Drawings - Cheever Construction

advertisement

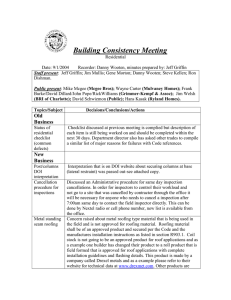

Concordia University - Nebraska

Weller Hall Interior Improvements

Phase 3

Architecture

Landscape Architecture

Engineering

Interiors

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

Kansas City, Missouri

800 N. Columbia Ave.

Seward, Nebraska

TCEP Project No.: 530-021-15

INDEX OF DRAWINGS

GENERAL

G0.0

Cover Sheet

G0.1

Standard Symbols & Abbreviations, Wall Type Schedule

G0.2

Code Compliance & General Notes

ARCHITECTURAL

A0.01

Lower Level Demo Plan

A0.02

Main Level Demo Plan

A0.03

Upper Level Demo Plan

A1.00

Lower Level Floor Plan

A1.01

Main Level Floor Plan

A1.02

Upper Level Floor Plan &

A4.01

Wall Sections - TO BE ISSUED BY ADDENDUM

A6.00

Interior Elevations

A6.01

Door Schedule, Door Types, Frame Types & Details

A6.02

Details

A6.03

Details

A6.04

Details

A6.05

Details - TO BE ISSUED BY ADDENDUM

ISSUED 04/01/2016

SHEET HISTORY:

AS PER CONSTRUCTION DOCUMENTS

North Columbia Avenue

April 1 , 2016

?

#

?- #

Bluff Road

INTERIOR FINISHES

F1.00

Lower Level Finish Plan, Finish Schedule & Finish Materials List

F1.01

Main Level Finish Plan, Finish Schedule & Finish Materials List

F1.02

Upper Level Finish Plan, Finish Schedule & Finish Materials List

ELECTRICAL

E0.00

Electrical Symbols Legend; One Line Diagrams

E1.01

Basement Power & Auxiliary Systems Plan

E1.02

First Floor Power & Auxiliary Systems Plan

E1.03

Second Floor Power & Auxiliary Systems Plan

Lincoln Street

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

Vicinity Map

NOT TO SCALE

TCEP No.: 530-021-15

April 1, 2016

Cover Sheet

Index of Drawings

ARCHITECT

(COORDINATING PROFESSIONAL)

ELECTRICAL ENGINEER

G0.00

MATERIALS SYMBOLS

REFERENCE SYMBOLS

STANDARD ABBREVIATIONS

DETAIL OR SECTION NUMBER

SHEET ON WHICH IT IS FOUND

9

Architecture

Landscape Architecture

Engineering

Interiors

DETAIL REFERENCE NUMBER

www.clarkenersen.com

SECTION REFERENCE

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

DETAIL REFERENCE

Kansas City, Missouri

ELEVATION REFERENCE

CROSS SECTION REFERENCE

CORRIDOR

015

ROOM IDENTIFIER

001

DOOR/OPENING IDENTIFIER

WINDOW/OPENING IDENTIFIER

LOUVER/OPENING IDENTIFIER

No.

GRID LINE

FIN. FLR.

EL: 100'-0"

[30,480]

ELEVATION REFERENCE

WALL TYPE REFERENCE

MATCH LINE

DEMOLITION INDICATOR

REVISION INDICATOR

?

#

?- #

ISSUED 04/01/2016

SHEET HISTORY:

AS PER CONSTRUCTION DOCUMENTS

WALL TYPE SCHEDULE

TAG

DESCRIPTION

SIZE

FIRE

RATING

6"

--

1A

6" 16ga STEEL STUD FRAMING @ 16" O.C. (BEARING WALL FOR 10" STEEL JOISTS AT FRONT OF

EXISTING STAGE ). BRACE AS REQUIRED.

1B

6" 16ga STEEL STUD FRAMING @ 16" O.C. 3/4" FIRE RETARDANT TREATED PLYWOOD

6 3/4"

--

1C

6" 16ga STEEL STUD FRAMING @ 16" O.C. W/ 3/4" FIRE RETARDANT TREATED PLYWOOD & 1/2"

PLASTIC LAMINATE CLAD MDF PANELS.

7 1/4"

--

1D

6" 16ga STEEL STUD FRAMING @ 16" O.C. (BEARING WALL FOR 10" STEEL JOISTS AT FRONT OF

7 1/4"

STAGE EXTENSION ) W/ 6" TALL BAND OF 3/4" FIRE RETARDANT TREATED PLYWOOD AS

SUBSTRATE FOR RADIUSED 1/2" PLASTIC LAMINATE CLAD MDF PANELS (KERF PLYWOOD &

MDF PANELS AS REQUIRED TO ACHIEVE RADIUS) SEE DETAILS

--

6" 16ga STEEL STUD FRAMING @ 16" O.C. (FACE PANEL WALL AT FRONT OF STAGE

EXTENSION ) 3/4" FIRE RETARDANT TREATED PLYWOOD AS SUBSTRATE FOR RADIUSED 1/2"

PLASTIC LAMINATE CLAD MDF PANELS (KERF PLYWOOD & MDF PANELS AS REQUIRED TO

ACHIEVE RADIUS) PROVIDE 2" ALUMINUM "Z" CLIPS @ 24" O.C. @ TOP AND BOTTOM OF

PLASTIC LAMINATE PANELS TO ALLOW FOR NO FASTENERS TO BE SEEN.SEE DETAILS

--

1E

7 1/4"

VISUAL REPRESENTATION

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

TCEP No.: 530-021-15

2A

35 8" STEEL STUD FRAMING (PARTIAL HEIGHT) @ 16" O.C. W/ 1- LAYER 1 2" PLYWOOD EACH SIDE

(PT. BLACK TO MATCH ADJACENT EAST WALL OF STAGE)- EXTEND ASSEMBLY FROM FINISHED

FLOOR TO STORAGE POCKET LID @ 5'-0".

4 5/8"

--

2B

35 8" STEEL STUD FRAMING (PARTIAL HEIGHT) @ 16" O.C. W/ 1- LAYER 5 8" TYPE 'X' GPDW EA.

SIDE - EXTEND ASSEMBLY FROM FINISHED FLOOR TO 104'-0" (4'-0" ABOVE MAIN LEVEL FINISH

FLOOR

4 7/8"

--

2C

35 8" 16ga. STEEL STUD FRAMING @ 16" O.C. W/ 1- LAYER 1 2" CEMENTITIOUS BACKER BOARD ON

TAG SIDE - EXTEND ASSEMBLY FROM SILL OF PROJECTED OPENING TO HEAD OF PROJECTED 4 1/8"

OPENING. APPLY THIN SET AND WALL TILE AS PER SPEC.

--

2D

35 8" 16ga STEEL STUD FRAMING @ 16" O.C. (BRACING WALL FRAMING @ PROJECTED WALL

OPENINGS / NEW PUNCHED OPENINGS). BRACE AS REQUIRED.

3 5/8"

April 1, 2016

--

WALL TYPE NOTES:

1. ALL WALL FRAMING WHICH EXTENDS ABOVE FINISH CEILING & NOT EXTENDED TO STRUCTURE ABOVE / NOT ATTACHED TO MASONRY SHALL BE BRACED AT 4'-0" O.C.

2. ALL STEEL STUDS ARE 25ga. UNLESS NOTED OTHERWISE OR REQ'D BY CODE TO BE HEAVIER.

3. REFER TO ROOM FINISH SCHEDULE FOR FINISHES AND SPECIAL INSTRUCTIONS.

4. ALL WALL/GENERAL PLAN DIMENSIONS ARE TO FACE OF GPDW, TYP.

5. WHERE INDICATED TO GO TO STRUCTURE, WALL ASSEMBLIES SHALL BE SEALED TO THE STRUCTURAL FRAMING/DECK TO PROVIDE AN AIR TIGHT/ACOUSTICAL SEAL FROM BOTH SIDES. PROVIDE

INSULATION AT SPACES BETWEEN STUD TRACK AND STRUCTURE, FIT/SHAPE DRYWALL TO ANY IRREGULARITIES INCLUDING DECK, TO A MAXIMUM 1 2" GAP, AND SEAL TO ALL SURFACES W/ SEALANT

PER SPECIFICATION.

6. PROVIDE DEEP LEG SLIP TRACK @ T.O. ALL INTERIOR WALLS/ STUDS EXTENDING TO STRUCTURE, TO ALLOW FOR DEFLECTION OF STRUCTURE (NOT REQUIRED @ EXTERIOR WALL FURRING).

7. PROVIDE BLOCKING AS REQUIRED IN GPDW/PLASTER CLAD WALL ASSEMBLIES (NEW OR EXISTING) AT ATTACHMENT LOCATIONS OF LIGHT SUPPORT PIPES.

Standard Symbols

and Abbreviations,

Wall Type Schedule

G0.01

EXISTING

STAGE FINISHED FLOOR

100'-0"

UP

2009 INTERNATIONAL BUILDING CODE & LOCAL AMENDMENTS (2009)

2000 UNIFORM PLUMBING CODE & LOCAL AMENDMENTS (2009)

2009 MECHANICAL CODE AMENDMENTS

2009 FUEL GAS CODE AMENDMENTS

2011 NATIONAL ELECTRICAL CODE

BUILDING CODES:

UP

FINISHED FLOOR

FRONT OF CHAPEL

96'-6"

ACCESSIBILITY

STANDARDS:

2010 AMERICANS WITH DISABILITIES ACT STANDARDS FOR ACCESSIBLE DESIGN

LIFE SAFETY CODE:

2009 INTERNATIONAL FIRE CODE

2000 LIFE SAFETY CODE 101

FIRE PREVENTION CODE AMENDMENTS

FIRE SUPPRESSION CODE AMENDMENTS

OCCUPANCY TYPES:

SEE TABLE BELOW

CONSTRUCTION TYPES:

SEE TABLE BELOW

FIRE SPRINKLER SYSTEM:

ADMINISTRATION BUILDING IS FULLY SPRINKLED / AUDITORIUM BUILDING IS NOT SPRINKLED

FIRE ALARM SYSTEM:

MANUAL FCI FIRE ALARM SYSTEM FOR ADMINISTRATION BUILDING

UP

UP

UP

DN

DN

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

Kansas City, Missouri

EACH CONTRACTOR SHALL INVESTIGATE, VERIFY, AND COORDINATE EXISTING CONDITIONS WITH NEW WORK AND NEW DIMENSIONS OF THE PROJECT

PERTAINING TO THEIR PORTION OF THE WORK AND CONFIRM SUCH TO BE APPROPRIATE AND COMPATIBLE WITH NEW CONSTRUCTION. CONTRACTOR SHALL

NOTIFY THE ARCHITECT OF ANY DISCREPANCY FOR CLARIFICATION OR ABOUT ANY CONDITION REQUIRING MODIFICATION OR CHANGE BEFORE PROCEEDING

WITH THE WORK.

2.

ALL FINISH COLORS, TEXTURE, AND PATTERNS TO BE SELECTED BY THE ARCHITECT AND APPROVED PRIOR TO INSTALLATION.

3.

DIMENSIONS NOTED ARE TO FINISHED FACE OF ASSEMBLY UNLESS OTHERWISE NOTED. GENERALLY, MASONRY, STD. STEEL PIPE, AND LUMBER ARE INDICATED

AS NOMINAL DIMENSIONS.

4.

ANY PIPE OR CONDUIT PENETRATION THRU EXTERIOR CONSTRUCTION SHALL BE SEALED AT BOTH SIDES FOR A WATERTIGHT CONDITION.

5.

ALL WORKMANSHIP AND MATERIALS SHALL CONFORM TO THE REQUIREMENTS OF THE CODES LISTED ON THIS SHEET.

6.

HIERARCHY FOR CONFLICTS SHALL BE SMALLER SCALE DRAWINGS, LARGER SCALE DRAWINGS, SPECIFICATIONS. NOTIFY ARCHITECT IN WRITING OF ANY

PERCEIVED CONFLICTS BEFORE COMMENCING WITH THE WORK.

7.

WATERPROOFING AND SEALANT INSTALLERS TO VERIFY IN WRITING COMPATABILITY OF RESPECTIVE PRODUCTS TO BE INSTALLED WITH ADJACENT PRODUCTS.

8.

CONTRACTOR IS RESPONSIBLE FOR INVENTORY OF ALL ITEMS FOR OWNER'S REUSE PRIOR TO DEMOLITION. CONTRACTOR TO SCHEDULE SITE WALK/VISIT W/OWNER.

9.

EXISTING ORGAN AND ORGAN PIPES TO BE PROTECTED FOR DURATION OF CONSTRUCTION, GC WILL BE RESPONSIBLE FOR ANY DAMAGE CAUSED BY CONSTRUCTION

OPERATIONS AND FOR CLEANING IF ORGAN CONSOLE AND PIPES ARE NOT KEPT CLEAN / & ARE NOT PROPERLY SEALED OFF FROM AREA OF CONSTRUCTION.

UP

UP

UP

DN

UP

DN

DN

UP

DN

UP

UP

www.clarkenersen.com

1.

SHOWCASE

SHOWCASE

SHOWCASE

SHOWCASE

DN

Architecture

Landscape Architecture

Engineering

Interiors

UP

CODE ITEM

BASEMENT FLOOR PLAN

LOWER LEVEL CODE COMPLIANCE PLAN

SCALE: NTS

ZONING:

MAIN LEVEL CODE COMPLIANCE PLAN

1A.) OCCUPANCY CLASSIFICATION:

IBC

REQUIREMENTS

ACTUAL

U/MC - UNIVERSITY MIXED USE

U/MC - UNIVERSITY MIXED USE

?

#

?- #

ISSUED 04/01/2016

SHEET HISTORY:

AS PER CONSTRUCTION DOCUMENTS

B/A-3

B/A-3

SCALE: NTS

1B.) CONSTRUCTION TYPE:

IBC

NFPA 101

TYPE II - B : EXISTING NON-SEPARATED -FULLY SPRINKLED - PROTECTED BUILDING

2A.) ALLOWABLE BUILDING HEIGHT:

IBC 2006 : TABLE 503

2 STORY (55 FEET)

3A.) ALLOWABLE BUILDING AREA:

IBC 2006 : AS PER 506.1, 506.2 & 506.3

BASE AREA: 9,500 SQ. FT. (A-3)

INITIAL

9,500 SQ.FT.

3B.) TOTAL BUILDING SQUARE FOOTAGE:

TOTAL EXISTING

FIRE RESISTIVE REQUIREMENTS:

IBC 2009 : AS PER TABLE 601 & TABLE 602

EXT. BEARING WALLS

INT. BEARING WALLS

EXT. NON-BEARING WALLS

STRUCTURAL FRAME

PARTITIONS - PERMANENT

SHAFT ENCLOSURES ( 707.4 & 707.7)

FLOORS / CEILINGS

ROOFS

UNPROTECTED EXT. OPENINGS (704.8.1)

STAIRWAYS (AS PER 1005.3.2)

STANDPIPE REQUIREMENTS

ABBREVIATIONS

0

N/A

SQ.FT.

HR.

2 STORY (NO CHANGE)

WITH INCREASES

15,010 SQ.FT.

EXISTING BUILDING

NO CHANGE OF EXISTING BUILDING SQUARE FOOTAGE UNDER THIS PROJECT/PERMIT

16,337 SQ.FT. (NO CHANGE)

0

0

0

0

0 / 1 HR WHERE REQ'D BY CODE

60 MIN. DOORS

0

0

UNLIMITED (DIST. > 30')

1 HR

0

N/A (THERE ARE NO NEW OR ALTERED INTERIOR BEARING WALLS AS PART OF THIS PROJECT)

0

0

0

NOT FULLY ENCLOSED / ISOLATED WITH RATED DOORS (SUBSEQUENT PHASE WILL ENCLOSE/RATE)

0

0

NO

NO

NOT ENCLOSED RATED (SUBSEQUENT PHASE WILL ENCLOSE)

NO GENERAL REQUIREMENTS FOR FIRE RESISTANCE

NOT APPLICABLE

SQUARE FEET

HOUR

SECTION 506.1. GENERAL AREA MODIFICATIONS.

A=A +

A t If

100

+

A t Is

9,500 +

100

(9,500)(58)

100

(9,500)(0)

100

5,510

0

= 15,010 SQ.FT.

A a = ALLOWABLE AREA PER FLOOR (SQUARE FEET)

A t = TABULAR AREA PER FLOOR IN ACCORDANCE WITH TABLE 503 (SQUARE FEET) = 9,500 SQ.FT.

I f = AREA INCREASE DUE TO FRONTAGE (PERCENT) AS CALCULATED IN ACCORDANCE WITH SECTION 506.2 = 58%

I s = AREA INCREASE DUE TO SPRINKLER PROTECTION (PERCENT) AS CALCULATED IN ACCORDANCE WITH SECTION 506.3 = 0% (BUILDING NOT FULLY SPRINKLED)

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

SECTION 506.2 FRONTAGE INCREASE.

I f= 100

F

P

- 0.25

W

30

I = 100

662.667 FT.

800.5 FT.

- 0.25

30

30

TCEP No.: 530-021-15

= 58

F = BUILDING PERIMETER WHICH FRONTS ON A PUBLIC WAY OR OPEN SPACE HAVING 20 FT. OPEN MINIMUM WIDTH = 662.667 FT.

April 1, 2016

P = PERIMETER OF ENTIRE BUILDING = 800.5 FT.

W = MINIMUM WIDTH OF PUBLIC WAY OR OPEN SPACE = 30 FT.

REQUIRED OCCUPANCY SEPARATIONS:

NONE REQUIRED PER TABLE 508.4

SECOND FLOOR PLAN

UPPER LEVEL CODE COMPLIANCE PLAN

SCALE: NTS

FIRE PROTECTION SYSTEMS (CHAPTER 9)

1. AN AUTOMATIC FIRE SPRINKLER SYSTEM IN ACCORDANCE WITH SECTION 902.1 SHALL BE PROVIDED THROUGHOUT.

-FIRE SPRINKLER SYSTEM EXISTS IN CHEMISTRY 200

-FIRE SPRINKLER SYSTEM EXISTS IN WEIGHT ROOM 171, WILL NEED TO BE RELOCATED BENEATH ISOLATED GPDW SUSPENDED CEILING / ABOVE APC-1 CEILING

2. A FIRE ALARM SYSTEM IS REQUIRED AND WILL BE INSTALLED AS SET FORTH IN THE INTERNATIONAL FIRE CODE.

EGRESS REQUIREMENTS (CHAPTER 10):

1. MINIMUM EGRESS WIDTH REQUIRED FOR AUDITORIUM / CHAPEL 102 IS 64.4" (322 OCCUPANTS @ .2" PER OCCUPANT / ) 184" OF EXIT WIDTH IS PROVIDED

1. MINIMUM EGRESS WIDTH REQUIRED FOR AUDITORIUM / CHAPEL BALCONY 203 IS 41.8" (209 OCCUPANTS @ .2" PER OCCUPANT / ) 68" OF EXIT WIDTH IS PROVIDED

3. MINIMUM NOMINAL EXIT DOOR SIZE IS 3'-0" WIDE BY 7'-0" TALL

4. MAXIMUM EXIT ACCESS TRAVEL DISTANCE ALLOWED IS 200 FEET (TABLE 1016.1).

SEE CODE COMPLIANCE PLANS

PROVIDE NEW CLOSER HARDWARE ON EXISTING DOOR

EXISTING 38"X32" TRANSFER WALL GRILLE TO BE REMOVED AND CMU WALL OPENING IN-FILLED WITH BLOCK TO MATCH

ADJACENT CMU WALL, PT. TO MATCH ADJACENT WALL FINISH; PROVIDE NEW WALL OPENING WITH FIRE/SMOKE DAMPER

AS NOTED; DAMPER TO BE WIRED TO FIRE ALARM PANEL

REMOVE FLOOR MOUNTED DOOR HOLD-OPEN HARDWARE

COMPONENTS TO ALLOW DOOR CLOSERS TO FUNCTION

Code

Compliance

& General Notes

G0.02

KEY NOTE DEMOLITION ITEMS

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 17'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-1)

Architecture

Landscape Architecture

Engineering

Interiors

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 14'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-1)

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 13'-0" A.F.F. TO 24'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.(ALTERNATE A-2)

Kansas City, Missouri

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 16'-0" A.F.F. TO 22'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-2)

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-3)

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-3)

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 21'-0" A.F.F OF SOUTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE

ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-4)

2d

2d

UP

UP

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 18'-0" A.F.F OF SOUTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-4)

UP

2d

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW

CONSTRUCTION. (ALTERNATE A-5)

REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY ADJACENT TO DEMO'D "CROOKED DOOR" AS REQUIRED TO ALLOW FOR INSTALLATION OF NEW FRY-REGLET

MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR. NEW DOOR FRAME IS TO BE INSTALLED PLUMB (OPPOSED TO PARALLEL TO THE RAKED

FLOOR LIKE DEMO'D DOOR). HEADER GPDW / PLASTER / STUD WALL ASSEMBLY AS REQUIRED AT NEW DOOR FRAME. INFILL WALL FRAMING & GPDW AS REQUIRED FOR

FLUSH INSTALL OF NEW DOOR FRAME PATCH EXISTING/ REMAINING WALLS AT INTERSECTION OF WALL BEING REMOVED AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION.

SHOWCASE

SHOWCASE

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-5)

?

#

?- #

REMOVE EXISTING "CROOKED" DOOR & WOOD FRAME IN ITS ENTIRETY. PREPARE ADJACENT SURFACES / ROUGH OPENING AS REQUIRED FOR INSTALLATION OF NEW

NEW FRY-REGLET MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR..

SHEET HISTORY:

ISSUED 04/01/2016

REMOVE AND PRESERVE EXISTING PAIR OF WOOD DOORS THAT ACT AS COVER TO STAINED GLASS WINDOW TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE FLOOR

ASSEMBLY, SALVAGE AND REINSTALL AT HIGHER ELEVATION UPON INSTALLATION OF BUILT-UP STAGE FLOOR ASSEMBLY. OPERATION TO REMAIN THE SAME UPON

REINSTALLATION

AS PER CONSTRUCTION DOCUMENTS

REMOVE AND PRESERVE EXISTING FIRE RATED SOLID CORE WOOD DOOR & FIRE RATED HOLLOW METAL FRAME TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE

FLOOR ASSEMBLY. SALVAGE AND REINSTALL AT NEW FINISH FLOOR ELEVATION OF BUILT-UP STAGE FLOOR ASSEMBLY. MODIFY HEIGHT OF DOOR AND FRAME AS

REQUIRED / IF NECESSARY FOR INSTALLATION BELOW EXISTING CONCRETE PLATFORM ABOVE.

REMOVE FLOOR MOUNTED DOOR HOLD-OPEN HARDWARE COMPONENTS TO ALLOW DOOR CLOSER TO FUNCTION

REMOVE ALL THEATER DRAPERIES / DRAPERY RIGGING IN THEIR ENTIRETY, PRESERVE AND PROVIDE TO OWNER; PREPARE FOR INSTALLATION OF NEW DRAPERY

RIGGING & DRAPES; SEE FINISH SHEETS / SPECS.

EXISTING AUDITORIUM SEATING (MAIN FLOOR AND BALCONY) WILL BE REMOVED UNDER SEPARATE CONTRACT BY OWNER. GC SHALL PATCH & REPAIR ALL ANCHOR

LOCATIONS IN SLAB, CRACKS, ETC. & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW FLOORING (EPOXY & TILE CARPETING).

REMOVE EXISTING TEMPORARY STAGE EXTENSION / FRAMING, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

SHOWCASE

SHOWCASE

REMOVE EXISTING 38"x32" THROUGH WALL TRANSFER GRILLE; CMU WALL OPENING IN-FILLED WITH BLOCK TO MATCH ADJACENT CMU WALL, PT. TO MATCH ADJACENT

WALL FINISH; PROVIDE NEW WALL OPENING WITH FIRE/SMOKE DAMPER AS NOTED; DAMPER TO BE WIRED TO FIRE ALARM PANEL

REMOVE EXISTING STEEL STAIR; VERIFY SALVAGE WITH OWNER PRIOR TO DEMOLITION.

REMOVE EXISTING STAGE LEFT AND STAGE RIGHT WOOD STAIRS STEEL RAILINGS, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

REMOVE EXISTING STEEL SPIRAL STAIR/RAILING & CENTER SUPPORT PIPE COLUMN. UPON DEMOLITION PROVIDE CONTINUOUS 2x8 LEDGER BOARD AT PERIMETER OF

C.I.P. CONC. FLOOR OPENING WITH NEW 3/4" PLYWOOD INFILL OF OPENING. LEDGER TO BE RECESSED 3 4" SO T.O. PLYWOOD IS LEVEL WITH T.O. SLAB. PROVIDE 2X8

FLOOR FRAMING @ 16" O.C. MAX. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

REMOVE EXISTING STEEL GUARDRAIL IN ITS ENTIRETY TO SURFACE OF EXISTING STEEL CHANNEL @ T.O. WALL (CHANNEL TO REMAIN). GRIND GUARD RAIL CONNECTIONS

AT POSTS SMOOTH & FLUSH W/ FACE OF CHANNEL, PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION INSTALLATION OF NEW ALUMINUM BASE

SHOE / NEW GLASS GUARD RAIL ASSEMBLY.

DN

REMOVE EXISTING PLASTER CEILING SYSTEM & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION / INSTALLATION OF NEW RECESSED MOTORIZED

PROJECTION SCREEN. MOUNT SCREEN PER MFR. SPECIFICATIONS. COORDINATE SIZE OF CEILING DEMOLITION WITH SCREEN SPECS. / REQUIREMENTS. LOCATE AS PER

DIMENSIONS. PATCH & REPAIR PLASTER CEILING @ RECESSED SCREEN UPON COMPLETION OF INSTALLATION

REMOVE EXISTING RETURN AIR GRILLE @ FRONT WALL OF EXISTING STAGE

PROVIDE CORE-DRILL OPENING / CUT-OUT THROUGH EXISTING FLOOR FOR NEW CONDUIT SYSTEM AS DIMENSIONED ON PLAN, SEE A1.01). SIZE OF CORE-DRILLING TO BE

COORDINATED WITH REQUIREMENTS OF ELECTRICAL CONDUIT (SEE ELECTRICAL). VERIFY FLOOR STRUCTURE LOCATION PRIOR TO CUTTING OPENING.

UP

UP

UP

REMOVE EXISTING RESILIENT BASE THROUGHOUT ENTIRE CHAPEL & CHAPEL ENTRY VESTIBULE, PREPARE ADJACENT SURFACES AS REQUIRED FOR INSTALLATION OF

NEW RESILIENT BASE FOLLOWING INSTALLATION OF NEW FLOORING FINISHES.

SCOPE OF WORK KEYPLAN

UP

3b

800 N. Columbia Ave.

Seward, Nebraska

GENERAL DEMOLITION NOTE ITEMS

1.

THE GENERAL CONTRACTOR SHALL VERIFY ALL EXISTING DIMENSIONS AND CONDITIONS SHOWN ON THE PLANS PRIOR TO DEMOLITION. ANY DEVIATIONS IN THE EXISTING

CONDITIONS OR DIMENSIONS INDICATED SHALL BE COORDINATED WITH THE ARCHITECT/ENGINEER AND OWNER IN ORDER TO MODIFY THE PLANS ACCORDINGLY.

2.

THE CONTRACTOR IS RESPONSIBLE FOR PRODUCING WEATHER TIGHT CONSTRUCTION.THE EXISTING BUILDING SHALL BE PROTECTED FROM WEATHER AT ALL TIMES.

OPENINGS AND PENETRATIONS SHALL BE PROTECTED WITH DURABLE, INSULATED TEMPORARY CONSTRUCTION. COORDINATE SECURITY REQUIREMENTS WITH THE OWNER.

3.

THE GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR PROTECTING ALL EXISTING ITEMS NOT BEING REMOVED FROM PROJECT AREA. ANY DAMAGE THAT MAY OCCUR

FROM WORK UNDER THIS CONTRACT SHALL BE RESTORED TO ITS ORIGINAL CONDITION.

4.

THE GENERAL CONTRACTOR SHALL NOTIFY THE ARCHITECT/ENGINEER IF DEMOLITION WORK APPEARS TO AFFECT THE STRUCTURAL INTEGRITY OF THE EXISTING

BUILDING BEFORE PROCEEDING.

5.

THE GENERAL CONTRACTOR TO COORDINATE ALL DEMOLITION WORK BETWEEN ALL TRADES. AREAS OF WORK SHALL BE KEPT CLEAN AND SAFE. DISPOSE OF DEBRIS

DAILY AND CLEAN AREAS OR WORK UPON COMPLETION.

6.

THE BUILDING WILL BE OCCUPIED DURING CONSTRUCTION PERIOD. GENERAL CONTRACTOR SHALL MINIMIZE DISTURBANCE TO BUILDING OCCUPANTS AND FUNCTIONS.

GENERAL CONTRACTOR TO COORDINATE WITH OWNER SO THAT CONSTRUCTION WILL NOT INTERFERE WITH BUILDING OPERATION AND SECURITY REQUIREMENTS.

7.

ALL WORK TO BE COORDINATED WITH THE GENERAL CONTRACTOR. THE GENERAL CONTRACTOR WILL BE RESPONSIBLE FOR COORDINATION OF ALL WORK WITH THE OWNER.

8.

OWNER HAS RIGHT TO CLAIM ANY MATERIALS AND/OR EQUIPMENT THAT IS SCHEDULED TO BE DEMOLISHED OR REMOVED FROM THE SITE.

3b

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

TCEP No.: 530-021-15

April 1, 2016

LOWER LEVEL DEMO PLAN

SCALE: 1/8"=1'-0"

GENERAL CONSTRUCTION PREPARATION NOTES

1.

CARPETING TO BE INSTALLED AS AN OVERLAY OVER EXISTING FLOOR TILE. PRIOR TO INSTALLATION OF CARPET, SURVEY EXISTING FLOOR TILE TO ENSURE SOUND

SUBSTRATE CONDITION. LOOSE TILE SHALL BE REMOVED AND VOID GROUTED FLUSH WITH ADJACENT TILE OR SECURED IN PLACE PRIOR TO INSTALLATION OF CARPET.

SEE SPEC AND MANUFACTURERS RECOMMENDATION FOR INSTALLATION.

2.

GENERAL CONTRACTOR IS TO ENCLOSE, COVER AND PROTECT EXISTING KUHN ORGAN CONSOLE AND ALL PIPES IN THEIR ENTIRETY FOR THE DURATION OF DEMOLITION AND CONSTRUCTION.

Lower Level Demo Plan

A0.01

KEY NOTE DEMOLITION ITEMS

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 17'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-1)

Architecture

Landscape Architecture

Engineering

Interiors

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 14'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-1)

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 13'-0" A.F.F. TO 24'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.(ALTERNATE A-2)

Kansas City, Missouri

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 16'-0" A.F.F. TO 22'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-2)

3e

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-3)

2b

EXISTING

STAGE FINISHED FLOOR

100'-0"

3a

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-3)

3a

3g

UP

2c

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 21'-0" A.F.F OF SOUTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE

ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-4)

3a

3a

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 18'-0" A.F.F OF SOUTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-4)

3k

DN

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW

CONSTRUCTION. (ALTERNATE A-5)

2c

FINISHED FLOOR

3k

FRONT OF CHAPEL

96'-6"

UP

UP

UP

3f

3d

3f

3d

UP

DN

3e

REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY ADJACENT TO DEMO'D "CROOKED DOOR" AS REQUIRED TO ALLOW FOR INSTALLATION OF NEW FRY-REGLET

MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR. NEW DOOR FRAME IS TO BE INSTALLED PLUMB (OPPOSED TO PARALLEL TO THE RAKED

FLOOR LIKE DEMO'D DOOR). HEADER GPDW / PLASTER / STUD WALL ASSEMBLY AS REQUIRED AT NEW DOOR FRAME. INFILL WALL FRAMING & GPDW AS REQUIRED FOR

FLUSH INSTALL OF NEW DOOR FRAME PATCH EXISTING/ REMAINING WALLS AT INTERSECTION OF WALL BEING REMOVED AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION.

1m

AS PER CONSTRUCTION DOCUMENTS

3'-0"

1h

3c

1'-0"

REMOVE FLOOR MOUNTED DOOR HOLD-OPEN HARDWARE COMPONENTS TO ALLOW DOOR CLOSER TO FUNCTION

ISSUED 04/01/2016

7'-4"

7'-4"

3'-0"

3'-4"

REMOVE AND PRESERVE EXISTING FIRE RATED SOLID CORE WOOD DOOR & FIRE RATED HOLLOW METAL FRAME TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE

FLOOR ASSEMBLY. SALVAGE AND REINSTALL AT NEW FINISH FLOOR ELEVATION OF BUILT-UP STAGE FLOOR ASSEMBLY. MODIFY HEIGHT OF DOOR AND FRAME AS

REQUIRED / IF NECESSARY FOR INSTALLATION BELOW EXISTING CONCRETE PLATFORM ABOVE.

1b

SHEET HISTORY:

3'-4"

1g

REMOVE AND PRESERVE EXISTING PAIR OF WOOD DOORS THAT ACT AS COVER TO STAINED GLASS WINDOW TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE FLOOR

ASSEMBLY, SALVAGE AND REINSTALL AT HIGHER ELEVATION UPON INSTALLATION OF BUILT-UP STAGE FLOOR ASSEMBLY. OPERATION TO REMAIN THE SAME UPON

REINSTALLATION

?

#

?- #

1'-0"

17'-0"

2a

3'-4"

REMOVE EXISTING "CROOKED" DOOR & WOOD FRAME IN ITS ENTIRETY. PREPARE ADJACENT SURFACES / ROUGH OPENING AS REQUIRED FOR INSTALLATION OF NEW

NEW FRY-REGLET MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR..

14'-0"

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-5)

1a

REMOVE ALL THEATER DRAPERIES / DRAPERY RIGGING IN THEIR ENTIRETY, PRESERVE AND PROVIDE TO OWNER; PREPARE FOR INSTALLATION OF NEW DRAPERY

RIGGING & DRAPES; SEE FINISH SHEETS / SPECS.

REMOVE EXISTING 38"x32" THROUGH WALL TRANSFER GRILLE; CMU WALL OPENING IN-FILLED WITH BLOCK TO MATCH ADJACENT CMU WALL, PT. TO MATCH ADJACENT

WALL FINISH; PROVIDE NEW WALL OPENING WITH FIRE/SMOKE DAMPER AS NOTED; DAMPER TO BE WIRED TO FIRE ALARM PANEL

EXISTING AUDITORIUM SEATING (MAIN FLOOR AND BALCONY) WILL BE REMOVED UNDER SEPARATE CONTRACT BY OWNER. GC SHALL PATCH & REPAIR ALL ANCHOR

LOCATIONS IN SLAB, CRACKS, ETC. & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW FLOORING (EPOXY & TILE CARPETING).

4a

REMOVE EXISTING TEMPORARY STAGE EXTENSION / FRAMING, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

4b

REMOVE EXISTING STEEL STAIR; VERIFY SALVAGE WITH OWNER PRIOR TO DEMOLITION.

REMOVE EXISTING STAGE LEFT AND STAGE RIGHT WOOD STAIRS STEEL RAILINGS, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

REMOVE EXISTING STEEL SPIRAL STAIR/RAILING & CENTER SUPPORT PIPE COLUMN. UPON DEMOLITION PROVIDE CONTINUOUS 2x8 LEDGER BOARD AT PERIMETER OF

C.I.P. CONC. FLOOR OPENING WITH NEW 3/4" PLYWOOD INFILL OF OPENING. LEDGER TO BE RECESSED 3 4" SO T.O. PLYWOOD IS LEVEL WITH T.O. SLAB. PROVIDE 2X8

FLOOR FRAMING @ 16" O.C. MAX. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

4b

REMOVE EXISTING STEEL GUARDRAIL IN ITS ENTIRETY TO SURFACE OF EXISTING STEEL CHANNEL @ T.O. WALL (CHANNEL TO REMAIN). GRIND GUARD RAIL CONNECTIONS

AT POSTS SMOOTH & FLUSH W/ FACE OF CHANNEL, PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION INSTALLATION OF NEW ALUMINUM BASE

SHOE / NEW GLASS GUARD RAIL ASSEMBLY.

REMOVE EXISTING PLASTER CEILING SYSTEM & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION / INSTALLATION OF NEW RECESSED MOTORIZED

PROJECTION SCREEN. MOUNT SCREEN PER MFR. SPECIFICATIONS. COORDINATE SIZE OF CEILING DEMOLITION WITH SCREEN SPECS. / REQUIREMENTS. LOCATE AS PER

DIMENSIONS. PATCH & REPAIR PLASTER CEILING @ RECESSED SCREEN UPON COMPLETION OF INSTALLATION

REMOVE EXISTING RETURN AIR GRILLE @ FRONT WALL OF EXISTING STAGE

UP

DN

DN

UP

REMOVE EXISTING RESILIENT BASE THROUGHOUT ENTIRE CHAPEL & CHAPEL ENTRY VESTIBULE, PREPARE ADJACENT SURFACES AS REQUIRED FOR INSTALLATION OF

NEW RESILIENT BASE FOLLOWING INSTALLATION OF NEW FLOORING FINISHES.

DN

DN

UP

PROVIDE CORE-DRILL OPENING / CUT-OUT THROUGH EXISTING FLOOR FOR NEW CONDUIT SYSTEM AS DIMENSIONED ON PLAN, SEE A1.01). SIZE OF CORE-DRILLING TO BE

COORDINATED WITH REQUIREMENTS OF ELECTRICAL CONDUIT (SEE ELECTRICAL). VERIFY FLOOR STRUCTURE LOCATION PRIOR TO CUTTING OPENING.

UP

SCOPE OF WORK KEYPLAN

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

GENERAL DEMOLITION NOTE ITEMS

1.

THE GENERAL CONTRACTOR SHALL VERIFY ALL EXISTING DIMENSIONS AND CONDITIONS SHOWN ON THE PLANS PRIOR TO DEMOLITION. ANY DEVIATIONS IN THE EXISTING

CONDITIONS OR DIMENSIONS INDICATED SHALL BE COORDINATED WITH THE ARCHITECT/ENGINEER AND OWNER IN ORDER TO MODIFY THE PLANS ACCORDINGLY.

2.

THE CONTRACTOR IS RESPONSIBLE FOR PRODUCING WEATHER TIGHT CONSTRUCTION.THE EXISTING BUILDING SHALL BE PROTECTED FROM WEATHER AT ALL TIMES.

OPENINGS AND PENETRATIONS SHALL BE PROTECTED WITH DURABLE, INSULATED TEMPORARY CONSTRUCTION. COORDINATE SECURITY REQUIREMENTS WITH THE OWNER.

3.

THE GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR PROTECTING ALL EXISTING ITEMS NOT BEING REMOVED FROM PROJECT AREA. ANY DAMAGE THAT MAY OCCUR

FROM WORK UNDER THIS CONTRACT SHALL BE RESTORED TO ITS ORIGINAL CONDITION.

4.

THE GENERAL CONTRACTOR SHALL NOTIFY THE ARCHITECT/ENGINEER IF DEMOLITION WORK APPEARS TO AFFECT THE STRUCTURAL INTEGRITY OF THE EXISTING

BUILDING BEFORE PROCEEDING.

5.

THE GENERAL CONTRACTOR TO COORDINATE ALL DEMOLITION WORK BETWEEN ALL TRADES. AREAS OF WORK SHALL BE KEPT CLEAN AND SAFE. DISPOSE OF DEBRIS

DAILY AND CLEAN AREAS OR WORK UPON COMPLETION.

6.

THE BUILDING WILL BE OCCUPIED DURING CONSTRUCTION PERIOD. GENERAL CONTRACTOR SHALL MINIMIZE DISTURBANCE TO BUILDING OCCUPANTS AND FUNCTIONS.

GENERAL CONTRACTOR TO COORDINATE WITH OWNER SO THAT CONSTRUCTION WILL NOT INTERFERE WITH BUILDING OPERATION AND SECURITY REQUIREMENTS.

7.

ALL WORK TO BE COORDINATED WITH THE GENERAL CONTRACTOR. THE GENERAL CONTRACTOR WILL BE RESPONSIBLE FOR COORDINATION OF ALL WORK WITH THE OWNER.

8.

OWNER HAS RIGHT TO CLAIM ANY MATERIALS AND/OR EQUIPMENT THAT IS SCHEDULED TO BE DEMOLISHED OR REMOVED FROM THE SITE.

TCEP No.: 530-021-15

April 1, 2016

MAIN LEVEL DEMO PLAN

SCALE: 1/8"=1'-0"

GENERAL CONSTRUCTION PREPARATION NOTES

1.

CARPETING TO BE INSTALLED AS AN OVERLAY OVER EXISTING FLOOR TILE. PRIOR TO INSTALLATION OF CARPET, SURVEY EXISTING FLOOR TILE TO ENSURE SOUND

SUBSTRATE CONDITION. LOOSE TILE SHALL BE REMOVED AND VOID GROUTED FLUSH WITH ADJACENT TILE OR SECURED IN PLACE PRIOR TO INSTALLATION OF CARPET.

SEE SPEC AND MANUFACTURERS RECOMMENDATION FOR INSTALLATION.

2.

GENERAL CONTRACTOR IS TO ENCLOSE, COVER AND PROTECT EXISTING KUHN ORGAN CONSOLE AND ALL PIPES IN THEIR ENTIRETY FOR THE DURATION OF DEMOLITION AND CONSTRUCTION.

Main Level Demo Plan

A0.02

KEY NOTE DEMOLITION ITEMS

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 17'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-1)

Architecture

Landscape Architecture

Engineering

Interiors

TO PREPARE FOR INSTALLATION OF ALF-1; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 14'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-1)

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 13'-0" A.F.F. TO 24'-0" A.F.F OF NORTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR

CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.(ALTERNATE A-2)

Kansas City, Missouri

TO PREPARE FOR INSTALLATION OF ALF-2; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 16'-0" A.F.F. TO 22'-0" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-2)

3e

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING BACK TO EXTERIOR CMU WALL. PATCH AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-3)

3a

3a

TO PREPARE FOR INSTALLATION OF ALF-3; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-3)

DN

3g

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 5'-8" A.F.F. TO 21'-0" A.F.F OF SOUTH

CHAPEL "EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY / FLARED APERTURE FRAMING @

HEAD / JAMB & SILL . HEADER OFF EXISTING WALL ASSEMBLY AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE

ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION. (ALTERNATE A-4)

3a

TO PREPARE FOR INSTALLATION OF ALF-4; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 6'-0" A.F.F. TO 18'-0" A.F.F OF SOUTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-4)

3a

2'-0"

2'-6"

16'-0"

3j

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE PLASTER / FURRING WALL ASSEMBLY FOR WIDTH DIMENSIONED FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL

"EXIT" ELEVATION (BASE OF BRICK) OR AS REQUIRED FOR INSTALLATION OF NEW ALUMINUM STOREFRONT WINDOW ASSEMBLY. HEADER OFF EXISTING WALL ASSEMBLY

AS REQUIRED. BRACE EXISTING/REMINING WALL @ PERIMETER OF DEMO'D OPENING. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW

CONSTRUCTION. (ALTERNATE A-5)

TO PREPARE FOR INSTALLATION OF ALF-5; REMOVE EXISTING FACE BRICK VENEER & CMU WALL ASSEMBLY FOR A WIDTH OF 3'-4" (OPENING TO ALIGN WITH NEAREST

HEAD JOINT TO DIMENSIONED WIDTH) , FROM 20'-8" A.F.F. TO 26'-8" A.F.F OF NORTH CHAPEL "EXIT" ELEVATION (BASE OF BRICK). REMOVE ADDITIONAL BRICK & CONC.

MASONRY AS REQUIRED FOR INSTALLATION OF CAST STONE SILL & STEEL LINTEL @ HEAD. PROVIDE NEW STEEL LINTEL AT HEAD OF OPENING AS NOTED . INFILL BRICK

ON COMPLETION OF LINTEL INSTALL. SALVAGE BRICK DURING DEMO AS REQUIRED FOR USE IN SOLDIER COURSE HEADER OF NEW PUNCHED OPENING TO MATCH

ADJACENT PUNCHED OPENINGS, SALVAGE BRICK AS REQUIRED FOR TOOTHING IN AT PERIMETER OF OPENING PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED

FOR NEW CONSTRUCTION & INSTALLATION OF NEW ALUM. STOREFRONT FRAMING.(ALTERNATE A-5)

14'-0"

1h

8'-0"

1'-0"

1b

AS PER CONSTRUCTION DOCUMENTS

3'-4"

7'-4"

3'-0"

1a

SHEET HISTORY:

ISSUED 04/01/2016

1g

3'-4"

REMOVE AND PRESERVE EXISTING FIRE RATED SOLID CORE WOOD DOOR & FIRE RATED HOLLOW METAL FRAME TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE

FLOOR ASSEMBLY. SALVAGE AND REINSTALL AT NEW FINISH FLOOR ELEVATION OF BUILT-UP STAGE FLOOR ASSEMBLY. MODIFY HEIGHT OF DOOR AND FRAME AS

REQUIRED / IF NECESSARY FOR INSTALLATION BELOW EXISTING CONCRETE PLATFORM ABOVE.

?

#

?- #

1'-0"

8'-0"

REMOVE AND PRESERVE EXISTING PAIR OF WOOD DOORS THAT ACT AS COVER TO STAINED GLASS WINDOW TO ALLOW FOR INSTALLATION OF BUILT-UP STAGE FLOOR

ASSEMBLY, SALVAGE AND REINSTALL AT HIGHER ELEVATION UPON INSTALLATION OF BUILT-UP STAGE FLOOR ASSEMBLY. OPERATION TO REMAIN THE SAME UPON

REINSTALLATION

3'-0"

1c

3'-0"

1d

5'-8"

REMOVE EXISTING "CROOKED" DOOR & WOOD FRAME IN ITS ENTIRETY. PREPARE ADJACENT SURFACES / ROUGH OPENING AS REQUIRED FOR INSTALLATION OF NEW

NEW FRY-REGLET MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR..

7'-4"

3'-4"

5'-8"

REMOVE GPDW / PLASTER / STUD WALL ASSEMBLY ADJACENT TO DEMO'D "CROOKED DOOR" AS REQUIRED TO ALLOW FOR INSTALLATION OF NEW FRY-REGLET

MINIMALIST ALUMINUM DOOR FRAME & FLUSH SLAB SOLID CORE WOOD DOOR. NEW DOOR FRAME IS TO BE INSTALLED PLUMB (OPPOSED TO PARALLEL TO THE RAKED

FLOOR LIKE DEMO'D DOOR). HEADER GPDW / PLASTER / STUD WALL ASSEMBLY AS REQUIRED AT NEW DOOR FRAME. INFILL WALL FRAMING & GPDW AS REQUIRED FOR

FLUSH INSTALL OF NEW DOOR FRAME PATCH EXISTING/ REMAINING WALLS AT INTERSECTION OF WALL BEING REMOVED AND PREPARE ADJACENT SURFACES AS

REQUIRED FOR NEW CONSTRUCTION.

8'-0"

REMOVE FLOOR MOUNTED DOOR HOLD-OPEN HARDWARE COMPONENTS TO ALLOW DOOR CLOSER TO FUNCTION

3h

1k

1f

1j

3'-4"

REMOVE EXISTING 38"x32" THROUGH WALL TRANSFER GRILLE; CMU WALL OPENING IN-FILLED WITH BLOCK TO MATCH ADJACENT CMU WALL, PT. TO MATCH ADJACENT

WALL FINISH; PROVIDE NEW WALL OPENING WITH FIRE/SMOKE DAMPER AS NOTED; DAMPER TO BE WIRED TO FIRE ALARM PANEL

1e

EXISTING AUDITORIUM SEATING (MAIN FLOOR AND BALCONY) WILL BE REMOVED UNDER SEPARATE CONTRACT BY OWNER. GC SHALL PATCH & REPAIR ALL ANCHOR

LOCATIONS IN SLAB, CRACKS, ETC. & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW FLOORING (EPOXY & TILE CARPETING).

3'-4"

REMOVE ALL THEATER DRAPERIES / DRAPERY RIGGING IN THEIR ENTIRETY, PRESERVE AND PROVIDE TO OWNER; PREPARE FOR INSTALLATION OF NEW DRAPERY

RIGGING & DRAPES; SEE FINISH SHEETS / SPECS.

3c

REMOVE EXISTING TEMPORARY STAGE EXTENSION / FRAMING, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

REMOVE EXISTING STEEL STAIR; VERIFY SALVAGE WITH OWNER PRIOR TO DEMOLITION.

REMOVE EXISTING STAGE LEFT AND STAGE RIGHT WOOD STAIRS STEEL RAILINGS, PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

REMOVE EXISTING STEEL SPIRAL STAIR/RAILING & CENTER SUPPORT PIPE COLUMN. UPON DEMOLITION PROVIDE CONTINUOUS 2x8 LEDGER BOARD AT PERIMETER OF

C.I.P. CONC. FLOOR OPENING WITH NEW 3/4" PLYWOOD INFILL OF OPENING. LEDGER TO BE RECESSED 3 4" SO T.O. PLYWOOD IS LEVEL WITH T.O. SLAB. PROVIDE 2X8

FLOOR FRAMING @ 16" O.C. MAX. PATCH AND PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION.

UP

REMOVE EXISTING STEEL GUARDRAIL IN ITS ENTIRETY TO SURFACE OF EXISTING STEEL CHANNEL @ T.O. WALL (CHANNEL TO REMAIN). GRIND GUARD RAIL CONNECTIONS

AT POSTS SMOOTH & FLUSH W/ FACE OF CHANNEL, PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION INSTALLATION OF NEW ALUMINUM BASE

SHOE / NEW GLASS GUARD RAIL ASSEMBLY.

REMOVE EXISTING PLASTER CEILING SYSTEM & PREPARE ADJACENT SURFACES AS REQUIRED FOR NEW CONSTRUCTION / INSTALLATION OF NEW RECESSED MOTORIZED

PROJECTION SCREEN. MOUNT SCREEN PER MFR. SPECIFICATIONS. COORDINATE SIZE OF CEILING DEMOLITION WITH SCREEN SPECS. / REQUIREMENTS. LOCATE AS PER

DIMENSIONS. PATCH & REPAIR PLASTER CEILING @ RECESSED SCREEN UPON COMPLETION OF INSTALLATION

REMOVE EXISTING RETURN AIR GRILLE @ FRONT WALL OF EXISTING STAGE

DN

DN

DN

REMOVE EXISTING RESILIENT BASE THROUGHOUT ENTIRE CHAPEL & CHAPEL ENTRY VESTIBULE, PREPARE ADJACENT SURFACES AS REQUIRED FOR INSTALLATION OF

NEW RESILIENT BASE FOLLOWING INSTALLATION OF NEW FLOORING FINISHES.

DN

PROVIDE CORE-DRILL OPENING / CUT-OUT THROUGH EXISTING FLOOR FOR NEW CONDUIT SYSTEM AS DIMENSIONED ON PLAN, SEE A1.01). SIZE OF CORE-DRILLING TO BE

COORDINATED WITH REQUIREMENTS OF ELECTRICAL CONDUIT (SEE ELECTRICAL). VERIFY FLOOR STRUCTURE LOCATION PRIOR TO CUTTING OPENING.

UP

SCOPE OF WORK KEYPLAN

800 N. Columbia Ave.

Seward, Nebraska

GENERAL DEMOLITION NOTE ITEMS

1.

THE GENERAL CONTRACTOR SHALL VERIFY ALL EXISTING DIMENSIONS AND CONDITIONS SHOWN ON THE PLANS PRIOR TO DEMOLITION. ANY DEVIATIONS IN THE EXISTING

CONDITIONS OR DIMENSIONS INDICATED SHALL BE COORDINATED WITH THE ARCHITECT/ENGINEER AND OWNER IN ORDER TO MODIFY THE PLANS ACCORDINGLY.

2.

THE CONTRACTOR IS RESPONSIBLE FOR PRODUCING WEATHER TIGHT CONSTRUCTION.THE EXISTING BUILDING SHALL BE PROTECTED FROM WEATHER AT ALL TIMES.

OPENINGS AND PENETRATIONS SHALL BE PROTECTED WITH DURABLE, INSULATED TEMPORARY CONSTRUCTION. COORDINATE SECURITY REQUIREMENTS WITH THE OWNER.

3.

THE GENERAL CONTRACTOR SHALL BE RESPONSIBLE FOR PROTECTING ALL EXISTING ITEMS NOT BEING REMOVED FROM PROJECT AREA. ANY DAMAGE THAT MAY OCCUR

FROM WORK UNDER THIS CONTRACT SHALL BE RESTORED TO ITS ORIGINAL CONDITION.

4.

THE GENERAL CONTRACTOR SHALL NOTIFY THE ARCHITECT/ENGINEER IF DEMOLITION WORK APPEARS TO AFFECT THE STRUCTURAL INTEGRITY OF THE EXISTING

BUILDING BEFORE PROCEEDING.

5.

THE GENERAL CONTRACTOR TO COORDINATE ALL DEMOLITION WORK BETWEEN ALL TRADES. AREAS OF WORK SHALL BE KEPT CLEAN AND SAFE. DISPOSE OF DEBRIS

DAILY AND CLEAN AREAS OR WORK UPON COMPLETION.

6.

THE BUILDING WILL BE OCCUPIED DURING CONSTRUCTION PERIOD. GENERAL CONTRACTOR SHALL MINIMIZE DISTURBANCE TO BUILDING OCCUPANTS AND FUNCTIONS.

GENERAL CONTRACTOR TO COORDINATE WITH OWNER SO THAT CONSTRUCTION WILL NOT INTERFERE WITH BUILDING OPERATION AND SECURITY REQUIREMENTS.

7.

ALL WORK TO BE COORDINATED WITH THE GENERAL CONTRACTOR. THE GENERAL CONTRACTOR WILL BE RESPONSIBLE FOR COORDINATION OF ALL WORK WITH THE OWNER.

8.

OWNER HAS RIGHT TO CLAIM ANY MATERIALS AND/OR EQUIPMENT THAT IS SCHEDULED TO BE DEMOLISHED OR REMOVED FROM THE SITE.

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

TCEP No.: 530-021-15

April 1, 2016

UPPER LEVEL DEMO PLAN

SCALE: 1/8"=1'-0"

GENERAL CONSTRUCTION PREPARATION NOTES

1.

CARPETING TO BE INSTALLED AS AN OVERLAY OVER EXISTING FLOOR TILE. PRIOR TO INSTALLATION OF CARPET, SURVEY EXISTING FLOOR TILE TO ENSURE SOUND

SUBSTRATE CONDITION. LOOSE TILE SHALL BE REMOVED AND VOID GROUTED FLUSH WITH ADJACENT TILE OR SECURED IN PLACE PRIOR TO INSTALLATION OF CARPET.

SEE SPEC AND MANUFACTURERS RECOMMENDATION FOR INSTALLATION.

2.

GENERAL CONTRACTOR IS TO ENCLOSE, COVER AND PROTECT EXISTING KUHN ORGAN CONSOLE AND ALL PIPES IN THEIR ENTIRETY FOR THE DURATION OF DEMOLITION AND CONSTRUCTION.

Upper Level Demo Plan

A0.03

Architecture

Landscape Architecture

Engineering

Interiors

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

Kansas City, Missouri

REMOVE FLOOR MOUNTED

DOOR HOLD-OPEN

HARDWARE COMPONENTS

TO ALLOW DOOR CLOSER

TO FUNCTION

008

011

REMOVE FLOOR MOUNTED

DOOR HOLD-OPEN

HARDWARE COMPONENTS

TO ALLOW DOOR CLOSER

TO FUNCTION

UP

UP

UP

015a

SHOWCASE

SHOWCASE

REMOVE FLOOR MOUNTED DOOR

HOLD-OPEN HARDWARE COMPONENTS

TO ALLOW DOOR CLOSER TO FUNCTION

?

#

?- #

SHEET HISTORY:

AS PER CONSTRUCTION DOCUMENTS

SHOWCASE

SHOWCASE

ISSUED 04/01/2016

DN

UP

UP

UP

SCOPE OF WORK KEYPLAN

03A

EXISTING 38"x32" TRANSFER WALL GRILLE TO BE REMOVED AND CMU WALL

OPENING IN-FILLED WITH BLOCK TO MATCH ADJACENT CMU WALL, PT. TO

MATCH ADJACENT WALL FINISH; PROVIDE NEW WALL OPENING WITH

FIRE/SMOKE DAMPER AS NOTED; DAMPER TO BE WIRED TO FIRE ALARM PANEL

M003

M009(PR)

M008

M007

M006

M005

M004

M002

M001

033B

UP

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

TCEP No.: 530-021-15

April 1, 2016

LOWER LEVEL FLOOR PLAN

SCALE: 1/8"=1'-0"

Lower Level Floor Plan

A1.00

PROVIDE NEW 24" WIDE STEEL SHIPS LADDER FROM

STAGE ELEVATION TO CONCRETE PLATFORM ABOVE;

REMOVE STEEL PIPE GUARDRAIL AT PLATFORM / T.O.

LADDER ABOVE AS REQUIRED. ATTACH AS PER MFR.

SPECIFICATIONS (BASIS OF DESIGN: FSINDUSTRIES

SHIPS LADDER 68 DEGREE INCLINE STANDARD

EXTENDED HANDRAIL SHIPS LADDER MODEL

SL2498-A; GREY ENAMEL, BLACK BAR GRATING

TREADS: 24" WIDE X 6" DEEP BLACK BAR GRATING

TREADS W/ WALK-THRU HANDRAIL)

LADDER TO ACCESS PLATFORM THAT IS 8'- 51 2"

ABOVE ORIGINAL STAGE FLOOR ELEVATION - GC TO

VERIFY HEIGHT REQUIRED PRIOR TO ORDER

NEW STAGE DRAPERIES: 3 LEGS STAGE

LEFT, 3 LEGS STAGE RIGHT, 1 BORDER @

EACH PAIR OF LEGS SEE FIRST FLOOR

FINISH PLAN FOR MORE INFORMATION

EXG. CONC. STAIR

3'-8": 4 TREADS @ 11" EA.

2'-11": 5 RISERS @ 7" EA TYP

1

S

S

H

SIM

DOWN

EQ.

EXISTING CONC. STAIR

CONSTRUCTION

UNDERSIDE OF LOFT

7'-4" A.F.F.

NEW BUILT-UP

STAGE FINISHED FLOOR

100'-2 5/8"

311

1133

264" "

EXISTING STEEL HAND

RAILS TO REMAIN

4"

R43'-6 3

1A 1B 1A

EXTERIOR STAIR ENLARGED PLAN

FINISHED FLOOR

FRONT OF CHAPEL

96'-6"

DN

UP

UP

5'-0"

EXG. WALL

CONSTRUCTION

1E

6'-71 8"

1A

PROVIDE CONT. LUMINESCENT NOSING STRIP AT TRANSITION TO EXISTING LANDING, RSN-3

NEW BUILT-UP

STAGE FINISHED FLOOR

100'-2 5/8"

FINISHED FLOOR AT EXISTING LANDING

100'-0"

UP

EQ.

FINISHED FLOOR AT EXISTING LANDING

96'-7"

1C

1C

1D

5'-0"

1E

DN

UP

5'-0"

EQ.

4'-0"

EXG. CONC. STAIR

CONSTRUCTION

1 1/2" NOMINAL SCHEDULE 40 STEEL PIPE

HANDRAIL (PT. ) TYP. FOR ENTIRE LENGTH

OF RAKED FLOOR, INSTALL AT 3'-0" A.F.F.

PROVIDE WALL BRACKET @ 4'-0" O.C. TYP.

& EACH SIDE WALL OF CHAPEL;PROVIDE

1'-0" HORIZONTAL EXTENSION AT T.O.

RAKED FLOOR AT TRANSITION TO LEVEL

FLOOR ELEVATION WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO NOMMA

FINISH LEVEL#2 OR BETTER, TYP. ALL

STEEL HANDRAILS ON PROJECT

CORE DRILL & GROUT SOLID 6"

MIN DEPTH TYP. PROVIDE

SEALANT @ STAIR SURFACE

17'-0"

1'-0"

PATCH, REPAIR & PERFORM SURFACE

PREP ON EXISTING PAINTED CONCRETE

FLOOR SLAB IN AREA OF CHAPEL SEATING

AS REQUIRED FOR INSTALLATION OF

EPOXY FLOORING

?

#

?- #

SHEET HISTORY:

ISSUED 04/01/2016

AS PER CONSTRUCTION DOCUMENTS

3'-0"

3'-4"

3'-0"

2B

2B

1'-0"

HANDRAIL TO

RETURN TO

GUARDRAIL POST

3'-4"

11"

106

1'-0"

PRE-FINISHED ALUM. STOREFRONT

ASSEMBLY W/ 1" INSULATING

GLASS (BASIS OF DESIGN EFCO 433

TRIPLE SET (T) STOREFRONT

SYSTEM (OUTSIDE SET) OR

APPROVED EQUAL DURING

BIDDING PERIOD.) STOREFRONT

SYSTEM TO HAVE INTEGRAL CLIPS

FOR OWNER PROVIDED STAINED

GLASS PANELS, SEE FRAME TYPES

FOR GLAZING TYPES. PROVIDE

RECESSED MOTORIZED WINDOW

SHADE (WS-1) W/ BLACKOUT

SHADE FABRIC. & CONT.

INTEGRALSHADELOC CHANNELS A

EACH JAMB (ALTERNATE A-1)

1'-0"

1'-0"

14'-0"

1 1/2" NOMINAL SCHEDULE 40 STEEL PIPE

GUARDRAIL (GALV) (PT. ) TYP. @ EA. SIDE

OF BOTH NORTH & SOUTH STAIRS

PROVIDE RAIL @ 21" & 42" ABOVE STAIR /

WALK SURFACE; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO NOMMA

FINISH LEVEL#2 OR BETTER

1 1/2" NOMINAL SCHEDULE 40 STEEL

PIPE HANDRAIL (GALV) (PT. ) TYP. @

EA. SIDE OF BOTH NORTH & SOUTH

STAIRS ; WELD ENTIRE ASSEMBLY &

GRIND SMOOTH TO NOMMA FINISH

LEVEL#2 OR BETTER

Kansas City, Missouri

EXISTING FIRE RATED DOOR AND FRAME TO BE REMOVED FOR INSTALALTION OF

NEW STAGE ASSEMBLY . RE-INSTALL DOOR / FRAME ASSEMBLY UPON INSTALATION

BUILT -UP STAGE

UP

1C

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

PROVIDE 1/2" PLYWOOD OVER GPDW FROM FINISHED FLOOR TO UNDERSIDE OF AMBO POCKET LID

2A

1A 1B 1A

1B

1D

1'-0"

SCALE: 1/4"=1'-0"

114 " 6

'-8"

1C

www.clarkenersen.com

PROVIDE LID TO AMBO STORAGE POCKET @ 5'-0" A.F.F. LID ASSEMBLY

TO BE 1/2" PLYWOOD ON 6" STEEL STUDS @ 16" O.C. PROVIDE 1 2"

PLYWOOD AT FACE OF STORAGE POCKET TO COVER STUD FRAMING

NEW GRAND DRAPE & VALANCE; SEE

FIRST FLOOR FINISH PLAN FOR

MORE INFORMATION

FINISHED FLOOR AT EXISTING LANDING

96'-7"

11"

NEW BORDER CURTAINS (3);

SEE FIRST FLOOR FINISH PLAN UNDERSIDE OF ORGAN LOFT

7'-4" A.F.F.

FOR MORE INFORMATION

NEW BUILT-UP

STAGE FINISHED FLOOR

100'-2 5/8"

Architecture

Landscape Architecture

Engineering

Interiors

PROVIDE NEW 24" WIDE STEEL SHIPS LADDER FROM STAGE ELEVATION TO CONCRETE

PLATFORM ABOVE; REMOVE STEEL PIPE GUARDRAIL AT PLATFORM / T.O. LADDER

ABOVE AS REQUIRED. ATTACH AS PER MFR. SPECIFICATIONS (BASIS OF DESIGN:

FSINDUSTRIES SHIPS LADDER 68 DEGREE INCLINE STANDARD EXTENDED HANDRAIL

SHIPS LADDER MODEL SL2498-A; GREY ENAMEL, BLACK BAR GRATING TREADS: 24"

WIDE x 6" DEEP BLACK BAR GRATING TREADS W/ WALK-THRU HANDRAIL)

LADDER TO ACCESS PLATFORM THAT IS 8'- 51 2" ABOVE ORIGINAL STAGE FLOOR

ELEVATION - GC TO VERIFY HEIGHT REQUIRED PRIOR TO ORDER

2'-0" 1'-0"

CONC. PLATFORM ABOVE

PROVIDE CONT. LUMINESCENT NOSING STRIP

AT TRANSITION TO EXISTING LANDING, RSN-3

FINISHED FLOOR AT EXISTING LANDING

100'-0"

1

EXISTING

STAGE FINISHED FLOOR

100'-0"

CONC. PLATFORM ABOVE

EXISTING FIRE RATED DOOR AND FRAME TO BE

REMOVED FOR INSTALALTION OF NEW STAGE

ASSEMBLY . RE-INSTALL DOOR / FRAME ASSEMBLY

UPON INSTALATION BUILT -UP STAGE

1'-0"

11"

59'-81 2"

NEW STAGE DRAPERIES: 1 REAR CURTAIN STAGE

LEFT, 1 REAR CURTAIN STAGE RIGHT; SEE FIRST

FLOOR FINISH PLAN FOR MORE INFORMATION

EQ

PROVIDE NEW STAGE FLOORING OVERLAY OVER EXG. STAGE FLOOR.

EXG. STAGE TO BE SECURED AND ANY LOOSE BOARDS TIGHTENED/SECURED PRIOR TO

STAGE OVERLAY INSTALLATION.

-OVERLAY ASSEMBLY - RESILIENT FLOORING (SHEET JOINTS SHALL ALIGN W/

PLYRON PANELS BELOW) OVER 3/4" TEMPERED PLYRON (HARDBOARD FACED

PLYWOOD PRODUCT) OVER 2X6 SLEEPERS; PROVIDE 3/8" NEOPRENE RUBBER PAD

ATTACHED TO SLEEPERS @ 12" O.C. AT ATTACHMENT TO EXG. FLOORING

3'-10"

EQ.

EQ

EQ.

4'-0" 45 8"

11"

HANDRAIL TO

RETURN TO

GUARDRAIL POST

EXISTING DOORS TO BE REMOVED AND HEIGHT MODIFIED TO

ACCOMMODATE FOR RAISED FLOOR ELEVATION DOOR SHALL MAINTAIN

SAME FUNCTIONALITY ON NEW FLOOR AS ON EXISTING STAGE FLOOR

2'-0" 1'-0"

11 2"

FINISHED FLOOR

@ EXISTING LANDING

96'-7"

EQ.

11'-21 4"

1 1/2" NOMINAL SCHEDULE 40 STEEL PIPE GUARDRAIL

(PT. ) TYP. @ EA. SIDE OF BOTH NORTH & SOUTH STAIRS

PROVIDE RAIL @ 21" & 42" ABOVE STAIR / WALK

SURFACE; WELD ENTIRE ASSEMBLY & GRIND SMOOTH

TO NOMMA FINISH LEVEL#2 OR BETTER

1 1/2" NOMINAL SCHEDULE 40 STEEL

PIPE HANDRAIL (PT. ) TYP. @ EA. SIDE

OF BOTH NORTH & SOUTH STAIRS ;

WELD ENTIRE ASSEMBLY & GRIND

SMOOTH TO NOMMA FINISH LEVEL#2

OR BETTER

NOTE:

NEW RIGGING TO BE PROVIDED FOR

ALL NEW STAGE DRAPERIES

PRE-FINISHED ALUM. STOREFRONT ASSEMBLY W/ 1" INSULATING GLASS (BASIS OF

DESIGN EFCO 433 TRIPLE SET (T) STOREFRONT SYSTEM (OUTSIDE SET) OR

APPROVED EQUAL DURING BIDDING PERIOD.) STOREFRONT SYSTEM TO HAVE

INTEGRAL CLIPS FOR OWNER PROVIDED STAINED GLASS PANELS, SEE FRAME

TYPES FOR GLAZING TYPES. PROVIDE RECESSED MOTORIZED WINDOW SHADE

(WS-1) W/ BLACKOUT SHADE FABRIC. & CONT. INTEGRALSHADELOC CHANNELS A

EACH JAMB (ALTERNATE A-4)

2B

NEW CHAPEL SEATING N.I.C; COORDINATE WITH OWNER

FOR OWNER PROVIDED INSTALL OF SEATING

FINISHED FLOOR

REAR OF CHAPEL

100'-0"

SOUNDBOOTH / ROLLING

SECURITY DOORS

2 EXT. STAIR GUARD / HANDRAIL

SCALE: 1/2"=1'-0"

1'-2"

EQ

EXISTING STONE BENCH

1 1/2" NOMINAL SCHEDULE 40

STEEL PIPE HANDRAIL (PT. )

TYP. @ EA. SIDE OF BOTH

STAIRS ; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH

TO NOMMA FINISH LEVEL#2 OR

BETTER, EXT. @ T.O. RAIL TO

FOLLOW CIRCUMFERENCE OF

POST CAP (FIELD VERIFY)

UP

UP

EXISTING STONE

BENCH

1'-1"

TYP

DN

EXISTING WOOD

RAILING

11 2" 10" 11 2"

SIM

UP

1 2"

1'-1"

DN

8"

1

11 2" 10" 11 2"

EXISTING WOOD

NEWEL POST

DN

DN

EXISTING WOOD RAILING

UP

R7 5

EQ

5 8" 1

R7 1 2"

1 8"

R6

1'-2"

8"

11 2"

11 2"

EQ

11 2"

DOWN

EXG. STAIR

3'-6": 3 TREADS @ 11" EA.

2'-2": 4 RISERS @ 6 1/2" EA

RADIUSED WOOD RAIL

POST CAP

112 "

EQ

R6 1

SCOPE OF WORK KEYPLAN

CORE DRILL & GROUT

SOLID 6" MIN DEPTH TYP.

PROVIDE SEALANT @

STAIR SURFACE

Concordia University Nebraska

Weller Hall Interior

Improvements - Phase 3

800 N. Columbia Ave.

Seward, Nebraska

3 LOBBY STAIR ENLARGED PLAN

SCALE: 1/4"=1'-0"

11 2"

TCEP No.: 530-021-15

11 2"

RADIUSED WOOD

RAIL POST CAP

1 1/2" NOMINAL SCHEDULE 40 STEEL

PIPE HANDRAIL (PT. ) TYP. @ EA. SIDE

OF BOTH STAIRS ; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO

NOMMA FINISH LEVEL#2 OR BETTER,

EXT. @ T.O. RAIL TO FOLLOW

CIRCUMFERENCE OF POST CAP (FIELD

VERIFY)

EXISTING WOOD

RAILING

EXISTING STAIR

11 2"

1'-2"

April 1, 2016

EXISTING STONE BENCH (BEYOND)

EQ EQ

1'-2"

4 LOBBY STAIR HANDRAIL

CORE DRILL & GROUT SOLID 6" MIN

DEPTH TYP. PROVIDE SEALANT @

STAIR SURFACE

MAIN LEVEL FLOOR PLAN

SCALE: 1/8"=1'-0"

Main Level Floor Plan

SCALE: 1/2"=1'-0"

A1.01

1 1/2" NOMINAL SCHEDULE 40 STEEL PIPE HANDRAIL (PT. ) TYP. @ T.O. EXG. GUARD WALL.

T.O. RAIL TO BE 3'-0" ABOVE LEADING EDGE OF STAIR NOSINGS TYP. PROVIDE 1 1/2" NOMINAL

SCHEDULE 40 STEEL PIPE POSTS @ EVEN SPACING ALONG LENGTH OF WALL W/ 4" ROUND

BASEPLATE AT T.O. WALL / FLOOR W/ ANCHORS / EXP. ANCHORS AS REQD.; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO NOMMA FINISH LEVEL#2 OR BETTER

3'-11 4"

11 2"

1-1/2" NOMINAL SCHEDULE 40 STEEL PIPE RETURN / BASE

PLATE @ EXG. WALL; PROVIDE ONE ATTACHMENT PIPE FOR

CONNECTION AT WALL AT EACH END OF 8'-0" LONG LIGHT

SUPPORT PIPE & AT CENTER , WELD ENTIRE ASSEMBLY &

GRIND SMOOTH TO NOMMA FINISH LEVEL#3 OR BETTER

PAINT TO MATCH WALL. PROVIDE BLOCKING / BRACING IN

EXISTING WALL AS REQUIRED

13'-23 4"

FIELD VERIFY ALL DIMENSIONS

BASEPLATE,

PT. TYP.

EQ.

EQ.

Architecture

Landscape Architecture

Engineering

Interiors

www.clarkenersen.com

Lincoln, Nebraska

1010 Lincoln Mall, Suite 200

Lincoln, NE 68508-2883

402 477.9291 Fax 402 477.6542

EQ.

BASEPLATE,

PT. TYP.

ALUMINUM

STOREFRONT

FRAME

(BEYOND)

BASEPLATE,

PT. TYP.

Kansas City, Missouri

1-1/2" NOMINAL SCHEDULE 40 STEEL LIGHT

SUPPORT PIPE; WELD ENTIRE ASSEMBLY &

GRIND SMOOTH TO NOMMA FINISH LEVEL#3

OR BETTER PAINT TO MATCH WALL

NOTE:

NEW RIGGING TO BE PROVIDED FOR ALL NEW STAGE DRAPERIES; SEE

FIRST FLOOR FINISH PLAN FOR THEATRICAL RIGGING AND DRAPERY

LP-2

BASEPLATE,

PT. TYP.

1'-0"

1'-6"

1'-6"

1 1/2" NOMINAL SCHEDULE 40 STEEL

PIPE HANDRAIL (PT. ) TYP. @ EA. SIDE

OF STEPS ; PROVIDE 4" ROUND

BASEPLATE AT FLOOR W/ EXP.

ANCHORS AS REQD. WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO

NOMMA FINISH LEVEL#2 OR BETTER

PROVIDE NEW 24" WIDE STEEL SHIPS LADDER FROM STAGE

ELEVATION TO CONCRETE PLATFORM ABOVE; REMOVE STEEL

PIPE GUARDRAIL AT PLATFORM / T.O. LADDER ABOVE AS

REQUIRED. ATTACH AS PER MFR. SPECIFICATIONS (BASIS OF

DESIGN: FSINDUSTRIES SHIPS LADDER 68 DEGREE INCLINE

STANDARD EXTENDED HANDRAIL SHIPS LADDER MODEL

SL2498-A; GREY ENAMEL, BLACK BAR GRATING TREADS: 24"

WIDE x 6" DEEP BLACK BAR GRATING TREADS) GC TO VERIFY

HEIGHT REQUIRED PRIOR TO ORDER

BASEPLATE, PT. TYP.

1'-6"

PROVIDE NEW 24" WIDE STEEL SHIPS LADDER FROM STAGE

ELEVATION TO CONCRETE PLATFORM ABOVE; REMOVE STEEL

PIPE GUARDRAIL AT PLATFORM / T.O. LADDER ABOVE AS

REQUIRED. ATTACH AS PER MFR. SPECIFICATIONS (BASIS OF

DESIGN: FSINDUSTRIES SHIPS LADDER 68 DEGREE INCLINE

STANDARD EXTENDED HANDRAIL SHIPS LADDER MODEL

SL2498-A; GREY ENAMEL, BLACK BAR GRATING TREADS: 24"

WIDE x 6" DEEP BLACK BAR GRATING TREADS) GC TO VERIFY

HEIGHT REQUIRED PRIOR TO ORDER

2'-0" 1'-0"

NEW MOTORIZED RECESSED

PROJECTION SCREEN; SEE SPEC

SCALE: 1/4"=1'-0"

1'-6"

1'-6"

BASEPLATE, PT. TYP.

1'-6"

1'-0"

9'-0"

14'-0"

1-1/2" NOMINAL SCHEDULE 40 STEEL LIGHT SUPPORT PIPE, PAINT

TO MATCH EXG. CEILING. PROVIDE 1-1/2" NOMINAL SCHEDULE 40

STEEL PIPE RETURN TO STRUCTURE; PROVIDE ONE VERTICAL

ATTACHMENT PIPE FOR CONNECTION AT ANGLE AT EACH END OF

9'-0" LONG LIGHT SUPPORT PIPE & @ CENTER , PAINT TO MATCH

EXG. CEILING.

1'-0"

3" X 3" X 3/16" CONT ANGLE; WELD TO EXISTING JOISTS @

BOTTOM CHORD, TYP.

3'-4"

?

#

?- #

SHEET HISTORY:

ISSUED 04/01/2016 AS PER CONSTRUCTION DOCUMENTS

SIM

LP-2

LP-2

8'-0"

3'-0"

1 1/2" NOMINAL SCHEDULE 40

STEEL PIPE HANDRAIL (PT. ) TYP. @

T.O. EXG. GUARD WALL. T.O. RAIL

TO BE 3'-0" ABOVE LEADING EDGE

OF STAIR NOSINGS TYP. PROVIDE 1

1/2" NOMINAL SCHEDULE 40 STEEL

PIPE POSTS @ EVEN SPACING

ALONG LENGTH OF WALL; WELD

ENTIRE ASSEMBLY & GRIND

SMOOTH TO NOMMA FINISH

LEVEL#2 OR BETTER

SCALE: 1/4"=1'-0"

9'-0"

9"

SIM

PROVIDE NEW CONT. MECHANICALLY ATTACHED ALUMINUM BASE

SHOE (CRL B5L10D) ATTACH T.O. EXG. 3"x4.1" CONT. STEEL

CHANNEL @ T.O. WALL. PROVIDE 12" TALL 1/2" FULLY TEMPERED

CLEAR GLASS PANELS WITH FLAT POLISHED EDGES IN BASE SHOE

(PROVIDE 18" TALL GLASS PANELS AT ENDS OF AISLES)

SIM

NEW CHAPEL SEATING N.I.C;

COORDINATE WITH OWNER

FOR OWNER PROVIDED

INSTALL OF SEATING

BALCONY T.O. WALL HANDRAIL /

AISLE HANDRAILS

9'-0" 1'-0"

3'-4"

1'-0"

BASEPLATE,

PT. TYP.

1'-0"

1'-0"

BASEPLATE,

PT. TYP.

LP-2

PRE-FINISHED ALUM. STOREFRONT

ASSEMBLY W/ 1" INSULATING

GLASS (BASIS OF DESIGN EFCO 433

TRIPLE SET (T) STOREFRONT

SYSTEM (OUTSIDE SET) OR

APPROVED EQUAL DURING

BIDDING PERIOD.) STOREFRONT

SYSTEM TO HAVE INTEGRAL CLIPS

FOR OWNER PROVIDED STAINED

GLASS PANELS, SEE FRAME TYPES

FOR GLAZING TYPES. PROVIDE

RECESSED MOTORIZED WINDOW

SHADE (WS-1) W/ BLACKOUT

SHADE FABRIC. & CONT.

INTEGRALSHADELOC CHANNELS A

EACH JAMB (ALTERNATE A-3)

9'-0"

3'-0"

BASEPLATE,

PT. TYP.

1'-0"

LP-1

1'-0"

1'-0"

1-1/2" NOMINAL SCHEDULE 40 STEEL

LIGHT SUPPORT PIPE; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO

NOMMA FINISH LEVEL#3 OR BETTER

PAINT TO MATCH WALL

ALUMINUM

STOREFRONT

FRAME

(BEYOND)

EQ.

9'-0"

EQ.

CENTER LIGHT SUPPORT PIPES ON CAT WALK

3'-4"

3"

EQ.

CENTER LIGHT SUPPORT PIPES ON CAT WALK

8'-0"

8'-71 2"

EQ.

1 1/2" NOMINAL SCHEDULE 40 STEEL

PIPE HANDRAIL (PT. ) TYP. @ EA. SIDE

OF STEPS ; PROVIDE 4" ROUND

BASEPLATE AT FLOOR W/ EXP.

ANCHORS AS REQD. WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO

NOMMA FINISH LEVEL#2 OR BETTER

PRE-FINISHED ALUM. STOREFRONT

ASSEMBLY W/ 1" INSULATING

GLASS (BASIS OF DESIGN EFCO 433

TRIPLE SET (T) STOREFRONT

SYSTEM (OUTSIDE SET) OR

APPROVED EQUAL DURING

BIDDING PERIOD.) STOREFRONT

SYSTEM TO HAVE INTEGRAL CLIPS

FOR OWNER PROVIDED STAINED

GLASS PANELS, SEE FRAME TYPES

FOR GLAZING TYPES. PROVIDE

RECESSED MOTORIZED WINDOW

SHADE (WS-1) W/ BLACKOUT

SHADE FABRIC. & CONT.

INTEGRALSHADELOC CHANNELS A

EACH JAMB (ALTERNATE A-2)

17'-0"

1 1/2" NOMINAL SCHEDULE 40 STEEL PIPE

HANDRAIL (PT. ) TYP. @ T.O. EXG. GUARD WALL.

T.O. RAIL TO BE 3'-0" ABOVE LEADING EDGE OF

STAIR NOSINGS TYP. PROVIDE 1 1/2" NOMINAL

SCHEDULE 40 STEEL PIPE POSTS @ EVEN

SPACING ALONG LENGTH OF WALL W/ 4" ROUND

BASEPLATE AT T.O. WALL / FLOOR W/ ANCHORS /

EXP. ANCHORS AS REQD.; WELD ENTIRE

ASSEMBLY & GRIND SMOOTH TO NOMMA FINISH

LEVEL#2 OR BETTER

1-1/2" NOMINAL SCHEDULE 40 STEEL PIPE RETURN /

BASE PLATE @ EXG. WALL; PROVIDE ONE

ATTACHMENT PIPE FOR CONNECTION AT WALL AT

EACH END OF 8'-0" LONG LIGHT SUPPORT PIPE & AT

CENTER , WELD ENTIRE ASSEMBLY & GRIND

SMOOTH TO NOMMA FINISH LEVEL#3 OR BETTER

PAINT TO MATCH WALL.CENTER PIPE ON CONTROL

BOOTH WINDOW OPENING @ HIEGHT INDICATED

3'-4"

1-1/2" NOMINAL SCHEDULE 40 STEEL LIGHT

SUPPORT PIPE; WELD ENTIRE ASSEMBLY & GRIND

SMOOTH TO NOMMA FINISH LEVEL#3 OR BETTER