Decision-Makerr Paralleling System

Generator Set Controller

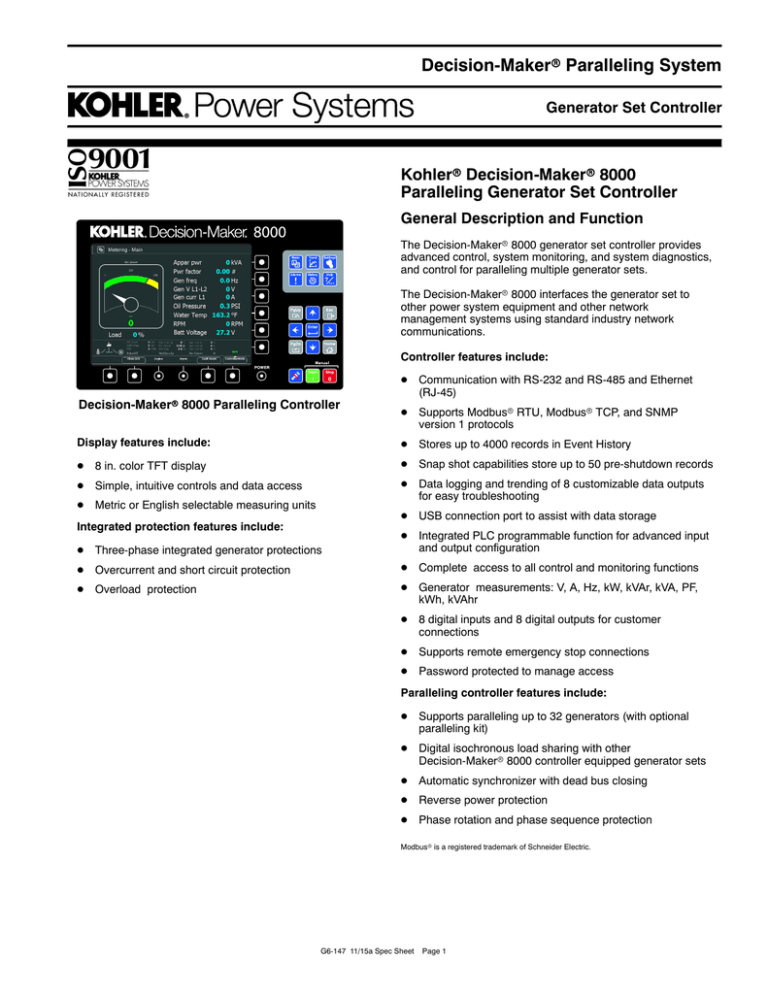

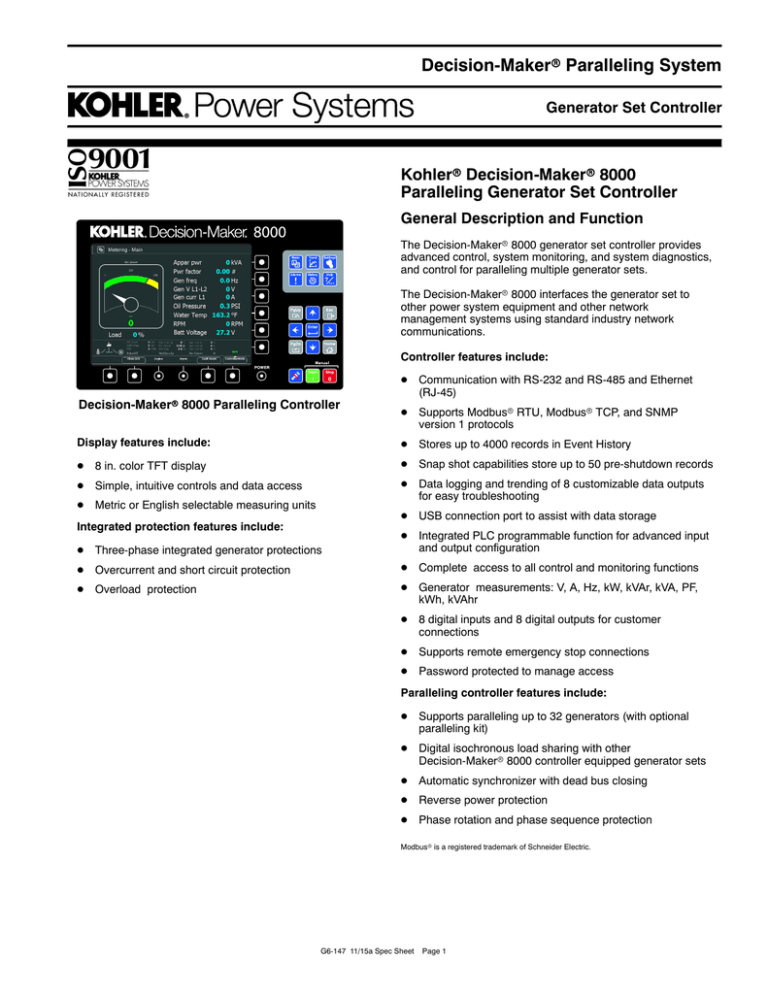

Kohlerr Decision-Makerr 8000

Paralleling Generator Set Controller

General Description and Function

The Decision-Makerr 8000 generator set controller provides

advanced control, system monitoring, and system diagnostics,

and control for paralleling multiple generator sets.

The Decision-Makerr 8000 interfaces the generator set to

other power system equipment and other network

management systems using standard industry network

communications.

Controller features include:

Decision-Makerr 8000 Paralleling Controller

Display features include:

D

Communication with RS-232 and RS-485 and Ethernet

(RJ-45)

D

Supports Modbusr RTU, Modbusr TCP, and SNMP

version 1 protocols

D

Stores up to 4000 records in Event History

D

8 in. color TFT display

D

Snap shot capabilities store up to 50 pre-shutdown records

D

Simple, intuitive controls and data access

D

D

Metric or English selectable measuring units

Data logging and trending of 8 customizable data outputs

for easy troubleshooting

D

USB connection port to assist with data storage

D

Integrated PLC programmable function for advanced input

and output configuration

Integrated protection features include:

D

Three-phase integrated generator protections

D

Overcurrent and short circuit protection

D

Complete access to all control and monitoring functions

D

Overload protection

D

Generator measurements: V, A, Hz, kW, kVAr, kVA, PF,

kWh, kVAhr

D

8 digital inputs and 8 digital outputs for customer

connections

D

Supports remote emergency stop connections

D

Password protected to manage access

Paralleling controller features include:

D

Supports paralleling up to 32 generators (with optional

paralleling kit)

D

Digital isochronous load sharing with other

Decision-Makerr 8000 controller equipped generator sets

D

Automatic synchronizer with dead bus closing

D

Reverse power protection

D

Phase rotation and phase sequence protection

Modbusr is a registered trademark of Schneider Electric.

G6-147 11/15a Spec Sheet

Page 1

1

2

3

12

11

1. Context Buttons -- select a submenu or sub--options

2. Hot Keys -- select main menu options

3. Navigation Buttons -- include arrows and page buttons for

scrolling as well as Escape and Enter buttons

4. Stop Button -- stops the generator

5. Start Button -- starts the generator

6. Horn Reset -- deactivates the horn (audible alarm)

7. Power LED Indication Light (green = power is on)

8. Controller Mode -- calls up the controller mode menu (the

mode can be changed then by appropriate context button)

10

9

8

7

6

5

4

9. Fault Reset -- acknowledges faults and alarms

(active only in Alarm screen)

10. Alarm LED Indication Light

(yellow = alarm of the first level, e.g. warning,

red = alarm of the second level, e.g. shutdown)

11. Engine LED Indication Light

(green = the engine is running)

12. Status Bar -- shows important values

Controller Specifications

NFPA 110 Requirements

Power supply: 8--36 volt DC

Power drain: 150 milliamps at 24 VDC

Humidity range: up to 95% noncondensing

Operating temperature range: --20C to +70C (--4F to +158F)

Storage temperature range: --30C to +80C (--22F to +176F)

Standards:

d Face sealed to IP65 standards

d CE, UL certified

d NFPA 110, Level 1

(requires optional RSA for standard NFPA outputs)

D Dimensions—W x H:

d 289.5 mm x 186 mm (11.4 in. x 7.3 in.)

D

D

D

D

D

D

User Interface Controls and Components

D Supports remote emergency stop connections

D Communication ports

d One RS-485 connector for Modbusr RTU communication ports

d One RS-232 connector for Modbusr RTU communication ports

d One Ethernet port for Modbusr TCP and SNMP

D Customer inputs and outputs:

d 8 binary inputs

d 8 binary outputs

[10 Amp normally open and normally closed (Form C)]

d Remote emergency stop

d Remote 2-wire start

D Digital outputs:

d NFPA 110 faults

d Defined common faults

In order to meet NFPA 110, Level 1 requirements, the generator

set controller monitors the engine/generator functions and faults

shown below. [

D Engine functions:

d Overcrank

d Low coolant temperature warning

d High coolant temperature warning

d High coolant temperature shutdown

d Low oil pressure shutdown

d Low oil pressure warning

d High engine speed

d Low fuel (pressure) *

d Low coolant level

d EPS supplying load

d High battery voltage

d Low battery voltage

D General functions:

d Master switch not in auto

d Battery charger fault

d Contacts for local and remote common alarm

d Audible alarm silence switch

d Remote emergency stop

* Function requires optional input sensors or kits.

[ Requires optional RSA for standard NFPA 110 outputs.

Modbusr is a registered trademark of Schneider Electric.

G6-147 11/15a Spec Sheet Page 2

Trends Monitoring Screen

Binary Input and Output Screen

The Trends screen displays up to 8 different values in real-time monitoring.

These value selections are customizable to meet various troubleshooting

and monitoring situations. Data is stored in internal controller memory or a

USB drive and can be easily exported and imported.

The Binary Input and Output screen displays a comprehensive view of the

status of all the inputs and outputs.

Synchroscope (Paralleling) Screen

AlarmList Screen

The AlarmList screen displays up to 16 shutdowns, warnings, and engine

messages in a color coded list. Features include an alarm summary at the

bottom of the AlarmList screen and an alarm alert on any of the metering

screens.

The Paralleling screen displays the key parameters to allow for generators

to synchronize together. The Paralleling screen provides a comprehensive

view of critical parameters to aid in easily adjusting paralleling system

settings.

History Screen

The History screen displays up to 4000 events, warnings, and shutdowns

with the reason, date, time, and critical system parameters. This extensive

event history allows for detailed analysis of reoccurring faults.

G6-147 11/15a Spec Sheet

Page 3

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

Kohler Power Systems

Asia Pacific Headquarters

7 Jurong Pier Road

Singapore 619159

Phone (65) 6264-6422, Fax (65) 6264-6455

Controller Functions

The following parameters are metered by the controller.

Electrical Metering

Battery Voltage

Generator output voltage L1-neutral (Vrms)

Generator output voltage L2-neutral (Vrms)

Generator output voltage L3-neutral (Vrms)

Generator output voltage Avg of 3 line-to-line values (Vrms)

Generator output voltage L1-L2 (Vrms)

Generator output voltage L2-L3 (Vrms)

Generator output voltage L3-L1 (Vrms)

Generator output frequency (Hz)

Generator output current L1 (Arms)

Generator output current L2 (Arms)

Generator output current L3 (Arms)

Total power factor (Cos-Phi)

Load Characteristic

L=Inductor (lagging), C=capacitor (leading), R=Resistor (PF=0)

Total real power output (kW)

Line 1 real power (kW)

Line 2 real power (kW)

Line 3 real power (kW)

Total reactive power output (kVAr)

Line 1 reactive power (kVAr)

Line 2 reactive power (kVAr)

Line 3 reactive power (kVAr)

Total apparent power output (kVA)

Line 1 apparent power (kVA)

Line 2 apparent power (kVA)

Line 3 apparent power (kVA)

L1 power factor

L2 power factor

L3 power factor

Maximum difference line-to-line voltage (% of nominal)

Maximum difference line current (% of nominal)

Load Characteristic L1

L=Inductor (lagging), C=capacitor (leading), R=Resistor (PF=0)

Load Characteristic L2

L=Inductor (lagging), C=capacitor (leading), R=Resistor (PF=0)

Load Characteristic L3

L=Inductor (lagging), C=capacitor (leading), R=Resistor (PF=0)

Load shed stage

Engine/Mechanical Metering

Engine crankcase oil temperature (F/C)

Engine crankcase oil pressure (PSI/kPa)

Engine coolant temperature (F/C)

Left bank exhaust outlet temperature (F/C)

Right bank exhaust outlet temperature (F/C)

Ambient air temperature (F/C)

Air-fuel mix temperature (F/C)

Engine/Mechanical Metering Continued

Engine coolant pressure (PSI/kPa)

Intake manifold air temperature (F/C)

Engine speed (RPM)

Intake manifold air pressure 1 (PSI/kPa)

Intake manifold air pressure 2 (PSI/kPa)

Post turbo pressure (PSI/kPa)

Engine run time (hours)

Number of successful engine starts

Number of unsuccessful engine start attempts

Total kW x time (kW-hours)

Total kVAr x time (kVAr-hours)

Total kVA x time (kVA-hours)

The following chart shows which functions cause a warning or shutdown.

Most functions are available as outputs.

Warning shows a yellow text message on the digital display and sounds

the alarm horn signaling an impending problem.

Shutdown shows a red text message on the digital display, sounds the

alarm horn, and stops the generator set.

D Standard functions

Status Event or Fault

Overspeed

Over voltage shutdown

Over frequency warning

Under frequency warning

High oil temp warning

Battery over voltage warning

Battery under voltage warning

Generator voltage unbalanced warning

Generator current unbalanced warning

High oil temp shutdown

High coolant temp warning

High coolant temp shutdown

Low coolant temp warning

High air/fuel mix temp warning

High air/fuel mix temp shutdown

High exhaust temp shutdown

Derate active

Over power shutdown

Reverse power

Reverse vars / loss of excitation

Low oil pressure shutdown

Low oil pressure warning

Low water pressure warning

DISTRIBUTED BY:

Availability is subject to change without notice. Kohler Co. reserves the

right to change the design or specifications without notice and without any

obligation or liability whatsoever. Contact your local Kohlerr generator

set distributor for availability.

2015 by Kohler Co., All rights reserved.

G6-147 11/15a Spec Sheet Page 4

Warning

Function

Shutdown

Function

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D