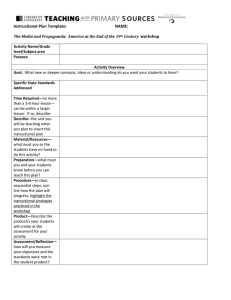

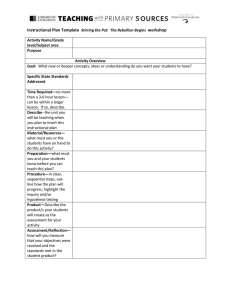

Guidance Notes on the Development of Procedures and

advertisement