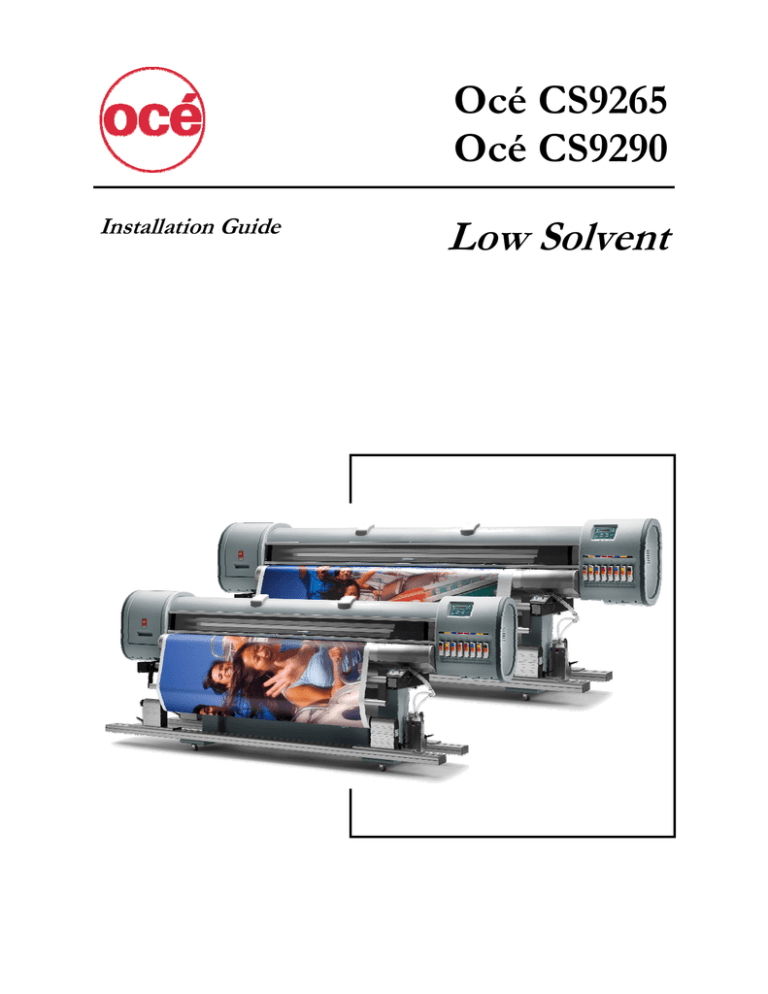

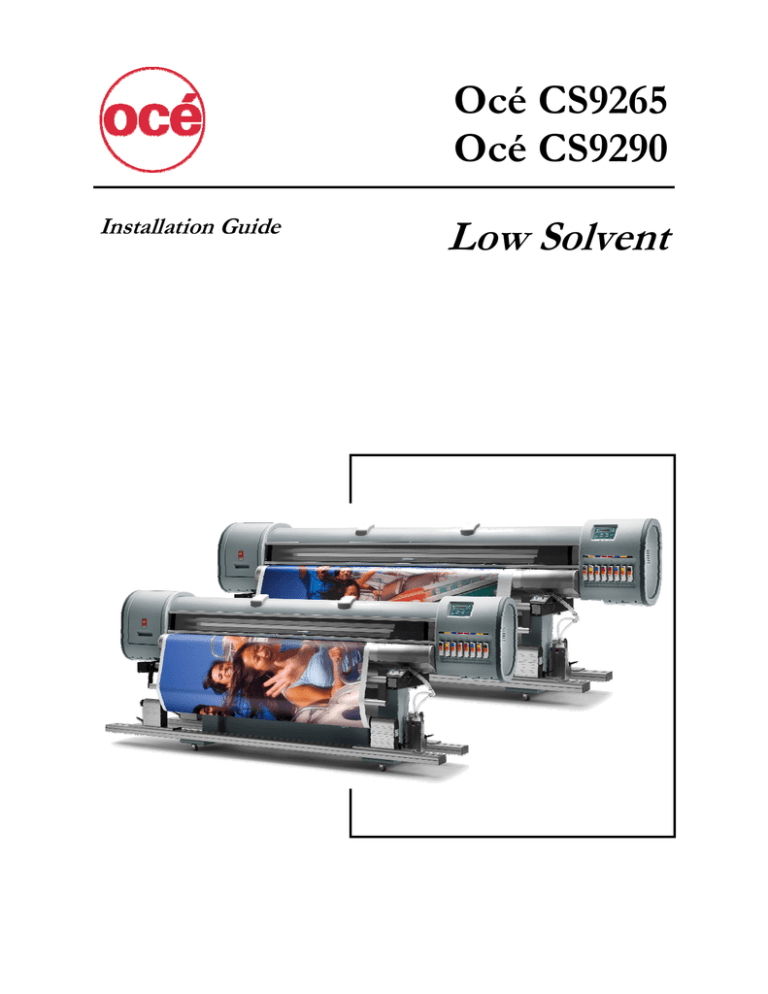

Océ CS9265

Océ CS9290

Installation Guide

Low Solvent

CS9200 Low Solvent series printers

2

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

COPYRIGHT NOTICE

COPYRIGHT © 2008 Océ-Technologies B.V. All rights reserved.

Océ reserves the right to modify the information contained in this manual at any time without prior notice.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Océ CS9200 Low Solvent series Printer. In consideration of the

furnishing of the information contained in this document, the party to whom it is given, assumes its custody

and control and agrees to the following:

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Océ-Technologies B.V.

This document or the contents herein under no circumstances shall be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or license to

do so.

May 2008

Published:

Océ-Technologies B.V.

St. Urbanusweg 43

Venlo, The Netherlands,

P.O. Box 101, NL 5900 MA Venlo

3

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Table of contents

1

Installation environment......................................................................................................... 9

1.1

1.2

1.3

2

Verification of packaged items ............................................................................................ 13

2.1

2.2

2.3

2.4

2.5

3

Parts needed ........................................................................................................................... 41

First ink load procedure ........................................................................................................... 42

Loading media....................................................................................................................... 47

7.1

7.2

8

Connecting the foot switch....................................................................................................... 33

Connecting the power cable .................................................................................................... 34

Connecting the printer to the PC ............................................................................................. 36

Loading ink for first time ...................................................................................................... 41

6.1

6.2

7

Assembling the stand .............................................................................................................. 25

Installing the printer on the stand............................................................................................. 26

Remove protective materials. .................................................................................................. 28

Levelling the printer ................................................................................................................. 29

Install the Unwinder/Winder 100.............................................................................................. 31

Install the waste bottle ............................................................................................................. 32

Connecting the cables.......................................................................................................... 33

5.1

5.2

5.3

6

Unpack the printer ................................................................................................................... 21

Unpack the stand..................................................................................................................... 24

Assembling the unit.............................................................................................................. 25

4.1

4.2

4.3

4.4

4.5

4.6

5

Contents unit box..................................................................................................................... 14

Contents Printer stand box ...................................................................................................... 14

Contents installation kit............................................................................................................ 15

Contents starter kit .................................................................................................................. 16

Contents Unwinder/Winder 100............................................................................................... 19

Unpacking procedure ........................................................................................................... 21

3.1

3.2

4

Installation environment requirements ....................................................................................... 9

Dimensions.............................................................................................................................. 10

Required Space....................................................................................................................... 11

Loading roll media ................................................................................................................... 47

Loading sheet media ............................................................................................................... 47

Head adjustments verification ............................................................................................. 49

8.1

8.2

8.3

8.4

8.5

Head Slant Check.................................................................................................................... 50

Front and Back ........................................................................................................................ 51

Bi-Directional ........................................................................................................................... 52

Uni-Directional ......................................................................................................................... 55

Micro Shift 1/720” for FAST modes.......................................................................................... 56

9

Test printing .......................................................................................................................... 59

10

Periodical Maintenance cycles ............................................................................................ 61

10.1

Done by the end user .............................................................................................................. 61

10.2

Done by an Authorized Technician .......................................................................................... 62

Feedback sheet first ink load procedure............................................................................................... 63

5

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step-by-step plan

1. Check installation environment

► Refer to chapter 1

2. Unpack the printer, stand and boxes

► Refer to chapter 3

3. Check in-the-box configuration

► Refer to chapter 2

4. Assemble the printer / winder

► Refer to chapter 4

5. Connect the cables

► Refer to chapter 5

6. Load ink

► Refer to chapter 6

7. Load media

► Refer to chapter 7

8. Verify head adjustment

► Refer to chapter 8

9. Make Test Print

► Refer to chapter 9

10. Get to know the periodical maintenance

► Refer to chapter 10

6

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Introduction

After reading this manual, an authorized service technician will be able to install Océ’s CS9265/CS9290

smoothly.

The complete installation procedure, from unpacking until sending a test file, is described in detail. Please

read this document carefully to know what to do during the installation at the site.

Caution

• NO

PART OF THIS PRODUCT OR MANUAL MAY BE REPRODUCED, COPIED OR TRANSMITTED IN ANY FORM OR BY

ANY MEANS, EXCEPT FOR PERSONAL USE, WITHOUT PERMISSION OF OCÉ TECHNOLOGIES.

• THE PRODUCT AND THE CONTENTS OF THIS MANUAL MAY BE CHANGED WITHOUT PRIOR NOTIFICATION.

• OCÉ TECHNOLOGIES HAS MADE THE BEST EFFORTS TO KEEP THIS PUBLICATION FREE FROM ERRORS. IF YOU

FIND ANY UNCERTAINTIES OR MISPRINTS, PLEASE CONTACT US OR THE SHOP WHERE YOU BOUGHT THIS

PRODUCT.

• OCÉ TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DAMAGES OR TROUBLES RESULTING FROM THE USE OF

THIS PRODUCT OR THIS MANUAL.

Safety terms in this manual are categorized into following three types, depending on the degree of the risk

(or the scale of accident)

Safety Terms

Details

WARNING

Must be followed carefully to avoid death or serious bodily injury.

CAUTION

Must be observed to avoid bodily injury (moderately or lightly) or damage to your product

NOTES

Contains important information and useful tips on the operation of your product

7

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

1 INSTALLATION ENVIRONMENT

It is very important that the installation environment fulfils following conditions to obtain stable print quality.

1.1 INSTALLATION ENVIRONMENT REQUIREMENTS

Choose a place for printer installation following the requirements in the table below.

Area

65” model

90” model

Floor loading capability

Electrical

Voltage

Frequency

Capacity

23,5 m² or larger (please refer to chapter “Required Space”)

25,7 m² or larger (please refer to chapter “Required Space”)

2940Pa (300kg/m²) or more

65”

AC 100-120V

AC 220-240V

60/50Hz

AC100V-120V : 11 A

AC220V-240V : 5.5 A

90”

AC 100-120V

AC 220-240V

60/50Hz

AC100V-120V : 12 A

AC220V-240V : 6 A

In order to protect the printer for over currents, short circuits and earth faults, the building

installation should be equipped with an automatic breaker double pole of 20 A and an earth

leakage switch of 300 mA.

Ambient

conditions

Recommended

working

environment

Operational

conditions for low

solvent ink

Rate of change

Storage and

transport conditions

Temperature: 23°C

Humidity: 55%, without condensation

Temperature: 20°C - 30°C

Humidity: 40% to 65%, without condensation

Temperature: No more than 2°C per hour

Humidity: No more than 5% per hour

Temperature: 4°C to 50°C

Humidity: 40 to 80%, without condensation (When ink has been

discharged.)

NOTES

•

AVOID

THE FOLLOWING TEMPERATURE AND HUMIDITY CONDITIONS.

APPEAR DIFFERENTLY FROM WHAT YOU EXPECT:

ο

•

•

ο

ο

OTHERWISE,

PRINTED IMAGES MAY

PLACES WHERE SUDDEN CHANGES IN TEMPERATURE AND HUMIDITY ARE EXPECTED, EVEN THOUGH

THE CONDITION IS WITHIN THE RANGE WRITTEN ABOVE.

PLACES WHERE DIRECT SUNLIGHT OR EXCESSIVE LIGHTING ARE EXPERIENCED.

PLACES WHERE AIR CONDITIONERS BLOW DIRECTLY.

OCÉ RECOMMENDS THAT THE PRINTER IS INSTALLED IN A PLACE WHERE AIR CONDITIONING CAN BE ADJUSTED

EASILY.

THE RECOMMENDED WORKING ENVIRONMENT CANNOT BE MET AND OUTPUT QUALITY ISSUES ARISE, THE

BEST APPROACH TO MINIMISE THE EFFECTS IN THIS CASE IS TO REDUCE THE OUTPUT SPEED. IN SUCH A CASE,

WE RECOMMEND SWITCHING FROM 360X360 DPI TO 540 X 720 DPI OR TO 720X720 DPI.

IF

9

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

1.2 DIMENSIONS

1.2.1 CS9265

1.2.2 CS9290

10

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

1.3 REQUIRED SPACE

1.3.1 Necessary free space

a = 1,5 m

b = 1,5 m

c = 2,5 m

d = 0,6 m

e = 1,3 m

Distance c and d are interchangeable. Just ensure to have at one side of the printer at least 2,5 m. This to

be sure that you can pass with a roll of media.

1.3.2 Required area

For the CS9265 series

Width x depth

=

(0.6 m + 3,074 m + 2,5 m)

x

(1,5 m + 0,791 m + 1,5 m)

=

6,174 m

x

3,791 m

=

23,4 m²

For the CS9290 series

Width x depth

=

(0.6 m + 3,677 m + 2,5 m)

x

(1,5 m + 0,791 m + 1,5 m)

=

6,777 m

x

3,791 m

=

25,7 m²

11

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

12

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2 VERIFICATION OF PACKAGED ITEMS

After unpacking the packaging box, inspect if the printer is not damaged and verify that all necessary parts

are present.

NOTES

THE CONTENTS OF THE PACKAGES MAY BE DIFFERENT DEPENDING ON THE

CONTACT YOUR LOCAL OCÉ REPRESENTATIVE OR DISTRIBUTOR FOR DETAILS.

IF ANY PART IS MISSING OR BROKEN, CONTACT EITHER OF THE FOLLOWING:

• THE SHOP WHERE YOU BOUGHT YOUR PRINTER.

• YOUR LOCAL OCÉ REPRESENTATIVE

MARKET WHERE THEY ARE USED.

The unit contains following boxes:

1

3

5

2

4

Nr

1

2

3

4

5

Description

Unit

Printer stand

Buffer with Installation kit inside

Starter kit

Unwinder/Winder 100

13

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.1 CONTENTS UNIT BOX

2.2 CONTENTS PRINTER STAND BOX

2

1

Nr

1

2

Description

Stay

Foot

14

Qty

1

2

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.3 CONTENTS INSTALLATION KIT

2

3

4

13

5

6

7

8

14

Nr

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

9

15

10

16

Description

Screwdriver Philips P2

Hexagon wrench 4 mm

Hexagon wrench 5 mm

Plain washer M6

Spring washer M6

Hexagon bolt M6x30

Hexagon bolt M6x16

Cable clamp

Tube clamp (not used)

Spacer 0,3 mm

Spacer 0,5 mm

Spacer 1,0 mm

Power cable

Media retainers (attached to machine)

Foot switch

APS bracket

Waste bottle assembly

SCREWSET

1

15

11

12

17

Qty

1

1

1

16

16

8

8

2

3

5

5

5

1

2

1

1

1

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.4 CONTENTS STARTER KIT

6

3

5

4

2

1

Nr

1

2

3

4+5+6

Description

Starter kit

Commercial kit

User and good shape kit

Ink starter set

Qty

1

1

1

1

2.4.1 Commercial kit

1

Nr

1

2

3

4

5

2

3

4

5

Description

User’s Guide CS9200 Low Solvent series printer

CD with all manual in digital version

Machine type label CS9265 and CS9290

Maintenance label

How to obtain impeccable printing quality with the WAVE stitching technology

16

Qty

1

1

1

1

1

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.4.2 User and good shape kit

Order number: 29801288

Kit content:

Nr

1

2

3

4

5

6

Description

Sponge plate

Wipers

Spitting box sponge

Cleaning Liquid 250 ml

Instruction sheet

Good shape kit

Qty

6

24

12

3

1

1

▼

▼

▼

* Good shape kit order number: 29801287

* Good shape kit content:

Nr

1

2

3

4

Description

Gloves

Pipette

Swabs

Polyknit wiper

Qty

300

60

150

300

17

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.4.3 Océ IJC920 HS Low Solvent Setup Cleaning

Nr

1

Description

Océ IJC920 HS Low Solvent Setup Cleaning

Qty

8

Part number

29952256

2.4.4 Océ IJC920 HS Low Solvent Cleaning

Nr

1

Description

Océ IJC920 HS Low Solvent Cleaning

Qty

8

Part number

29952255

Qty

2

2

2

2

Part number

29952237

29952238

29952239

29952240

2.4.5 Océ IJC920 HS Low Solvent ink

Nr

1

2

3

4

Description

Océ IJC920 HS Low Solvent ink - Black

Océ IJC920 HS Low Solvent ink - Yellow

Océ IJC920 HS Low Solvent ink - Cyan

Océ IJC920 HS Low Solvent ink - Magenta

NOTES

PLEASE REFER TO INSTALLATION GUIDE TO KNOW HOW TO LOAD INK PROPERLY.

18

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

2.5 CONTENTS UNWINDER/WINDER 100

Notes

PLEASE

REFER TO THE USER’S GUIDE OF THE UNWINDER WINDER

CONFIGURATION.

19

100

FOR THE COMPLETE IN-THE-BOX

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

20

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

3 UNPACKING PROCEDURE

Caution

WHEN REMOVING THIS PRODUCT FROM THE PACKAGING BOX, ALWAYS REMOVE THE VINYL PLASTIC, AND HOLD ON

THE SIDE OF THE PRODUCT. HOLDING THE UNIT OVER THE VINYL PLASTIC WRAPPING CAN RESULT IN SLIPPAGE AND

DROPPING THE UNIT, RESULTING IN DAMAGE.

3.1 UNPACK THE PRINTER

Step 1 :

Remove the winder box and starter kit. Be sure to use a forklift to remove the winder box.

Step 2 :

Remove the top card board.

21

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 3 :

Remove the 2 boxes (stand and installation kit).

Step 4 :

Remove the top card board of the printer body.

Step 5 :

Remove the 3 buffers.

22

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 6 :

Remove the covering plastic.

Step 7 :

Prepare the printer to be installed on the stand.

Please refer to chapter 5 for all necessary information.

►

Flip open the box when using a forklift.

►

Cut away the complete box when you want to use the lifting tubes.

23

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

3.2 UNPACK THE STAND

Step 1 :

Move the stand box to the location to unpack.

Step 2 :

Open the package.

Step 3 :

Remove the following items consecutively:

1. Buffers

2. Stand

3. Box with feet

4. Feet

1

1

1

1

2

4

3

24

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4 ASSEMBLING THE UNIT

Caution

WHEN ASSEMBLING THIS PRODUCT, ALWAYS WORK WITH AT LEAST 4 PEOPLE OR MORE

4.1 ASSEMBLING THE STAND

Assemble the stand according to the following procedure.

Step 1 :

Unpack the stand assembly as described in chapter 3.

Step 2 :

Turn the stand upside down.

Step 3 :

Mount each foot to the stand.

Pay attention to the following:

1. Use each time (8x) a hexagon screw (M6x30) + spring washer (M6) + plain washer (M6).

2. Be sure that the feet are mounted correctly, with the screw holes pointing to the inside.

25

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.2 INSTALLING THE PRINTER ON THE STAND

Install the stand to the main unit according to the following procedure:

Step 1 :

Position the stand correctly (with the PCB box screw holes to the right).

FRONT

Step 2 :

Insert the lifting tubes in the brackets and tighten them with each two wing screws.

Step 3 :

Lift the body with at least 4 people (refer to local regulations) and put it on the stand.

Step 4 :

Remove the lifting tube brackets. Use a 5 mm hexagon key (inside accessory kit).

26

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 5 :

Fix the body to the stand using each time (8x) a hexagon screw (M6x16) + spring washer (M6) +

plain washer (M6).

Do not fix the screws tightly yet.

Step 6 :

Step 7 :

Check if there is no gap between the body and the stand.

►

If there is a gap, proceed to the next step.

►

If not, tighten the eight screws.

Insert 1 or more spacers between printer body and stand until all gaps are filled.

The following spacers are available:

Step 8 :

•

5 pieces with a thickness of 0,3 mm.

•

5 pieces with a thickness of 0,5 mm.

•

5 pieces with a thickness of 1,0 mm.

Tighten the eight screws.

27

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.3 REMOVE PROTECTIVE MATERIALS.

To ensure that nothing can be damaged during transport, temporary buffers and brackets are installed on the

printer. Remove them before powering ON the printer.

1

2

3

4

Step 1 :

Remove the protective film on the plexi front cover.

Step 2 :

Remove the two screws fixing the left maintenance cover.

Step 3 :

Remove the two buffers fixing the front plexi cover.

Step 4 :

Remove the two wing screws fixing the head carriage.

28

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.4 LEVELLING THE PRINTER

4.4.1 Levelling the printer in X – direction

Step 1 :

Position the printer on its final position.

Step 2 :

Turn down all feet of the printer stand with an equal pressure until the wheels come off the

ground. Use a fork spanner SW 14.

Step 3 :

Place the level on the right leg and level the printer by adjusting the feet. Do the same at the left

side of the printer.

Step 4 :

The printer is now levelled in X-direction. Go to the next chapter to level the printer in the Ydirection.

29

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.4.2 Levelling the printer in Y – direction

Step 1 :

Open the front cover.

Step 2 :

Place the level on the print platform.

Step 3 :

Adjust the levelling feet until the printer is completely level.

As for the example below ► higher or lower the left side or lower the right side

•

Notes

Make sure to turn the front or rear feet an equal amount of turns, otherwise the levelling in X direction

was useless.

30

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.5 INSTALL THE UNWINDER/WINDER 100

•

Notes

Please refer to the User’s Guide of the Unwinder/Winder 100 for the proper installation.

31

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

4.6 INSTALL THE WASTE BOTTLE

Step 1 :

Hook the waste bottle assembly over the four pre-mounted screws and push it downwards.

Step 2 :

Tighten the four screws.

Step 3 :

Loosen the 2 waste tubes attached to the printer with some tape.

Step 4 :

Install the tubes at the top of the waste bottle.

Be sure that the tubes are installed strongly over the nipples to be sure that no waste liquid can

leak out during printing.

32

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5 CONNECTING THE CABLES

5.1 CONNECTING THE FOOT SWITCH

If the pressure rollers need to be raised or lowered, it is possible to do this by way of the foot switch, instead

of doing so at the operation panel.

Caution

•

WHEN HANDLING THE FOOT SWITCH, BE AWARE OF THE FOLLOWING:

o DO NOT PLACE ANYTHING HEAVY ON THE FOOT SWITCH.

o DO NOT BEND THE CABLE OF THE FOOT SWITCH WITH FORCE AND DO NOT PULL.

o DO NOT PLACE THE FOOT SWITCH NEAR THERMAL DEVICES.

Install the foot switch according to following procedure:

Step 1 :

Make sure that the power of the unit is OFF.

Step 2 :

Connect the foot switch cable connector to the foot switch connector at the rear of the unit and fix

it with the pre-installed screw.

Step 3 :

Place the foot switch on the floor under the stand.

33

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5.2 CONNECTING THE POWER CABLE

The connection procedure for the power cable is explained below.

•

•

•

Important

MAKE SURE THAT THE ENCLOSED POWER CABLE IS USED. USE OF A DIFFERENT CABLE MAY RESULT IN

ELECTRIC SHOCK OR FIRE.

DO NOT USE A DAMAGED POWER CABLE. DOING SO MAY RESULT IN ELECTRIC SHOCK OR FIRE.

THE DISCONNECT DEVICE IS THE PLUG ON THE POWER SUPPLY CORD.

Caution

BE CAREFUL OF THE FOLLOWING WHEN HANDLING THE POWER CABLE:

• DO NOT MAKE ANY MODIFICATIONS TO THE POWER CABLE.

• DO NOT PLACE ANYTHING HEAVY ON THE POWER CABLE.

• DO NOT BEND, TWIST, OR PULL THE CABLE.

• DO NOT WIRE THE CABLE NEAR EQUIPMENT THAT GENERATES HEAT.

Notes

IF THE POWER CABLE IS DAMAGED, CONTACT ONE OF THE FOLLOWING :

•

THE SHOP WHERE YOU BOUGHT YOUR OCÉ PRINTER.

•

YOUR LOCAL OCÉ REPRESENTATIVE.

Notes

BEFORE INSTALLING THE POWER CABLE, ENSURE THAT THE POWER BUTTON ON THE KEYBOARD IS NOT PUSHED IN.

OTHERWISE THE MACHINE START-UP WILL BEGIN.

34

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 1 :

Plug in the power cable to the inlet at the back of the printer.

Step 2 :

Plug it in the power cable to the outlet

Important

•

•

•

•

•

•

•

•

•

•

DO NOT ATTEMPT TO PLUG IN ELECTRICAL PLUGS WITH WET HANDS. DOING SO MAY RESULT IN ELECTRICAL

SHOCK.

BE SURE TO USE THE SPECIFIED VOLTAGE (AC 100V-120V/220V-240V). OTHERWISE, ELECTRICAL SHOCK

OR FIRE MAY OCCUR.

USE ELECTRICITY DIRECTLY FROM A POWER OUTLET (AC 100V-120V/220V-240V). DO NOT PUT MANY

LOADS ON ONE ELECTRICAL OUTPUT. OTHERWISE, HEAT MAY BE GENERATED AND CAUSE FIRE.

BE SURE TO USE AN OUTLET WITH AN EARTH TERMINAL, AND USE THE TERMINAL CORRECTLY. OTHERWISE,

ELECTRICAL SHOCK OR FIRE MAY OCCUR.

DO NOT CONNECT EARTH CABLES IN THE FOLLOWING AREAS :

► GAS PIPES. DOING SO MAY CAUSE FIRE OR AN EXPLOSION.

► EARTH TERMINALS FOR TELEPHONE LINES OR LIGHTNING RODS. DOING SO MAY CAUSE A LARGE FLOW

OF VOLTAGE IF LIGHTNING OCCURS.

► WATER PIPES OR FAUCETS. IF THERE IS A PLASTIC PART IN THE PIPE, THE EARTH WILL NOT WORK

CORRECTLY.

Caution

FOLLOW THE INSTRUCTIONS BELOW WHEN HANDLING THE POWER PLUG. OTHERWISE, FIRE MAY OCCUR.

► WIPE AWAY DUST AND ANY OTHER RESIDUE BEFORE INSERTING THE PLUG.

► ENSURE THAT THE PLUG IS FIRMLY INSERTED AS FAR AS IT WILL GO.

ENSURE THAT THE PLUG HAS BEEN DISCONNECTED FROM THE POWER SOCKET WHEN IT IS NOT USED FOR A

LONG TIME.

EARTH WIRES MUST BE CONNECTED TO WIRES OR TERMINALS THAT FULFIL THE CONDITIONS :

► EARTH TERMINALS OF POWER SOCKET

► EARTH WIRES WITH COPPER MORSEL THAT IS AT LEAST 650 MM UNDER GROUND

Notes

IF YOU CANNOT USE EARTH TERMINALS OR FIND ANY OF THEM, CONTACT THE SHOP WHERE YOU BOUGHT

YOUR PRINTER.

DO NOT UNPLUG THE POWER CABLE WHEN THE PRINTER IS ON. IF THE POWER CABLE HAS BEEN UNPLUGGED,

LEAVE THE PRINTER FOR AT LEAST 1 MINUTE BEFORE PLUGGING THE CABLE IN AGAIN.

35

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5.3 CONNECTING THE PRINTER TO THE PC

5.3.1 System requirements

To use the printer with RIP software, you need the following minimum requirements.

System OS

CPU

Memory (RAM)

Hard disk space

Windows 2000 Professional

Pentium III 1 GHz or higher

512 MB or more

10 GB or more

Notes

•

•

THE MEMORY REQUIREMENTS MAY VARY DEPENDING ON THE TYPE OF APPLICATIONS YOU ARE USING AND THE

COMPLEXITY OF THE FILES YOU WANT TO PRINT.

PLEASE ALSO REFER TO THE RECOMMENDATION MADE BY THE MANUFACTURER OF THE RIP SOFTWARE YOU

HAVE SELECTED.

5.3.2 Selecting cables

This printer is compatible with following interfaces:

¾

Centronics interface

¾

Network interface

The following cables are necessary to connect your printer to the computer. Prepare appropriate cables

according to the computer to be connected.

¾

Centronics interface: Centronics interface cable

¾

Network interface: 10BASE-T/100BASE-TX Ethernet cable that is compatible with both.

(Category 5)

Notes

•

•

SEE BELOW FOR THE CONNECTION PROCEDURE.

o REFER TO ‘CONNECTING THE CENTRONICS INTERFACE’

o REFER TO ‘CONNECTING THE NETWORK INTERFACE’

REFER TO "INTERFACE SPECIFICATIONS" FOR THE CONNECTION PROCEDURE.

36

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5.3.3 Connecting the Centronics interface

5.3.3.1

Installation

The procedure for connecting the Centronics interface is explained below.

To connect the printer to your computer, follow the steps below.

Step 1 :

Power OFF the printer and your computer.

Step 2 :

Plug the cable connector of the interface cable into the interface connector at the back of the

printer. Squeeze the wire clips together until they lock into place.

Step 3 :

Plug the other end of the cable into the computer's port.

•

Notes

REFER TO YOUR COMPUTER'S USER’S GUIDE FOR THE PROCEDURE TO CONNECT TO YOUR COMPUTER.

37

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5.3.3.2

Specifications

(1) Interface Specifications

Item

Transmission modes

Data length

Transmission direction

Connector pin number

Specifications

Compatible , Nibble , ECP Mode

8 bits

Unidirectional (receiving only), Bidirectional

(2) Table of parallel interface pin numbers and signals

Pin

number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Connection

signal

STROBE

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

DATA8

ACK

BUSY

P ERROR

SELECTED

AUTOFD

Not connected

SG

FG

+5V

Signal direction

To printer Å

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

To and from printer Å Æ

From printer Æ

From printer Æ

From printer Æ

From printer Æ

To printer Å

Pin

number

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Connection signal

SG

SG

SG

SG

SG

SG

SG

SG

SG

SG

SG

SG

INIT

FAULT

Not connected

Not connected

Not connected

SELECTIN

Signal

direction

To printer Å

From printer Æ

To printer Å

(3) Recommended Centronics cable specifications

Item

Interface

Structure

Shield construction

Characteristic impedance

Specifications

Dual-direction Parallel Interface:IEEE1284

AWG28×18 (twisted pair wiring)

Metallic tape + weaving (double shielded cable)

62 Ω

38

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

5.3.4 Connecting the network interface

5.3.4.1

Installation

The procedure for connecting the network interface is explained below.

To connect the printer to the network environment, follow the steps below.

Caution

•

FOLLOW THE INSTRUCTIONS BELOW WHEN CONNECTING THE NETWORK INTERFACE CABLE. OTHERWISE,

ELECTRICAL SHOCK OR FIRE MAY OCCUR.

► DO NOT TOUCH THE CONNECTOR.

► DO NOT CONNECT THE NETWORK CABLE CONNECTOR TO THE INTERFACE BOARD HAVING DIFFERENT

SPECIFICATIONS.

Step 1 :

Power OFF the printer.

Step 2 :

Plug the connector of the Ethernet cable into the connector of the network interface board at the

back of the printer.

Step 3 :

Connect the other end of the Ethernet cable to the network.

•

Notes

REFER TO "NETWORK INTERFACE BOARD OPERATION MANUAL" TO USE THE NETWORK INTERFACE BOARD.

5.3.4.2

Specifications

Item

NetWork Type

NetWork I/F

Protocol

Mode

Functions

Specifications

Ethernet IEEE802.3

10 Base-T,100 Base-TX (automatic switching)

(RJ-45 connector, twisted pair cable, category 5)

TCP/IP

• ftp

• socket

• Automatic protocol recognition

• Transmission speed up to 4 MB/s

39

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

40

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

6 LOADING INK FOR FIRST TIME

Read these cautions first, before powering on the printer and installing ink cassettes for the first time.

Caution

•

•

•

BEFORE

USING THE INK AND CLEANING CASSETTES, BE SURE TO READ AND UNDERSTAND THE MSDSSHEETS WHICH COME TOGETHER ON A CD WITH PRINTER.

WHEN POWERING ON THE UNIT FOR THE FIRST TIME, A CLEANING CYCLE AUTOMATICALLY STARTS.

FOLLOW THE INSTRUCTIONS MENTIONED ON THE DISPLAY.

PLEASE

BE SURE TO WEAR GLOVES AND GOGGLES AT ANY TIME DURING THIS PROCEDURE.

Notes

DURING INK INSTALLATION, NOTE THE FOLLOWING:

•

DO NOT POWER OFF THE PRINTER.

•

DO NOT UNPLUG THE POWER CABLE.

Notes

THIS PRODUCT HAS BEEN TUNED FOR THE USE OF OCÉ IJC920 HS LOW SOLVENT INK AND CLEANING CASSETTES. IF

OTHER MANUFACTURERS’ PRODUCTS ARE USED, THE OUTPUT QUALITY MAY BE INFERIOR, FAINT OR INK ENDS MAY

NOT BE PROPERLY DETECTED. IF NON OCÉ PRODUCTS ARE USED, THE WARRANTY WILL NOT COVER (REPAIRS WILL

REQUIRE A FEE) ANY RESULTANT BREAKDOWN.

6.1 PARTS NEEDED

Before powering ON the unit for the first time, please be sure to have:

When loading Low Solvent Ink

Part number

Description

Qty

29952256

Low Solvent Setup Cleaning First Wash

8

Ink starter box 1/3

29952255

IJC920 HS Low Solvent cleaning

8

Ink starter box 2/3

29952237

IJC920 HS Low Solvent ink Black

2

Ink starter box 3/3

29952240

IJC920 HS Low Solvent ink Yellow

2

Ink starter box 3/3

29952239

IJC920 HS Low Solvent ink Magenta

2

Ink starter box 3/3

29952238

IJC920 HS Low Solvent ink Cyan

2

Ink starter box 3/3

IJC920 HS Low Solvent cleaning bottle 250 ml

1

User and Maintenance Kit

41

Where to find …

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

6.2 FIRST INK LOAD PROCEDURE

Step 1 :

Power ON the unit.

Step 2 :

The carriage will automatically move to the left side of the

machine. Open the front cover and moisten the rubber sides

of the caps with Solvent Cleaning liquid when asked. This to

optimize the ink loading cycle.

Step 3 :

Close the front cover when done and press the [ENTER] key.

Step 4 :

Please wait.

Step 5 :

Remove dummy cassettes when following message is

displayed.

Step 6 :

Please wait while printer is sucking air.

Step 7 :

Insert 8 NEW cassettes with Low Solvent Setup

Cleaning when following message is displayed.

42

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 8 :

The printer will automatically start pumping cleaning fluid.

Step 9 :

Empty the waste bottle when asked and confirm later on with ENTER.

Step 10 : At this time, we want to make sure that the ink tube system is completely airtight and that the

shipping liquid has been replaced with first stage transition liquid. To verify proper behaviour, a

weight measurement of the cassettes has to be carried out.

Please fill in the document on the last page of the present document and follow further

instructions.

a. Remove the first cassette. If the weight is higher than 270 gram, not enough liquid has been

pumped through the ink tube system. This may damage the heads if you continue.

Make sure that at all times, at least one ink cassette remains inserted. Otherwise the

automatic ink load cycle will continue.

b. Remove the pump cover if the weight is too high.

c.

Install a syringe to the nipple of the appropriate head (cassette) and pull until the cassette

weighs less than 270 gram.

Nipple 1 = Head 1 = Cassette 1

Nipple 2 = Head 2 = Cassette 2

…

1 3

2 4

5 6

7 8

d. Repeat this for all eight cassettes.

e. When finished, remove all cleaning cassettes.

43

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 11 : Please wait while the printer is sucking air.

Step 12 : Insert 8 NEW cassettes with Low Solvent Cleaning when following message is displayed:

Step 13 : The printer will automatically start pumping cleaning fluid when all cassettes are inserted.

Step 14 : Empty the waste bottle when asked and confirm later on with ENTER.

Step 15 : At this time, we want to make sure that the ink tube system is completely airtight and that the first

stage transition liquid has been replaced with Low Solvent Cleaning liquid. To verify proper

behaviour, a weight measurement of the cassettes has to be carried out.

Please fill in the document on the last page of the present document and follow further

instructions.

a. Remove the first cassette. If the weight is higher than 250 gram, not enough liquid has been

pumped through the ink tube system. This may damage the heads if you continue.

Make sure that at all times, at least one ink cassette remains inserted. Otherwise the

automatic ink load cycle will continue.

b. Remove the pump cover if the weight is too high.

c.

Install a syringe to the nipple of the appropriate head (cassette) and pull until the cassette

weighs less than 250 gram.

Nipple 1 = Head 1 = Cassette 1

Nipple 2 = Head 2 = Cassette 2

…

1 3

2 4

5 6

7 8

44

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

d. Repeat this for all eight cassettes.

e. When finished, remove all cleaning cassettes.

Step 16 : Please wait while printer is sucking air

Step 17 : Insert 8 NEW cassettes with Low Solvent Ink in the correct order when following message is

displayed.

Step 18 : The printer will automatically start pumping ink when all cassettes are inserted.

Step 19 : Empty the waste bottle when asked and confirm later on with ENTER.

Step 20 : Perform a NozzleCheck and some cleanings if necessary.

Step 21 : If all nozzles are present, the first ink load procedure has been finished successfully.

Notes

When you have used a syringe to complete the first ink load procedure, it doesn’t mean necessarily that

there is something wrong with the printer.

During an ink load, air columns will be created to ease the switch between two liquids. When these air

columns are too big, it might be possible that the pump experiences difficulties and that you have to

intervene manually.

+

When you perform a NozzleCheck and all nozzles are present, no problems will occur during normal

printing activities.

-

When you perform a NozzleCheck and still a lot of nozzles are missing, you will have to search for the

reason, may be a pump is broken or the tube cycle is not complete air tight.

45

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

46

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

7 LOADING MEDIA

7.1 LOADING ROLL MEDIA

Please refer to the User’s Guide of the Unwinder/Winder 100 to know how to load roll media properly.

7.2 LOADING SHEET MEDIA

To load sheet media, follow the steps below.

Step 1 :

Power ON the printer.

Step 2 :

Unload media if necessary.

Step 3 :

Be sure that the pressure rollers are raised before loading sheet media.

Step 4 :

When no media is loaded and …

… the pressure rollers are raised, the following message will be displayed.

… the pressure rollers are lowered, the following message will be displayed.

Step 5 :

Open the front cover.

Step 6 :

Load a sheet of media at the right side of the printer. Position the media next to the media setting

position (line of little holes in the media guide platform). The maximum distance between the

guideline and media is 5 mm.

Machine

CS9265

CS9290

Minimum Media Width

A4 (210 mm – 8,27”)

A4 (210 mm – 8,27”)

Maximum Media Width

1651 mm (65.00”)

2240 mm (88.18”)

47

Printing Width

1640 mm (64.56”)

2230 mm (87.79’)

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 7 :

Make measurement settings in following menu:

SetupMenu (1/7) ► MediaSet [F4] ► SheetSize

Menu Choice

F1

Auto

Description

Media measurement sequence ► REAR – RIGHT – LEFT – TOP

Media measurement sequence ► RIGHT – LEFT – TOP

Media orientation

F2

Length

Media measurement sequence ► RIGHT – LEFT – TOP

Media orientation

F3

Width

Step 8 :

Close the front cover.

Step 9 :

Start media initialisation.

Menu Choice

Description

F2

Sheet / Roll

F3

Lever Up

Raise the pressure rollers if necessary

F4

User 1-8

Select user profile (1-8)

ENTER

Select which kind of media is loaded

Start media initialization

Step 10 : Media will be measured according to the settings made before.

Step 11 : If the media has been loaded correctly, the following message will be displayed:

48

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8 HEAD ADJUSTMENTS VERIFICATION

When the printer leaves the company, the heads are already adjusted. During transportation, the heads can

be moved slightly. Therefore, it is recommended to verify the different head adjustments.

The most important thing to know before adjusting is which nozzle row corresponds with which colour, ink

cassette, head …

Head number

Nozzlerow number

Cassette number

HEAD 1

HEAD 2

HEAD 3

HEAD 4

HEAD 5

HEAD 6

HEAD 7

HEAD 8

1a 1b

2a 2b

3a 3b

4a 4b

5a 5b

6a 6b

7a 7b

8a 8b

1

2

3

4

5

6

7

8

Please print and evaluate each pattern described below in the same order.

1. Head Slant Check

▼

2. Front and back adjustment

▼

3. Bi-Directional adjustment

▼

4. Uni-Directional adjustment

▼

5. Micro Shift 1/720” for FAST modes

49

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8.1 HEAD SLANT CHECK

Purpose of this check

► Check if the heads are positioned straightly.

How to print the file

► Power ON the printer in diagnostics mode ►Adjustment [F2] ►HeadSlant [F4] ►Slant [F1]

Pattern

8B

8A

7B

7A

6B

6A

5B

5A

4B

Before adjustment

4A

2B

2A

1B

1A

3B

3A

Adjusted head slant

50

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8.2 FRONT AND BACK

Purpose of this check

► To check if the heads are all positioned in one line.

Notes

Please note that heads 1 to 4 has been shifted in production 1/720 of an inch (as explained in chapter 8.5)

compared to heads 5 to 8. Which means that you only have to check if head 1, 2, 3 and 4 are in one line

and the same for head 5, 6, 7 and 8!

How to print the file

► Power ON the printer in diagnostics mode ►Adjustment [F2] ►HeadSlant [F4] ►F&B [F2]

Pattern

1B 1B+8A 8A 2B 2B+7A 7A 3B 3B+6A 6A 4B 4B+5A 5A 5B 5B+4A 4A 6B 6B+3A 3A 7B 7B+2A 2A 8B 8B+1A 1A

6B is the

reference head

1B 6B 2B 6B 3B 6B 4B 6B 5B 6B 7B 6B 8B 6B 1B 6B 2B 6B 3B 6B 4B 6B 5B 6B 7B 6B 8B 6B

3A is the

reference head

8A 3A 7A 3A 6A 3A 5A 3A 4A 3A 2A 3A 1A 3A 8A 3A 7A 3A 6A 3A 5A 3A 4A 3A 2A 3A 1A 3A

51

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8.3 BI-DIRECTIONAL

Purpose of this check

► To check if each head fires the ink at the same position when printing from right to left and left to right.

► The check will be done for all head heights

# 1 = Low

# 2 = Middle

# 3 = High

► Perform all 3 checks

Bi-D

= Standard Check

Bi-D400 = Extra check for printing in FAST 540

Bi-D480 = Extra check for printing in FAST 360

How to print the files

Bi-D

Bi-D400

Bi-D480

► Power ON the printer in diagnostics mode ► Adjustment [F2]

► Power ON the printer in diagnostics mode ► Adjustment [F2]

► Power ON the printer in diagnostics mode ► Adjustment [F2]

► Menu 2/5

► Menu 4/5

► Menu 5/5

► Bi-D [F1]

► Bi-D400 [F4]

► Bi-D480 [F1]

Pattern

#3 ALL

#2 ALL

#1 ALL

8B

8A

7B

7A

6B

6A

5B

5A

4B

52

4A

3B

3A

2B

2A

1B

1A

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Adjustment procedure

Please follow the instructions below to adjust the printer.

Step 1 :

Print the first file ► [Bi-D] ► [F1] – key.

Step 2 :

Set the thickness of the media and press ENTER.

Step 3 :

Confirm with ENTER to start printing.

Step 4 :

Each nozzle row (1A, 1B, 2A, 2B …) will print 4 blocks from left to right and then 4 from right to

left.

First swath printed

Second swath printed

Final Pattern

#3 ALL

#2 ALL

#1 ALL

8B

8A

7B

7A

6B

6A

5B

5A

4B

53

4A

3B

3A

2B

2A

1B

1A

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 5 :

Step 6 :

The first printed blocks are the reference and the blocks printed secondly should be aligned with

the reference blocks. Refer to the image below to know in which direction.

Second blocks are printed too much

to the right side (too late)

Second blocks are printed too much

to the left side (too soon)

► decrease (-) the bi-dir value as

described in the next step

► increase (+) the bi-dir value as

described in the next step

Increase or decrease all necessary bi-dir values as follows:

a. Select the head height in which you want to adjust the bi-dir values.

b. All nozzle rows (1A, 1B, 2A, 2B …) will pass in order on the display. If you do not want to

change the value, press the ENTER key. The setting will be kept unchanged.

Change the value with the [F2] or [F4] key and confirm with the ENTER key.

c.

Step 7 :

After setting all values (8B as last one), the adjustment pattern for the particular head height

will be printed once again.

Perform this procedure for all head heights and for all carriage speeds; which means

Bi-D

►

Adjustment [F2]

►

Menu 2/4

►

Bi-D [F1]

Bi-D400

►

Adjustment [F2]

►

Menu 4/4

►

Bi-D400 [F3]

Bi-D480

►

Adjustment [F2]

►

Menu 4/4

►

Bi-D480 [F4]

54

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8.4 UNI-DIRECTIONAL

Purpose of this check

► To check if each head fires at the same time compared with the reference head 1.

How to print the files

► Power ON the printer in diagnostics mode ►Adjustment [F2] ►Menu 2/4 ► Uni-D [F2]

Pattern

Reference

Reference

8B

8A

7B

7A

6B

6A

5B

5A

4B

4A

3B

3A

1B

1A

1B

1A

1B

1A

1B

1A

1B

1A

1B

1A

55

2B

1B

2A

1A

Reference

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

8.5 MICRO SHIFT 1/720” FOR FAST MODES

Purpose of this check

► When all heads are in one line, and you want to print in one of the FAST modes (FAST 720, FAST 540

or FAST 360), head 5-8 (headset 2) have to be shifted 1/720 of an inch downwards compared with heads

1-4 (headset 1). The pattern below will help you to fine tune this µ-shift.

How to print the files

► To perform this adjustment, you will need to have the print file which is located on the firmware download

FTP: ftp://firmware@ftp.mutoh.be/firmware_download (please refer to TIB117bis to log in)

56

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Step 1 :

Copy the files to your computer’s hard disk.

Step 2 :

Power ON the printer in user mode (no diagnostics mode needed).

Step 3 :

Turn OFF all heaters and make sure head height is low in user 1.

Step 4 :

Load media. In order to get the best visible result, we recommend coated media.

Step 5 :

Edit the IP-address in the PRINT.BAT file in Notepad or Ultra-edit 32.

Step 6 :

Drag the file into the PRINT.BAT file. Be sure that the printer is connected to the network.

Step 7 :

A print will be launched.

Step 8 :

Verify if all heads are in one perfect line (3A – 6A and 1B-2B-…-8B).

6A

3A

6A

3A

8B

•

•

7B

6B

4B

5B

3B

2B

1B

Notes

Use a magnifying glass with a magnification factor of at least 25.

Pay attention to the fact that some magnifying glasses give a mirror view.

57

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Adjustment procedure

Please follow the instructions below to perform the micro shift.

Step 1 :

LOOSEN the screws (1) fixing head 5-8.

These heads have to be shifted 1/720 inch. In general, the µ-shift can be accomplished by turning

screws number 3 (see drawings) both by 1/4 of a turn counter clock wise!

This is only a rough adjustment!!

1 = Screws (M2.5x5) fixing the head stationary plate

2 = Angle Adjustment screw

3 = Front and Back adjustment screw

•

Notes

This image is only intended for visual support, do not disassemble the heads. Only loosen the two

indicated screws.

Step 2 :

Tighten the screws (1) fixing head 5-8

Step 3 :

Print the file once again.

Step 4 :

Check if nozzle row 6A is shifted 1/720 inch compared with nozzle row 3A which means that nozzle

row 6A has to be positioned exactly between 3A en 4B. Please refer to the picture below for

visual support.

3A

6A

3A

6A

8B

7B

6B

4B

5B

3B

2B

1B

Step 5 :

Adjust head 6 until it is well positioned.

Step 6 :

Adjust head 5, 7 and 8 until there are in one line with nozzle row 6B and between 6A.

Step 7 :

After this adjustment, head block 5-6-7-8 is shifted 1/720 inch with head block 1-2-3-4

58

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

9 TEST PRINTING

Follow the steps below to do a test print and confirm if your printer operates correctly.

Step 1 :

Power ON the printer.

Step 2 :

Load media.

Step 3 :

Make sure that your printer is in normal [Ready to print] - status.

Step 4 :

Go to SetupMenu 1/7 ► [F3] – TestPrint.

Step 5 :

Select which test pattern you want to print.

Prints a test pattern to check if there are any

nozzles missing. Depending on the amount of

missing nozzles, perform a little, normal or powerful

cleaning to regain all nozzles.

Prints a pattern to check if the distance adjustment

(“step”) is set correctly. If not, you can change it

easily.

Prints a list with important information regarding the

printer, such as InkStatus, Printer Config info, Media

settings, Network settings, …

Prints an overview of the lifetime of some parts in

the printer. This to know if they should be replaced

soon.

The lifetime is visualized on the basis of stars.

E

F New part

E

F Part needs to be replaced

Prints the uni-directional test pattern. The purpose

of this print is to check if the heads are still well

aligned. If necessary, adjust the heads. Please refer

to the maintenance manual for all necessary

information.

59

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

Prints the bi directional test pattern at 300 cps. The

purpose of this print is to check if the heads are still

well adjusted. If necessary, adjust the heads.

Please refer to the maintenance manual for all

necessary information.

Prints the bi directional test pattern at 400 cps. The

purpose of this print is to check if the heads are still

well adjusted. If necessary, adjust the heads.

Please refer to the maintenance manual for all

necessary information.

Prints the bi directional test pattern at 480 cps. The

purpose of this print is to check if the heads are still

well adjusted. If necessary, adjust the heads.

Please refer to the maintenance manual for all

necessary information.

Prints a test pattern to compare the colour settings

of the computer to the print colour of the printer.

This palette is printed in the mode you are currently

working (PrintMode settings).

We recommend to print the palette in 360x360.

60

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

10 PERIODICAL MAINTENANCE CYCLES

10.1 DONE BY THE END USER

No°

1

2

3

4

5

6

7

8

9

Action

Clean wipers

Flush caps in maintenance station

Clean the edges of the caps in maintenance station

Clean the area around the caps

Clean around bottom of the heads

Clean cover window

Replacing the sponge in the spitting box

Change the wipers

Change upper sponge at the back of the capping station

Frequency

Morning and evening

Daily maintenance

(in the evening)

Weekly maintenance

2 weekly maintenance

Monthly maintenance

Available kits for the end user and their order numbers

1. User and good shape kit for 6 months

No

1

2

3

4

5

6

29801288

Description

Sponge plate

Wipers

Spitting box sponge

Cleaning Liquid 250 ml

Instruction sheet

Good shape kit

Quantity

6

24

12

3

1

1

29801287

2. Good shape kit

No

1

2

3

4

Description

Gloves

Pipette

Swabs

Polyknit wiper

Quantity

300

60

150

300

3. Long store kit

No

1

2

xxxxxxxx

Description

Océ IJC920 HS Low Solvent Cleaning

Liquid

Ink kit

Black

Cyan

Magenta

Yellow

4. Solvent cleaning in a bottle

Quantity

8

2

2

2

2

xxxxxxxxx

61

AP-40301 – Rev. 2.0 – 02/05/2008

CS9200 Low Solvent series printers

10.2 DONE BY AN AUTHORIZED TECHNICIAN

No°

1

2

3

4

5

6

7

8

9

10

11

Action

Changing the dampers

Changing the spitting box + tube + L connection

Applying grease on the head up-down cams when needed

Applying grease on the Y-motor belt if needed

Applying grease on the roller path carriage if needed

Applying grease on the capping station cam and gears if needed

Removing dust in the fan area underneath the print platform

Changing the pumps

Changing the tubes from the pumps to the waste bottle

Change wiper arm assembly

Changing the maintenance station

Frequency

Every 6 months

Every 12 months

Available kits for Authorized Technicians only and their part numbers:

maintenance cycle Kit 6 months

KY-81810

maintenance cycle kit 12 months

KY-81820

62

AP-40301 – Rev. 2.0 – 02/05/2008

FEEDBACK SHEET FIRST INK LOAD PROCEDURE

Dear customer,

During the first few months after the CS9065-CS9090 launch, we want to collect data of all installations.

During installation, the transition from water-based state to low solvent state is a key procedure, which we want to

monitor for different reasons:

•

•

Verify proper behaviour of the automatic ink load procedure.

Load procedure optimization based on direct field feedback.

To gather information about the ink load procedure and at the same time ensure a proper initial ink load, we require you

to keep track of the different steps of the initial ink load.

To assist you with the progress, we have prepared a feedback sheet, which we would like you to fill in and send back to us.

Please fill in this form and mail/fax it back to our service department

Distributor/Dealer and printer details

Distributor / Dealer

Serial number printer

Date first ink load

Cassette Number

Cassette 1

Cassette 2

Cassette 3

Cassette 4

Cassette 5

Cassette 6

Cassette 7

Cassette 8

Cassette Number

Cassette 1

Cassette 2

Cassette 3

Cassette 4

Cassette 5

Cassette 6

Cassette 7

Cassette 8

LOW SOLVENT SETUP CLEANING FIRST WASH

Weight after filling > 270 gram?

Weight after filling cleaning

► Intervention with syringe necessary?

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

LOW SOLVENT CLEANING CASSETTES

Weight after filling > 250 gram?

Weight after filling cleaning

► Intervention with syringe necessary?

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

gram

NO / YES

REMARKS

63

AP-40301 – Rev. 2.0 – 02/05/2008