pepco - Maryland Public Service Commission

advertisement

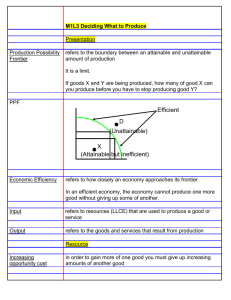

STAFF REVIEW OF ANNUAL ELECTRIC RELIABILITY REPORTS Kevin Zhong, TEAM LEAD Felicia Shelton DeAndre Wilson August 9, 2016 OUTLINE Background and History System Wide Reliability Standards Additional Reliability Standards Service Interruption Standard Downed Wire Response Standard Customer Communications Standards Vegetation Management Requirements Outage Types and Causes Multiple Device Activation Standard Poorest Performing Feeder Standard Conclusions Recommendations 2 BACKGROUND AND HISTORY On Jan. 12, 2011, PSC initiated an Administrative Docket, RM 43, to consider revisions to COMAR 20.50 On May 28, 2012, PSC enacted new benchmark COMAR 20.50.12 for Reliability and Service Quality Standards On July 25, 2012, then Governor Martin O’Malley signed Executive Order 01.01.2012.15 directing his Energy Advisor, in collaboration with identified agencies, to solicit input and recommendations from experts on how to improve the resiliency and reliability of the Maryland electric distribution system. 2012 partial year report from July to December 2012 2013, 2014, and 2015 full year summary reports 3 DEFINITION OF RELIABILITY INDICES SAIFI – System Average Interruption Frequency Index SAIDI – System Average Interruption Duration Index CAIDI – Customer Average Interruption Duration Index CEMI – Customers Experiencing Multiple Interruptions A reliability indicator, usually measured in interruptions or events per customer, used by electric companies to represent how often a customer may experience an interruption in a given year. A reliability indicator, usually measured in minutes or hours, used by electric companies to represent how much total time a customer may not have service in a given year. A reliability indicator, usually measured in minutes or hours, used by electric companies to represent the average outage duration that any given customer would experience in a given year. A reliability indicator used by electric companies which represents the number of interruptions that a customer would experience in a given year. CEMI2 stands for customers experiencing > 2 interruptions, CEMI4 > 4, ... A Major Outage Event is defined by COMAR as: • More than 10 percent or 100,000, whichever is less, of the electric utility's Maryland customers experience a sustained interruption of electric service; and • restoration of electric service to any of these customers takes more than 24 hours; or o the federal, State, or local government declares an official state of emergency in the utility's service territory and the emergency involves interruption of electric service. 8/9/2016 4 2015 SYSTEM-WIDE RELIABILITY STANDARDS (COMAR 20.50.12.02) Utility SAIFI (Interruptions) SAIDI (Minutes) CAIDI (Minutes) COMAR Reported COMAR Reported Reported BGE 1.39 0.92 206.4 100.8 109.2 CHOPTANK 1.39 1.29 154.8 121.8 94.2 DELMARVA 1.46 1.19 157.2 110.0 92.4 P.E. 1.08 0.89 167.4 123.5 138.6 PEPCO 1.49 1.13 143.4 117.0 103.8 SMECO 1.36 1.37 139.2 218.4 159.4 SAIFI, SAIDI & CAIDI are reported with the exception of MOE COMAR standards are with the exception of MOE Five companies met system-wide SAIFI and SAIDI requirements SMECO missed SAIFI (narrowly) and SAIDI SMECO has submitted a Corrective Action Plan 5 2013-2015 SYSTEM-WIDE RELIABILITY STANDARDS SAIFI (All Interruptions Minus MOE) Utility SAIDI (Hours Minus MOE) 2013 2014 2015 Actual 3-Yr Average 2013 2014 2015 Actual 3-Yr Average BGE 0.93 0.91 0.92 0.92 1.67 1.96 1.68 1.77 CHOPTANK 1.33 0.78 1.29 1.13 1.58 1.16 2.03 1.59 DELMARVA 1.95 1.89 1.19 1.68 3.54 2.68 1.84 2.69 P.E. 1.01 1.12 0.89 1.01 2.38 2.88 2.06 2.44 PEPCO 1.49 1.27 1.13 1.30 2.46 2.11 1.95 2.17 SMECO 0.93 0.88 1.37 1.08 1.36 1.36 3.64 2.16 2013 to 2015 are the first three years, when full year indices are available The SAIFI table shows that four of the six Electric Companies performed better in 2015 than their three year averages The SAIDI table shows the same pattern as that of SAIFI, where four Electric Companies performed better than their three year averages Choptank & SMECO performed below their respective three year averages in 2015 6 2012 – JUNE, 2016 SMECO MONTHLY CUMULATIVE SAIDI 4.00 SMECO SAIDI YTD (Excluding COMAR Major Events) 2012 2013 3.50 2014 2015 3.00 PSC 2016 GOAL 2016 Hours 2.50 2.00 1.50 1.00 0.50 0.00 JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 7 JUNE 2015 SMECO WEATHER EVENTS 4.00 6/27 severe thunderstorms and two confirmed EF-1 tornados affected 6,600 customers. Crew worked overnight to restore all outages by 8 AM, 6/28, within 24 hours. SAIDI impact = 0.079 SMECO SAIDI YTD (Excluding COMAR Major Events) 3.50 3.00 6/23 severe thunderstorms affected 11,000 customers. Crew worked overnight to restore all outages by 630 PM, 6/24, within 24 hours. SAIDI impact = 0.320 6/20 severe thunderstorms affected 28,000 customers. Crew worked overnight to restore all outages by 4PM, 6/21, within 24 hours. SAIDI impact = 0.671 Hours 2.50 2.00 1.50 2015 1.00 PSC 2016 GOAL 0.50 2016 0.00 SMECO customers ~= 151,000 JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 8 CORRECTIVE ACTION PLAN (SMECO) System Planning Completion of the final phase of a 69kV Line Differential Project in February 2016 which consisted of installation of new equipment and protective relaying upgrades at multiple stations Construction of three new distribution substations and rebuild of one distribution substation Proactive system inspections, maintenance, and operations Implementation of an asset management system to identify aging infrastructure Continue a program to proactively replace aging copper distribution lines with new aluminum cable or steel reinforced aluminum conductor lines. Fifty miles of aging copper conductor are planned to be replaced in 2016 Utilization of modern technology Replace all old hydraulic distribution line reclosers with new electronic line reclosers over a six year period Continued advancement of the Cooperative's AMI initiative 9 2012 – 2015 COMPOSITE SAIFI/SAIDI SAIDI (Minutes) 180.0 1.20 160.0 156.2 1.18 140.0 1.16 1.16 120.0 115.7 1.14 100.0 1.12 80.0 1.10 SAIFI 60.0 SAIDI (All Interruption Minutes minus MOE) 1.08 40.0 SAIFI (All Interruptions Minus MOE) 1.06 20.0 1.04 1.02 0.0 2012 2013 2014 1.02 2015 The composite SAIFI and SAIDI are weighted averages based on the number of customers each Electric Company serves: BGE - 1,240,000 Pepco - 531,000 P.E. - 252,000 Delmarva - 199,000 SMECO - 151,000 Choptank - 52,000 From 2012 to 2015, SAIFI improvement was 12%; SAIDI improvement was 26% 10 2016-2019 PROJECTED SAIFI BY COMPANY 1.5 1.4 BGE 1.3 CHOPTANK SAIFI 1.2 1.1 Delmarva P.E. SMECO 1 Pepco 0.9 0.8 2015A 2016 2017 2018 2019 2020 2015 figures depict actual performance Pepco and Delmarva indices reflect Exelon merger commitments Four Companies would have met 2016-2018 SAIFI targets 8/9/2016 11 2016-2019 PROJECTED SAIDI BY COMPANY 240.0 210.0 SAIDI (Minutes) BGE CHOPTANK 180.0 Delmarva P.E. 150.0 SMECO Pepco 120.0 90.0 2015A 8/9/2016 2016 2017 2018 2019 2020 2015 figures depict actual performance Pepco and Delmarva indices reflect Exelon merger commitments Four Companies would have met 2016-2018 SAIDI targets Three Companies would have met both SAIFI/SAIDI targets for 2019 12 2013-2015 RM 43 PERFORMANCE BY ELECTRIC COMPANIES COMAR Standards SAIFI SAIDI Interruptions restored within 8 hours MOE restored within 50 hours Downed % Call Wire Answered Response within 30s % % Annual Vegetation Abandoned Managemt. Calls performed Repeat Multiple Poorest Device Performing Activation Feeder 2013 BGE CHOPTANK DELMAR VA PE PEPCO SMECO 2014 2015 2013 2014 2015 2013 2014 2015 2013 2014 2015 2013 2014 2015 2013 2014 2015 Legend Non-compliance Compliance N/A 13 2012-2015 ADDITIONAL RELIABILITY INDICES (COMAR 20.50.12.05) 100.00% 31.16% 10.00% 13.43% 10.64% CEMI2 3.14% 3.00% CEMI4 CEMI6 1.00% CEMI8 0.95% 0.79% 0.23% 0.10% 2012 2013 2014 2015 State-wide, combined performance indices under all conditions CEMI2 showed the most steady improvement (57% between 2012 and 2015) The rest of indices showed more improvement (72% and 75%, respectively) 14 2015 SERVICE INTERRUPTION RESTORATION & DOWNED WIRE RESPONSE (COMAR 20.50.12.06, 07) MOE Normal Conditions Utility All Conditions Government % of % of Emergency > 92% Interruptions > 95% > 90% Interruptions COMAR Restored COMAR Responder Guarded COMAR Restored Standard within 50 Standard downed wires within Standard within 8 Hours 4 Hours Hours BGE 97.00% Yes N/A N/A 97.90% Yes CHOPTANK 99.30% Yes N/A N/A 100.00% Yes DELMARVA 99.53% Yes 100% Yes 100.00% Yes P.E. 96.70% Yes N/A N/A 99.66% Yes PEPCO 97.94% Yes N/A N/A 100.00% Yes SMECO 96.21% Yes N/A N/A 100.00% Yes All Electric Companies met the Service Interruption Restoration Standard under normal conditions Delmarva met the Service Interruption Restoration Standard during MOE All Electric Companies met the Government Emergency Responder Guarded Downed Wires Standard 15 2013 – 2015 CUSTOMER COMMUNICATIONS STANDARD (COMAR 20.50.12.08) Utility % of Calls Answered within 30 seconds Met COMAR Standard ≥75% % Annual Abandoned Calls Met COMAR Standard ≤ 5% 2013 2014 2015 2013 2014 2015 2013 2014 2015 2013 2014 2015 BGE 84.6 87.0 86.3 Yes Yes Yes 2.11 1.65 1.93 Yes Yes Yes CHOPTANK 95.9 93.9 89 Yes Yes Yes 0.79 0.94 1.5 Yes Yes Yes DELMARVA 83.1 84.2 81.9 Yes Yes Yes 0.4 0.29 0.51 Yes Yes Yes P.E. 80.34 80.35 77 Yes Yes Yes 3.19 3.61 4.29 Yes Yes Yes PEPCO 78.55 80.5 73.9 Yes Yes No 4.31 4.55 8.26 Yes Yes No SMECO 88.98 88.52 84.73 Yes Yes Yes 1.07 1.03 1.77 Yes Yes Yes In 2015 five Electric Companies met the standards for calls answered within 30 seconds and the annual abandoned call rate Pepco attributes the non-conformance to a new Customer Relationship Management and Billing System, which went live on 1/5/2015 Pepco has submitted a Corrective Action Plan 16 2014 – 2015 AVERAGE TIME TO ANSWER CALLS WITH IVR (IN SECONDS) 250 2014 2015 200 150 100 50 0 BGE CHOPTANK DELMARVA P.E. PEPCO SMECO Average speed to answer customer calls in seconds IVR stands for Interactive Voice Response Across the board decline despite five companies meeting COMAR requirements Staff recommends close monitoring of performance in this area going forward 17 2014-2015 AVERAGE TIME TO ANSWER CALLS WITHOUT IVR (IN SECONDS) 250 2014 without IVR 200 2015 without IVR 150 100 50 0 BGE CHOPTANK DELMARVA P.E. PEPCO SMECO Staff DR #2 (7/22/2016) pending complete response: “please provide data for Average Speed to Answer a Call (seconds) without the use of technology, i.e. automated call answering systems such as IVR, Call Over Flow, etc., for 2013, 2014, and 2015.” 18 CORRECTIVE ACTION PLAN (PEPCO) Pepco’s communication CAP includes Additional training and coaching to improve customer service representative proficiency Working with technical teams to make prudent enhancements or modifications to the system or screens that will improve call centers transaction efficiency Analyzing how work flows and resources that do that work with an eye on process improvements Taking aggressive steps to back fill for the attrition Trends of 4th quarter 2015 8% improvement of service levels 15% reduction in average handle time Trends of first six months into 2016 indicate continued improvement 19 VEGETATION MANAGEMENT (COMAR 20.50.12.09) Utility Overhead Circuit Miles as of 2015 Cumulative % of Total COMAR Minimum System Trimmed to Required Trimming Standard (%) BGE 9,404 76% 70% CHOPTANK 1,985 97% 75% DELMARVA 3,493 87% 70% P.E. 6,059 62% 56% PEPCO 3,949 77% 70% SMECO 3,375 84% 70% All Companies are currently in their first trim cycles COMAR minimum required trimming varies on year in trim cycle Whether on a four-year or a five-year cycle, all met the COMAR minimum required trimming percentages for the given year 20 2013 – 2015 OUTAGE TYPES AND CAUSES 14,000 2013 Total 12,000 2014 Total 10,000 2015 Total 8,000 6,000 4,000 2,000 0 Vegetation Equipment Failure Weather (not lightning) Lightning Equipment Strike Hit Animals Overload Other* Unknown Chart represent sum of all outages reported by Electric Companies 2015 total outages among all Electric Companies are 37,197, a three year low Two leading causes are Equipment Failure and Vegetation Other* may represent contamination, line failure, corrosion, member own, and loose connection All companies achieved in reducing reporting under “Other” 21 MULTIPLE DEVICE ACTIVATION STANDARD (COMAR 20.50.12.04) Protective Device Type Utility BGE Line or Recloser Tap Fuse Circuit Breaker Transformer Sum of Device activated 5 or more times # of Total # of Repeat Activation devices Events 16 2 1 0 19 0 86 Choptank 0 0 0 0 N/A N/A N/A Delmarva 0 0 1 0 1 0 7 P.E. 5 1 0 0 6 0 39 PEPCO 5 0 7 1 13 0 65 SMECO 2 0 0 0 2 0 Total 28 3 9 1 41 0 10 207 The 2015 sum of device of 41 is a vast improvement over any previous year, be it a stormy year (2012, 2014) or relatively storm free 2013. For reference: 2013 registered 91 devices experiencing multiple activations Zero repeat devices were found, another achievement by all Electric Companies 22 POOREST PERFORMING FEEDER STANDARD (COMAR 20.50.12.03) A feeder is an electric circuit that emanates from a substation, serves customers, and is normally electrically isolated at all endpoints In 2015, the electric companies in Maryland had a total of 2,873 feeders The 3% PPF affect approximately 4.5% of all customers in Maryland Delmarva exceeds the 3% threshold by selecting and addressing 10 feeders Utility BGE CHOPTANK DELMARVA P.E. PEPCO SMECO Total # of Feeders in Maryland 1,300 115 183 346 704 225 SUMMARY 2,873 Percentage Average # Average # of of customers of # of 2015 Customers # of 2015 affected by Customers Repeat per Repeat PPF PPF per PPF PPF PPF 39 3.1% 987 7 947 4 3.9% 512 0 N/A 10 9.1% 1,803 3 2,402 10 4.8% 1,218 3 1,382 21 6.0% 1,514 2 1,653 7 3.9% 838 3 946 91 4.5% 1,145 18 1,466 23 PPF RANKING METHODOLOGY 1. Ranking based methodologies: BGE PE Select and rank feeder with less than or equal to 100 customers Select and rank feeder with more than 100 customers For each feeder calculate a circuit SAIFI using only distributioncaused outages; Select the worst 20% of feeders based on the highest circuit SAIFI Rank the selected feeders based on SAIDI using only distributioncaused customer minutes Rank by SAIFI, using all interruption data excluding major outage event interruption data, planned outage data, and substation event data. The poorest performing 4% of feeders based on the SAIFI rankings, would then be ranked by SAIDI. Rank by SAIFI, using all interruption data excluding major outage event interruption data, planned outage data, and substation event data. The poorest performing Select the required number of 4% of feeders based on the feeders based on the highest SAIFI rankings, would then customer minutes. be ranked by SAIDI. The top 3% of the final rankings were selected, combined These feeders are then identified and sorted by SAIFI as the poorest performing feeders. as the poorest performing. Choptank A ranking number was assigned to each feeder using the SAIDI index for each feeder; A ranking number was assigned to each feeder using the SAIFI index for each feeder; Both ranking numbers are added together for each feeder to determine the Total Rank The top 3% feeders with the highest Total Rank were chosen 2. Formula based methodologies: SMECO: Feeder Index Value = [(0.50 X SAIFI) + (0.50 X SAIDI)] Pepco/Delmarva: Feeder Composite Index = [(75% X SAIFI) + (25% X SAIDI)] 24 2015 POOREST PERFORMING FEEDERS Utility # of PPF Interruption Data (Minus MOE) Average PPF Average PPF SAIFI SAIDI (Interruptions) (Minutes) % Above System % Above System Average Average SAIFI SAIDI 39 2.79 319.2 203% 217% CHOPTANK 4 3.32 316.3 157% 160% DELMARVA 10 4.02 344.7 237% 176% P.E. 10 2.93 743.4 229% 502% PEPCO 21 3.92 455.7 247% 289% SMECO 7 5.72 1203.0 318% 451% 91 3.45 463.6 227% 276% BGE Summary 91 were identified as poorest performing feeders, same as in 2013 and in 2014 Their SAIFI and SAIDI performance is 2-3 times above the Maryland average 25 REPEAT POOREST PERFORMING FEEDER Repeat Poorest Performing Feeder defined by COMAR 20.50.12.03(A)(5): No feeder ranked in the poorest performing 3 percent of feeders shall perform in the poorest performing 3 percent of feeders during either of the two subsequent 12-month reporting periods, after allowing one 12-month reporting period for the utility to implement remediation measures, unless the utility has undertaken reasonable remediation measure to improve the performance of the feeder. in year 4 Under Remediation 8/9/2016 26 2015 REPEAT POOREST PERFORMING FEEDERS Utility # of Repeat PPF 2015 Interruption Data (Minus MOE) % Above System Average Average PPF SAIFI (Interruptions) Average PPF SAIDI (Minutes) SAIFI SAIDI BGE CHOPTANK DELMARVA PE PEPCO SMECO 7 0 3 3 2 3 2.46 N/A 3.13 1.80 3.50 6.54 240.1 N/A 320.3 538.8 836.8 1194.7 168% N/A 163% 85% 210% 377% 138% N/A 190% 336% 615% 477% Summary 18 3.23 528.6 193% 284% 2015 is the second year, where repeat PPF’s are tallied As in 2014, five out of six Electric Companies reported repeat PPF’s As in 2014, there were 16 repeating from two years ago. Two more were from 2012. 27 2012 – 2015 PPF, REPEAT PPF VS. COMPOSITE SAIFI/SAIDI COMPARISON 1000 4.5 900 4 800 3.5 700 SAIFI 3 Average PPF SAIFI 2.5 Repeat PPF SAIFI 2 Composite SAIFI 1.5 SAIDI ((Minutes) 5 600 500 400 300 1 200 0.5 100 0 2012 2013 2014 2015 Average PPF SAIDI Repeat PPF SAIDI Composite SAIDI 0 2012 2013 2014 2015 No significant difference between PPF and repeat PPF performances 28 POOREST PERFORMANCE FEEDER REMEDIAL PLANS 2015 Repeat PPF SAIFI/SAIDI Widely varying SAIFI/SAIDI among repeat PPFs Work plans tailored for individual feeders 35 30 25 SAIFI (Interuptions) SAIDI (hours) 20 15 10 5 0 BGE reported seven repeat PPF’s (first seven to the left). Action Plan included Corrective Maintenance as well as invoking the RPI program as a long-term solution. The work plan for one feeder includes a new underground loop segment, a new OH DA, and a new feeder to divert approximately 800 customers. Delmarva reported three repeat PPF’s. Delmarva is addressing this by employing sectionalization schemes to limit the number of customers affected by each outage to between 400 and 500. In addition, all three were placed on Delmarva’s 2016 Priority Feeder’s list, as part of the Feeder Reliability Improvement Work Plan. P.E. reported three repeat PPF’s. The SAIDI of one feeder, which suffered a localized wind event on 6/23/2015, was particularly high. Another feeder landed on this list due to an accident, when farm machinery snagged the guy wire, breaking two poles. Circuit hardening and additional sectionalizing are the two major approaches. Pepco reported two repeat PPF’s. Both feeders showed SAIDI’s well in excess of ten hours, which were almost six-fold of the system average performance. Both feeders were placed on Pepco’s 2016 Priority Feeder’s list, as part of the Feeder Reliability Improvement Work Plan. SMECO reported three repeat PPF’s. It is conducting expansive upgrades on Mason Springs feeders. Convert ~2.0 miles of OH old copper to UG. Upgrade of existing Cedarville substation and its three main feeders. Coordinate with neighboring Pepco to increase capacity at interconnection locations. 29 CONCLUSIONS AND RECOMMENDATIONS Conclusions 1. Five Electric Companies met system-wide SAIFI and SAIDI requirements 2. State-wide composite SAIFI, SAIDI and CEMI have improved between 2012 and 2015 3. All Electric Companies met the Multiple Device Activation Standard 4. All Electric Companies met the Service Interruption Restoration Standard 5. All Electric Companies met the Downed Wire Response Standard 6. Five Electric Companies met Customer Communications Standard 7. All Electric Companies have fully integrated Vegetation Management requirements, and are ahead of the minimum tree trimming requirement Recommendations 1. Staff to continue monitoring of customer communications performance 2. To establish a Working Group to review and provide recommended improvements to the existing Poorest Performing Feeder and Repeat Poorest Performing Standards & Processes 30 RECOMMENDATIONS FOR PPF WORKING GROUP Working Group Leader: Staff Member from the PSC Engineering Division. Team Members: Representatives from each of the state's investor owned electric distribution companies as well as cooperatively-owned utilities; OPC and other interested parties Suggested near-term actions: 1. Perform research to determine what other state regulatory commissions are doing with respect to PPF and repeat PPF. This would include conducting a NARUC Benchmark Survey. 2. Gain alignment and implement a consistent definition for the identification of PPFs 3. Establish a common toolkit of corrective actions that can be performed to improve the reliability of PPF's. The goal would be to establish a common approach to analyzing fault causes and developing corrective action plans. Plans should indicate projected SAIFI and SAIDI improvements 4. Take a fresh look at the existing COMAR Standard for identifying and developing corrective action plans for repeat PPFs. Possible considerations: - Establish an absolute threshold for: ---- PPF's identification ---- Repeat PPF's - Possibilities: ---- 3.0 SAIFI or some other value ---- 300% of the overall system average or some other value 8/9/2016 31 THANK YOU!