262260 surge protective devices

advertisement

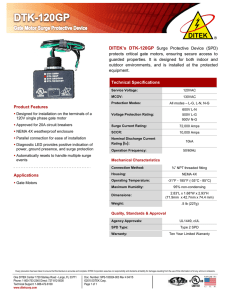

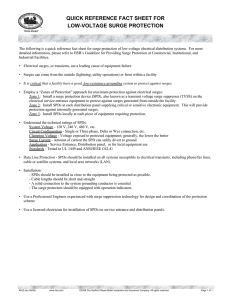

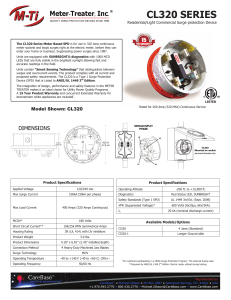

SECTION 262260 SURGE PROTECTIVE DEVICES PART 1 - GENERAL 1.1 WORK INCLUDES Surge Protective Devices (SPDs) 1.2 RELATED WORK SPECIFIED ELSEWHERE A. Electrical General Provisions B. Electrical Basic Materials and Methods C. Power Distribution Equipment 1.3 QUALITY ASSURANCE A. 1.4 The Surge Protective Devices in this Specification are associated with power distribution systems and shall be designed and manufactured according to the latest revision of the following standards (unless otherwise noted): 1. UL 1449 - 3rd Edition: Standard for Safety for Surge Protective Devices 2. UL 1283: Standard for Safety for Electromagnetic Interference Filters 3. ANSI / IEEE C62.41.1: Guide on the Surge Environment in Low Voltage AC Power Circuits 4. ANSI / IEEE C62.41.2: Recommended Practice on the Characterization of Surges in LowVoltage AC Power Circuits 5. ANSI / IEEE C62.45: Guide on Surge Testing for Equipment Connected to Low-Voltage AC Power Circuits 6. ANSI / IEEE C62.62: Standard Test Specifications for Surge Protective Devices (SPDs) for Use on the Load Side of the Service Equipment in Low Voltage AC Power Circuits PROJECT SUBMITTALS A. 1.5 Submittals shall include the following published data and/or reports: 1. Electrical ratings and performance characteristics for each model type. 2. Drawings that include product layout and dimensional data. 3. Installation, operation and maintenance manual with pre-startup, detailed wiring, connection and power source configuration diagrams and instructions. 4. Certified third party test report from an NVLAP accredited laboratory, demonstrating the performance specified herein at the listed surge (kA) rating including all fusing. WARRANTY A. Manufacturer shall provide a five (5)-year warranty against failure or workmanship defects when installed in compliance to the Manufacturer’s written installation instructions, UL listing requirements and the National Electrical Code. PROJECT NO. 2161037 262260 - 1 PART 2 - PRODUCTS 2.1 GENERAL REQUIREMENTS A. Furnish and install Surge Protective Devices (SPDs) as herein specified and as shown on the Drawings. The SPDs shall provide continuous protection from damaging transients and electrical line noise. B. Components shall be suitable for voltage systems as shown on the Drawings. C. SPDs shall be of a solid state, parallel multi-staged hybrid design and shall be bi-directional and voltage limiting. SPDs shall utilize Metal Oxide Varistors (MOVs) as suppression components. Devices that use spark gaps, gas tubes, rectifiers, silicon diodes or selenium cells are prohibited. D. SPDs shall utilize high energy (> 40mm) MOVs that are protected by a combination of thermal fuses and 8 x 20µs surge rated fuses. Designs that include high component count arrays of electronic grade MOVs (< 40mm) are prohibited. E. Devices employing per mode or per phase modular design shall provide proof of testing as a complete assembly to the Maximum Single Impulse and Repetitive Surge Current ratings. Subordinate modules or arrays shall not be tested in a standalone configuration for the purpose of calculating theoretical ratings of a full protection mode. F. SPD designs that use current limiting fuses in the surge path shall be fully tested as a complete unit for Maximum Single Impulse Surge Current withstand. Per the requirements of IEEE C62.62, fuses shall neither be removed nor bypassed for this test. Devices that rely on the electrical equipment main circuit breaker or fuse to interrupt fault currents resulting from a failed suppression component are prohibited. G. The SPD’s shall be life cycle tested to withstand a 10 kA, Category 3 surge (8 x 20µs) and 20 kA, Category 3 surge (1.2 x 50µs). After testing the suppression module shall not degrade more than 5% of the pre-test clamping voltage. H. Fuse grade silica shall be used for encapsulating the SPD suppression circuits or components where required. Encapsulant utilizing epoxy based potting compound is prohibited. I. Surge paths integral to the SPD suppression component array shall be of low impedance, planar copper and shall not include round wire or cabling. J. Plug-in type suppression modules shall not be used. 2.2 SERVICE ENTRANCE SURGE PROTECTIVE DEVICES A. Service entrance SPD’s shall be as manufactured by Current Technology Inc. - Transguard Series, Liebert Corporation - LM Series, Thor – TSRc Series, or equivalent by Eaton, General Electric, Square D or Siemens. B. Service entrance SPDs shall have the following design and performance ratings: 1. Surge Rating per Mode: 125 kA 2. Surge Rating per Phase: 250 kA 3. Protection Modes: L-L, L-N, L-G, N-G 4. Noise Attenuation: 63 dB Max from 10 kHz to 100MHz 5. Life Cycle Surges per Mode: 16,000 PROJECT NO. 2161037 262260 - 2 6. C. D. 2.3 Life Cycle Surges per Phase: 32,000 SPD Monitoring and Control: 1. Each SPD Mode shall be capable of being visibly monitored with a green LED. If protection is unavailable in any Mode, the green LED will be extinguished and a red LED shall illuminate. 2. Each SPD Mode shall include Form C auxiliary contacts. In addition, Form C contacts shall be provided for 70% under-voltage, and phase loss and power loss. 3. SPD shall include a surge counter on the face of the enclosure which shall count all transients above the system clamping voltage. 4. SPD shall include a solid state audible alarm system. Components shall include an alarm silence switch and an alarm test switch. An LED shall be provided to indicate audible alarm is disabled. SPD shall be provided with a NEMA 12 dust-tight enclosure with an integral disconnect switch. PANELBOARD SURGE PROTECTIVE DEVICES A. Branch panelboard SPDs shall be as manufactured by Current Technology Inc., Liebert Corporation, Thor, Eaton, General Electric, Square D or Siemens. B. Branch Panelboard SPDs shall have the following design and performance ratings: C. D. 1. Surge Rating per Mode: 60 kA 2. Surge Rating per Phase: 120 kA 3. Protection Modes: L-L, L-N, L-G, N-G. 4. Noise Attenuation: 63 dB Max from 10 kHz to 100MHz. 5. Life Cycle Surges per Mode: 8,000 6. Life Cycle Surges per Phase: 16,000 SPD Monitoring and Control: 1. Each SPD Mode shall be capable of being visibly monitored with a green LED. If protection is unavailable in any Mode, the green LED will be extinguished and a red LED shall illuminate. 2. Each SPD Mode shall include Form C auxiliary contacts. Branch circuit panelboard SPDs shall be mounted as an integral part of the panelboard assembly. Refer to addition requirements specified in Paragraph 3.3 if the SPD’s are not provided be the panelboard Manufacturer. PART 3 - EXECUTION 3.1 INSTALLATION A. Installation and wiring shall be in accordance with each Manufacturer’s recommendations and shall be performed in compliance with the National Electrical Code. PROJECT NO. 2161037 262260 - 3 B. The Electrical Contractor shall install the SPD with short and straight conductors as practically as possible. SPD input conductors shall be twisted together to reduce input conductor inductance. C. Perform visual and mechanical inspection. Verify that electrical wiring installation complies with Manufacturer’s installation requirements. D. After installation of each SPD, prior to energizing, complete all system startup checks per the Manufacturer’s written instructions. 3.2 SERVICE ENTRANCE SURGE PROTECTIVE DEVICES A. Service entrance SPDs shall be flush mounted in the face of the power distribution equipment, surface mounted to or wall mounted adjacent to the power distribution equipment, in accordance with the Manufacturer’s instructions. B. SPDs shall be direct bus connected (no cabling) if so listed by the SPD Manufacturer. Otherwise, connect to a 60 amp circuit breaker or fused switch. Wiring shall be 4 #6, 1 #10 ground, unless otherwise directed by the SPD Manufacturer. C. Electrical Contractor shall limit conductor length between terminals of surge protection devices and disconnect devices or bus connections to less than 48 inches. The wiring shall be twisted and tie-racked with no 90° bends. 3.3 PANELBOARD SURGE PROTECTIVE DEVICES A. Branch circuit panelboard SPDs shall be mounted as an integral assembly with the panelboard. SPDs mounted adjacent to new panelboards shall not be acceptable. Fully coordinate SPD installation and procurement with both SPD and panelboard Manufacturers. SPD Manufacturers commonly modify the panelboards by providing an extended enclosure and cover – refer to SPD Manufacturers “electronic grade panelboard” options. B. Contractor shall limit conductor length between terminals of surge protection devices and disconnect devices or bus connections to less than 24 inches. The wiring shall be twisted and tie-racked with no 90° bends. END OF SECTION PROJECT NO. 2161037 262260 - 4