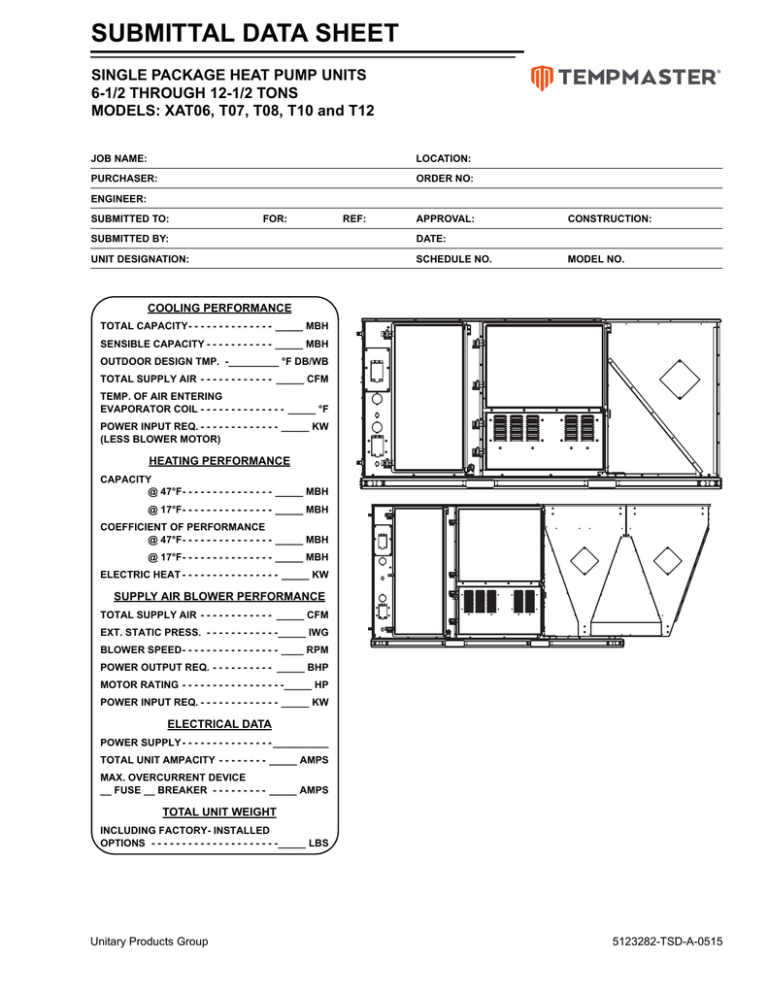

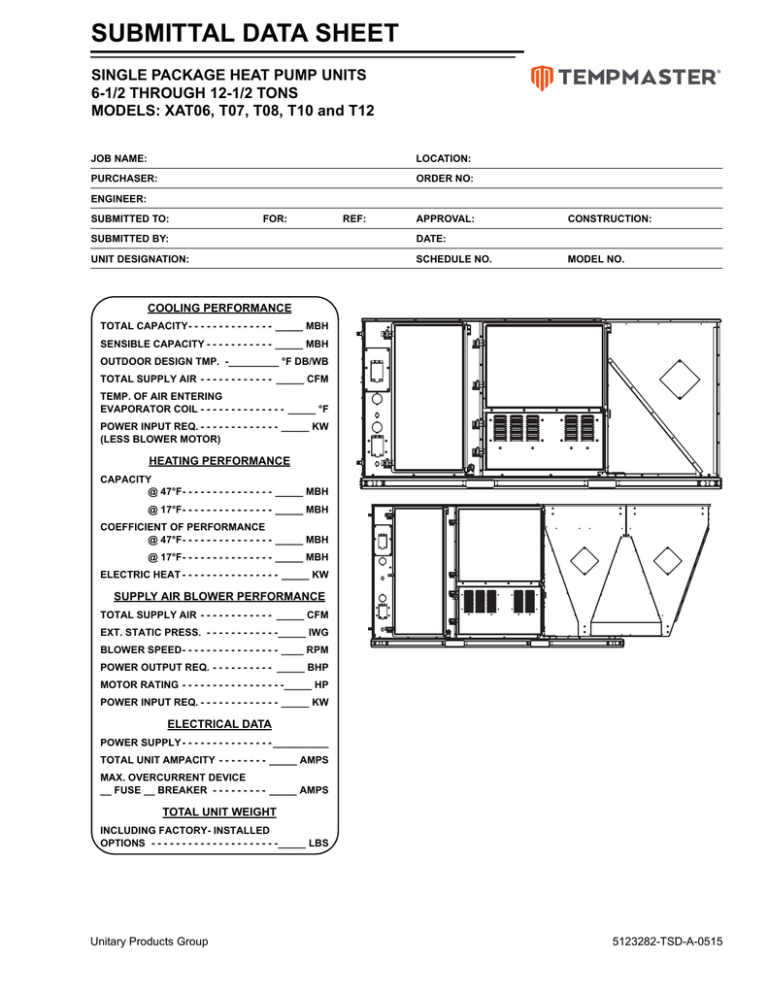

SUBMITTAL DATA SHEET

SINGLE PACKAGE HEAT PUMP UNITS

6-1/2 THROUGH 12-1/2 TONS

MODELS: XAT06, T07, T08, T10 and T12

JOB NAME:

LOCATION:

PURCHASER:

ORDER NO:

ENGINEER:

SUBMITTED TO:

FOR:

REF:

APPROVAL:

SUBMITTED BY:

DATE:

UNIT DESIGNATION:

SCHEDULE NO.

CONSTRUCTION:

MODEL NO.

COOLING PERFORMANCE

TOTAL CAPACITY- - - - - - - - - - - - - - _____ MBH

SENSIBLE CAPACITY - - - - - - - - - - - _____ MBH

OUTDOOR DESIGN TMP. -_________ °F DB/WB

TOTAL SUPPLY AIR - - - - - - - - - - - - _____ CFM

TEMP. OF AIR ENTERING

EVAPORATOR COIL - - - - - - - - - - - - - - _____ °F

POWER INPUT REQ. - - - - - - - - - - - - - _____ KW

(LESS BLOWER MOTOR)

HEATING PERFORMANCE

CAPACITY

@ 47°F- - - - - - - - - - - - - - - _____ MBH

@ 17°F- - - - - - - - - - - - - - - _____ MBH

COEFFICIENT OF PERFORMANCE

@ 47°F- - - - - - - - - - - - - - - _____ MBH

@ 17°F- - - - - - - - - - - - - - - _____ MBH

ELECTRIC HEAT - - - - - - - - - - - - - - - - _____ KW

SUPPLY AIR BLOWER PERFORMANCE

TOTAL SUPPLY AIR - - - - - - - - - - - - _____ CFM

EXT. STATIC PRESS. - - - - - - - - - - - -_____ IWG

BLOWER SPEED- - - - - - - - - - - - - - - - ____ RPM

POWER OUTPUT REQ. - - - - - - - - - - _____ BHP

MOTOR RATING - - - - - - - - - - - - - - - - -_____ HP

POWER INPUT REQ. - - - - - - - - - - - - - _____ KW

ELECTRICAL DATA

POWER SUPPLY - - - - - - - - - - - - - - - __________

TOTAL UNIT AMPACITY - - - - - - - - _____ AMPS

MAX. OVERCURRENT DEVICE

__ FUSE __ BREAKER - - - - - - - - - _____ AMPS

TOTAL UNIT WEIGHT

INCLUDING FACTORY- INSTALLED

OPTIONS - - - - - - - - - - - - - - - - - - - - -_____ LBS

Unitary Products Group

5123282-TSD-A-0515

5123282-TSD-A-0515

6.5 to 12.5 Ton

See detail A for drain location

12.5 Ton

See detail A for drain location

6.5 to 12.5 Ton Unit Physical Dimensions

Unit Model Number

XAT06

XAT07

XAT08

XAT10

XAT12

2

A

50 3/4

50 3/4

50 3/4

50 3/4

50 3/4

B

89

89

89

89

119 1/2

Dimension (in.)

C

D

30 3/16

24 3/16

30 3/16

24 3/16

30 3/16

24 3/16

30 3/16

24 3/16

30 3/16

24 3/16

E

17 3/16

17 3/16

17 3/16

17 3/16

17 3/16

F

6 3/16

6 3/16

6 3/16

6 3/16

6 3/16

Unitary Products Group

5123282-TSD-A-0515

Detail A

5-3/8

6.5 to 12.5 Ton Unit Side Duct Openings

18-1/4

Dot Plugs

A

Return

Air

Supply

Air

D

B

2-31/32

5-5/32

C

31-11/16

12.5 Ton Unit Side Duct Openings

Dot Plugs

18-1/4

A

D

B

5-5/32

2-7/8

C

Unitary Products Group

31-5/8

3

5123282-TSD-A-0515

6.5 to 12.5 Ton Side Duct Dimensions

Unit Model Number

XAT06

XAT07

XAT08

XAT10

XAT12

Dimension (in.)

A

B

C

D

28 1/4

28 1/4

28 1/4

28 1/4

28 1/4

18 1/16

18 1/16

18 1/16

18 1/16

18 1/16

28 1/4

28 1/4

28 1/4

28 1/4

28 1/4

18 1/4

18 1/4

18 1/4

18 1/4

18 1/4

6.5 to 12.5 Ton Unit Clearances

Direction

Top1

Front

Rear

Distance (in.)

72

36

36

Direction

Right

Left

Bottom2

Distance (in.)

12

36

0

1. Units must be installed outdoors. Over hanging structure or shrubs should not obscure condenser air discharge outlet.

2. Units may be installed on combustible floors made from wood or class A, B or C roof covering materials.

6.5 to 12.5 Ton Unit Bottom Duct Openings

4

Unitary Products Group

5123282-TSD-A-0515

6.5 to 12.5 Ton Unit Electrical Entry

Disconnect Swith Cover

Power Entry Ø 2-1/2

Control Entry Ø 7/8

Power Entry Ø 2-1/2

Convenience Outlet Cover

Convenience Outlet

Power Entry Ø 7/8

FRONT

6.5 to 12.5 Ton Unit Left Duct Opening

30-3/8

4-5/16

Unitary Products Group

5

5123282-TSD-A-0515

6.5 to 12.5 Ton Unit Roof Curb

RIGHT

80-5/8

INSULATED DECK UNDER

CONDENSER SECTION

20

SUPPLY

20

6

RETURN

2 TYP.

30

INSULATED DECK UNDER

COMPRESSOR SECTION

50-1/2

FRONT

8 or 14

6.5 to 12.5 Ton Unit Transition Roof Curb

2 TYP

50-1/2

30-1/2

23 4

80-5/8

26

RETURN

SUPPLY

10

76-5/8

94

FRONT

6

59-1/4

64-1/4

RIGHT

Unitary Products Group

5123282-TSD-A-0515

Economizer Downflow W/Power Exhaust

Fresh Air Hood

Low Leak Economizer

Power Exhaust

Barometric

Relief Damper

Barometric Relief

Hood

Economizer End Return W/Power Exhaust

Fresh Air Hood

Field Installed

Duct Work

Low Leak

Economizer

Power Exhaust

Barometric Relief Damper

Barometric Relief Hood

Unitary Products Group

7

5123282-TSD-A-0515

Field Installed Horizontal Economizer W/Power Exhaust

Return Air Damper

Field Installed

Duct Work

Fresh Air Damper

Power Exhaust

Barometric

Relief Damper

Barometric

Relief Hood

Fresh Air Hood

Roof Curb Cutaway

3/4” X 1-1/4” WIDE GASKETING FOR CURB

FRAME AND ALL DUCT SUPPORT SURFACES

2“

UNIT BASE

3.75”

WOOD NAILER

3.56”

UNIT BASE RAILS

14”

8“ MIN. ABOVE FINISHED ROOF

CURB FRAME

COUNTERFLASHING

CAN’T STRIP

INSULATION AND ROOFING MATERIAL

INSULATION

ROOF DECK AND SUPPORT STRUCTURE

8

Unitary Products Group

FACTORY INSTALLED OPTIONS

ELECTRIC HEATER MODEL - KW_____VOLTS_____

STAINLESS STEEL DRAIN PAN- - - - - - - - - - - - - - - - -

ECONOMIZER, DOWNFLOW, END RETURN HORIZONTAL- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

POWER EXHAUST - - - - - - - - - - - - - - - - - - - - - - - - - -

MOTORIZED AIR DAMPER - - - - - - - - - - - - - - - - - - - -

HIGH STATIC INDOOR BLOWER MOTOR - - - - - - - - -

DISCONNECT SWITCH - - - - - - - - - - - - - - - - - - - - - - -

CONVENIENCE OUTLET, POWERED - - - - - - - - - - - -

CONVENIENCE OUTLET, NON-POWERED - - - - - - - -

SMOKE DETECTOR (RETURN) - - - - - - - - - - - - - - - - -

SMOKE DETECTOR (SUPPLY) - - - - - - - - - - - - - - - - -

PHASE MONITOR1 - - - - - - - - - - - - - - - - - - - - - - - - - -

COIL GUARD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

DIRTY FILTER SWITCH - - - - - - - - - - - - - - - - - - - - - - -

FILTERS, 2" PLEATED, MERV 7 - - - - - - - - - - - - - - - -

FILTERS, 4" PLEATED, MERV 13 - - - - - - - - - - - - - - -

PHENOLIC COATED EVAPORATOR COILS - - - - - - - -

PHENOLIC COATED CONDENSER COILS - - - - - - - - -

E-COAT EVAPORATOR COILS - - - - - - - - - - - - - - - - -

E-COAT CONDENSER COILS - - - - - - - - - - - - - - - - - -

INTELLISPEED WITH VFD - - - - - - - - - - - - - - - - - - - - -

INTELLISPEED, VFD AND MANUAL BYPASS - - - - - - -

INTELLISPEED, VFD READY (FOR CUSTOMER-PROVIDED, FIELD-INSTALLED DRIVE)- - - - - - - - - - - - - - -

BAS OPTION

Simplicity® Smart Equipment (SSE) w/Communication

BACnet MS/TP (programmable to Modbus or N2 protocols) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Honeywell™ - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Novar® - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CPC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

FIELD INSTALLED ACCESSORIES

ROOF CURB, 8" - - - - - - - - - - - - - - - - - - - - - - - - - - - -

ROOF CURB, 14"- - - - - - - - - - - - - - - - - - - - - - - - - - - -

TRANSITION ROOF CURB - - - - - - - - - - - - - - - - - - - -

COIL GUARD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

HAIL GUARD- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

PERMANENT FILTERS - - - - - - - - - - - - - - - - - - - - - - -

METAL FILTER FRAME KIT - - - - - - - - - - - - - - - - - - - -

DIRTY FILTER SWITCH - - - - - - - - - - - - - - - - - - - - - - -

AIR PROVING SWITCH - - - - - - - - - - - - - - - - - - - - - - -

BURGLAR BARS (DOWNFLOW ONLY) - - - - - - - - - - -

LOW AMBIENT KIT - - - - - - - - - - - - - - - - - - - - - - - - - -

SMOKE DETECTOR (RETURN) - - - - - - - - - - - - - - - - -

SMOKE DETECTOR (SUPPLY) - - - - - - - - - - - - - - - - -

CO2 SENSOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

PHASE MONITOR1 - - - - - - - - - - - - - - - - - - - - - - - - - -

ECONOMIZER, DOWNFLOW, END RETURN HORIZONTAL- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

ECONOMIZER, HORIZONTAL - - - - - - - - - - - - - - - - - -

SINGLE ENTHALPY- - - - - - - - - - - - - - - - - - - - - - - - - -

DUAL ENTHALPY - - - - - - - - - - - - - - - - - - - - - - - - - - -

POWER EXHAUST - - - - - - - - - - - - - - - - - - - - - - - - - -

MOTORIZED OUTDOOR AIR DAMPER - - - - - - - - - - -

MANUAL OUTDOOR AIR DAMPER - - - - - - - - - - - - - -

ELECTRIC HEATER MODEL - KW_____VOLTS_____

WALL MOUNT TEMPERATURE SENSOR- - - - - - - - - -

WALL MOUNT TEMPERATURE SENSOR WITH

OVERRIDE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

WALL MOUNT TEMPERATURE SENSOR WITH

OVERRIDE & SET POINT ADJ. - - - - - - - - - - - - - - - - - -

HUMIDITY SENSOR - - - - - - - - - - - - - - - - - - - - - - - - -

1. Phase monitor standard on units with scroll compressors.

Subject to change without notice. Printed in U.S.A.

Copyright © 2015 by Johnson Controls, Inc. All rights reserved.

York International Corporation

5005 York Drive

Norman, OK 73069

5123282-TSD-A-0515

Supersedes: Nothing