Solutions in Action

FGWA and CBI Fleetwood

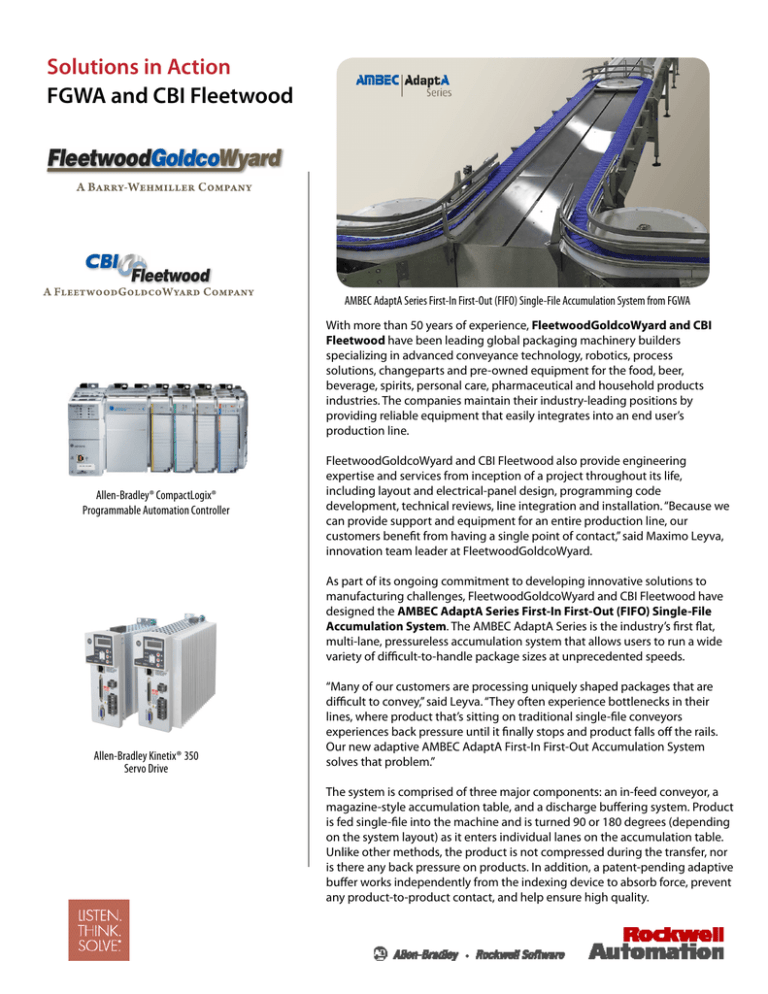

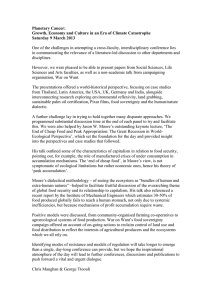

AMBEC AdaptA Series First-In First-Out (FIFO) Single-File Accumulation System from FGWA

With more than 50 years of experience, FleetwoodGoldcoWyard and CBI

Fleetwood have been leading global packaging machinery builders

specializing in advanced conveyance technology, robotics, process

solutions, changeparts and pre-owned equipment for the food, beer,

beverage, spirits, personal care, pharmaceutical and household products

industries. The companies maintain their industry-leading positions by

providing reliable equipment that easily integrates into an end user’s

production line.

Allen-Bradley® CompactLogix®

Programmable Automation Controller

FleetwoodGoldcoWyard and CBI Fleetwood also provide engineering

expertise and services from inception of a project throughout its life,

including layout and electrical-panel design, programming code

development, technical reviews, line integration and installation. “Because we

can provide support and equipment for an entire production line, our

customers benefit from having a single point of contact,” said Maximo Leyva,

innovation team leader at FleetwoodGoldcoWyard.

As part of its ongoing commitment to developing innovative solutions to

manufacturing challenges, FleetwoodGoldcoWyard and CBI Fleetwood have

designed the AMBEC AdaptA Series First-In First-Out (FIFO) Single-File

Accumulation System. The AMBEC AdaptA Series is the industry’s first flat,

multi-lane, pressureless accumulation system that allows users to run a wide

variety of difficult-to-handle package sizes at unprecedented speeds.

Allen-Bradley Kinetix® 350

Servo Drive

“Many of our customers are processing uniquely shaped packages that are

difficult to convey,” said Leyva. “They often experience bottlenecks in their

lines, where product that’s sitting on traditional single-file conveyors

experiences back pressure until it finally stops and product falls off the rails.

Our new adaptive AMBEC AdaptA First-In First-Out Accumulation System

solves that problem.”

The system is comprised of three major components: an in-feed conveyor, a

magazine-style accumulation table, and a discharge buffering system. Product

is fed single-file into the machine and is turned 90 or 180 degrees (depending

on the system layout) as it enters individual lanes on the accumulation table.

Unlike other methods, the product is not compressed during the transfer, nor

is there any back pressure on products. In addition, a patent-pending adaptive

buffer works independently from the indexing device to absorb force, prevent

any product-to-product contact, and help ensure high quality.

small, integrated and cost-effective package. It also enables

seamless upstream and downstream communication, so the

system can bring surrounding equipment to a synchronized

stop when needed.

The controller is tightly synchronized with compact

Allen-Bradley PowerFlex® 40 AC drives and Allen-Bradley

Kinetix 300 or Kinetix 350 servo drives (depending on

specific application needs) via the EtherNet/IP™ network,

providing up to 16 axes of complex motion, all on one

standard industrial network.

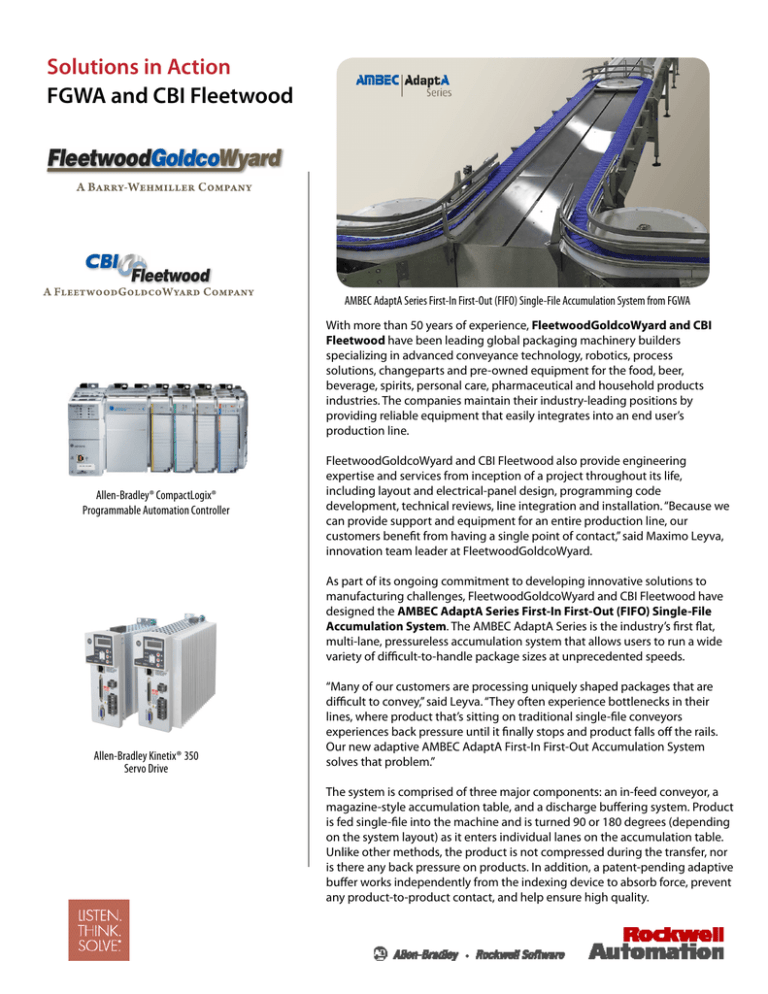

AMBEC AdaptA Series First-In First-Out (FIFO) Single-File Accumulation

System from FGWA

The AMBEC AdaptA Accumulation System can

accommodate ever-changing product sizes and shapes

with minimum changeover time. The rail-less magazine

style accumulation table allows the system to run single

or multiple chains per product lane to fit a wide range of

package sizes. Because it is flat, rather than vertical, the

system prevents any product stability or inertia issues,

and it can accommodate a wider range of product heights

without sacrificing valuable accumulation capacity.

“This system ultimately improves production line efficiency

by either providing accumulation of product or available

space, depending on what is needed, to maintain smooth

operation at any given time,” said Leyva. “In addition, users

can load and unload product at different speeds, providing

product-flow control that helps prevent the snowball effect

of production issues.”

The modular design of the system allows users to adapt to

unforeseen production line layout needs, including straight,

curvy, perpendicular or parallel transfers. In addition, the

flat and low design allows maximum product stability and

helps ease maintenance, cleaning and quality control.

Putting a focus on technologies that deliver high-speed

control in a small machine footprint, an Allen-Bradley

CompactLogix 5370 L3 programmable automation

controller (PAC) is used for the AMBEC AdaptA System. The

controller provides right-sized integrated motion control

while leveraging the common design and networking

environment of the Rockwell Automation

Integrated Architecture™ system. This gives users access to

the extensive capabilities of the Logix Control Platform in a

Adding to the machine’s ability to execute high levels of

motion control, FleetwoodGoldcoWyard and CBI Fleetwood

have implemented CIP Motion™ over EtherNet/IP, which

combines deterministic, real-time, closed-loop motion

control with standard, unmodified Ethernet to deliver an

open, high-bandwidth solution. The system is also expected

to reduce product changeover and troubleshooting time

because users can store and recall recipes using the

Allen-Bradley PanelView™ Plus 1000 human-machine

interface.

“Many manufacturers are just living with the problem,” said

Leyva. “Some only have a traditional single file conveyor

running between two machine centers. When their lines

stop, any product sitting on the conveyor can easily pile up.

The AMBEC AdaptA Accumulation System not only solves

this problem, but also provides users with a robust, adaptive

way to keep production running smoothly when frequent

changes are necessary.”

For more information, contact:

FleetwoodGoldcoWyard

CBI Fleetwood

Phone: 630.759.6800

Email: sales@fgwa.com

Allen-Bradley, CompactLogix, Kinetix, PowerFlex and Integrated Architecture are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication OEM-AP219A-EN-P – April 2013

Copyright © 2013 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.