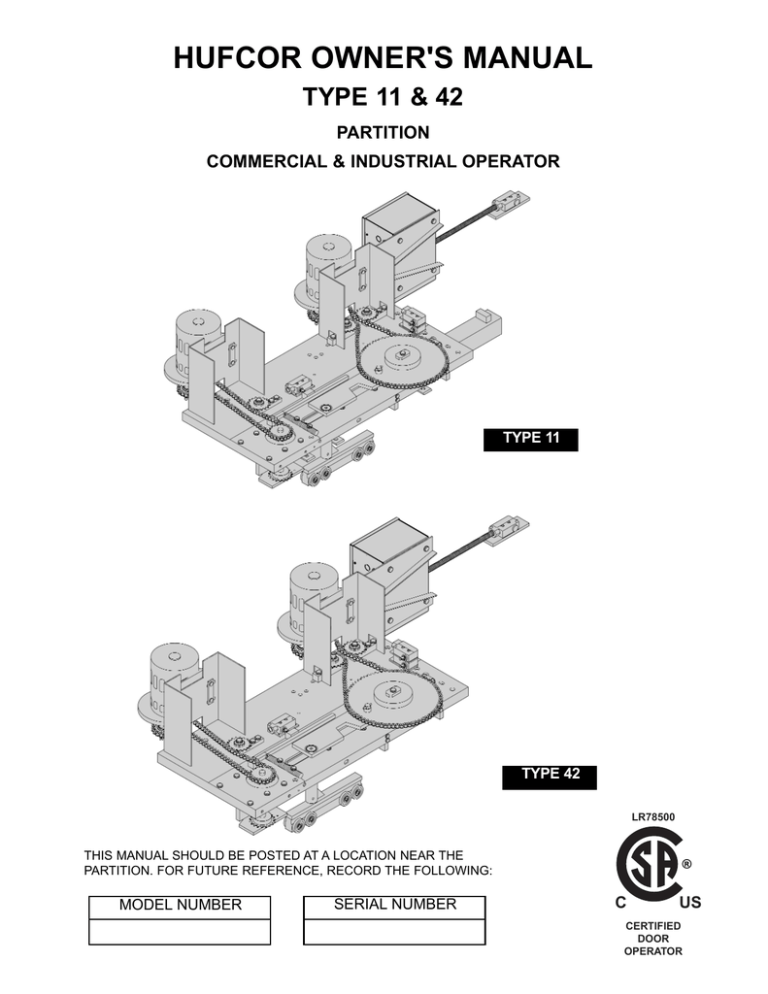

HUFCOR OWNER'S MANUAL

TYPE 11 & 42

PARTITION

COMMERCIAL & INDUSTRIAL OPERATOR

TYPE 11

TYPE 42

LR78500

THIS MANUAL SHOULD BE POSTED AT A LOCATION NEAR THE

PARTITION. FOR FUTURE REFERENCE, RECORD THE FOLLOWING:

MODEL NUMBER

SERIAL NUMBER

C

US

CERTIFIED

DOOR

OPERATOR

RNING

UTION

TABLE OF CONTENTS

WARNINGS

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PRODUCT INFORMATION

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Duty Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .3

OPERATOR PREPARATION

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Optional Equipment . . . . . . . . . . . . . . . . . . . . .3

ENTRAPMENT PROTECTION

Hulgard System . . . . . . . . . . . . . . . . . . . . . . . .4

WIRING

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .4

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .4

Schematic Diagram . . . . . . . . . . . . . . . . . . . . .5

Control Wiring Connections . . . . . . . . . . . . . . .12

REPLACEMENT PARTS

Operator Illustration . . . . . . . . . . . . . . . . . . . . .6

Operator Replacement Parts List . . . . . . . . . . .7

Electrical Box Illustration . . . . . . . . . . . . . . . . . .8

Electrical Box Replacement Parts List . . . . . . .9

MAINTENANCE OF OPERATOR

Maintenance Schedule . . . . . . . . . . . . . . . . . . .10

Technical Support . . . . . . . . . . . . . . . . . . . . . . .10

Parts Ordering Information . . . . . . . . . . . . . . . .10

IMPORTANT SAFETY NOTES

WARNINGWARNING

WARNING

BE SURE YOU HAVE BEEN FULLY INSTRUCTED ON THE

OPERATION AND HAZARDS OF YOUR SPECIFIC SYSTEM. IF

YOU HAVE ANY QUESTIONS OR DOUBTS ABOUT THE

SAFETY OF YOUR SYSTEM, CALL THE NUMBER ON THE

BACK OF THIS BOOKLET.

DO NOT LET CHILDREN NEAR THE PARTITION. SERIOUS

INJURIES OR DEATH MAY RESULT IF CHILDREN ARE

ALLOWED TO PLAY NEAR THE PARTITION WHEN IT IS

BEING OPERATED.

CAUTION WARNING

WARNING

WARNING

G

CAUTION

WARNING

WARNING

DO NOT OPERATE YOUR PARTITION UNLESS YOU CAN

SEE IT AND THE PATH OF THE PARTITION MOVEMENT IS

CLEAR OF PEDESTRIANS AND OBSTRUCTIONS.

BE SURE THESE INSTRUCTIONS ARE DISTRIBUTED TO

ALL POTENTIAL USERS OF THE DOOR OPERATING SYSTEM. BE SURE THAT EVERYONE WHO WILL OPERATE

THE PARTITION IS AWARE OF THE HAZARDS OF THE SYSTEM.

WARN

ING

G

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

PARTITION OPERATING

SYSTEMS REPAIR AND SERVICE

SHOULD ONLY BE PERFORMED BY A CERTIFIED HUFCOR

TECHNICIAN. FOR THE NAME OF THE CERTIFIED HUFCOR TECHNICIAN NEAREST YOU, CALL THE NUMBER ON

THE BACK OF THIS MANUAL.

KEEP CLEAR OF THE PARTITION AREA AT ALL TIMES.

YOUR AUTOMATIC DOOR IS NOT FOR PEDESTRIAN USE.

SERIOUS INJURY OR DEATH MAY RESULT FROM

ENTRAPMENT IN ANY MOVING PARTS OF THE PARTITION

OPERATING SYSTEM.

CAUTION

WARNING

2

WARNING

W

GENERAL PRODUCT INFORMATION

PRODUCT APPLICATION

The partition operator will electrically operate a multiple partition up to 140 feet long. This unit is built in

accordance with CSA/NRTL standards for door operators.

DUTY RATING

Due to the size of the partition this model will operate, it is to be considered limited duty and carries a

maximum cycle rating of 5 cycles per hour @ 140 feet.

HORSEPOWER

This unit is a dual motor operator. It has a 1/4 HP motor that is used to start the partition moving and to

lock the partition at the end of its travel. It also has a 1/2 HP motor that is used in the actual movement of

the partition through its cycle.

VOLTAGE and PHASE

This unit is presently available in 115vac single phase, 60 hertz.

CONTROL WIRING

The partition operator has constant pressure wiring in both the open and close directions. In addition the

unit is supplied with 2 key stations that must be wired in series. The key stations must be operated

simultaneously in order to initiate the partition movement. This is a safety issue and must not be

tampered with.

ANY CHANGE MADE TO THIS DUAL KEY STATION WIRING WILL INVALIDATE THE CSA/NRTL CERTIFICATION.

OPERATOR PREPARATION

OPERATOR PREPARATION

Remove the operator from its carton, check for any damage during shipment. Any claims for damage,

shortage, defective material etc. must be reported within 15 days of receipt of goods. Refer to the

warranty policies in this manual for return policies.

The following parts are included in the carton:

1) Operator Powerhead

2) Limit Switch

3) Misc. Hardware

4) Caution Label

OPTIONAL EQUIPMENT

1) Pocket door switch: These interlock switches will make the partition opener inoperable if the pocket

doors are not fully open. These switches are recommended if your partition contains pocket doors.

2) Hufgard safety system: See page 4

IT IS HIGHLY RECOMMENDED THAT A SAFETY SYSTEM BE INSTALLED ON ALL MOTORIZED PARTITIONS!!

CONSULT HUFCOR FOR INFORMATION REGARDING THIS SAFETY SYSTEM.

3

RNING

UTION

ENTRAPMENT PROTECTION ACCESSORIES (OPTIONAL)

HUFGARD SAFETY SYSTEM

ding the partition. Mats only work when stacking the partition.

This is a safety system that consists of a lead edge sensor and mat sensors; the edge sensor will detect

obstructions at the lead end of the partition and the mats

will detect an object standing on them. The mats are

located in the pocket where the partition will fold into.

Both the lead edge sensor and mats will disable the partition opener from operation if they detect an obstruction.

Lead edge sensor only works when exten-

IT IS STRONGLY RECOMMENDED THAT A

SAFETY SYSTEM BE INSTALLED ON ALL

MOTORIZED PARTITIONS.

POWER & CONTROL WIRING CONNECTIONS

Before making any power or control wiring connections be sure to follow all warnings described below. Failure

to do so may result in severe injury to persons and/or damage to operator. Remove the cover from the electrical enclosure. Refer to the diagram on page 5 of the manual for all connections described below. If this diagram

is missing, call the number on page 10 of this manual. DO NOT INSTALL ANY WIRING OR ATTEMPT TO RUN

THIS OPERATOR WITHOUT CONSULTING THE WIRING DIAGRAM.

POWER WIRING

CONTROL WIRING

WARNING

WARNING

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

PERMANENTLY WIRED IN ACCORDANCE WITH

LOCAL ELECTRICAL CODES. NOTE: THE OPERATOR SHOULD BE ON A SEPARATE FUSED LINE OF

ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

INSTALL ONE WALL SWITCH ON EACH SIDE OF

LEAD END OF PARTITION FOR FULL VIEW OF EACH

SIDE OF THE PARTITION DURING OPERATION. A

SAFETY DEVICE MUST BE INSTALLED ON THE PARTITIONS. FAILURE TO INSTALL A SAFETY DEVICE

UNDER THESE CIRCUMSTANCES MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONS

TRAPPED IN THE PARTITIONS.

WARNING

CAUTION

WARNINGWARNING

TO AVOID DAMAGE TO PARTITIONS AND OPERATOR, MAKE ALL PARTITION LOCKS INOPERATIVE.

SECURE LOCK(S) IN "OPEN" POSITION.

1.

Be sure that the power supply is of the correct

voltage, phase, frequency, and amperage to supply the

operator.

CAUTIONCAUTION

DO NOT TURN POWER ON UNTIL YOU HAVE FINISHED MAKING ALL POWER AND CONTROL WIRING

CONNECTIONS AND HAVE COMPLETED THE LIMIT

SWITCH ADJUSTMENT PROCEDURE.

WARNINGWARNING

DISCONNECT POWER AT THE FUSE BOX BEFORE

PROCEEDING.

OPERATOR MUST BE PROPERLY GROUNDED AND

PERMANENTLY WIRED IN ACCORDANCE WITH

LOCAL ELECTRICAL CODES. NOTE: THE OPERATOR SHOULD BE ON A SEPARATE FUSED LINE OF

ADEQUATE CAPACITY.

ALL ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

WARNINGWARNING

Additional Access Control Equipment

Locate any additional access control equipment as desired

(but so that the partitions will be in clear sight of the person

operating the equipment. DO NOT USE THE CONTROL CIRCUIT TRANSFORMER (24VAC) IN THE OPERATOR TO POWER

ANY ACCESS CONTROL EQUIPMENT.

IMPORTANT: THIS UNIT MUST BE PROPERLY

GROUNDED. A GROUND SCREW IS SUPPLIED IN

THE ELECTRICAL BOX FOR CONNECTION OF THE

POWER SUPPLY GROUND WIRE. FAILURE TO PROPERLY GROUND THIS UNIT COULD RESULT IN ELECTRIC SHOCK AND SERIOUS INJURY.

4

W

SCHEMATIC

1905

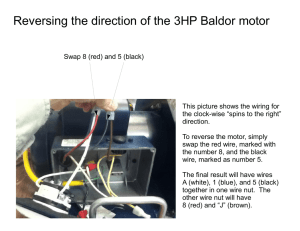

1. TO REVERSE MOTOR DIRECTION, REVERSE RED

AND BLACK WIRES ON EACH MOTOR.

W

L2

COIL

BK

BK

R6

115V

DPDT

W

5

CMS

6

CMS

4

1

W

3

CME

GY

WIRE

NUT

P

DPDT

COIL

CMS

2

W

MOTOR WIRE

SEE 1/2HP MOTOR CONNECTIONS

(DETERMINE MOTOR TYPE, EMMERSON OR GE)

1

4

BL

W

CME

6

CHAIN MOTOR (1/2 HP)

115 VOLT 1 PHASE

1

2

BK

IRC

115V

115 VOLT 1 PHASE

INCOMING FEED

W

BK

BK

W

3

W

OL (10 AMP)

BK

CME

4

5

Y

WIRE

NUT

MOTOR WIRE

WIRE

NUT

Y

W

W

W

OL

L1

W

BK

BK

115V

IRA

W

3

5

AMS

6

W

(6 AMP)

BK

AME

4

AMS

4

1

W

3

AME

GY

INTERNAL BLACK WIRE

(START WINDING)

2

1

P

BK

DPDT

COIL

2

RELAYS IRA AND IRC ARE WIRED NORMALLY

OPEN AND ARE HELD CLOSED WHENEVER

THE POWER IS ON AND THE MOTOR IS NOT

RUNNING.

W

6

AMS

1

WIRE

Y NUT R

5

G

GROUND

SCREW

(OPTIONAL)

EMERGENCY STOP

3

115V PRI.

W

BR

(OPTIONAL)

POCKET SWITCHES

P

4

ON

ON

P

7

OFF

EXTEND STACK

C.

N.O.

2 R

24V SEC.

11

GY

IRA

OR

N.C.

C.

13

12

W

BL

BR

OR

1

8

C.

N.O.

Y

13

BL

BL

P

AUX.

L/S #3

C.

13

9

P

N.C.

R

P

CME A1

Y

A2

CMS A1

Y

P

14

IRA

GY

A2

SYMBOLS:

AME = ARM EXTEND

AMS = ARM STACK

CME = CHAIN EXTEND

CMS = CHAIN STACK

L/S#1 = CHAIN MTR. EXTEND LIMIT

L/S#2 = ARM MTR. EXTEND LIMIT

L/S#3 = ARM MTR. STACK LIMIT

L/S#4 = CHAIN MTR. STACK LIMIT

BL

CMS

R

AME A1

Y

14

IRC

N.C.

A2

OR

BR

CME

13

L/S #4

X2

14

IRC

N.C.

CONTROL POWER

SWITCH

Y

AME

Y

AUX.

L/S #1

6

Y

XF

10 L/S #2

GY

100VA

T1

FUSE

4A

BR

5

BR

OFF

R6

INTERNAL START SWITCH

G

BK

BR

ARM MOTOR (1/4 HP)

115 VOLT 1 PHASE

2

BL

W

AME

BK

A

AMS

13

P

A2

AMS A1

Y

GY

14

1/2HP MOTOR CONNECTIONS

EMERSON 1/2HP MOTOR

INTERNAL BLUE WIRE

(RUN WINDING)

GY

P

WIRE

NUT

Y

BL

GE 1/2HP MOTOR

1

Y

INTERNAL BLACK WIRE

(START WINDING)

Y

5

P

BK

CHAIN MOTOR (1/2 HP)

115 VOLT 1 PHASE

(REVERSE RED AND BLACK

LEADS FOR MOTOR ROTATION)

4

WIRE

NUT

R

WIRE

NUT

BL

G

G

INTERNAL YELLOW WIRE

(RUN WINDING)

GY

INTERNAL START SWITCH

Y

GROUND

SCREW

1

BL

INTERNAL BLACK WIRE

(START WINDING)

Y

5

BK

CHAIN MOTOR (1/2 HP)

115 VOLT 1 PHASE

(REVERSE RED AND BLACK

LEADS FOR MOTOR ROTATION)

4

WIRE

NUT

R

G

G

GROUND

SCREW

5

INTERNAL START SWITCH

6

53

54

41

23

55

40

48

42

9

52

8

46

60

31

45

17

22

21

19

22

1

37

47

32

42

12 54

41

40

56

40

23

42

23

8

62

25

45 61

45

10

50

26

39

30

21

38

24

27

44 47

SEE PAGE 8

56

46

63

26

4

56

44 47

65

64

63

46

51

15

13

TYPE 42 ONLY

TYPE 11 ONLY

35

11

4

38 46

14

65

64

28

50

66

10

72

2

6

67

73

36

5

45

53

49

43

74

16

50

57

18

71

70

68 69

29

3

7

20

58

40

BOTH UNITS

TYPE 42 ONLY

TYPE 11 ONLY

33

44

34

59

ILLUSTRATED PARTS - TYPE 11 & TYPE 42

REPAIR PARTS – TYPE 11 & TYPE 42 OPERATORS

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

PART #

34-652

16-973

18-179

18-197

16-535

17-949

18-201

17-055

16-802

16-967

34-850

16-803

18-203

16-964

18-202

18-206

16-741

17-119

18-009

34-189

60-002

34-842

34-849

55-247

55-245

55-356

52-270

55-359

64-020

64-033

64-730

65-834

65-335

65-351

65-887

64-003

31-910

65-523

52-930

52-675

52-700

52-198

51-845

51-834

51-840

51-844

51-857

51-853

51-864

51-740

50-029

51-909

52-195

52-655

52-675

52-750

53-265

60-202

60-202

60-202

17-264

51-909

51-822

52-187

34-825

51-730

52-785

64-326

64-259

64-308

53-270

34-963

51-635

18-204

DESCRIPTION

PART RELEASE

ADJUST BLOCK

SPACER

CONTROL ARM STOP

CAP CARRIER BOLT

SLEEVE SPACER

TRIP FINGER

NUT PLATE

IDLER BRACKET

MOUNTS, LIMIT SWITCH

SPRING, TENSION

IDLER BRACKET

NUT PLATE

PLATE #4 LIMIT SW

SPACER BAR

CARRIER BOLT SPACER

GUIDE PLATE

CLAMP PLATE

DRIVE SHAFT

CARRIER BOLT

BEARING

SPROCKET #40 19 TEETH

SPROCKET #40 18 TEETH

MOTOR, 1/4 HP

MOTOR, 1/2 HP

LIMIT SWITCH

COTTERPIN, 5/32”

LIMIT SWITCH (#4)

SPROCKET WELDMOUNT

BEARING TUBE

SWING ARM WELDMENT

BASE CHANNEL WELDMOUNT

SPROCKET STUB WELDMOUNT

CHAIN MOUNTS

STACK TRACK WELDMOUNT

CONTROL ARM WELDMOUNT

TORQUE LIMITER

TIE PLATE

KEY, WOODRUFF

SHIM 5/8" (.062 THICK)

WASHER, SHIM (.032 THICK)

NUT 3/8-16 FLANGE (G2)

SOCKET SCREW, 1" LONG

HEX BOLT, 3/8-16 X 3/4"

HEX BOLT, 1" LONG

HEX BOLT, 3/8-16 X 1-1/4"

HEX BOLT, 3/8 X 1-3/4"

HEX BOLT, 2" LONG

HEX BOLT, 2-1/2" LONG

SOCKET SCREW, #10-24 X 1-1/2"

SOCKET SCREW, #10-24 X 3"

SOCKET SCREW, #1-1/4" LONG

HEX NUT, 3/8-16

FLAT WASHER, 3/8"

WASHER, 5/8"

LOCK WASHER, 3/8"

ROLL PIN

CHAIN, #40 X 35 LINKS

CHAIN, #40 X 73 LINKS

CHAIN, #40 X 77 LINKS

MOTOR STRAP

SOCKET SCREW, 5/8-18 x 1-1/2

HEX BOLT, 5/16-18 x 7/8”

FLANGE NUT, 5/16-18

FLATWASHER, 5/16” ID

SOCKET SCREW, 10-24 x 3/8”

WASHER, .062 x 3/4” ID

UPPER CARRIER ASSEMBLY

UPPER CARRIER ASSEMBLY

LOWER CARRIER ASSEMBLY

ROLL PIN, 7/32” X 1-1/4” LONG

CONDUIT STRAP

SCREW

SPACER

7

QTY.

1

1

1

2

1

1

1

3

1

4

1

2

2

1

2

1

1

1

1

1

2

2

3

1

1

3

2

1

1

1

1

1

1

2

1

1

2

4

2

2

5

10

1

9

9

10

12

1

1

5

2

1

2

10

3

10

1

1

1

1

1

2

4

4

4

2

3

1

1

1

1

1

1

1

ILLUSTRATED PARTS - ELECTRICAL BOX

14

8

2

12

13

3

1

15

15

9

10

11

5

4

6

7

8

REPAIR PARTS – ELECTRICAL BOX

Below are replacement parts available for your operator. Please consult a parts and service representative regarding availability

of individual components specified below.

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PART #

03-8024-K

21-3240-1

24-115-1

25-2006

25-2010

28-10747

28-12029

35-204

42-103

42-114

44-21202

82-PX06-06T

82-PX06-08T

82-PX08-06T

82-PX08-10T

DESCRIPTION

CONTACTOR

TRANSFORMER

RELAY 115V

OVERLOAD, 6 AMP

OVERLOAD,10 AMP

CONNECTOR, DOUBLE

CONNECTOR, STRAIGHT

FUSE, 4 AMP

TERMINAL BLOCK, 3 POLE

TERMINAL BLOCK, 14 POLE

ENCLOSURE, ASSY HUFCOR

PAN HEAD SCREW, 3/8" LONG

PAN HEAD SCREW, 1/2" LONG

PAN HEAD SCREW, 3/8" LONG

PAN HEAD SCREW, 5/8" LONG

9

QTY

2

1

3

1

1

2

2

1

1

1

1

6

8

4

4

OPERATOR MAINTENANCE

-AT LEAST ANNUALLY1. Clean and lightly lubricate all track running surfaces.

2. Check trolleys for any signs of abnormal wear or breakage. Replace as needed.

3. Check out of plumb panels (indicating loose trolley bolts). Correct by adjusting to plumb

and tightening trolley nuts.

4. Check any exposed bolts in panel vertical edges- tighten if required.

5. Check track misalignment at all joints- correct any misalignment.

6. Check and make sure all top and bottom seals are functioning properly.

7. Operate pass door and adjust as needed.

8. Check for torn vinyl or fabric, repair or replace.

ADDITIONAL STEPS FOR ELECTRICAL OPERATORS

1. Check chain hooked to partition and chains on motor unit for tightness- adjust as needed.

2. HUFGARD- Check lead edge and mats for proper operation. (This should be done no less

than monthly.) Contact Factory/Distributor immediately if these checks fail to stop

partition.

3. Check partitions stack and extend mode- adjust as necessary to fit the opening.

Hufcor recommends that a certified Hufcor distributor perform annual preventive maintenance to preserve the life of your product.

WARRANTY POLICY

This is to certify that the HUFCOR Operable Partitions furnished on the above mentioned project are herewith

guaranteed against defects in materials and workmanship for a period of two (2) years from the date of shipment.

Any malfunction of the product during the warranty period is to be reported by the owner/user to the local HUFCOR distributor within five (5) working days.

Malicious damage and damage resulting from delays in reporting malfunctions are excluded from this warranty.

This warranty is void unless the system is serviced annually by a certified HUFCOR distributor or HUFCOR authorized service representative.

HUFCOR, Inc.

HUFCOR, Inc.

P.O. Box 591, 2101 Kennedy Rd., Jamesville, WI 53547

800-356-6968 or 608-756-1241; Fax- 608-758-8297

Direct phone- 608-758-8314; www.hufcor.com

Email: aduesterbeck@hufcor.com

10

NOTES

11

LR78500

41B6

C

ATTENTION ELECTRICIAN:

USE 16 GAUGE OR HEAVIER WIRE

FOR ALL CONTROL CIRCUIT WIRING.

KEYSWITCHES

1

2

Extend

Stack

Switch

US

CERTIFIED

DOOR

LISTED DOOR

OPERATOR

POCKET SWITCHES

3

41B6

4

5

OPERATOR

EMERGENCY STOP

3

4

Control

Power

Switch

Extend

Stack

BE SURE TO REMOVE JUMPER

BETWEEN 4 AND 5 BEFORE WIRING

POCKET SWITCHES.

01-16583E

c 2000, The Chamberlain Group, Inc.

All rights Reserved

BE SURE TO REMOVE JUMPER

BETWEEN 3 AND 4 BEFORE WIRING

STOP SWITCH.