.5

(2015),

the

drive

cycle

is

displayed

in

Figure

1.

The

NEDC

defines

1. INTRODUCTION

INTRODUCTION

ive

cycle

is

displayed

in

Figure

1.

The

NEDC

defines

E/ECE/TRANS/505/Rev.1/Add.82/Rev.5

(2015),

the

drive speed

cycle is

is

displayedthat

in isFigure

Figure

1. The

The

NEDC

defines

ive

cycle

displayed

in

1.

NEDC

defines

the

trajectory

supposed

to

followed

and

the speed

speed

trajectory

that

isFigure

supposed

to be

be

followed

and

ive

cycle is

displayedthat

in is

1. The

NEDC

defines

Todays

concern

of

the

environment

has

resulted

in

difthe

trajectory

supposed

to

be

followed

and

Todays

concern

of

the

environment

has

resulted

in

difthe

speed

trajectory

that

is

supposed

to

be

followed

and

which

gears

that

should

be

selected.

The

cycle

consists

Todays

concern

of

the

environment

has

resulted

in

difwhich

gears

that

should

be

selected.

The

cycle

consists

the

speed

trajectory

that

is

supposed

to

be

followed

and

Todays

concern

of

the

environment

has

resulted

in

different

standards

and

regulations

concerning

vehicle

emiswhich

gears

that

should

be

selected.

The

cycle

consists

ferent standards

standards

andthe

regulations

concerning

vehicleinemisemisTodays

concern of

environment

has resulted

dif- which

gears

that

be

The

consists

of

standstills

and

accelerations.

ferent

and

regulations

concerning

vehicle

of constant

constant

speeds,

standstills

and constant

constant

accelerations.

which

gearsspeeds,

that should

should

be selected.

selected.

The cycle

cycle

consists

ferent

standards

and

concerning

vehicle

emissions,

regulations

are

for

and

deof

constant

speeds,

standstills

and

constant

accelerations.

sions, these

these

regulations

are drivers

drivers

for improving

improving

and

de- of

ferent

standards

and regulations

regulations

concerning

vehicle

emisconstant

speeds,

standstills

and

constant

accelerations.

The

behavior

of

the

cycle

can

be

hard

to

follow

precisely

in

sions,

these

regulations

are

drivers

for

improving

and

deThe

behavior

of

the

cycle

can

be

hard

to

follow

precisely

in

of

constant

speeds,

standstills

and

constant

accelerations.

sions,

these

regulations

are

drivers

for

improving

and

developing

better

vehicles.

The

regulations

have

a

large

imThe

behavior

of the

the

cycle

can be

befrom

hardregions

to follow

follow

precisely

in

veloping

better

vehicles.are

Thedrivers

regulations

have aa large

large

imsions,

these

regulations

for improving

and imde- The

behavior

of

cycle

can

hard

to

precisely

in

a

vehicle

due

to

rapid

changes

with

constant

veloping

better

vehicles.

The

regulations

have

a

vehicle

due

to

rapid

changes

from

regions

with

constant

The

behavior

of

the

cycle

can

be

hard

to

follow

precisely

in

veloping

better

vehicles.

The

regulations

have

a

large

impact

on

the

technical

development

concerning

automotive

a vehicle

vehicle due

due to

to rapid

rapid changes

changes

from regions

regions

with

constant

pact on

on the

the

technical

development

concerning

automotive

veloping

better

vehicles.

The regulations

have automotive

a large im- aacceleration

from

with

speed.

The

question

pact

technical

development

concerning

acceleration

totoregions

regions

with constant

constant

speed. with

The constant

question

aacceleration

vehicle dueto

rapid changes

from regions

with

constant

pact

on

the

technical

development

concerning

automotive

industry

(Eriksson

and

Nielsen

(2014)).

To

sell

vehicles

to

regions

with

constant

speed.

The

question

industry

(Eriksson

and

Nielsen

(2014)).

To

sell

vehicles

pact

on

the

technical

development

concerning

automotive

acceleration

to

regions

with

constant

speed.

The

question

raised

here

is,

how

much

can

much

can

you

gain

in

industry

(Eriksson

and

Nielsen

(2014)).

To

sell

vehicles

raised

here

is,

how

much

can

much

can

you

gain

in terms

terms

acceleration

to

regions

with

constant

speed.

The

question

industry

(Eriksson

and

Nielsen

(2014)).

To

sell

vehicles

in

regions,

they

have

fulfill

regional

reraised

here

is, how

how

much

can much

much

can you

you

gain in

in

terms

in different

different

regions,and

theyNielsen

have to

to

fulfill the

the

regional

re- raised

industry

(Eriksson

(2014)).

To sell

vehicles

here

is,

much

can

can

gain

terms

of

fuel

consumed

by

the

vehicle,

if

taking

advantage

of

the

in

different

regions,

they

have

to

fulfill

the

regional

reof

fuel

consumed

by

the

vehicle,

if

taking

advantage

of

the

raised

here

is,

how

much

can

much

can

you

gain

in

terms

in

different

regions,

they

have

to

fulfill

the

regional

requirements

regarding

how

much

pollutant

emissions

the

of fuel

fuel consumed

consumed

byinthe

the

vehicle,

if taking

taking

advantage

of the

the

quirements

regarding

how have

muchtopollutant

pollutant

emissions

the

in

different regarding

regions, they

fulfill theemissions

regional the

re- of

by

vehicle,

if

advantage

of

allowed

deviation

vehicle

speed?

The

investigation

is

quirements

how

much

allowed

deviation

in

vehicle

speed?

The

investigation

is

of

fuel

consumed

by

the

vehicle,

if

taking

advantage

of

the

quirements

regarding

how

much

pollutant

emissions

the

vehicle

releases.

To

fulfill

the

emission

legislations

today,

allowed

deviation

in vehicle

vehicle

speed?

The

investigation

is

vehicle releases.

releases.

To fulfill

fulfill

the

emission

legislations

today,

quirements

regarding

howthe

much

pollutant

emissions

the allowed

deviation

in

speed?

The

investigation

is

made

using

both

specified

gear

changes

and

freely

selected

vehicle

To

emission

legislations

today,

made

using

both

specified

gear

changes

and

freely

selected

allowed

deviation

in

vehicle

speed?

The

investigation

is

vehicle

releases.

To

fulfill

the

emission

legislations

today,

electric

hybrids

are

introduced

on

the

market,

using

both

made

using

both

specified

gear

changes

and

freely

selected

electric

hybrids

are

introduced

on

the

market,

using

both

vehicle releases.

To introduced

fulfill the emission

legislations

today,

both

gear

selected

gears,

to

the

from

gear

selections

on

electric

hybrids

are

on the

the market,

using

both made

gears, using

to investigate

investigate

the impact

impact

from and

gear freely

selections

on

made

using

both specified

specified

gear changes

changes

and

freely

selected

electric

hybrids

are

on

both

an

machine

and

engine.

By

gears,

to

investigate

the

impact

from

gear

selections

on

an electric

electric

machine

and aaa combustion

combustion

engine. using

By downdownelectric

hybrids

are introduced

introduced

on the market,

market,

using

both gears,

to

investigate

the

impact

from

gear

selections

on

the

savings

in

terms

of

fuel

consumption.

During

vehicle

an

electric

machine

and

combustion

engine.

By

downthe

savings

in

terms

of

fuel

consumption.

During

vehicle

gears,

to

investigate

the

impact

from

gear

selections

on

an

electric

machine

and

a

combustion

engine.

By

downsizing

the

internal

combustion

engine

and

adding

a

electhe savings

savings in

in terms

terms

ofNEDC

fuel consumption.

consumption.

During

vehicle

sizing

the internal

internal

combustion

engine and

and

adding

elec- the

an

electric

machinecombustion

and a combustion

engine.

By aadownfuel

During

simulations,

full

(full

low

speed

sizing

the

engine

adding

elecsimulations,

both

fullof

NEDC

(full cycle)

cycle) and

and

lowvehicle

speed

the

savings inboth

terms

ofNEDC

fuel consumption.

During

vehicle

sizing

the

internal

combustion

engine

and

adding

aa electric

machine

with

aa battery,

energy

can

be

regenerated

simulations,

both

full

(full

cycle)

and

low

speed

tric

machine

with

battery,

energy

can

be

regenerated

sizing

the

internal

combustion

engine

and

adding

elecsimulations,

both

full

NEDC

(full

cycle)

and

low

section

of

NEDC

(city

cycle)

are

investigated.

Low

speed

tric

machine

with

a

battery,

energy

can

be

regenerated

section

of

NEDC

(city

cycle)

are

investigated.

Low

speed

simulations,

both

full

NEDC

(full

cycle)

and

low

tric

machine

with

aa Hybrid

battery,

energy

can

be

regenerated

and

used

if

needed.

Electric

Vehicles

(HEV)

are

section

of

NEDC

(city

cycle)

are

investigated.

Low

speed

and

used

if

needed.

Hybrid

Electric

Vehicles

(HEV)

are

tric

machine

with

battery,

energy

can

be

regenerated

of

NEDC

are

investigated.

Low

is

to

visualize

different

to

and used

used

if needed.

needed.

Hybrid of

Electric

Vehicles

(HEV)

are section

is displayed

displayed

to cycle)

visualize

the

different solutions

solutions

to

section

of

NEDC (city

(city

cycle)

arethe

investigated.

Low speed

speed

and

if

Hybrid

Electric

Vehicles

(HEV)

are

used

to

the

released

emissions.

Wang

section

is

displayed

to

visualize

the

different

solutions

to

used used

to reduce

reduce

the amount

amount

of

released

emissions.

Wang

and

if needed.

Hybrid of

Electric

Vehicles

(HEV)

are section

is

displayed

to

visualize

the

different

solutions

to

the

problem,

depending

on

which

optimization

goal

that

is

used

to

reduce

the

amount

released

emissions.

Wang

the

problem,

depending

on

which

optimization

goal

that

is

section

is

displayed

to

visualize

the

different

solutions

to

used

to

reduce

the

amount

of

released

emissions.

Wang

and

Lukic

(2012)

have

used

dynamic

programing

to

find

the problem,

problem,

depending

on

which

optimization

goal

that

is

and Lukic

Lukic

(2012)

have

used of

dynamic

programing

toWang

find the

used

to reduce

thehave

amount

released

emissions.to

depending

on

which

optimization

goal

that

is

selected

and

if

choosing

gears

according

to

cycle

or

freely

and

(2012)

used

dynamic

programing

find

selected

and

if

choosing

gears

according

to

cycle

or

freely

the

problem,

depending

on

which

optimization

goal

that

is

and

Lukic

(2012)

have

used

dynamic

programing

to

find

optimal

control

strategies

for

different

configurations

of

selected and

and

if choosing

choosing

gears

according

to cycle

cycle

or freely

freely

optimal

control

strategies

fordynamic

differentprograming

configurations

of selected

and

Lukic

(2012)strategies

have usedfor

to find

if

to

or

selecting

gears.

The

cycle

is

in

1,

optimal

control

different

configurations

of

selectingand

gears.

The full

fullgears

cycleaccording

is displayed

displayed

in Figure

Figure

1,

selected

if choosing

gears

according

to cycle

or freely

optimal

control

for

different

of

HEV’s.

programing

been

used

selecting

gears.

The

full

cycle

is

displayed

in

Figure

1,

HEV’s. Dynamic

Dynamic

programing

have

beenconfigurations

used by

by several

several

optimal

control strategies

strategies

for have

different

configurations

of selecting

gears.

The

full

cycle

is

displayed

in

Figure

1,

one

city

cycle

is

displayed

in

Figure

2,

in

both

figures

the

HEV’s.

Dynamic

programing

have

been

used

by

several

one

city

cycle

is

displayed

in

Figure

2,

in

both

figures

the

selecting

gears.

The

full

cycle

is

displayed

in

Figure

1,

HEV’s.

Dynamic

programing

have

been

used

by

several

authors

(for

example

Luu

et

al.

(2010)

and

Wollaeger

one city

city cycle

cycle

is allowed

displayed

in Figure

Figure

2, in

in both

both

figuresgear

the

authors Dynamic

(for example

example

Luu et

et have

al. (2010)

(2010)

and by

Wollaeger

HEV’s.

programing

been used

several one

is

displayed

in

2,

figures

the

reference

speed,

speed

deviation

specified

authors

(for

Luu

al.

and

Wollaeger

reference

speed,

allowed

speed

deviation

and

specified

gear

one

city cycle

is allowed

displayed

in Figure

2, inand

both

figuresgear

the

authors

(for

example

Luu

et

al.

(2010)

and

Wollaeger

et

al.

(2012))

to

solve

vehicle

optimization

problems

conreference

speed,

speed

deviation

and

specified

et

al.

(2012))

to

solve

vehicle

optimization

problems

conauthors

(for

example

Luu

et

al.

(2010)

and

Wollaeger

speed,

allowed

speed

deviation

and

specified

gear

selections

are

displayed.

et al.

al. (2012))

(2012))

to

solve vehicle

vehicle

optimization

problems

con- reference

selections

are

displayed.

reference

speed,

allowed

speed

deviation

and

specified

gear

et

to

solve

optimization

problems

concerning

speed

trajectories

and

fuel

consumption.

Mensing

selections are

are displayed.

displayed.

cerning

speed to

trajectories

and optimization

fuel consumption.

consumption.

Mensing

et

al. (2012))

solve vehicle

problems

con- selections

cerning

speed

trajectories

and

fuel

Mensing

cerning

speed

trajectories

and

fuel

et

dynamic

to

optimal

et al.

al. (2011)

(2011)

uses

dynamic

programing

to find

find Mensing

optimal selections are displayed.

cerning

speed uses

trajectories

andprograming

fuel consumption.

consumption.

Mensing

et

al.

(2011)

uses

dynamic

programing

to

find

optimal

et

al.

uses

programing

to

optimal

ECO-driving

Vehicles

are

according

to

1.1 Contributions

Contributions

ECO-driving

trajectories.

Vehicles

are tested

tested

according

to 1.1

et

al. (2011)

(2011) trajectories.

uses dynamic

dynamic

programing

to find

find

optimal

1.1

Contributions

ECO-driving

trajectories.

Vehicles

are

tested

according

to

1.1

ECO-driving

trajectories.

Vehicles

are

tested

according

to

standardized

drive

cycles

to

make

it

possible

to

compare

1.1 Contributions

Contributions

standardized

drive

cycles

to

make

it

possible

to

compare

ECO-driving

trajectories.

Vehicles

are

tested

according

to

standardized

drive

cycles to

to make

it possible

possible

toincompare

compare

standardized

drive

cycles

it

different

manufactures.

Vehicles

tested

specific

This paper

paper uses

uses aaa dynamic

dynamic programing

programing approach

approach to

to show

show

different vehicle

vehicle

manufactures.

Vehicles

testedto

incompare

specific This

standardized

drive

cycles to make

make

it possible

toin

This

paper

uses

dynamic

programing

approach

to

show

different

vehicle

manufactures.

Vehicles

tested

specific

This

paper

uses

aa dynamic

programing

approach

to

show

different

vehicle

manufactures.

Vehicles

tested

in

specific

how

fuel

economy

is

affected

by

smart

driving,

within

drive

cycles

can

today

be

driven

by

robots

to

achieve

how

fuel

economy

is

affected

by

smart

driving,

within

drive

cycles

can

today

be

driven

by

robots

to

achieve

This

paper

uses

dynamic

programing

approach

to

show

different

vehicle

manufactures.

Vehicles

tested

in

specific

how

fuel

economy

is

affected

by

smart

driving,

within

drive

cycles

can

today

be

driven

by

robots

to

achieve

fuel

by

within

drive

cycles

today

robots

to

the

limits

the

drive

The

contribution

is

good

following,

but

NEDC

(New

European

Drive

the legal

legal

limits of

of is

theaffected

drive cycle.

cycle.

The driving,

contribution

is

good reference

reference

following,

but driven

NEDC by

(New

European

Drive how

how

fuel economy

economy

is

affected

by smart

smart

driving,

within

drive

cycles can

can

today be

be

driven

by

robots

to achieve

achieve

the

legal

limits

of

the

drive

cycle.

The

contribution

is

good

reference

following,

but

NEDC

(New

European

Drive

the

legal

limits

of

the

drive

cycle.

The

contribution

is

good

reference

following,

but

NEDC

(New

European

Drive

a

quantification

how

much

the

fuel

consumption

can

Cycle)

allows

some

deviation

in

vehicle

speed

during

vehia

quantification

how

much

the

fuel

consumption

can

Cycle)

allows

some

deviation

in

vehicle

speed

during

vehithe

legal

limits

of

the

drive

cycle.

The

contribution

is

good

reference

following,

but

NEDC

(New

European

Drive

a quantification

quantification

of how

how

much the

the

fuel

consumption

can

Cycle)

allows

some deviation

deviation

in vehicle

vehicle

speed

during

vehi- abe

of

much

consumption

can

Cycle)

allows

some

in

during

vehireduced

taking

advantage

of

the

deviation

cle

Regulations

concerning

the

drive

NEDC

bequantification

reduced by

by

taking

advantage

of fuel

the allowed

allowed

deviation

cle testing.

testing.

Regulations

concerning

the speed

drive cycle

cycle

NEDC

of how

much the

fuel

consumption

can

Cycle)

allows

some deviation

in vehicle

speed

during

vehi- abe

reduced

by

taking

advantage

of

the

allowed

deviation

cle

testing.

Regulations

concerning

the

drive

cycle

NEDC

be

reduced

by

taking

advantage

of

the

allowed

deviation

cle

testing.

Regulations

concerning

the

drive

cycle

NEDC

speed

during

drive

paper

allows

aa deviation

in

speed

following

of

km/h

in reference

reference

speed

during

drive cycle

cycle

testing,

the

paper

allows

deviation

in reference

reference

speedthe

following

of ±2

±2NEDC

km/h in

be

reduced by

taking

advantage

of thetesting,

allowed the

deviation

cle

testing.

Regulations

concerning

drive cycle

in

reference

speed

during

drive

cycle

testing,

the

paper

allows

a

deviation

in

reference

speed

following

of

±2

km/h

speed

drive

testing,

paper

allows

in

following

of

km/h

also

show

gear

if

and

±1

during

decelerations

constant

alsoreference

show optimal

optimal

gear selections

selections

if gears

gears

arethe

selected

and

±1aa sssdeviation

during accelerations,

accelerations,

decelerations

and

constant

in

reference

speed during

during

drive cycle

cycle

testing,are

theselected

paper

allows

deviation

in reference

reference speed

speed

followingand

of ±2

±2

km/h in

also

show

optimal

gear

selections

if

gears

are

selected

and

±1

during

accelerations,

decelerations

and

constant

also

show

optimal

gear

selections

if

gears

are

selected

and

±1

s

during

accelerations,

decelerations

and

constant

freely.

Two

different

optimization

goals

are

analyzed,

High

speed

traveling,

see

E/ECE/324/Rev.1/Add.82/Rev.5freely.

Two

different

optimization

goals

are

analyzed,

High

speed

traveling,

see

E/ECE/324/Rev.1/Add.82/Rev.5also

show

optimal

gear

selections

if

gears

are

selected

and

±1

s

during

accelerations,

decelerations

and

constant

freely. Two

Two different

different optimization

optimization goals

goals are

are analyzed,

analyzed, High

High

speed traveling,

traveling, see

see E/ECE/324/Rev.1/Add.82/Rev.5E/ECE/324/Rev.1/Add.82/Rev.5- freely.

speed

speed traveling, see E/ECE/324/Rev.1/Add.82/Rev.5- freely. Two different optimization goals are analyzed, High

Copyright

© 2016,

2016

669

2405-8963 ©

IFAC (International Federation of Automatic Control)

Copyright

2016 IFAC

IFAC

669 Hosting by Elsevier Ltd. All rights reserved.

Copyright

©

2016

IFAC

669

Copyright

©

2016

IFAC

669

Peer

review

under

responsibility

of

International

Federation

of

Automatic

Copyright © 2016 IFAC

669Control.

10.1016/j.ifacol.2016.08.095

IFAC AAC 2016

658

June 19-23, 2016. Norrköping, Sweden

(1) Low Fuel as possible, using manual gearbox with gear

selections specified by the drive cycle.

(2) High Mileage as possible, using manual gearbox with

gear selections specified by the drive cycle.

(3) Low Fuel as possible, using automatic gearbox with

free possibility to select gears.

(4) High Mileage as possible, using automatic gearbox

with free possibility to select gears.

Cycle speed and Speed limits

150

Velovity [km/h]

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

Vref

Vmin

100

Vmax

50

0

0

200

400

6

Gear [-]

600

800

1000

1200

Time [s]

Gear selections

2.1 Vehicle model

To calculate the fuel consumption for a specific vehicle

driving according to the drive cycle, a vehicle model is

implemented. The model calculates the amount of fuel

needed for a certain energy requirement at the wheels.

During simulations, vehicle data according to Table 1 is

used. The gearing setup γ is used for both the specified

and unspecified gear changes.

4

2

0

0

200

400

600

800

1000

1200

Time [s]

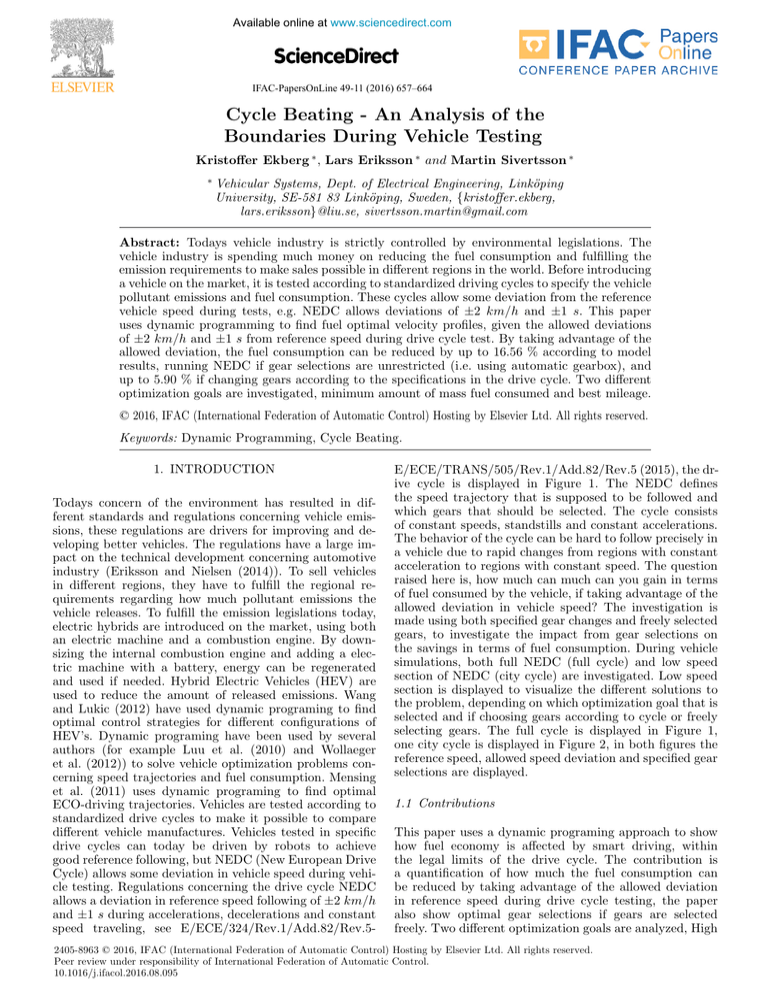

Fig. 1. Full NEDC, displays speed in km/h, time in seconds

and gear number. Speed trajectory is displayed in top

figure and which gears to select is displayed in bottom

figure. Gear number 0 corresponds to neutral gear.

Cycle speed and Speed limits

Velovity [km/h]

60

Vref

Vmin

40

Vmax

20

0

0

50

3

Gear [-]

100

150

200

150

200

Time [s]

Gear selections

2

1

0

0

50

100

Time [s]

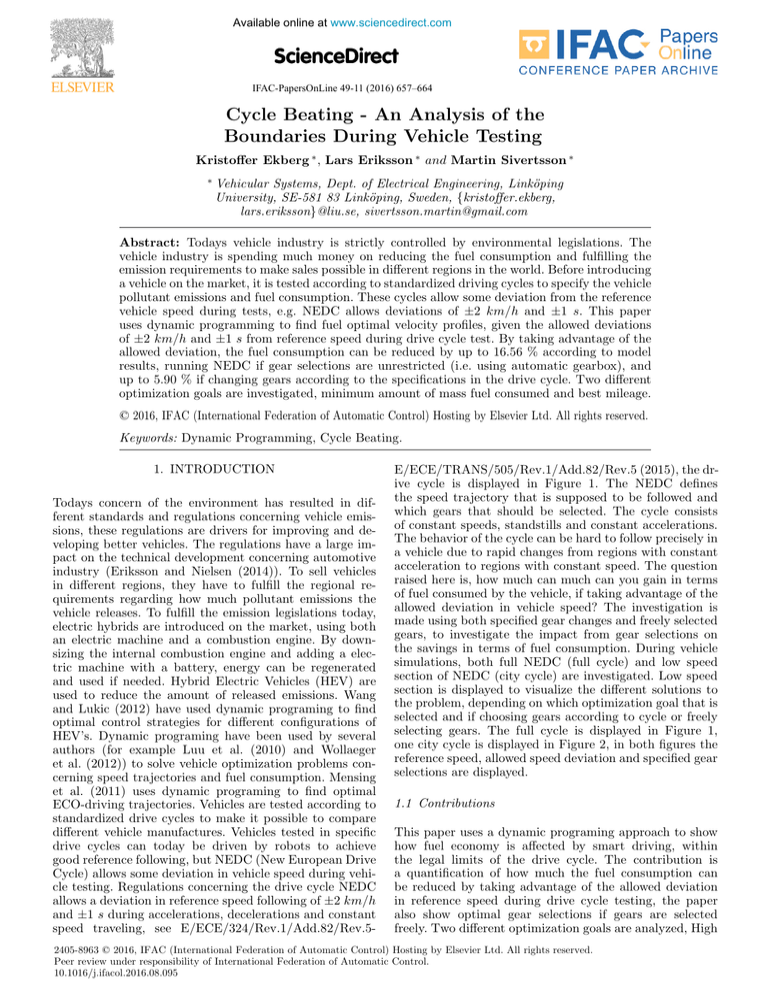

Fig. 2. Section from NEDC, city cycle, displays speed

in km/h, time in seconds and gear number. Speed

trajectory is displayed in top figure and which gears

to select is displayed in bottom figure. Gear number

0 corresponds to neutral gear.

Mileage and Low Fuel, with and without restrictions on the

gear changes made in the vehicle. Drive cycle simulations

are performed on both low speed part of NEDC cycle and

full NEDC cycle.

2. CYCLE BEATING

Table 1. Vehicle data used during simulations.

Parameter

Value

Unit

ρair

ρf uel

Cd

Cr

A

g

m

rw

Jw

γ

ηgearbox

Je

Te,max

Ne,max

Vd

e

pme0

Hl

1.18

737.2

0.32

0.015

2.31

9.81

1500

0.30

0.6

0 13.0529 8.1595 5.6651 4.2555 3.2623

0.98

0.2

115

5000

1.497 × 10−3

0.4

1 × 105

44.6 × 106

kg/m3

kg/m3

−

−

m2

m/s2

kg

m

kg m2

−

−

kg m2

N m

rpm

m3

−

Pa

J/kg

The forces acting on a vehicle traveling on flat road are

described in equations (1a), (1b) and (1c) (see Guzzella

and Sciarretta (2007)):

1

(1a)

Fdrag = ρair Cd Av 2

2

Jw

(1b)

Facc = a(m + 2 )

rw

Froll = Cr mg

(1c)

The energy dissipated during one time step, from time tn

to tn+1 , with the assumption that the vehicle acceleration

a is constant, is described by:

! tn+1

F vdt

(2)

E=

tn

Cycle beating refers to performing well while fulfilling the

specifications of the cycle. By using a vehicle model to

simulate the forces acting on the vehicle during driving,

the required fuel consumption is calculated. This paper

uses dynamic programing to find the least fuel consuming

driving strategies. The analysis consists of four cases.

The cases have different setups and different optimization

goals. Optimizing the speed trajectory within the limit of

±2 km/h and ±1 s from reference speed, to achieve as

670

If using equations (1a), (1b) and (1c) together with (2),

following energy equations can be derived:

1

2

Edrag = ρair Cd A(vn+1

+ vn2 )(vn+1 + vn )∆t

(3a)

8

Jw

a

(3b)

Eacc = (m + 2 )(vn+1 + vn )∆t

2

rw

1

Eroll = Cr mg(vn+1 + vn )∆t

(3c)

2

IFAC AAC 2016

June 19-23, 2016. Norrköping, Sweden

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

Energy required at the wheels is Ereq = Edrag + Eacc +

Eroll .

659

ω1 θ1

ω2 θ2

T

2.2 Gearbox and clutch model

To extend the analysis of the drive cycle, a gearbox model

and clutch model are implemented. These models are used

to analyze the use of free gear selections. The models takes

following actions into account:

(1) Changes in kinetic energy due to engine rotation.

(2) Dissipated energy in clutch during gear changes.

(3) Start/stop model, restricts the engine speed to 800

rpm during starts and stops.

The total amount of energy required by the combustion

engine is described in equation (4).

Eice = Egearbox + Eengine + Eclutch

(4)

Energy required by gearbox (Egearbox ), with gearbox efficiency ηgearbox and gear ratio γ (se values in Table 1) is

displayed in equation (5).

Ereq

Egearbox =

(5)

ηgearbox

The kinetic rotational energy inside the engine is included

in the analysis, to enable the use of engine braking, the

kinetic rotational energy in the engine at current and next

time step is expressed in equations (6a) and (6b).

Je

vcurr

2

, where ωice0 =

Eeng0 = ωice0

ginit

(6a)

2

rw

vnext

Je

2

, where ωice1 =

Ggrid

(6b)

Eeng1 = ωice1

2

rw

Where Ggrid represents all possible gear changes from the

current time step with gear, ginit to next time step. The

cost to perform a gear change, is both the change in engine

rotational speed (which can be both positive and negative)

and the energy dissipated in the clutch. The kinetic energy

needed to change the engine speed from current time step

to next time step (Eengine ) is described in equation (7).

Eengine = Eeng1 − Eeng0

(7)

The energy dissipated in the clutch (Eclutch ) is described

in equation (14). Eclutch will always be positive, since the

clutch, independent of if there is a upshift or downshift

maneuver, will dissipate heat when performing clutch lock

maneuver.

A graphical representation of the clutch model is displayed

in Figure 3. The description of the energy dissipated

in the clutch during a clutch maneuver is described in

Bhandari (2007). The rotational speeds in the clutch can

be described by the incoming and outgoing shaft torques,

see equation (8).

T1

T2

θ̈1 =

and θ̈2 =

(8)

J1

J2

The rotational speeds θ̇i are received by integrating the

above functions from time t = 0 to time t = tclutch . The

initial rotational speeds att t = 0 are ω1 and ω2 .

! tclutch

T1

T1

θ̇1 =

dt =

tclutch + ω1

(9a)

J

J1

1

!0 tclutch

T2

T2

dt =

tclutch + ω2

(9b)

θ̇2 =

J

J2

2

0

671

J1

J2

Fig. 3. Clutch discs, index 1 corresponds to disc connected

to driveline, index 2 corresponds to engine disc. The

torque T indicates the torque delivered between the

two clutch discs.

The rotational speed difference between the incoming and

outgoing disc in the clutch is described as:

∆θ̇ = θ̇1 − θ̇2 =⇒

T2

T1

tclutch + ω1 − tclutch − ω2

∆θ̇ =

J1

J2

Torque balance T = −T1 = T2 gives:

J1 + J2

)T tclutch + ω1 − ω2

∆θ̇ = −(

J1 J2

The clutch lockup is completed when the rotational

difference ∆θ̇ equals 0, equation (11) gives:

J1 + J 2

0 = −(

)T tclutch + ω1 − ω2 =⇒

J1 J2

ω 1 − ω2 J 1 J2

tclutch =

T

J1 + J2

(10a)

(10b)

(11)

speed

(12a)

(12b)

The energy dissipated in the clutch during a clutch lockup

is described in equation (13b).

! tclutch

T ∆θ̇dt =⇒

(13a)

Eclutch =

0

Eclutch

1 J 1 J2

=

(ω1 − ω2 )2

2 J1 + J2

(13b)

2

By introducing J1 = Jv = γ12 (mrw

+ Jw ), J2 = Je . A gear

change is assumed to take place during one time step, ∆t,

therefore the rotational speeds ω1 = ωice0 and ω2 = ωice1 ,

when a gear change is performed. If no gear change is

performed, Eclutch = 0.

"

0

if ∆θ̇ = 0

Eclutch = 1 Jv Je

(14)

2

(ω

−

ω

)

if

∆θ̇ ̸= 0

ice0

ice1

2 Jv +Je

2.3 Combustion engine model

Total mass fuel consumed during one time step can be

calculated using an engine model based on Willans approximation (see Guzzella and Sciarretta (2007)), the mass fuel

consumed during one time step is described in equation

(15).

wice

pme0 Vd

∆mf =

(Tice +

+ Je ω̇ice )∆t

(15)

Hl e

4π

Equation (15) is rewritten with equation (16) to form the

expression in equation (17a). In both equations (17a) and

(17b) the inertia Je in equation (15) is included in Eice .

The mass fuel consumed during one time step from tn to

tn+1 , is used to form the cost function in the dynamic

programming algorithm.

IFAC AAC 2016

660

June 19-23, 2016. Norrköping, Sweden

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

ωice1 − ωice0

2ω̇ice

, where ω̇ice =

2

2

ωice1

− ωice0

∆t

(16)

During starts, stops and standstills, the engine speed ωice0

and ωice1 are restricted to a constant speed of 800 rpm.

During starting maneuvers, the rotational speed is kept

at 800 rpm until the rotational speeds of the engine

and gearbox (clutch incoming and outgoing rotational

speeds) equals each other. This restriction is implemented

to include the energy dissipated during starting maneuver

when clutch is slipping and first gear is engaged.

2

w2 − wice0

pme0 Vd

∆mf = ice1

) (Acceleration)

(Tice +

Hl e2ẇice

4π

(17a)

wice0

pme0 Vd

(Tice +

)∆t (Constant speed)

∆mf =

Hl e

4π

(17b)

Tice = Eice

2.4 Dynamic Programing Solving Optimization problem

The drive cycle is driven with the specified gearbox and

clutch model in all four cases, two of these where the gears

are selected freely by the optimization, and two where the

gear changes are according to the specified drive cycle.

Dynamic programing (Bertsekas (2000)) is used to find

the best driving pattern to reduce the fuel consumption

as much as possible.Two different optimization goals are

investigated, one where the total mass fuel is minimized

and one where the mean fuel consumption is minimized.

When the free gear selection mode is simulated, the vehicle

is free to select gears as long as the cycle requirements

and vehicle restrictions are fulfilled. The problem size

changes from 1D to 2D, when changing from specified gear

changes to free gear changes, a graphical representation

of the different gear and speed possibilities are displayed

in Figure 4. A backward algorithm is used, solving the

problem from the final states at time tend to the states at

starting time tstart . The restrictions in the vehicle model

are listed in Table 2.

Table 2. Constraints on the vehicle model.

Constraints

γ ̸= 0 if vavg > 0

ω̇e < ω̇e,max

Tice < Tice,max

Ne ≤ Ne,max

If γωw < ωe,min =⇒ γ = 1 st gear.

!T

JHM = min ! 0T

JLF = min

2.5 Optimization problem

The two different optimization problems solved during

the simulation cases are displayed in equations (HM) and

(LF).

672

vopt dt

0

" T

ṁf dt

(HM)

(LF)

0

where mf is the mass of fuel consumed, v is the vehicle

speed. Equation (HM) for High Mileage and equation (LF)

is the problem to solve for Low Fuel during the cycle.

The problem consists of three states, vehicle speed, driven

distance and selected gear. The states driven distance and

vehicle speed are linked to each other. The vehicle speed

is defined by the drive cycle and the allowed deviation

from the speed reference, the driven distance is solved

with the knowledge of the vehicle speed and the time step

length. Since the total driven distance is not specified by

the drive cycle, the state driven distance is unconstrained.

By solving the problem with dynamic programing, a twodimensional grid at each time step is needed, consisting of

all possible gears and all possible vehicle speeds from tn

to tn+1 .

3. RESULTS

Results for the european city cycle are displayed in Figures

A.1, A.3 and A.5. Results for the full cycle are displayed in

Figures A.2 , A.4 and A.6. The figures displays the optimal

speed trajectory for each case, fuel flow to combustion

engine, selected gear and deviation from cycle reference

speed. The results in Figures A.1 and A.2 (when using

specified gear changes) are used as references when calculating the savings in terms of fuel consumption. All

the simulations are summarized and displayed in Table

3, where the savings in fuel consumption is calculated

according to equation (18), where ∅ref is fuel consumption (l/100 km) for reference simulation and ∅case is fuel

consumption for the case that is to be compared.

ηsavings

Fig. 4. Graphical representations of the dynamic programing algorithm. At each time step from tn to tn+1 , the

cost for each opportunity of selecting speed, v, and

gear γ, is calculated.

ṁf dt

case

= 100

∅ref − ∅case

∅ref

(18)

The vehicle speed trajectory is optimized within the limit

of ±2 km/h and ±1 s from reference speed, to achieve as

Low Fuel consumption as possible, and as High Mileage as

possible, using both manual and automatic gearbox with

free possibility to select gears. The Low Fuel consumption

optimization corresponds to comparing the fuel consumed

by the nominal cycle distance in the drive cycle, with

the fuel actually consumed. Since the vehicle speed and

nominal cycle speed are unconnected, the solution ends

up with minimizing the total amount of fuel used during

the drive cycle. The High Mileage optimization uses the

driven distance and amount of fuel consumed, since the

vehicle speed is allowed to deviate from the cycle speed

reference, also the driven distance will vary. All solutions

IFAC AAC 2016

June 19-23, 2016. Norrköping, Sweden

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

where a deviation in vehicle speed is allowed, have one

thing in common, the optimal solution is to extend the

time in fuel-cut (e.g. where the engine brakes) compared

to reference simulations. Due to the speed variance from

the reference speed, the total driven distances are different

for the different simulations.

3.1 Low speed part of NEDC

Speed deviations not allowed (optimizing for Low Fuel)

If the deviations in vehicle speed had been forbidden,

the gear changes had been the only degree of freedom

if using automatic gearbox. In Figure A.1 the solutions

for specified gear changes and optimized gear changes are

displayed. The optimal solution when gear selections are

unrestricted, is to select highest gear possible, to reduce

the fuel flow and thereby reduce fuel consumed (the fuel

consumption is reduced from 6.79 to 5.49 l/100 km).

Optimizing for High Mileage When vehicle speed is allowed to deviate from reference speed, the problem has two

degrees of freedom (when gear changes are unrestricted),

gear changes and vehicle speed. In Figure A.3 the solutions

for the High Mileage optimizations are displayed. The

optimal solution when the gear selections are unrestricted,

is to extend the driven distance, from 1018 m (in reference

case) to 1042 m. When using specified gear changes, the

optimal solution is to shorten the driven distance, from

1018 m (in reference case) to 971 m, the driven distance is

only extended when using fuel cut during engine braking.

Also the solver uses highest gear possible when optimized

gear changes are used.

Optimizing for Low Fuel When vehicle speed is allowed

to deviate from reference speed, the problem has two

degrees of freedom (when gear changes are unrestricted),

gear changes and vehicle speed. In Figure A.5 the solutions

for the Low Fuel optimizations are displayed. It is visible

that the optimal solution is to keep the vehicle speed as low

as possible, to keep the fuel flow low. The lowest allowed

speed is kept along the cycle, except during engine braking,

where the possibility to run on low or no fuel is present.

3.2 Full NEDC

The low speed part of NEDC is previously displayed, to

show the different optimal solutions found by the dynamic

programming algorithm. The full NEDC cycle is also

simulated, to investigate how the allowed deviation in

vehicle speed may be used during a full drive cycle test.

Speed deviation not allowed (optimizing for Low Fuel) In

Figure A.2 it is visible that the optimal solution for the low

speed parts of the drive cycle looks similar to the city cycle

simulation (see Figure A.1). The solver uses the ability

to change gears, by selecting the highest gear possible,

to reduce the fuel flow and thereby the fuel consumed.

Investigating the gear selections pattern in Figure A.2, at

around 900s, the solver changes from 5th to 4th and down

to 3rd gear for a short moment and then up to 5th gear

again, during this time the vehicle does not require any fuel

flow. The optimal solution at that moment is therefore to

store kinetic energy in the engine (changing down to 3rd

673

661

gear), then use the kinetic energy stored in the engine

when needed (changing from 3rd to 5th gear).

Optimizing for High Mileage Studying the vehicle velocity profile in Figure A.4, it shows that the optimal

solution for both specified and optimized gear selections is

to increase the driven distance by driving faster than the

reference profile at some occasions (such as accelerating

earlier than the reference profile). It is also visible that

the driven distance when using specified gear changes is

shorter (10790 m) compared to optimal gear selections

(11306 m). The optimal solution when gear selections are

unrestricted, is to choose the highest gear possible while

fulfilling the vehicle constraints, the use of higher gear

reduces the fuel flow.

Optimizing for Low Fuel As for the city cycle optimized

for LF, the optimal vehicle speed is following the low speed

boundary, except during roll outs when engine braking

is possible (which cuts the fuel flow). Even though the

highest gear is selected when possible (running the case

when gear changes are unrestricted), the optimal vehicle

speed stays below the reference speed (on the lower vehicle

speed boundary condition). This is visible in Figure A.6.

3.3 Summary Results

Table 3 summarizes all the results for the different cycles.

Table 3. Results from all the different simulation cases. The case ”LF (vref )” follows the

specified vehicle speed exactly.

Case

Description

Savings

%

City Cycle

Reference

LF

HM

City Cycle

LF (vref )

LF

HM

Full Cycle

Reference

LF

HM

Full Cycle

LF (vref )

LF

HM

Manual

4.71%

8.40 %

Automatic

19.15 %

24.60 %

29.60 %

Manual

3.61 %

5.90 %

Automatic

9.67 %

13.28 %

16.56 %

Mass Fuel

g

Mean Fuel

l/100 km

Distance

m

50.95

44.14

44.53

6.79

6.47

6.22

1018

925

971

41.22

35.52

36.72

5.49

5.12

4.78

1018

941

1042

495.57

450.32

456.63

6.10

5.88

5.74

11021

10394

10790

448.01

408.25

424.28

5.51

5.29

5.09

11021

10469

11306

3.4 Parameter sensitivity analysis

A parameter sensitivity analysis has been performed, investigating the change in fuel consumption, if changing

parameters vehicle mass m, tire rolling resistance cr and

vehicle frontal area A. The analysis is performed for the

reference case in Figure A.2, with the full NEDC cycle,

where both the vehicle speed and gear changes are specified. The result of the parameter sensitivity analysis is

displayed in Table 4. The result is displayed as the difference in fuel consumption, calculated according to Equation

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

Table 4. Parameter sensitivity analysis. The

top percentage shows the size of the change in

the parameters A, m and cr . The result shows

the relative difference in fuel consumption,

compared to the reference case in Figure A.2,

using specified gear selections (increased fuel

consumption in negative numbers).

Parameter

10%

5%

A

m

cr

-1.743

-4.504

-2.410

-0.872

-2.250

-1.205

−5%

0.871

2.249

1.204

−10%

1.742

4.495

2.409

4. CONCLUSION

Results show that by optimizing the driving pattern within

the allowed deviation from the drive cycle reference velocity of ±2 km/h and ±1 second, the fuel consumption

of the driven vehicle can be clearly reduced. A dynamic

programming, backward algorithm has been used, to find

the optimal solutions for High Mileage and Low Fuel over

a specified drive cycle, with allowed deviations in vehicle

speed. The use of free possibility to change gears was

also examined. The results in table 3, show that the fuel

consumption can be clearly reduced by taking advantage

of the allowed deviation in vehicle speed. Optimization

results shows that it is optimal to use engine braking when

possible, to enable fuel cut, independent of if the optimization goal is High Mileage or Low Fuel. The possibility

to deviate from reference speed leads to different driven

distances for the different cases. To increase High Mileage,

the driven distance is increased, while fuel flow is kept low.

When optimizing for Low Fuel, the vehicle speed is made

as low as possible, to lower the fuel flow in the engine.

Comparing the savings of fuel consumption in Table 3 with

the changes of fuel consumption in Table 4, it shows that

the savings when taking advantage of the allowed speed

deviation is generally larger than a 10% decrease of any

of the parameters frontal area A, rolling resistance cr or

vehicle mass m used during simulations.

Eriksson, L. and Nielsen, L. (2014). Modeling and Control

of Engines and Drivelines. John Wiley and Sons Ltd,

United Kingdom.

Guzzella, L. and Sciarretta, A. (2007). Vehicle Propulsion

Systems. Springer, New York.

Luu, H.T., Nouvelière, L., and Mammar, S. (2010). Dynamic programming for fuel consumption optimization

on light vehicle. In Prep. IFAC symp. Advances in

Automotive Control. AAC2010.

Mensing, F., Trigui, R., and Bideaux, E. (2011). Vehicle

trajectory optimization for application in eco-driving.

In Vehicle Power and Propulsion Conference (VPPC),

2011 IEEE, 1–6. doi:10.1109/VPPC.2011.6042993.

Wang, R. and Lukic, S. (2012). Dynamic programming

technique in hybrid electric vehicle optimization. In

Electric Vehicle Conference (IEVC), 2012 IEEE International, 1–8. doi:10.1109/IEVC.2012.6183284.

Wollaeger, J., Kumar, S., Onori, S., Filev, D., Ozguner,

U., Rizzoni, G., and Di Cairano, S. (2012). Cloudcomputing based velocity profile generation for minimum fuel consumption: A dynamic programming based

solution. In American Control Conference (ACC), 2012,

2108–2113. doi:10.1109/ACC.2012.6314931.

Appendix A. OPTIMIZATION RESULTS

20

1

20

40

60

100

120

140

160

180

Specified Gear

Optimal Gear

0

0

20

40

60

80

100

120

140

160

180

140

160

180

160

180

Gear selections

6

4

2

0

0

20

40

60

80

100

120

Difference from reference velocity

1

Velocity [km/h]

80

Fuel Consumption Spec/Opt 6.79/5.49 l/100 km

0.5

Gear [-]

674

0

×10-3

This work was supported by the Vinnova Industry Excellence Center: LINK-SIC Linköping Center for Sensor

Informatics and Control.

Bertsekas, D.P. (2000). Dynamic Programming and Optimal Control, volume 2. Athena Scientific, Bellmonth,

Massachusetts.

Bhandari, V.B. (2007). Design of Machine Elements. Tata

McGraw-Hill.

E/ECE/324/Rev.1/Add.82/Rev.5E/ECE/TRANS/505/Rev.1/Add.82/Rev.5

(2015).

Regulation no. 83 uniform provisions concerning the

approval of vehicles with regard to the emission of

pollutants according to engine fuel requirements.

Boundary

Boundary

Specified Gear

Optimal Gear

40

0

ACKNOWLEDGEMENTS

REFERENCES

Driven distance Spec/Opt 1018/1018 m

60

Velocity [km/h]

(18). If comparing best saving in fuel consumption in Table

4 with for example Full Cycle - Manual - LF in Table 3, one

of the smaller savings due to the allowed speed deviation

corresponds the biggest change of mass in table 4.

Fuel Flow [kg/s]

IFAC AAC 2016

662

June 19-23, 2016. Norrköping, Sweden

0.5

0

-0.5

-1

0

20

40

60

80

100

120

140

Time [s]

Fig. A.1. Exact speed reference following with cycle specified gear changes and automatic gear changes. Optimizing for LF with specified vehicle speed and both

specified and optimal gear changes. It shows in figure

that fuel cut is used with both specified and optimal

gear changes.

IFAC AAC 2016

June 19-23, 2016. Norrköping, Sweden

Kristoffer Ekberg et al. / IFAC-PapersOnLine 49-11 (2016) 657–664

Velocity [km/h]

100

50

0

0

200

Fuel Flow [kg/s]

400

600

800

1

0

200

400

800

200

400

600

800

0

0

200

Velocity [km/h]

0

400

600

800

600

0

200

400

600

-5

200

400

600

Velocity [km/h]

80

100

120

140

160

20

40

60

100

120

140

160

0

Gear [-]

20

40

60

80

100

120

40

140

160

Velocity [km/h]

Velocity [km/h]

-5

60

80

100

120

140

120

140

160

180

0

20

40

60

80

100

120

140

160

180

140

160

180

160

180

Gear selections

2

0

20

40

60

80

100

120

Difference from reference velocity

0

40

100

4

0

180

5

20

80

Specified Gear

Optimal Gear

Difference from reference velocity

0

60

Fuel Consumption Spec/Opt 6.47/5.12 l/100 km

6

2

0

20

0.5

180

4

0

1

Gear selections

6

Gear [-]

80

0

×10-3

Specified Gear

Optimal Gear

0

20

0

0.5

0

Boundary

Boundary

Specified Gear

Optimal Gear

40

180

Fuel Flow [kg/s]

Velocity [km/h]

Fuel Flow [kg/s]

60

Driven distance Spec/Opt 925/941 m

60

Fuel Consumption Spec/Opt 6.22/4.78 l/100 km

×10-3

1

40

1000

Fig. A.4. Optimizing for HM, full cycle, when velocity

deviations are allowed. Both specified and optimal

gear changes. The optimal gear changes case has

longer driven distance than specified gear case.

Driven distance Spec/Opt 971/1042 m

20

800

Time [s]

Boundary

Boundary

Specified Gear

Optimal Gear

0

1000

0

0

20

0

800

5

1000

Fig. A.2. Exact speed reference following with cycle specified gear changes and automatic gear changes. Optimizing for LF with specified vehicle speed and both

specified and optimal gear changes. It shows in figure

that fuel cut is used with both specified and optimal

gear changes.

40

1000

2