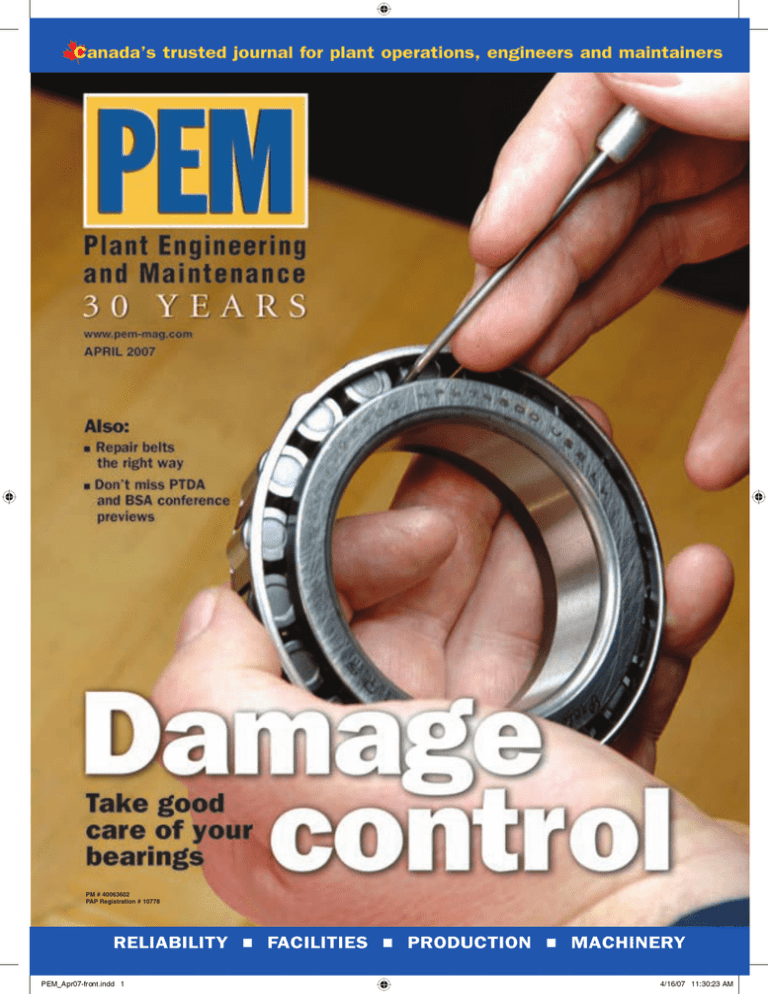

Canada’s trusted journal for plant operations, engineers and maintainers

PM # 40063602

PAP Registration # 10778

RELIABILITY n FACILITIES n PRODUCTION n MACHINERY

PEM_Apr07-front.indd 1

4/16/07 11:30:23 AM

INDUSTRY TESTED.

CUSTOMER APPROVED.

Loctite® Wear Resistant Coatings....

Everything you need to

protect your plant equipment.

• Trowelable, beaded protection from sliding abrasion,

erosion, and corrosion

• Brushable, ceramic coatings provide smooth, corrosion and

wear resistant protection

• Epoxy putties for rebuilding, restoring, sealing, and

protecting worn surfaces

• Specialty products like Loctite® Nordbak® Thin Mil Brushable Ceramic

for tight clearance applications

• Easy-to-use accessories

and packaging

• Application assistance

• Widely available

through your local

Loctite® Products

Distributors

For more information, call 1-800-LOCTITE

or visit us on the web at www.loctite.com

ABS

CFIA

Navy

Environmental

Health Center

Except as otherwise mentioned, ® and TM designate trademarks of Henkel Corporation or its Affiliates. NSF is a reg. TM of NSF International.

® = registered in the U.S. and elsewhere. © Henkel Corporation, 2006. All rights reserved. 3464 LT-4416 (3/06)

To contact this advertiser turn to page 49

PEM_Apr07-front.indd 2 1

Henkel_PEM_Apr_07.indd

4/19/07

4:01:49 PM

4/4/07 2:28:17

GATES DRIVEN

DRIVEN TO

MOVE A DRAGSTER

TO 336 MPH IN

4.43 SECONDS.

G-236C

Gates belt drive systems power NHRA world champions.

Imagine what they can do for you.

For applications from the extreme to the routine, Gates engineers and

manufactures the world’s best belt drive systems, backed by unmatched drive design

and problem-solving support. There’s no better value for power

transmission or motion control. Let us show you how to minimize downtime, reduce

maintenance, and save money. We’ll get you up to speed – fast! Request a free Plant

Survey or Preventive Maintenance Seminar at www.gates.com/driven

Gates Poly Chain® GT®2 blower belt drive system is

the “belt of choice” for the leading NHRA Top Fuel

and Funny Car teams.

The Driving Force in Power Transmission®

To contact this advertiser turn to page 49

PEM_Apr07-front.indd

Gates_PEM_Apr_07.indd

3

1

4/16/07

3/23/07 11:30:42

11:53:34AM

AM

Table of Contents

VOLUME 30, ISSUE 2

APRIL 2007

FEATURES

Your Bearings

24 Get

Prevent bearing failures with proper lubrication

Lubrication plays a critical role in extending the life of bearings and

improving equipment uptime.

By Ken Bannister

and Bruises

30 Bumps

Handle bearings properly to improve operating life

Companies spend lots of money on new bearings. Handle your bearings with care or pay a big price for neglect.

24

Uptime

32 Belt

Repair conveyor-belt cleats faster on the shop floor

These helpful and back-to-basic tips will make your next conveyor-belt

cleat repair go a little easier.

By Beth Miller

Belle Province

38 La

PTDA Canadian conference set for Québec City

The Power Transmission Distributors Association (PTDA) will hold its

Canadian conference in Québec City.

By Robert Robertson

In the next issue of PEM:

FUTURE LOOK

n

As PEM highlights the past 30 years, we'll also chart

the future of maintenance.

YOUNG GUNS

n

Spot

40 Hot

BSA set to hold annual

convention in Florida

New breed of savvy maintenance professionals set to

make shop-floor change happen.

Also see our preview of the upcoming

Bearing Specialists Association annual

convention in Florida.

By Robert Robertson

FOR HIRE

n

Industry strives to find critical answers to Canada's

looming skilled trades shortage.

P

PLANT ENGINEERING

AND MAINTENANCE

A CLB MEDIA INC. PUBLICATION

EDITOR

Robert Robertson

rrobertson@clbmedia.ca

(905) 726-4655

SENIOR ART DIRECTOR

Nicole Diemert

ndiemert@clbmedia.ca

PROD./OPERATIONS EDITOR

ASSOCIATE PUBLISHER

SUBSCRIBER SERVICES

David Berger, P.Eng. (Alta.)

Mike Rightmyer

mrightmyer@clbmedia.ca

(905) 726-4665

Kristen Schulz

kschulz@clbmedia.ca

CONTRIBUTORS

Wilfred List

Ken Bannister

Terry Wireman, CPMM

John Gross, P.Eng.,

CPE, CQE

Joel Levitt

Galen Burdeshaw

John Lambert

4

Lisa Drummond

ldrummond@clbmedia.ca

ACCOUNT MANAGER

CREATIVE DIRECTOR

PRODUCTION CO-ORDINATOR

GROUP PUBLISHER

Kathryn Nyenhuis

knyenhuis@clbmedia.ca

(905) 713-4334

Frank Shoniker

fshoniker@clbmedia.ca

(905) 713-4379

Return undeliverable addresses to:

CLB Media Inc., 240 Edward St.,

Aurora, ON L4G 3S9

VICE-PRESIDENT, HUMAN RESOURCES

Susan Bishop

VICE-PRESIDENT, IT AND OPERATIONS

David Overall

DIRECTOR, SALES & MARKETING

Frank Shoniker

DIRECTOR, EDITORIAL & PRODUCTION

Jackie Roth

DIRECTOR, CIRCULATION

James Zammit

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 4

MANAGER, PRODUCTION

Peter Helston

peterhelston@yahoo.com

(416) 236-7852

PRESIDENT

Stuart Morrison

VICE-PRESIDENT MEDIA, PUBLISHING

Niel Hiscox

VICE-PRESIDENT FINANCE/

CORPORATE DEVELOPMENT

Kent Milford

38

Einar Rice

erice@clbmedia.ca

DIRECTOR, FACILITY MGT & LOGISTICS

Steve Dale

DIRECTOR, HUMAN RESOURCES

Denise Desrosiers

DIRECTOR, IT & SUPPORT

Phillip Danianidis

MEMBER, CLB MEDIA INC.

MANAGEMENT COMMITTEE

Nigel Bishop

PEM Plant Engineering and Maintenance is published six

times yearly by CLB Media Inc., 240 Edward St., Aurora,

ON L4G 3S9. All rights reserved. The contents of PEM are

copyright by ©2007 CLB Media Inc. and may not be

reproduced in whole or part without written consent.

CLB Media Inc. disclaims any warranty as to the accuracy,

completeness or currency of the contents of this publication

and disclaims all liability in respect of the results of any

action taken or not taken in reliance upon information in this

publication. Issue dates are February, April, June, September,

November and December. Yearly subscription rates: Canada

$84 plus GST*; U.S. $96; Others $240. Single copy prices:

Canada $15; U.S. $20.

Canada Post – Canadian Publications Mail Product Sales

Agreement 40063602. International Standard Serial Number

(ISSN) 0710-362X. PAP Registration No. 10778. We acknowledge the financial support of the Government of Canada

through the publications Assistance Program toward our

mailing costs.

*Goods & Services Tax Registration No. R101006989.

Printed in Canada.

For information on reprints of any article that appear

in this publication, contact The Reprint Outsource at

1-877-394-7350.

c a

w w w . p em - m ag . com

4/16/07 11:53:30 AM

EDITOR’S NOTE

COLUMNS

16

Plant Safety

16

Sell this to

your boss

and CEO

Put a stop to workplace injuries

Safety is everyone's business.

by Fred Matthews

18

A

Power Transmission

Get the most out of your V-belts

Install V-belts the right way.

by Ryan LaFevre

22

Maintenance Software

Work hard to achieve CMMS success

6

It all starts with simple steps.

by David Berger, P.Eng. (Alta.)

6

DEPARTMENTS

Hands On

Industry Update

Ask Ken

n Back to Basics

n

n

43

Marketplace

46

MRO Express

49

FYI

50

People and Productivity

43

Industrial products and services.

PEM’s bonus showcase of the

latest product innovations.

Advertiser contact information.

Cup runneth over.

by Wilfred List

Celebrating 30 years in publishing!

50

Please join PEM as we celebrate

30 years in publishing. Our mandate

remains to provide you with mustread editorial, while contibuting and

giving back to the industry. Watch

ccording to a recent report

published by the U.S.-based

Aberdeen Group, nearly 87

percent of asset owner/operators in asset-intensive industries agree that proper maintenance of their production

assets is crucial to their organizations.

The report titled: “Collaborate Asset Maintenance

Strategies” (www.aberdeen.com) further reveals that

leading companies have achieved success with key performance metrics, including a larger return on invested

capital, greater asset productivity, improved asset uptime

and lower maintenance costs.

Report findings were based on the results of a study,

which examined how 300 companies (i.e. Coors Brewing,

DuPont and Nova Chemicals) in asset-intensive industries are excelling with process definition, organizational

alignment, data management, technology integration

and performance management.

“We found proactive maintenance processes that

augment regularly scheduled preventive maintenance

routines tend to boost companies into the best-in-class

category,” says Michael Israel, research director, service

chain research at Aberdeen and author of the report.

“Corollary data strongly suggests that best-in-class organizations operate in a ‘break-fix’ mode far less often than

do their laggard counterparts.”

Israel offers the following recommendations, which he

says will lead to maintenance improvement:

· Implement aggressive proactive maintenance strategies;

· Use analytics software to measure actual asset performance against established goals;

· Centralize management and control of asset maintenance;

· Build a case for the CFO that focuses on the importance

of investing to support proper service and maintenance

practices; and

· Consider spare parts/MRO inventory planning and

strategies.

More than ever, maintenance managers require

the financial support from management to get the

job done. Check out the useful online report and

push it up the corporate ladder.

for the June 2007 issue, as it will

Robert Robertson, Editor

PEMAC Allied Member

rrobertson@clbmedia.ca

be PEM's official 30th anniversary

issue. The issue will include a new

graphic design and more!

w w w . p em - m ag . com

PEM_Apr07-front.indd 5

AP R I L 2 0 0 7

5

4/16/07 11:31:10 AM

Hands On

0n

NEWS AND NOTES FOR THE PLANT PROFESSIONAL

INDUSTRY UPDATE

SKF celebrates its 100th anniversary

around the world

GÖTEBORG, SWEDEN—When SKF was estab-

6

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 6

PHOTOS: PEM

in the second half of 2007. SKF also

lished on February 16, 1907, it was with an

says the European Commission’s LIFEoffer not only of a revolutionary new bearing,

Environment program 2006 supports

but also of the technical support and service

its efforts to lower machinery energy

to get the most value out of it. One hundred

consumption.

years later, providing service is as essential to

“Innovation isn’t new to SKF and

SKF as the product itself.

bearings have been the core of the comBut when Swedish engineer and founder

pany in the past—today and tomorrow,”

of SKF, Sven Wingquist, invented the selfsays Johnstone. “With this announcealigning ball bearing in 1907, service was far

ment, you could say that SKF started its

from a matter of course. At that time, most

first 100 years with an innovation—and

If you have the chance to visit SKF in Sweden, make

of the suppliers of mechanical components

we have started our second 100 years

sure that you check out the informative display that’s

just sold their products. Then it was up to

with another innovation. Energy is a

available to visitors. You won’t be disappointed.

the customer to learn—often through trial

top issue for industry. At SKF, energy

and error—how to put it to use.

will be a big focus in the future.

(i.e. railway, ships, wind energy, conveyors and

Wingquist, on the other hand, knew that

“This new family of bearings is the reextruders). The initial size range will be 200being in the forefront of

sult of a focused effort

600 mm outside diameter and SKF is expected

technology, having a keen

from the SKF organizato first apply the bearings in wind turbines.

knowledge of customer

tions to develop a bearTechnical improvements of the bearneeds, as well as offering

ing family, that while

ings that deliver the energy savings include:

technical support and sermaintaining the service

surface topography; raceway profiles and

vice, would pay off in the

life and load-carrying

geometry, together with a special polymer

long run. This strategy has

capacity of standard

cage; and an optimized set of rollers. The

worked for SKF.

ISO bearings, will suboptimized roller set means a lighter bearing,

“As in 1907, SKF is From left: Tom Johnstone, SKF presi- stantially reduce energy

which itself is more energy efficient because

dedicated today to help dent and CEO and PEM editor Robert consumption. Our goal

it takes less power to move the rolling elecustomers get optimal Robertson at the SKF press conference is to reduce world enments, says SKF. It also lowers inertia of the

value out of their invest- in Göteborg, Sweden.

ergy consumption and

moving parts, reducing the chance of skidments,” says Tom Johncustomer energy costs.”

ding and smearing that would otherwise

stone, president and CEO of SKF. “So over

affect performance and service life.

a hundred years, there’s a straight line that

TAPERED-ROLLER BEARINGS

combines cutting-edge technology with an

The bearings will deliver energy savings on

DEEP-GROOVE BALL BEARINGS

exact knowledge of customer-service needs.

average of at least 30 percent. SKF says it will

The bearings will deliver energy savings on

This leads to knowledge-engineering soluinitially target industrial segments where apaverage of at least 30 percent. SKF says it

tions.”

plications exceed 1 MW of power consumpwill initially target light-loaded applications,

While SKF celebrated its 100th annivertion. Such applications include heavy industry

with the first including industrial-electrical

sary in the many countries it serves, Sweden

motors that drive machinery in many

was the place to be to discover what the

sectors. Production will initially cover the

company has planned for the future. At

smaller diameter-sized series.

the forefront was the announcement that

“Two years ago at the SKF annual genSKF will soon bring to market a new family

eral meeting, we launched the BeyondZeof “green” bearings, which reduce energy

ro initiative. This means that the energy

consumption by at least 30 percent comsavings from the products and solutions

pared to standard ISO products, says the

that SKF supplies to its customers will be

company.

greater than the SKF Group’s own energy

This new bearing family comprises the

consumption,” says Johnstone. “For SKF,

From left: Gord Duncan, Kinecor LP; Pierre Bouchard,

two bearing types that are most widely used

it means more than being energy neuGeneral Bearing Service; Jan Lindhe, SKF Canada;

in the world: deep-groove ball bearings and

tral—it means being energy positive. We

and Farrokh Khalili, Canadian Bearings, attended

tapered-roller bearings. According to SKF,

will achieve our BeyondZero target.”

the SKF gala dinner.

manufacturing of the new bearings will start

www.skf.ca

w w w . p em - m ag . com

4/16/07 11:31:24 AM

Lafe

To contact this advertiser turn to page 49

PEM_Apr07-front.indd

Lafert_PEM_Feb_07.indd

7

1

4/16/07

1/30/0711:31:37

2:14:37AM

PM

Hands On

NEWS AND NOTES FOR THE PLANT PROFESSIONAL

ENERGY

Less is more at SKF facilities in Sweden

GÖTEBORG, SWEDEN—For a number of years,

SKF has worked together with the Massachusetts Institute of Technology (MIT) to define

new models to evaluate and measure the energy

use of systems. This includes the development of

bearings where SKF determines the energy im-

pact of any change in design along the lifecycle—

during manufacturing, in use and in the recycle

stages. SKF also works closely with the School of

Business, Economics and Law at Göteborg University and Chalmers University of Technology

to further support its BeyondZero program.

faster. safer. easier.

Victaulic Mechanical

Pipe Joining Solutions

• up to 30% faster than welding

• no flame for enhanced safety

• ease of installation and maintenance

• proven reliability for over 80 years

tel: 905-884-7444

www.victaulic.com

To contact this advertiser turn to page 49

8

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 8

“Climate change is real and a lot of Co2 emissions are going into the air—and will be there

for 200 years,” says David H. Marks, co-director,

MIT Labs for Energy and the Environment. “The

battle [energy] is going on now and can’t be

ignored. SKF isn’t waiting 50 years to reduce Co2

emissions—since 50 years will be too late.”

As part of the BeyondZero program, SKF

implemented a number of actions to reduce

Co2 emissions and save energy in its production

facilities. Already in 13 Swedish factories, energy

savings of 24 GWh have been achieved through

the installation of more energy efficient pumps

and motors; new heating and energy recovery

systems; new exhaust systems, recovering what

would be “waste heat”; reducing compressed air

usage; and installing energy efficient lighting.

Most savings will come from improvements

in the production lines where reducing the use

of compressed air offers the biggest opportunity.

There are also large savings to be made in machining and assembly. Here factory audits have

shown that savings of five percent of the total

energy consumption can be achieved in each

factory. A series of actions are in place to garner

these savings (i.e. replacing pneumatic cylinders

on positioning machines with SKF electromechanical actuators where the energy saving per

machine is 35 percent).

The expected total savings will be made systematically with a transition to more energy efficient processes and an increased focus placed on

energy conversion efficiency across SKF’s plants.

Due to the need to make changes, while continuing manufacturing, improvements have to be

made sequentially and are expected to deliver

a 15 percent saving, in terms of SKF’s current

energy consumption within three years.

In 2005, SKF launched a target to reduce

its Co2 emissions by five percent per annum.

At that time, a reduction of seven percent was

achieved; in 2006 the reduction was more than

five percent.

“The United Nations recent report on world

climate shows that we have a problem and there

are many views and discussions on the subject,”

says Tom Johnstone, SKF president and CEO.

“Each of us, however, has to make a contribution and this is the start of ours. We have

developed and offer technical solutions that

can significantly reduce energy consumption.

In addition, we’re addressing our own energy

consumption to reduce Co2 emissions.”

www.skf.ca

w w w . p em - m ag . com

4/16/07 11:31:49 AM

Unti

Tired of the same routine?

Buy a Vac that lasts!

Stop throwing your money away on electric vacuum cleaners that are sure to fail. EXAIR

vacuums have been engineered to withstand the dust, dirt, chips and liquids common to

industrial environments. Ours have no electric motors or other moving parts to clog or wear out.

EXAIR’s 30 Day Unconditional Guarantee assures your complete satisfaction. Let our five

year “Built To Last” warranty give you the peace of mind that your vacuum will always work

and end your trips to the dumpster.

Two-Way Drum

Pump

Chip Vacuum Has

No Moving Parts

Vacuum, Blow

and Transfer

Vacuum Source

Nine Sizes

The compressed air powered

Reversible Drum Vac will

quickly fill or empty a 55

gallon drum in 90 seconds.

Coolant sumps can be easily

refilled, floor spills vacuumed

or contaminated liquids

transferred to filtration tanks

in minutes.

Chip Vac is powered by

compressed air and vacuums

chips directly into your

ordinary 55 gallon drum. It

is easy to move from drum

to drum to keep materials

separate for recycling. Clean

chips from floors, fixtures,

work surfaces and machines.

The Vac-u-Gun uses

compressed air to provide

solutions to a wide variety

of industrial housekeeping

problems. This versatile tool

is a vacuum gun, blow gun

and a transfer tool all in one.

Three Vac-u-Gun systems are

available.

The Line Vac air powered

conveyors convert ordinary

hose or pipe into a complete

conveying system for bulk

materials, plastic granules,

scrap, trim and other complex

shapes. Generate a vacuum

on one end and high output

flows on the other.

• Durable stainless steel

• Recover coolant, sludge, spills

• No motors to clog or wear out

• Dust free operation

• Powerful cyclonic action

• 50% quieter than electric vacs

• Durable construction

• Lightweight, portable

• No moving parts

• Low cost

• Aluminum and stainless steel

• Attaches to hose, tube or pipe

www.exair.com/39/462.htm

www.exair.com/39/465.htm

To contact this advertiser turn to page 49

PEM_Apr07-front.indd

Untitled-4 1

9

www.exair.com/39/463.htm

www.exair.com/39/464.htm

11510 Goldcoast Drive, Cincinnati, OH 45249-1621

(800) 903-9247/Fax (513) 671-3363

4/16/07

9/11/0611:33:14

9:11:59AM

AM

Hands on

NEWS AND NOTES FOR THE PLANT PROFESSIONAL

P O W E R TR A N S MISSION

PTDA announces year-end industry results

CHICAGO—The Power Transmission Distribu-

tors Association (PTDA) released 2006 year-end

trend data for distributors and manufacturers of

power transmission/motion control (PT/MC)

products in the U.S. and Canada.

Following the previous year’s annual increase

of 10.7 percent, U.S. distributors saw a 10.2 percent increase in PT/MC product sales in 2006.

The annualized sales-to-inventory ratio for 2006

dropped to 7.3 compared to 7.7 in 2005.

Canadian distributors also continued the

trend of growth in PT/MC sales with a 2006 in-

Advanced Science.

Advanced Grease Lubrication.

At Petro-Canada we designed our line of PRECISION Greases to deliver longer life,

*

less water wash-out and better surface protection. Petro-Canada grease crafters

combine our ultra-pure base oils together with other selected oils and specific

performance additives. Then we process them using the advanced science of our

distinctive two stage manufacturing process. The results speak for themselves: less

wear on equipment and improved productivity for your operation.

Put the Advanced Science of PRECISION to work in your plant.

Contact 1-866-335-3369 or www.petro-canada.com

crease of 8.9 percent. As with the U.S. market, the

annualized sales-to-inventory ratio for Canadian

distributors also showed a slight decline from 7.5

in 2005 to 7.1 in 2006.

U.S. manufacturers experienced sales growth

in 2006 although at a slower rate than in 2005.

Year-to-date sales of PT/MC products were up

6.9 percent in 2006 versus a more robust growth

rate of 9.6 percent in 2005. The same trend holds

true for year-to-date orders of PT/MC products

for U.S. manufacturers, gaining 3.9 percent in

2006 compared to 11.3 percent in 2005. The annualized sales-to-inventory ratio dropped to 9.0

at year-end 2006 from 9.6 in 2005.

Canadian manufacturers continued to show

positive sales growth although also at a slower

rate. Year-to-date sales of PT/MC products in

2006 increased 1.0 percent versus a 3.4 percent

increase in 2005. The annualized sales-to-inventory ratio jumped to 7.9 for Canadian manufacturers compared to 6.6 at the end of 2005.

Considering sales growth on a product-byproduct basis in 2006, all product categories

for U.S. manufacturers showed positive growth.

For Canadian manufacturers, only three categories—clutches and brakes, mechanical-drive

systems and other PT products and positioning

systems/linear motion products—showed a

reduction in sales.

www.ptda.org

AWARDS

PEM 2007 Maintenance Awards

We're calling for PEM 2007 Maintenance Award

submissions. Here are general guidelines for the

awards:

•How big is your maintenance department? Tell

us about your operating structure.

•Why is your maintenance team better than the

rest (i.e. quality, innovation and performance)?

• Tell us about a maintenance success story.

•What kind of maintenance best-practice strategies and tools are you using and why?

• How have you reduced asset management costs

and improved equipment uptime?

• What kind of return on investment (ROI),

equipment reliability and production capacity

improvements have been achieved?

Email your submissions to PEM editor Robert

Robertson: rrobertson@clbmedia.ca.

*Marque de commerce de Petro-Canada - Trademark

To contact this adver tiser turn to page 49

10

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 10

w w w . p em - m ag . com

4/16/07 11:33:37 AM

M A TE R I A LS H ANDL ING

Toyota introduces new 8-series lift trucks

TORONTO—Toyota Industrial Equipment, a

division of Toyota Canada Inc., in conjunction with Toyota Material Handling USA, Inc.

(TMHU), recently introduced its line of 8-series

lift trucks, which includes 3,000-6,500-pound,

internal-combustion cushion and pneumatictire models.

The 8-series also features a programmable

planned-maintenance hour meter that notifies

operators of the need for routine maintenance

and service via the digital display monitor.

“We’re very excited about providing the new

8-series to the Canadian market. The reliabil-

ity, ergonomic and serviceability enhancements

make the truck suited for any type of application,

including the harshest of environments,” says

Rob Reinders, director, Industrial Equipment

Division, Toyota Canada, Inc.

www.forklift.toyota.ca p

Toyota Canada Inc. is offering its new 8-series

lift trucks, which have been designed to meet

stringent U.S. environmental standards.

PHOTO: TOYOTA

Toyota says that its 4Y engine features an

exclusive closed-loop fuel system design that

automatically adjusts and optimizes the air-fuel

mixture ratio. This system works in conjunction with a three-way catalytic muffler, together

minimizing emissions, such as hydrocarbons

(HC), oxides of nitrogen (NOx) and carbon

monoxide (CO).

As a result, the 8-series gasoline, LPG and

CNG-configured models will produce 70 percent

less smog-forming emissions than the 2007 U.S.

federal EPA standards. This emission system also

meets the more stringent 2010 California Air

Resource Board (CARB) emission standards,

says the company.

“In the 8-series, we’ve delivered an environmentally friendly lift truck that reduces operation costs, enhances operator safety and also

meets California 2010 emission standards three

years early,” says Shankar Basu, president and

CEO of TMHU.

With the optional multi-function digital display, the 8-series lift truck performs self-diagnostics through a built-in analyzer, which eliminates

the need for a hand-held unit, says the company.

When the truck is in Analyzer Mode, it displays

the status of the electrical system and allows

instantaneous access to information detected by

the controller, which reduces downtime, says the

company.

To contact this advertiser turn to page 49

w w w . p em - m ag . com

PEM_Apr07-front.indd 11

APRIL 2007

11

4/16/07 11:33:45 AM

Hands on

NEWS AND NOTES FOR THE PLANT PROFESSIONAL

By Ken Bannister

ASK KEN

How can managers become better?

Do you want to know how to improve

equipment uptime and reduce costs? Or maybe

you have a question about predictive maintenance (PdM) tools or how to enhance MRO performance. In each PEM issue, respected industry

practitioner Ken Bannister will provide the answers. If your question is picked, PEM will send

you a maintenance textbook for your library.

Email your questions to Ken Bannister today!

Work with staff and peer groups

to recognize and develop

areas in which cooperation

is required by either group.

of equipment reliability and availability, it

must establish healthy working relationships

on two levels: inter-departmentally between

clerical staff, trades, planners, schedulers and

managers; and intra-departmentally between

management, production, purchasing, accounting and human resources.

Building these vital relationships commences with understanding and mapping

the difference between what you must manage versus what you can actually control.

For example, maintenance managers are responsible for managing all equipment repairs, but aren’t always able to control access

to equipment (production), access to parts

RELATIONSHIPS ARE KEY

In the 2006 edition of the ground-breaking

book, “Leadership and the New Science: Discovering Order in a Chaotic World,” management guru Margaret Wheatley writes: “In

organizations, real power and energy is generated through relationships. The pattern of

relationships and the capacities to form them

are more important than tasks, functions,

roles and positions.”

If a maintenance department is to succeed in its mission to provide adequate levels

(purchasing) or access to funds (management/accounting). They also must rely on

a mutual working relationship with other

stakeholders to deliver on the maintenance

mandate.

As a result, the single best piece of advice

I can offer is to manage your maintenance

department with full open disclosure. Work

with staff and peer groups to recognize and

develop areas in which cooperation is required by either group. This involves performing duties (input/output model) and

establishing mutual agreements that benefit

everyone, including the company. Measure

and track what you can control, while providing regular updates and reports to your

partners. p

Ken Bannister of Innerkip, ON-based Engtech

Industries Inc. is a production and maintenance

management specialist. You can email your questions to him at kbannister@engtechindustries.com.

Point? Shoot? Predict?

Scopemeter®

Thermal imagers

Power quality

clamp meters

Find it. Fix it. Fast.

Get the power of thermal imaging without

specialist training. The Fluke Ti20 offers

one-handed operation and intuitive on-screen

guidance. Just point, focus and it automatically

adjusts the temperature range to show a crisp

image up to 350 °C (662 ºF). It’s the safe and

easy way to identify problems and reduce

unplanned down-time for:

• Electrical power distribution systems

• Electro-mechanical equipment

• Process instrumentation

• Facility maintenance

For more information call 800 36-FLUKE

or visit www.flukecanada.ca/point

Rugged and reliable test tools

for industrial predictive and

preventative maintenance.

All in the Fluke family.

Insulation

Multimeters

Fluke. Keeping your world

up and running.™

To contact this advertiser turn to page 49

12

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 12

w w w . p em - m ag . com

4/16/07 11:34:27 AM

Gru

To contact this advertiser turn to page 49

PEM_Apr07-front.indd

Grundfos_PEM_Apr_07.indd

13

1

4/16/07

3/22/0711:34:40

4:13:17AM

PM

Hands On

NEWS AND NOTES FOR THE PLANT PROFESSIONAL

By John Lambert

BACK TO BASICS

Shaft alignment can cause problems

In each PEM issue, top industry practitioner

John Lambert will provide you with useful tips

on maintenance fundamentals. His many

years of experience will help you get back

to the basics, which is the first step to advancing to world-class maintenance. In this

column, John Lambert talks about machine

shaft alignment.

GET THE BOLTS RIGHT

Do you need to loosen the bolts of a coupling when performing shaft alignment on a

machine unit? It depends on the coupling—

not the style, but the amount of stiffness it

has. Many couplings are very stiff and when

you clamp them together, they force the two

shafts into alignment. Gear couplings that

have shoulder bolts in the flanged sleeves are

a stiff coupling.

If you work with these couplings, this

won’t surprise you as they are well-machined

couplings that are very popular because of

Do you need to loosen

the bolts of a coupling

when performing shaft

alignment on a machine unit?

the high torque they can withstand. Other

couplings have the look of being flexible, but

they’re not. One that comes to mind is an

elastomeric-style coupling.

When you assemble them on the shafts,

they go together very easily. The rubber

insert is bolted into place. As you tighten

all the bolts, you draw the two shafts into

alignment. When all the bolts are tight, the

coupling is now like a solid block. When you

measure across this coupling with a laser,

you can get a result that’s within your tolerance guide.

If you release the bolts and re-measure

with the laser, however, you can get a different result. This isn’t a big issue as long as

you’re aware of it. All you need to do is make

sure that the insert bolts are backed off. This

allows for a lot of play (flexibility). Be careful,

however, as some laser systems are sensitive

to backlash in couplings.

For gear couplings, I would suggest that

you do an open-coupling alignment (the

best method of alignment). Better still—my

suggestion is to try it yourself and learn

how stiff the couplings are. Start with the

coupling together (coupled) and measure

the shaft alignment, then open it up and

re-measure. p

John Lambert is president of Pickering, ONbased Benchmark Maintenance Services Inc. You

can reach him by email: info@withinspec.com.

For a more detailed abstract of this column, visit:

www.withinspec.com/articles.

To contact this advertiser turn to page 49

Kinecor_PEM_June_06.indd 1

PEM PLANT ENGINEERING AND MAINTENANCE

14

PEM_Apr07-front.indd 14

w w w . p em - m ag . com

5/17/06 3:53:18 PM

4/16/07 11:34:56 AM

Lov

To contact this advertiser turn to page 49

PEM_Apr07-front.indd

Lovejoy_PEM_Apr_07.indd

15

1

4/16/07

4/16/07 11:35:09

10:31:17AM

AM

Plant Safety

BY FRED MATTHEWS

Put a stop to

workplace injuries

As a health and safety practitioner over the

years, I have encountered many attitudes and beliefs

about who is responsible for health and safety in the

workplace. In some organizations, the opinion is that

safety is the responsibility of management. In others,

however, it’s perceived as the responsibility of workers.

There are also those who think it’s the sole responsibility of the safety officer or safety committee. Are

these beliefs about responsibility and accountability for

health and safety correct? If not, then what’s the answer?

At the end of the day, who is responsible for health and

safety? To help us find the answer, we need to look at the

past and the origins of modern safety legislation.

When compared to most Canadian law, health and

safety legislation is relatively new.

In fact, it wasn’t until the mid 1970s

Most of the injuries suffered that we observed the creation of

occupational health and safety law in

by mature workers involve

Canada. The emergence of such legislation occurred after the release of

muscoskeletal disorders.

the “Report of the Royal Commission

on the Health and Safety of Workers

in Mines,” which is affectionately

known by Canadian safety professionals as the “Ham

Report.” What the report gave us was a concept that

we’ve come to refer as the internal responsibility system

(IRS). This concept is the foundation for much of our

existing health and safety legislation.

To put it simply, the IRS is a system in which

every individual is responsible for health and

safety. The term “internal” in the IRS refers to the

primary responsibility for health and safety being

internal to the workplace. It means that health and

safety is integrated into each and every aspect of

the workplace. The term “responsibility” in the IRS

refers to the personal health and safety responsibility that everyone must own. Finally, the term “system” refers to a system of internal feedback loops,

which are required to ensure the health and safety

of company stakeholders. An example of these

feedback loops include many of the elements of our

TH E C OL UM NIS T :

health and safety management system, such as health

Fred Matthews is the prairie and

and safety committees, hazard identification, inspecnorthern regional health and safetions, incident investigations and system audits, etc.

Under the IRS, responsibility for health and safety

ty coordinator for Edmonton-based

increases as you go up the corporate ladder. Senior

Golder Associates Ltd. For more

managers and executives are responsible for setting

information call (780) 930-8647

policy, ensuring the development of the occupational

or visit www.golder-ehs.com.

health and safety (OHS) management system, allocat-

16

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 16

ing sufficient resources and holding middle managers

accountable for health and safety performance. Middle

managers are responsible for the implementation and

monitoring of the OHS management system, responding to safety reports, evaluating safety performance and

managing the resources allocated for health and safety.

Supervisors are responsible for identifying and controlling hazards, enforcing company safety standards,

communicating with workers about health and safety

issues, discipline, training, resolving health and safety

problems (as they arise) and investigating incidents/

taking corrective action when they occur. Finally, workers are responsible for reporting unsafe conditions and

incidents, following safe-work procedures and participating in hazard identification. Clearly, “doing health

and safety” isn’t the responsibility of the safety coordinator or the safety committee—it’s the responsibility of

all concerned in the plant.

The concept of “safety is everyone’s responsibility”

is reflected in provincial safety legislation across the

country. The responsibility for health and safety is also

reflected in changes to the Criminal Code of Canada.

Section 217.1 of the Criminal Code holds anyone who

directs the work activities of another worker criminally

responsible should a serious injury or death occur that

could have been prevented. Front-line workers can also

be held accountable under the Criminal Code as parties

to the offence.

"Doing health and

safety" isn't the

responsibility of the

safety coordinator or the

safety committee—it's

the responsibility of all

concerned in the plant.

To improve health and safety performance, it’s

important to ask the following questions: What can I

do to prevent incidents? What do I need to do to ensure

that I am fulfilling my health and safety responsibilities? What do I need to do to enable my co-workers and

I go home in one piece at the end of the shift? After

reflecting on these questions, the next step is to take

responsible action and always keep your health and

safety goals in sight. p

w w w . p em - m ag . com

4/16/07 11:35:20 AM

Imagine a company that will send you a

consultant at no charge to show you how

to use less of the product they deliver.

Sounds incredible. But that’s what we do.

• Energy Efficiency Incentives

• Free Technical Advice

• Business Associate Network

Enbridge Gas Distribution can help you develop a comprehensive energy management plan that will prioritize

your energy-efficiency opportunities, as well as identify

available incentives – with the objective of minimizing

your expenditures and maximizing your returns.

We will review the natural gas use of your facility

and assist you in identifying those areas of highest

energy-saving potential – compliments of Enbridge

Gas Distribution.*

*Applies to Enbridge Gas Distribution Inc. customers only. Please contact your local

Energy Solutions Consultant for details and information on the terms and conditions

of this offer.

Call now to arrange a

meeting at your convenience.

convenience.

1-866-844-9994

TM

email: energyser vices@enbridge.com

To contact this adver tiser turn to page 49

PEM_Apr07-front.indd

Enbridge_PEM_Apr_07.indd

17

1

2007-02-00011

4/16/07

3/30/07 11:35:32

12:35:38AM

PM

Power Transmission

BY RYAN LAFEVRE

Get the most

out of your V-belts

Excessive

can result

V-drives are a common means of transmitting

power between two shafts. When properly designed,

they should achieve a life of 20,000 to 25,000 hours.

If the drive isn’t installed properly, however, that life

can be drastically shortened. In addition, improperly

installed belts can place excess loads on other components of a machine, including shafting and bearings.

This is why proper V-belt installation procedures are

crucial to machine performance and longevity.

When replacing belts on existing sheaves, the first

step of V-drive installation is to inspect the grooves of

the sheaves for wear. Excessive wear in the grooves can

result in belt slippage. Slippage reduces the power the

belts are able to carry in addition to

wear in the grooves accelerating wear on the belts. Most

drive manufacturers sell inexpenin belt slippage.

sive gauges, which can be placed in

the grooves to check for wear.

If a gauge is unavailable, check

for wear by running a ballpoint pen across the groove

sidewall. Any inconsistency felt should be noted as

wear and the sheave should be replaced. The grooves

on both new and used sheaves should be checked for

dirt, corrosion, grease or oil. Dirt and corrosion will

accelerate belt wear, whereas grease or oil will reduce

the friction between the belt and sheave. This reduces

the power rating of the belt.

The next step in properly installing a V-belt drive is

alignment. Excess misalignment places extra loads on

the belt and sheaves, while reducing the power-carrying

capacity of the belts. Misalignment can also cause the

belts to roll in the grooves. Excess misalignment also

results in extra thrust load on the bearings of both the

driver and driven shafts.

V-drives tolerate a maximum of 1/2° misalignment. It’s best to align the sheaves as close to 0° as

possible, however, for maximum belt life. To check the

misalignment on drives with shorter centre distances,

TABLE 1: Take-up allowances for 3V, 5V and 8V belts

Belt Length

Designation

Over

Up to &

including

3V

3V

Joined

5V

5V

Joined

8V

8V

Joined

Minimum

Allowance

Above

Centre

Distance

--475

710

1000

1250

1700

2000

2360

2650

3000

3550

3750

475

710

1060

1250

1700

2000

2360

2650

3000

3550

3750

5000

.05

.8

.8

.8

.8

---------------

1.2

1.4

1.4

1.4

1.4

---------------

--1.0

1.0

1.0

1.0

1.0

1.2

1.2

1.2

1.2

-----

--2.1

2.1

2.1

2.1

2.1

2.4

2.4

2.4

2.4

-----

----1.5

1.5

1.5

1.8

1.8

1.8

1.8

2.0

2.0

2.0

----3.4

3.4

3.4

3.6

3.6

3.6

3.6

4.0

4.0

4.0

1.0

1.2

1.5

1.8

2.2

2.5

3.0

3.2

3.5

4.0

4.5

5.5

Take-up Allowance Below Centre (in)

TABLE 2: Take-up allowances for classical belts

Belt Length

Designation

THE C OL UM NIS T :

Ryan LaFevre is an application

engineer with Baldor-Dodge-Reliance). For more information, call

(905) 792-1739 or visit www.

dodge-pt.com

18

Over

Up to &

including

--35

55

85

112

144

180

210

240

300

390

35

55

85

112

144

180

210

240

300

390

---

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 18

Take-up Allowance Below Centre (in)

A

0.75

0.75

0.75

1.00

1.00

-------------

A

Joined

B

B

Joined

C

C

Joined

D

1.20

1.20

1.30

1.30

1.50

-------------

1.00

1.00

1.25

1.25

1.25

1.25

1.50

1.50

1.50

-----

1.50

1.50

1.60

1.60

1.80

1.80

1.90

2.00

2.20

-----

--1.50

1.50

1.50

1.50

2.00

2.00

2.00

2.00

2.00

2.50

--2.00

2.00

2.00

2.10

2.20

2.30

2.50

2.50

2.70

2.90

--------2.00

2.00

2.00

2.50

2.50

2.60

3.00

Minimum

Allowance

Above

D

Centre

Joined Distance

--------2.90

3.00

3.20

3.20

3.50

3.60

4.10

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

6.00

1.5% of belt

length

w w w . p em - m ag . com

4/19/07 2:54:05 PM

Our commitment to

friction management has

just been sealed.

Signed. Delivered. And sealed

to you.

As we launch our line of National®

seals throughout the U.S. and

Canada, we take another step

towards our commitment to being

your single source for friction

management solutions.

Now, our full line of seals includes

precision oil, grease, fluid-sealing

and dirt-exclusion sealing products

in small-bore sizes, zero to 13 inch.

And because our seals are all

backed by our worldwide reputation

for quality and reliability, it’s clear

that now, more than ever, working

with us means one-stop shopping

for industrial bearing and seal

technology.

The fact is, whether it’s products,

services or innovative thinking, we’ll

do whatever it takes to be there for

you. At every turn.

To find out more about our new

line of industrial seals, contact your

local sales representative, or visit us

at www.timken.com/industrialseals.

Timken® is the registered trademark of The Timken Company (NYSE: TKR).

National® is a registered trademark of Federal-Mogul Corp., licensed for use by the Timken Company.

©2005 The Timken Company

www.timken.com

Bearings

|

Specialty Steel

|

Precision Components

|

Lubrication

|

Seals

|

Remanufacture and Repair

|

Engineering Services

To contact this advertiser turn to page 49

PEM_Apr07-front.indd 19

4/16/07 11:35:54 AM

Power Transmission

Key Focus

Key Factor

Reliable

Predictable

Profitable

Machines

performing

at optimum

Partner in Plant Maintenance

+EEPINGäAäPLANTäRUNNINGäATäOPTIMUMäEFFICIENCYä

ISäAäKEYäFACTORäTOäREMAINäCOMPETITIVEä4AKEä

ADVANTAGEäOFä2EXROTH@SäCOMPREHENSIVEäRANGEäOFä

SERVICESäTOäSUPPORTäAUTOMATIONäSYSTEMSäINäTHEä

FIELDä7EäADAPTäOURäSERVICESäTOäSUITäYOURä

INDIVIDUALäREQUIREMENTSäENSURINGäOPTIMUMä

RESOURCEäDEPLOYMENTä/URäSERVICEäOFFERINGäISä

AVAILABLEäFROMäSTRATEGICALLYäLOCATEDäSERVICEä

CENTERSäACROSSä#ANADAä"OSCHä2EXROTHä

The Drive & Control Company

Bosch Rexroth Canada

boschrexroth.ca

905 735 0510

To contact this adver tiser turn to page 49

For more information,

go to boschrexroth.ca and

enter webcode CA0013

PEM_Apr07-front.indd 20

a straight edge can be placed flat

against the face of both sheaves. If

not, adjust one of the sheaves until

the straight edge is flat against

both faces.

If the centre distance is too large

to use a straight edge, string can

be applied in a similar fashion. For

extremely long centre distances,

laser-alignment tools may be necessary. Generally, this involves a

laser transmitter and a reflector

mounted on a machined surface

on both the driver and driven

sheave. Usually the rims of the

sheaves act as a mounting point

for the laser-alignment devices.

Once the sheaves are aligned,

the next step is to actually place the

belts in the sheave grooves. Always

replace all of the belts in the drive

at the same time. V-belts stretch

during use and used belts will

require a longer centre distance to

achieve the same tension as new

belts. It’s also not recommended

to mix belts from different manufacturers.

The belts should be installed,

while the sheaves are close enough

that the belts don’t need to be

stretched. To do this, first find the

calculated centre distance from the

drive design and then subtract the

amount shown in Table 1 and

Table 2. The last column in each

table shows how much extra takeup beyond the calculated centre

distance should be available.

This allows the belts to be adjusted, as they break in to maintain

their proper tension. The sheaves

will then need to be moved away

from each other until the correct

tension is reached. There are many

ways to check the tension in the

belts. The most accurate method, however, is the force-deflection method. The force-deflection

method involves measuring the

amount of force required to deflect

each belt by a given distance.

The first step is measuring the

span length of the drive. The span

is the distance between the points

where the belt is tangent or touches the sheaves. It can be measured

using a yardstick or tape measure

from the point where the belt is

just touching the driver sheave

to the point where the belt is just

touching the driven sheave. The

belt should be deflected 1/64th of

the span.

New belts will seat themselves in the grooves and

stretch during operation,

which results in reduced

tension in the belt. If not

corrected—then belt

slippage is probable.

For example, if a 32-inch span

is measured, the force required to

deflect the belt 1/2-inch should

be measured. The second step is

to determine how much force it

should take to deflect the belt. This

can be done by looking at charts

published by different belt manufacturers. Generally, the amount of

force varies by the size of the driver sheave, the RPM of the driver

sheave and the type of belt being

used. It’s also important to not

use any belt dressing. These can

degrade the rubber compound in

the belts and reduce their life.

It’s best to re-check the initial

tension within the break-in period or after the first 24 hours of

loaded operation. New belts will

seat themselves in the grooves and

stretch during operation, which

results in reduced tension in the

belt. If not corrected—then belt

slippage is probable. This is why

there needs to be an allowance for

take-up over the nominal centre

distance, as shown in the right

hand columns in Table 1 and

Table 2.

V-drives can be a trouble-free

method of transmitting power.

Installing them correctly is the

optimum way to ensure that they

will last for their intended life without the need for costly and timeconsuming maintenance. p

4/20/07 10:10:21 AM

*Marque de commerce de Petro-Canada - Trademark. †Measured against the number one selling Nor th American hydraulic oil brand.

LUB 1981 (05.08)

Non-stop Productivity.

HYDREX* lasts 3x longer.

HYDREX hydraulic fluids deliver outstanding lubrication protection and extended drain capabilities to help

you reduce downtime and maintenance costs. In fact, HYDREX lasts three times longer and provides two

times better wear protection than the leading global hydraulic brand†. Put HYDREX to the test today.

Call 1-866-335-3369 to improve productivity in your operation.

To contact this adver tiser turn to page 49

PEM805HYD

PEM_Apr07-front.indd 21

4/16/07 11:36:15 AM

Maintenance Software

BY DAVID BERGER, P.ENG. (ALTA.)

Work hard to

achieve CMMS success

Regardless of how many computerized maintordination of the CMMS system implementation, inenance management software (CMMS) systems your comcluding liaison with management and workers from all

pany has implemented over the years, the probability

departments and software vendor(s). The most difficult

of failure is surprisingly high for these new projects.

task of the system champion is to constantly motivate

Many studies have shown that the failure rate ranges

senior management and users by removing barriers to

from about 50 to 65 percent, despite ever-improving

success.

NEED ANALYSIS: Before the CMMS system

software functionality, decades of experience and even

design is finalized, it’s imperative to conduct a

knowledge of these dreadful statistics.

thorough investigation as to the perceived needs of all

It's critical to improve your odds for a successful

parties—from maintainers to management across all

CMMS implementation. Although most senior mandepartments. This is a long and arduous process, as

agement teams will nod their heads in agreement when

the more people you solicit, the more data you must

they hear what needs to be done, the industry track

sift through to build consensus. The work is well worth

record speaks louder than words. Sadly, there are so

the effort, however, because of the ownership factor

few organizations with a solid track record for CMMS

discussed earlier.

project implementations. I’m talkA proper needs analysis should be process-driven,

ing about being on time, on budIt's critical to improve your

in light of a qualitative and quantitative definition of

get and delivering a quality product

success for the project that clearly defines goals, objecthat meets all performance targets.

odds for a successful CMMS The following are eight key CMMS

tives, performance measures and targets. There are two

key deliverables that are driven out of a needs-analysis

implementation action items:

INVOLVEMENT: Without top

implementation.

exercise, including new and improved processes (i.e.

management support, CMMS

process maps, detailed procedures or simple notations

systems are doomed to failure. All of

that pertain to process improvements) and technology

the other seven key success factors depend on managespecification in support of the process changes.

ment support, in terms of resource allocation

and/or using the information coming from

the new CMMS system. Almost as important

is the backing by maintenance. If maintainers want to sabotage the system—they can by

distorting the entered source data.

Cooperation of production management

and other plant workers is also vital for proper requesting, scheduling and reporting of

maintenance-related work. Use of a steering

committee, project team, frequent departTH E C OL UM NIS T :

mental meetings and written communications

Use of a steering committee, project team, frequent

David Berger, P.Eng. (Alta.) is

will help ensure company-wide commitment.

departmental meetings and written communications will

PEM’s production/operations ediMaximizing involvement in the decision-makhelp ensure company-wide commitment.

ing process—right from the start—increases

tor and a principal with Western

the feeling of ownership of the CMMS system

Management Consultants. He’s

Many successful CMMS implementations began

and the likelihood of success.

also the founding president of

SYSTEM CHAMPION: A highly motivated senior

as inexpensive, manual trial-and-error periods prior

the Plant Engineering and Mainperson, with excellent people skills and a positive

to implementing costly hardware and software. Once

tenance Association of Canada

attitude towards computers, ideally fills this position.

proper maintenance management practices have been

Best results are achieved when the person comes from

mastered, computerization is less onerous or intimidat(PEMAC). For more information

operations as opposed to maintenance, since this will

ing. As well, system selection is facilitated as needs are

call (416) 362-6863 ext. 237;

deepen the partnership with production and the level of

clearly identified during the manual pilot.

email: david@wmc.on.ca or visit

ownership felt by everyone on the shop floor.

A needs analysis should include hardware/software

www.wmc.on.ca.

The system champion is responsible for overall cospecification, system-performance expectations, se-

3

1

2

22

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-front.indd 22

w w w . p em - m ag . com

4/16/07 11:36:22 AM

We keep them running,

curity requirements and vendor

criteria, etc. Before the selection is

finalized, you should go on-site for

short-listed vendors, conduct telephone reference checks, participate

in extensive vendor demos using

your test data and possibly bring

the software on-site to test drive in

your environment.

EDUCATION: Training and

implementation costs are

typically more expensive than

hardware and software combined.

Without such a heavy expenditure

on education, however, computerization will do more harm than

good. It’s imperative that all users

be adequately trained in overall

CMMS system operation to appreciate the “big picture.” Each user

must then have plenty of personalized “just-in-time” hands-on training to maximize retention.

Note that the better software

packages can minimize required

training through proper system

design, good documentation and

user-customization capability.

There are also numerous online

tools, such as computer-based

training (CBT), wizards, videos

and Web-based help.

4

5

RESOURCE ALLOCATION:

The level of management support can, in part, be determined

by the quality and quantity of resources thrown at the CMMS project. This includes people, capital

and facilities required to successfully implement process and system changes. Every manager in an

organization is fighting for management attention and the best

resources, since the success of the

project depends on it. It’s far better

to wait until the right resources

are available—instead of proceeding down a path of failure with a

poorly resourced project.

IMPLEMENTATION: “Change

management” is a buzz-term

that still hasn’t lost its relevance.

People tend to resist change. It also

takes time to prepare for and provide a level of comfort with new

CMMS processes. Be prepared for

a long haul of up to two years—

6

from needs analysis through system selection and installation—to

meeting performance targets expected by all key project stakeholders.

Proper change management involves regular communication with

major stakeholders in the project.

This includes using a variety of

techniques, such as “town-hall”

meetings, workshops, newsletters

and other correspondence with

employees. Above all, regular

meetings with first-line supervisors will have the highest impact,

according to years of change-management research. This is because

the level of trust is highest between

employees and immediate supervisors. During the entire CMMS

process—it’s imperative to keep

first-line supervisors informed and

motivated.

VENDOR SUPPORT: Over

the long haul, choose a CMMS

vendor(s) that will provide the appropriate level of hardware and

software support for installation

and maintenance. Some companies require more assistance from

vendors because they have minimal in-house resources. Additionally, software vendors can play a

key role in training users.

FOLLOW-UP: Listen to the

users and respond with at

least a reason why a suggestion

can’t be implemented. The process

and CMMS system should be flexible enough to meet the changing needs of individual users and

the organization as a whole. There

should be a formal mechanism

for dealing with idea generation

and implementing continuous improvement.

Maintainers always seem to have

enough time and money to deal

with “fires” and emergencies when

a project goes off the rails—no

matter how long things drag on.

Many never seem to have enough

time or resources, however, to plan

out a CMMS system properly in

the first place. Always remember

that you get out of a CMMS system

what you put in. p

7

8

with Rietschle Thomas

quality vacuum pumps.

CompreVac is your single source supplier

for Rietschle Thomas environmentally

friendly vacuum pumps, blowers and

central systems. Take your first step today

and call CompreVac to enjoy huge

energy savings and optimized performance.

For:

• Environmental Cleanup

• Packaging

• Plastic Thermoforming

• Paper Handling

• Dental/Medical/Laboratory

• Food Applications

• Electronics

• Capsule Filling

• Pick and Place Applications

• Air Tables

• Pneumatic Conveying

• Central Vacuum System

ZEPHYR

Multi-claw vacuum pumps

and compressors. Dry, frictionless

and economical at high

pressure differentials.

Features and Benefits:

• Highly energy efficient

• Compact footprint

• Maximum reliability

• Environmentally friendlyno pollution or contamination

VACFOX

Rugged oil lubricated rotary

vane vacuum pumps for all

applications. The “smartest”

vacuum pump in the

field-delivers optimal value and

performance.

Features and Benefits:

• 5 year vane warranty

• Excellent water vapour handling capability

• Efficient - high cfm per hp

• Compact space saving design

BORA

Series Regenerative Blowers

Contactless design for top

reliability.

Features and Benefits

• Maintenance free

• Higher vacuum and pressures

• Whisper quiet operation

For sales information please call or email us:

COMPREVAC INC.

1585 Sedlescomb Drive Mississauga, Ontario, CANADA, L4X 1M4

Phone: 1-888-603-6172 or (905) 624-4096 Fax: (905) 624-4099

E-mail: sales@comprevac.com

Visit our Web Site at www.comprevac.com

To contact this advertiser turn to page 49

w w w . p em - m ag . com

PEM_Apr07-front.indd 23

APRIL 2007

23

4/16/07 11:36:30 AM

Get Your

Bearings

Prevent

bearing failures

with proper

lubrication

24

The majority of bearings are manufactured

with a design life target, which is designated

by its L10 rating. Under ideal conditions when

bearing loads are moderate—ambient temperatures are moderate, bearing-material quality is excellent, the bearing is installed the right

way and lubrication is correctly chosen and

applied—a bearing can be expected to outlive

the machinery in which it resides. Reality often

provides a different scenario, however, in which

the maintenance department must compensate

for what's gone wrong. Since maintainers are

rarely able to influence bearing-manufacturing

quality, engineering-design choice and productivity abuse, they must focus on what can be

controlled—bearing lubrication.

PHOTOS: SKF

A

s it supports a sliding or rotating part,

a bearing can take on many forms. It

can be flat where mating surfaces

slide over one another (i.e. as in a

machine gib or way). It can also

be cylindrical where a mating surface either

rotationally slides over another (i.e. as in a plain

journal-style bearing or where one surface rolls

over the other as in a rolling-element bearing).

Regardless of bearing design or function, the

common denominator for achieving acceptable

life span is the need for effective lubrication—be

it in solid, liquid or gaseous form.

by Ken Bannister

Four major causes of bearing failure

Many years ago, Dr. Ernest Rabinowicz of MIT

performed a landmark study on the effect of

lubrication on the U.S. gross national product (GNP). At the time, the study concluded

that American manufacturing companies spent

more than US$600 billion annually to repair

damage caused by mechanical wear. The study

further determined that more than 70 percent

PEM PLANT ENGINEERING AND MAINTENANCE

PEM_Apr07-features.indd 24

4/16/07 11:40:33 AM

A Case for NTN Tapered Roller Bearings

Special Features

Crowned rollers provide

lower friction and smooth

operation through even

load distribution.

Case carburized steel enhances

long life operation and improves

shock loading capabilities.

Preferred by leading manufacturers, NTN tapered roller

bearings are renowned for their ability to operate reliably

in some of the world’s harshest environments. NTN

Soft Core

tapered roller bearings are ideally suited for heavy duty

applications ranging from rail to aggregate and mining

equipment, where marginal lubrication, vibration and

impact loads are considered the norm. NTN tapered roller

Hardened

Surface Layer

bearings are made to meet or exceed industry standards

and feature case carburized steel. Carburizing hardens

Optimized roller/rib interface

promotes lubrication and lowers

bearing running torque

Honed raceways ensure low

friction for miles of trouble

free operation.

the steel from the surface to the proper depth, leaving a

relatively soft core, improved durability and longer life.

These results make the material ideal for shock loading

and extreme conditions. Like all NTN products, our

tapered roller bearings are backed by knowledgeable

technical support from our engineering and technical

service team, competitive pricing, 24/7 service and

Creative Solutions... Delivering Value

unmatched inventory capability.

Better Support Makes a Better Bearing

• In depth bearing failure and machine troubleshooting

As an integral part of after-sales service and support, NTN provides

• Bearing (re)selection and machine redesign to prolong bearing life and up time

an engineering and service staff across Canada to assist customers

• Liaison with original equipment manufacturers and third party suppliers

in gaining maximum service from the life of their bearings

• Preparation or review of maintenance schedules and procedures

• End user in-house training seminars

www.ntn.ca

PEM_Apr07-features.indd

NTN_PEM_Apr_07.indd 1

25

To contact this advertiser turn to page 49

• Accurate part number crossover to one of NTN’s complete range of products

4/16/07

4/11/0711:40:48

3:43:41AM

PM

lubricant in a timely manner when additives are

depleted from the oil, will prevent corrosion;

Mechanical wear by adhesion: Adhesive

wear occurs when a lubricant film, which

separates two sliding surfaces fails to completely

separate the two surfaces. This allows metal-tometal contact to occur, causing metal fragment

transfer from one surface to the other. This is

commonly referred to as seizing, galling, scuffing or scoring of surfaces. Correct lubricant

viscosity and application frequency will significantly reduce or eliminate adhesive wear;

Mechanical wear by abrasion: Abrasive

wear, sometimes referred to as “cutting

wear,” is the result of hard particles (wear particles or introduced contaminant particles)

bridging two moving surfaces—scraping and

cutting either one surface (two-body abrasion)

or both bearing surfaces (three-body abrasion).

Reducing adhesive wear, along with contamination control of the lubricant transfer, application and filtration processes, is needed to stem

abrasive wear; and

Mechanical wear by fatigue: Fatigue

wear results when bridged wear particles

cause small surface-stress risers (surface rippling), which will eventually expand and break

away from the parent metal as a spall (flake

or splinter) due to repeated cyclic stress of

the damaged area. Correct lubricant viscosity

choice and contamination control is essential to

retard fatigue wear.

2

3

Maintainers should use lubrication strategies to improve and extend bearing

life. For example, the correct choice of lubricant viscosity and contamination control is essential to retard fatigue wear.

of bearing loss of usefulness (failure) is directly

attributable to surface degradation—a totally

preventable condition. In his study, Rabinowicz

determined there are four major contributors

to surface degradation:

Corrosive wear: All metallic-bearing surfaces will corrode if left unprotected from

contact with water and corrosive acids. Water

is introduced into lubricated environments

1

from outside sources that penetrate the sealed

reservoir or bearing (washout, product contamination) or through condensation, which

causes ferrous metals to rust. Corrosive acids

are caused when the lubricant becomes oxidized and suffers loss or breakdown of its corrosion-inhibitor additive packages. Specifying and

using a lubricant with rust-inhibitor and corrosion-inhibitor additives, as well as replacing the

4

Make the right lubricant choice

▲

In the above four cases of wear, the primary

strategy to retarding wear lies in the correct

choice of lubricant. Industrial bearings can

be lubricated with oil or grease. According to

SKF, approximately 90 percent of all bearings

are currently grease-lubricated. Grease enjoys

an advantage over oil thanks to its ability to

“stay put” in the bearing and a requirement for

a simpler and less expensive delivery system.

Grease obtains its lubricating properties from

an 80-95 percent oil base, which is mixed with

fatty acids and alkaline soap to provide a semisolid lubricating gel.

Oil becomes the preferred lubricating medium when operating speeds and temperatures

make it difficult to retain grease in the bearing,

when the lubricant must transfer heat from

the bearings and when oil can be physically

contained or protected (gearbox). A lubricant’s

(oil or grease) primary function is to reduce

friction and wear by forming a separating film

between the two sliding surfaces. When viewed

under a microscope, machined-metal surfaces

will appear “jagged” with peaks and valleys that

can easily collide with another bearing surface.

This results in mechanical wear if not separated

by a lubricant film.

To contact this advertiser turn to page 49

26

PEM PLANT ENGINEERING AND MAINTENANCE

Shat-R-Shield_PEM_Feb_07.indd 1

PEM_Apr07-features.indd 26

1/30/07 12:28:54 PM

4/16/07 11:45:00 AM

The Good Vibrations

of Increased Operational Reliability

With a comprehensive range of products and

services from F'IS - FAG Industrial Services –

Schaeffler Group offers increased competence to

help customers save maintenance costs, optimize

machine availability and avoid unexpected

machine downtime.

From tools and equipment available from stock to

the most highly tailored solutions, Schaeffler is an

invaluable maintenance partner for:

• Bearing installation and repair

• Lubrication

• Alignment

• Condition monitoring and balancing

• Maintenance management

Conceived and designed to promote efficiency

around bearing applications, Schaeffler

maintenance solutions and services support

reliable, longer service life.

SCHAEFFLER GROUP

To contact this advertiser turn to page 49

INDUSTRIAL

Schaeffler Canada Inc. • 2871 Plymouth Drive • Oakville ON L6H 5S5 • 905/829-2750

PEM_Apr07-features.indd

Untitled-6 1

27

4/16/07

4/10/07 11:41:12

12:12:34AM

PM

To contact this advertiser turn to page 49

28

By the shearing action of the fluid along its

viscous planes, the lubricant film adheres to

both bearing surfaces and effortlessly allows

one part to move over the other. The resistance

to flow along these shear planes is named

“fluid friction” and measured as a lubricant’s

viscosity—the most important attribute of a

lubricant. If the viscosity is too low (thin oil)