© 2013 Western Environmental Services Corporation. All rights reserved.

Permission granted to reproduce for personal and educational use only.

Design considerations for commercial

air-to-water heat pumps

Advantages of using air to water heat pumps

Using air to water heat pumps (AWHPs) as the primary source of heating and cooling commercial

buildings gives architects and engineers a long-term solution to designing sustainable buildings.

The heat pumps provide all the benefits of a hydronic system with the performance and energy

efficiency of variable refrigerant flow (VRF) designs. Their many features include:

capability

AWHPs can provide energy for a building’s cooling, heating, and domestic hot water

demands at outdoor temperatures from 5°F to 105°F. AWHPs can produce water

temperatures similar to condensing boilers running at their peak efficiencies,

depending on outside air temperatures.

efficiency

Energy recovery options, including true simultaneous heating and cooling, result in

energy use comparable to VRF systems:

Average annual energy savings of over 40% compared to a typical boiler-plus-chiller

application.

Installation costs are generally lower (savings are site specific).

flexibility

Hydronic systems powered by heat pumps allow long-term heating and cooling

flexibility as tenant requirements and building use change. AWHPs can be the energy

source for:

water-source heat pumps

fan coils

radiant heating and cooling

perimeter baseboard heating

central system air handlers

make-up air handlers

VAV units

a combination of systems

In addition, AWHP equipment can be sized to maximize seasonal efficiency by using a

trim boiler for the few hours a year of the coldest-design-or-below temperatures. VRF

systems must be sized to provide all of the heat at design conditions, meaning that the

equipment is oversized for the vast majority of the heating season.

1

adaptability AWHP technology adapts to existing water pipe systems. Configurations are

available that provide both domestic hot water and heating or cooling for two-pipe fan

coil systems; provide simultaneous heating and cooling for four-pipe fan coil systems;

or maintain loop temperature for water-source heat pumps systems. And as technology

changes or refrigerant requirements change, the building’s energy system can be easily

retrofitted to adapt to new technologies.

safety

Hydronic systems minimize refrigerant volume and components both inside and

outside the building envelope, reducing costs and risk of leaks and eliminating the need

for leak detection systems in occupied spaces.

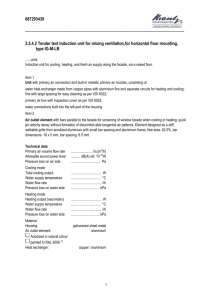

AWHP unit with factory-installed circulation pumps and buffer tank

AWHP basics

Two white papers on the Wescor website provide introductions to how AWHPs work, their

efficiencies, and financial comparisons:

Heat Pump Water Heater Basics

Heat Pump Water Heaters: Design Details

This white paper goes beyond the basics of heating domestic hot water and explains how to use

AWHP technology to heat and cool buildings in a whole-building design.

2

Basic operating designs

The following two sections provide schematics for designing basic two- and four-pipe AWHP

systems. For more involved system designs, call your local Wescor representative.

We’re here to help—call your Wescor representative for assistance when designing AWHP

projects.

Two-pipe systems

In a typical two-pipe fan coil system, the entire building is either in heating or cooling mode, and

seasonal change-over is usually required. (Aermec systems do not require seasonal changeovers,

because the system easily changes between heating and cooling.) In two-pipe systems, the heat

pump has two separate operations, one for each mode.

In cooling mode, the heat pump can provide all the chilled water while also capturing energy from

the chilled water loop to provide energy to the domestic hot water circuit if there is a demand.

In heating mode, the heat pump can provide energy to the building’s hot water loop while also

providing energy to the domestic hot water loop.

If a building is using water source heat pumps for heating and cooling individual zones, the AWHP

can be used to maintain the loop temperature throughout the year.

Basic internal AWHP operating production for two-pipe system + DHW

Cold water production only to system

Compressor

3

3

Compressor

2

1

Description

Functioning

1

Heat exchanger

system side

Evaporator

cold water production

2

Heat exchanger

DHW side

not running

3

Heat exchanger

source side

Condenser

heat exchange with air

Bldg cooling return

Bldg cooling supply

3

Hot water production only to system

3

3

Description

Functioning

1

Heat exchanger

system side

Condenser

hot water production

2

Heat exchanger

DHW side

not running

3

Heat exchanger

source side

Evaporator

heat exchange with air

2

1

Bldg heating return

Bldg heating supply

Production hot water only to DHW

3

3

2

Description

Functioning

1

Heat exchanger

system side

not running

2

Heat exchanger

DHW side

Condenser

DHW production

3

Heat exchanger

source side

Evaporator

heat exchange with air

DHW supply

DHW return

1

4

Production cold water to system and hot water to DHW

3

Description

Functioning

1

Heat exchanger

system side

Evaporator

cold water production

2

Heat exchanger

DHW side

Condenser

DHW production

3

Heat exchanger

source side

not running

3

DHW supply

2

DHW return

1

Bldg cooling return

Bldg cooling supply

Production hot water to system and hot water to DHW

Description

Functioning

1

Heat exchanger

system side

Condenser

hot water production

2

Heat exchanger

DHW side

Condenser

DHW production

3

Heat exchanger

source side

Evaporator

heat exchange with air

3

3

2

DHW supply

DHW return

1

Bldg heat return

Bldg heat supply

5

Four-pipe systems

Four-pipe systems can handle simultaneous and independent demands for hot and cold water, and

changeover is not required. In this configuration, the advanced microprocessor control logic

operates the unit in one of the following modes.

Cooling only

The controller activates the cold water circuit, and the heat pump acts as a traditional chiller

with energy taken from the cold water loop and sent to the outside air through the finned coils.

With dual compressors on this circuit, the unit can operate efficiently at part-load conditions.

If there is a demand for domestic hot water, the energy taken from the cold water loop can be

transferred to the domestic water loop.

Heating only

The controller activates the hot water circuit, and the heat pump’s evaporator coil takes energy

from the outside air and uses the condenser’s heat exchanger to heat the water in the hot water

loop. This is different from the usual approach of a reverse cycle heat pump, because the hot

water is produced in a different heat exchanger than the one used to produce cold water. This

separates the two hot-cold sections required for four-pipe systems.

Simultaneous heating and cooling

The unit operates as a water-to-water heat pump, moving energy from the cold-water circuit to

the hot-water circuit. The on-board microprocessor controller controls the evaporator and

condenser operation of each circuit and automatically changes from one configuration to the

other depending on the building’s demand. Because it uses separate circuits for the hot-water

and cold-water loops, the unit can provide partial to full cooling while at the same time

providing partial to full heating. Having multiple circuits and compressors ensures maximum

efficiency while in part-load or full-load conditions.

Domestic hot water while heating the building system loop

A water to water heat exchanger can be added so excess energy can be transferred to the

building’s domestic water system from the building hot water system loop.

6

Basic operating layout for four-pipe system

Cold water production only to system

Description

Functioning

1

Heat exchanger

cooling side

Evaporator

cold water

production

2

Heat exchanger

heating side

not running

3

Heat exchanger

source side

Condenser

heat exchange

with air

Description

Functioning

1

Heat exchanger

cooling side

not running

2

Heat exchanger

heating side

Condenser

hot water

production

3

Heat exchanger

source side

Evaporator

heat exchange

with air

3

3

2

Bldg cooling return

1

Bldg cooling supply

Hot water production only to system

3

3

2

Bldg heat supply

Bldg heat return

1

7

Simultaneous hot and cold water production to system

3

3

Description

Functioning

1

Heat exchanger

cooling side

Evaporator

cold water production

2

Heat exchanger

heating side

Condenser

hot water production

3

Heat exchanger

source side

not running

Bldg heat supply

2

Bldg heat return

1

Bldg cooling return

Bldg cooling supply

8

Why we chose Aermec’s AWHPs

We are impressed with Aermec AWHPs and think you will be, too.

experience Aermec, a European company with over 1500 employees, is one of the largest HVAC

manufacturers in the world. They have over 50 years experience building HVAC

systems and over 20 years building AWHPs.

quality

Aermec uses axial fans, scroll compressors, and plate heat exchangers. Each unit has at

least two compressors and refrigerant circuits for redundancy and good performance

under part-load conditions.

Aermec’s 46-person Research and Develop Department has six test chambers sized to

test units up to 250 tons at temperatures ranging from 5°F to 130°F and RH from 20%

to 95%.

Aermec test chamber

certification All Aermec systems are tested and rated in-house to Eurovent standards (including

operation during defrost conditions, included in their COP calculations) and are

certified by AHRI in the US. When an energy analysis shows a unit’s output at design

conditions, be assured that these are the equipment’s actual operating parameters.

9

innovation Aermec units can provide simultaneous heating and cooling under full or part load

conditions and can provide free cooling when in simultaneous operation. On-board

microprocessor controllers provide autonomous operation with full control and

minimum management required by the building management system. Hydronic

accessories (such as pumps, buffer tanks, or a second hydronic circuit fed by a

desuperheater) can be factory installed within the same footprint.

selection

Aermec manufacturers a full range of AWHPs, water-to-water heat pumps, and

chillers. Heat pumps for commercial applications (buildings that have independent

requirements for heating and cooling) range from 12 to 262 tons. Larger tonnage units

with screw compressors are also available.

Aermec robotic assembly

10