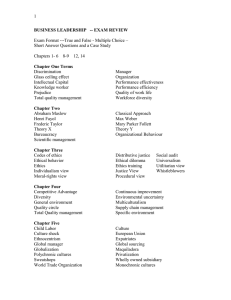

Fourth Edition

advertisement

Digital Print Finishing Solutions Books | Direct Mail | Commercial Digital Print Finishing Fourth Edition MBO – Transactional and Transpromo Finishing Systems Available as an inline or near-line solution MBO – High Speed Letterfold Finishing System 820 ft/min! Available as an inline or near-line solution The Transactional Finishing Systems from The MBO Group are number of touches required. Thanks to MBO’s modular The High Speed Letterfold System from The MBO Group was production output speed up to 100,000 letters/hour. This level designed with the highest dependability, flexibility, and job approach to finishing, these solutions can be easily adapted developed for high speed letter processing. One of the most of production means that printers can do the same amount of integrity features. This makes them ideal for processing bank for specialty needs such as camera inspection, gluing, or common tasks that can slow down production is a chipout, work on fewer finishing systems by installing the High Speed statements, letterfold products and sensitive materials at high complex folding applications. Furthermore, a variety of infeed but with the High Speed Letterfold System from MBO, printers Letterfold System. As with all the solutions from The MBO speeds. With automation, these solutions can be quickly and systems are available - meaning that this solution can be can run up to 810 ft/min even with a chipout down to 3/16 of Group, this solution can be easily adapted for specialty needs easily configured for a variety of job applications with just the configured for cut-sheet or web-finishing processes. an inch (5 mm)! By incorporating the latest advancements in such as camera inspection, split and merge production, or finishing technology, the High Speed Letterfold System from glue applications thanks to MBO’s modular approach to post- MBO can run 2-Up letterfolding applications with a maximum press finishing. touch of a button, which minimizes waste and reduces the This solution generally consists of the following modules: Feeder Unit (Pile Fed or Web Fed) Split and Merge or Plow Unit (Web Fed Only) Folding Machine with 4 or 6 Plates Shingled Stream Delivery Additional Modules For Specialty Applications • Automated Banding Delivery • Camera Inspection Systems • Glue Application Systems (Hot or Cold) This solution generally consists of the following modules: Unwinder Sheeting Unit Folding Machine with 4 or 6 Plates Automated Banding Delivery Additional Modules For Specialty Applications • Split And Merge Unit • Camera Inspection Systems • Glue Application Systems (Hot or Cold) MBO – Direct Mail Finishing Case Study MBO – Modularity And The “Parking Lot Concept” Delivery 820 Cutting Unit Delivery 820 Cutting Unit Pile Feeder relevant media channels in order to develop effective cross media marketing strategies for its customers. As one of the pioneers in one-to-one (1:1) consumer communications, Fenske Media was one of the first marketing service providers Folder Folder to provide information services across many different and Folder Pile Feeder totally digital environment. By doing so, the company is able Delivery South Dakota, Fenske Media Corporation now operates in a Folder Established in 1957 as a commercial printer in Rapid City, Delivery 820 Cutting Unit Sheeter Unwind 820 Cutting Unit Sheeter Unwind Cutting Unit direction of variable data direct mail. This evolution took place Delivery 820 Cutting Unit Delivery 820 Cutting Unit specifically to hit the variable data “sweet spot”. Owner Dave Fenske says, “If you want to get a relevant message out and stay in front of that customer to make a conversion, direct mail still opens a lot of doors.” Variable Data + Variable Printing = Variable Finishing Fenske Media and MBO America have a long-standing history working together. Fenske was one of the first to use MBO’s specialty folder technology from Herzog + Heymann (H+H). During the transition to digital, MBO worked closely with Fenske to ensure that its existing equipment could integrate into MBO’s digital web finishing lines. This meant that the new equipment was not replacing the specialty units, but instead Fenske was gaining new capabilities while retaining its specialty machines. By implementing MBO technology, Fenske Media was able to streamline production into a twostep operation and truly maximize the company’s ROI: 1- Print without intervention - Load the job on the press and no more touches again until it’s a roll. 2- One-step to finish - Complete all finishing work in one step. “At Fenske Media, we’re all about digital – and that means finishing systems from MBO. Digital print is a complex, time sensitive business that requires flexibility. With our MBO equipment we are able to fulfill a wide variety of work with the highest quality standards.” Dave Fenske Fenske Media Corporation This concept is a major advantage for MBO customers, who can then easily, and quickly, change out equipment to produce more customizable, variable jobs. “In order to handle the volume of variable data that we do, and the variable finishing that goes along with it, we have to be sensitive to the ‘origami’ around it all, and modularity is key,” says Fenske. He continues, “Critical triggers don’t work for our customers if we can’t get the job out on time. So, to ensure we fulfill our end of the bargain, we rely on MBO finishing technology.” Looking Ahead It started out for Fenske 25 years ago by being able to imprint The best way to explain how Fenske uses MBO equipment is the “modular” concept. Fenske began as a Herzog + Heymann (H+H) customer, the wholly owned subsidiary of MBO with specialty finishing solutions for handling light stocks and complex buckle folds. Fenske also has MBO folders, gluers, transfer tables, and different deliveries and stackers. As job demands change, the different MBO and H+H modules can be easily rolled in and out, as needed, to fulfill new job demands. Cutting Unit Delivery Parking Lot Concept The MBO Group’s modular approach to finishing gives digital unwinder and sheeter. With this core in place, a printer needs printers several unique advantages. Because MBO offers only to purchase the modules necessary for a given job (i.e.: separate but compatible modules that are mobile, rather than letterfold requires a folder and delivery). This model is also one-size-fits-all solutions, the finishing solutions from MBO can ideal for printers who expect growth because adding modules come in all shapes and sizes to produce an infinite number of to the Parking Lot is a much more cost effective investment job applications - they are not fixed solutions locked in for one than purchasing entirely new solutions. type of production, they are interchangeable modules! This numerous modules are on hand, a printer needs only to roll creates a Mix-and-Match finishing department that allows modules into place to create one-step finishing production printers to meet customer needs on a true 1:1 basis rather than systems. The result is a tremendously flexible and efficient offer cookie cutter solutions that may not meet customer needs. finishing department that can produce a wide range of products The Parking Lot Concept is one particular business model that and can meet some of the toughest on-demand deadlines takes full advantage of MBO’s modular approach in a digital which are commonplace in today’s event-based, time-sensitive print environment. At the core of the Parking Lot concept is the marketing strategies. Furthermore, once a pre-printed 8 ½ x 11 shell on a copy machine. That evolved to producing larger shells for more variable printed space, and finally to roll-fed inkjet production. The next step for the company is continuing to close the perceived gap between offset and digital using optimized substrates. Fenske is also The “Modular” Concept Folder digital print, almost 90% of the print work has moved in the Pile Feeder While Fenske media produces both traditional offset and Folder to offer innovative, relevant cross-media solutions. looking to do more with unusual shapes and higher volumes -- where all pieces are personalized. “Print today needs to deliver relevant communication and entertainment,” Fenske says. “Our challenge is to continue to create and deliver work that drives the customer to engage. This is right up MBO’s alley, and it fits our business model too.” ### Benefits of the Modular Approach: Tremendous flexibility to meet customer needs 1:1 • No cookie-cutter solutions One-Step Finishing reduces job turn-around Mix-and-Match modules to create new products Available Modules • Pile, Pallet, Continuous Feeders • Cutting Units • Folding Machines • Transfer Tables • Plowfolding • Knife Folding Units • Glue Application Systems (Hot or Cold) • Shingled or Stacking Deliveries MBO – Traditional Book Block Finishing Systems MBO – Variable Book Block Finishing Systems Variable Page Count Book Blocks with MBO’s Selective Folding Technology Book Blocks from a Web with Signatures and Perforation The Selective Folding Book Block Finishing Solution The MBO Group offers digital web finishing modules for 20 inch GRAPH EXPO 14 and 30 inch web finishing systems. Because of this modular approach to finishing, MBO digital web finishing solutions are 30 inch web finishing productions and received the 2014 Best of Available as an inline or near-line solution highly versatile - simply configure a line with the required modules and incorporate new modules as the job demands Category Must See Ems Award. Prior to the introduction of MBO’s “Selective Folding Technology,” digitally printed books were limited to a single sheet and plowfolding technologies that may not have change. This compatibility allows printers to finish digitally Variable printed products from a web via inline or offline systems and quickly transition from one job application to another. Page Count | Signatures Available as an inline or near-line solution from The MBO Group is available for both 20 inch and Book Blocks made from Digital Cut-Sheet using Signatures and Perforation Fully Variable Book Blocks with MBO’s Variable Finishing Technology MBO’s Digital Cut-Sheet Finishing Solutions are ideal for MBO’s Variable Finishing Technology takes finishing processing ordered and coded sheets at high speeds with farther than any other solution on the market. With the supreme accuracy and control - resulting in an extremely flat ability to reconfigure on-the-fly based off of job data folded signature and, by consequence, ultra-flat book blocks. from a code, MBO’s Fully Variable Book Block Production The ability to produce ultra-flat book blocks from digital cut- Solution gives printers the unprecedented capability to sheet stacks is hugely significant because flatness greatly produce different digitally printed books in succession. increases the efficiency of downstream binding processes. This means that books of different formats and Furthermore, MBO’s Digital Cut-Sheet Finishing Solutions can signatures, such as a 6 x 9 inch 12-page signature and an be equipped with glue systems at the stacker in order to apply 8 ½ x 11 inch 16-page signature, can be printed and spot glue along the backbone of each signature for an even finished off of the same roll. been ideal for the binding of the book. With Selective Folding Technology, finishers have the ability to process multiple signatures on-the-fly – meaning that the optimum signature combination can be printed in succession on a roll. higher quality book block that adheres to itself. These solutions generally consist of the following modules: These solutions generally consist of the following modules: Feeder Unit (Pile Fed or Web Fed) Folding Machine with 4 or 6 plates (20 or 30 inch) 8-Page Folding Unit Shingled Stream Delivery Additional Modules For Specialty Applications • Automated Stacking Delivery • Automated Setup • Knife Folding Unit • Glue Application Systems (Hot or Cold) • Perforating and Cutting Variable Format | Page Count | Signatures Feeder Unit (Pile Fed or Web Fed) Unwinder/Sheeter (20 inch or 30 inch Web) Digital Folding Machine (20 inch or 30 inch) Digital Folding Unit II (20 inch or 30 inch) Stacking Delivery System Additional Modules For Specialty Applications • Selective Fold Plates for Variable Page Count Book Blocks Signatures | Page Count • Fully Variable Fold Plates for Fully Variable Book Blocks Format | Signatures | Page Count MBO – High-Pile Stacking Case Study MBO – High-Pile Stacking Solution Ferndale, Michigan-based Allied Printing Company has helped its clients push the envelope on traditional print for more than 60 years. Established in 1952 as a commercial printer, the company has added digital inkjet capabilities, and successfully integrated a digital workflow into its existing commercial offset workflow by incorporating both traditional commercial finishing and web-finishing solutions. The Move to High Speed Inkjet Allied Printing first started looking at high-speed inkjet technology around 2010 and saw right away that high-speed inkjet was poised to be the next disruptive technology in the industry. Four years later, Allied executives made the decision “We’ve been working with MBO since the 90’s when we were still to embrace high-speed inkjet technology and purchased their on the conventional side. When we started our move towards first inkjet press. digital we were very comfortable with MBO technology and now our high-speed lines can run what used to be one-week’s worth of It was important to fully immerse employees into this plan so Tony Pelc COO, Allied Printing Company forward. This transition was a lengthy process; not just for the inkjet device, but for the finishing department as well. Available as an inline or near-line solution work in 17 hours without sacrificing quality!” that everyone understood and accepted the strategy moving Client Feedback When asked about quality since the transition to inkjet and At the onset of this transition, both digital and conventional MBO digital web finishing technology, Tony Pelc, Allied offset work were in the same facility. Now, as the demand for Printing Company COO, says, “The quality can be summed The High-Pile Stacking Solution from MBO America is a fully- the finishing stage by creating palletized stacks and diverting digital work continues to increase, Allied Printing has made up in a UV-coated direct mail piece we were doing for a luxury automatic cut sheet palletizing production system that gives digital and inkjet web applications to traditional cut-sheet the conscious effort to separate the two workflows in order auto-maker, which we printed on our inkjet press and finished printers the ability to create palletized stacks from a 30 inch finishing lines, which can result in faster job turnaround and to make room for an even more expanded digital operation. on our high-speed MBO line. We were able to run at high web. Because the system can produce up to a 28” x 40” increased press up-time. The stacker can also stack 2-up, speeds and the result was a beautiful product that the client sheet, commercial printers can integrate digital and inkjet 3-up, and 4-up sheets in addition to the full sheet size. With loved! web applications into a traditional commercial finishing the SVC 775 C Fully Variable Sheeter inline with the stacker, workflow. With the High-Pile Stacking Solution, a hybrid a multitude of commercial cut-sheet products can be printer can minimize the production workflow bottleneck at efficiently produced using a single operator. 1- Decrease time-to-market and allow clients to spend more time with creative and messaging. 2- Increase production capability without sacrificing quality or production flexibility “When we’re doing digital runs, time-to-market is much quicker than in the conventional sense and that is where the advantage lies. Thanks to MBO digital web finishing technology, we can run much tighter timelines with confidence in our ability to produce a high-quality result.” MBO in Action Having both sheet-fed and web-fed digital and conventional Future Expansion, Now offset printing created issues on the finishing end because With its inkjet presses and digital finishing technologies in work could no longer be allocated across all the finishing place, Allied Printing has renovated a 40,000 sq. ft. facility (that equipment. To address this, Allied Printing installed a previously housed its warehouse operations) to create a state- finishing line from MBO that can create palletized stacks of of-the-art digital direct mail center. This facility supplements full size sheets (28” x 40”), or be reconfigured for folded work. its existing 40,000 sq. ft. conventional print operation and By separating the stacking modules from the unwinding and 60,000 sq. ft. fulfillment center. These changes are all part of sheeting modules, MBO was able to provide a solution that Allied’s 5-year growth plan. When described in terms of pages, can swap a mobile folding system in before the stacking Allied Printing fully expects to be doing at least 1 billion pages system, thus eliminating the bottleneck that existed before. per year. This is all part of the long-term strategy to become a nationally renowned printer. ### This solution generally consists of the following modules: Unwinder (Near-Line Only) Sheeting Unit (SVC 775 C) Shingled Stream Accumulator (SSD 770) Stream Compactor (SSC 770) High Pile Stacker (SHP 800) Additional Modules for Specialty Applications • Transfer Tables • Mobile Folding Machines • Plowfolding • Die Cutting • Edge Trim, Gully Cut, 3-Knife Trim • Knife Folding Units MBO – Saddlestitched Book Finishing Systems MBO – Direct Mail Self Mailer Finishing Systems Available as an inline or near-line solution Available as an inline or near-line solution The MBO Group’s front-end finishing modules can be easily commercial printhouses, and digital printhouses. As with integrated with saddlestitching solutions for digital and all MBO solutions, the saddlestitching solutions can be commercial applications. This combination means that configured for inline or near-line applications. Furthermore, commercial printers would have the ability to process by incorporating variable technologies, customers could saddlestitched books, even down to four-page booklets - produce high-integrity, variable page-count saddlestitched making MBO solutions ideal for hybrid printhouses, books by reading a code off the printed roll. This solution generally consists of the following modules: Feeder Unit (Pile Fed or Web Fed) Sheeting Unit (For Web Fed) Folding Machine with 4 or 6 Plates (20 or 30 inch) Saddlestitcher (Glue or Stitch) Additional Modules For Specialty Applications • Automated Stacking Delivery • Cover Feeder • Lay Flat Technology • Offset Inserts • Selective Folding Technology The MBO Group’s Direct Mail Finishing Systems feature mail products that help them differentiate their products modules from MBO, Bograma, and specialty finishing from everyday pieces. Card affixing, tipping, plowfolding, experts, Herzog+Heymann. By combining the versatility of gluing, and die cutting can all be incorporated to produce a the Herzog+Heymann mailing table with the speed and simple direct mail piece or an elaborate variable content, precision of the MBO web-finishing equipment, this solution pop-up self-mailer! gives customers the ability to produce a huge range of direct This solution generally consists of the following modules: Feeder System (Pile Fed or Web Fed) Die Cutting and Stripping Unit Mailing Table for plowfolding, tipping, or gluing processes Shingled Stream Delivery System Additional Modules for Specialty Applications • Window Patching • Inline Inkjet + Drying for Variable Data • Inline Cutting Table • Camera Inspection Systems MBO – Unwind-Rewind Systems MBO – Unwind-Rewind Expands OEM Capabilities Compatible With: High Speed Inkjet Presses HD Digital Web Presses Variable Data Inkjet Web MBO Unwind-Rewind Solutions were engineered specifically is a line of robust, commercial-grade, MBO unwind-rewind for the 24/7 commercial print environment. One of the biggest solutions that are capable of processing a wide range of issues facing digital printers is optimizing the uptime their substrates at high-speeds, with minimal setup time and press. Furthermore, much of the available auxiliary equipment maintenance requirements – allowing printers to do more, cannot handle all the work that the press would otherwise be faster, while producing a higher quality roll off their digital able to process. To address this issue, MBO developed a new press. This has even further implications downstream from line of unwind-rewind solutions specifically for the digital the press because a high quality roll is much easier to process print market to give printers the ability to maximize the profit at the finishing stages; resulting in shorter setup times and earning potential of their digital press. The resulting product reduced paper waste. MBO Rewinder Inkjet Printer #2 MBO Pull Station Module & Web Turning Station Inkjet Printer #1 MBO Unwinder Pulls web from Inkjet Printer #2 Pulls web from MBO Pull Station Module Pulls web from Inkjet Printer #1 Pulls web from unwinder Unwind Direction Screen Graphics and Precision Group’s (Screen GP), a global Lance Martin, Director of Sales at MBO America, says that leader in digital inkjet technology, can now produce heavier MBO is able to meet digital press challenges of individual substrate jobs without speed or quality compromise as the companies, as well as large vendors like Screen, because it result of a development partnership with MBO. Custom is bringing highly accurate and flexible technologies to the versions of the MBO Group’s entire line of unwinders, market via its modular systems. “It’s the perfect business rewinders, angle bar turning stations, and tension control model for the digital market and digital presses which are units have been specifically engineered to support users of solid state, sturdy, consistent machines that offer plenty of Screen GP’s latest digital inkjet presses. flexibility, but only through programming and software, not hardware,” he says. “We at MBO can provide that missing In 2013 MBO first met with Screen to discuss efforts to piece of flexibility through our modular finishing equipment venture into heavier stocks on digital inkjet presses. In order and turn the latest in digital print technology into a sellable to use heavier stocks there needed to be a way to increase product.” the pull strength through the press and eliminate some of the tight turns made by the web on a traditional web turning All MBO Unwind-Rewind units are designed with heavy station and small diameter rollers. stock capabilities, large diameter rollers, world class tension control, built in buffering and the ability to use up to 60” 1- Increase pull strength to account for the demands diameter roll stock or rewinds. After receiving test data and and nuances of working with heavy stock papers customer feedback on prototypes, production models were placed into factory production. Screen America’s Ken Ingram, This solution generally consists of the following modules: UW/RW Series Unwinder and Rewinder PSM Pull Station Module WTS Web Turning Station MBO Unwind Rewind Systems Feature: Max. 60” roll capacity Large Diameter Rollers for 40 - 300 gsm stocks! 20 inch web width nominal Noise Output < 80 dB 2- Eliminate tight turns to reduce curling or wrinkling Vice President of Sales, says, “We are thrilled with the results which is common to heavy stock papers when being of this pairing of sophisticated technology between the two handled by small diameter rollers groups,” To solve this two part problem, MBO developed a strong pull MBO is now delivering an entire line of unwinders, rewinders, station module (PSM6) and air cushion turning station (WTS) angle bar turning stations, and tension controls units for to better transport the web from press unit 1 to press unit 2. Screen USA. This latest partnership further portrays MBO Furthermore, the MBO Group developed a new class of America’s New MBO philosophy, introduced during MBO unwinders and rewinders based on experience with its UW7 America’s 30th anniversary year. The New MBO is the and RW7 machines built for the converting industry. The culmination resulting new products are the UW500/RW500 series development, a highly precise acquisition strategy to move unwinders and rewinders for 150m/min class machines and into growing markets, and a state-of-the-art headquarters the UW60/RW60 for 250 m/min class machines. with demonstration center in Marlton, New Jersey - just of a decade of outside of Philadelphia. ### product research and MBO – Rotary Die Cutting Case Study MBO – Pharmaceutical Finishing Systems Graficol is a full-service, family-run printing company located in Almere, Netherlands. It has found success in the growing niche market for short-run, specialty packaging, die cutting Pharmaceutical Inserts and PI Work with MBO’s Specialty Finishing Equipment and creasing operations thanks to the finishing systems from MBO. Most recently, Graficol purchased the newly introduced Stamina folder-gluer system for inline folding The requirements for pharmaceutical applications are constantly carton production. changing - which is why MBO’s modular approach to finishing is perfect for this market. Keeping Up With Technology One of the original Graficol owners had a progressive vision modules and allows the processing of ultra-lightweight paper used in that every ten years, the company would introduce a new pharmaceutical inserts, outserts, and PI work. With the vast array of product offering to its customers. After visiting drupa 2012, the company decided that their next step would need to take the company from the forms and label business -- producing integrated letters with die cut shapes and tear out cards, and more; into a niche folding carton and packaging business operation. The specialty finishing equipment from Herzog+Heymann is 100% compatible with MBO web finishing modules available in its product portfolio, MBO America can offer With the BSR 550 Servo, Graficol gained the ability to die cut both lightweight paper AND heavy folding carton board stock. This allows them to meet demands in short-run pharmaceutical and short-run specialty packaging markets. Available as an inline or near-line solution pharmaceutical finishing solutions for both highly custom packaging applications and simple miniature folded insert pieces. The Opportunity: Bograma BSR 550 Servo Rotary Die Cutting Specialized short-run jobs are not cost effective when they are Why Short-Run Pharmaceutical and Specialty Packaging? produced on “big box” die cutting machines, but they are a Graficol observed that new and prospective customers are sweet spot for the BSR 550 Servo Rotary Die Cutter. Folding increasingly demanding short-run die cutting products. This carton producers simply do not have ability to offer die was particularly evident in cosmetic, pharmaceutical, and cutting, folding and gluing services cost effectively because specialty packaging market segments. To address this trend, the machines are too large with tooling, and setup is too management at Graficol began looking into rotary die cutting costly. In their quest for a solution, the management team at solutions in order to capitalize on the growing demand for Graficol were particularly impressed with the BSR 550 Servo short-run, specialty finishing in these market segments. because it could reduce three lengthy steps down to one, thanks to “nickless” die cutting and job storage software. It 70% of Graficol’s business comes from large printers was also clear that shorter runs with shorter turnaround times who are unable to handle short-run jobs effectively would continue to be the norm as the customer demographic and digital printing market grew, and so they purchased their Nickless die cutting eliminates the need for additional By integrating the BSR 550 Servo Rotary Die Cutter inline with equipment from MBO and its wholly owned subsidiary, Herzog+Heymman, printers gain the ability to produce die cut pharmaceutical products via a cut sheet feeder or a web fed production. Unlike traditional flat-bed die cutters, the BSR 550 Servo Rotary Die Cutter is capable of clean cuts on paper stock as light as 35 lb offset (50 gsm). Because of its compatibility with MBO digital finishing equipment, this first BSR 550 Servo Rotary Die Cutter. integrated system can be easily adapted for a variety of Taking The Next Step With H+H Stamina Folder-Gluer booklet production, or miniature folding systems. pharmaceutical finishing processes, like labelcert production, grinding and refinement of the product. To further utilize the BSR 550 Servo functionality, Graficol In a typical circumstance, printers with high-volume jobs were invested willing to set up full size die cutters with long make ready times Herzog+Heymann, a wholly owned subsidiary of MBO; the for each stage of the process -- die cutting, waste removal, and next logical step after the implementation of the BSR 550 additional grinding or refinement to remove imperfections-- Servo. The BSR 550 Servo produces flawless blanks with which resulted in higher labor and set up costs. This business no nicks while removing the waste matrix and internal scrap model is completely impractical for short-run die cutting. inline. This means that the product coming off the BSR 550 in Stamina Folder-Gluer technology from Servo is able to run directly into a folder-gluer. MBO worked Additionally, many of Graficol’s customers were not looking alongside the company to integrate the Stamina Folder-Gluer for extraordinarily large orders beffitting the larger packaging right into Graficol’s existing operation and, as a result of the giants; but rather, were requesting smaller, more personalized collaboration and new implementation, Graficol was able to runs that could easily be executed in concert with a special, successfully transition into a new market - making it more limited-time offer or sweepstakes. Most product runs for this competitive than ever before. kind of work are typically between 50,000 to 100,000. Die Cut Pharmaceutical Labelcerts with MBO’s Integrated Die Cutting Systems ### These solutions generally consist of the following modules: Feeder System (Pile Fed or Web Fed) Sheeting Unit (For Web Fed) Herzog+Heymann Specialty Folding Unit Vertical Stacking Delivery System for Miniature Folded Products Additional Modules for Specialty Applications • Die Cutting • Water Scoring • Edge Trim, Gully Cut, 3-Knife Trim • Camera Inspection Systems • Labeling/Tabbing Devices • Affixing/Tipping Units • Knife Folding Units • Pick and Pack Delivery System MBO – Folding Carton Finishing Systems Available as an inline or near-line solution The MBO Group’s Folding Carton Solutions can produce flatbed diecutting to hold the product during transport, but blanks or completed cartons inline with any digital press or they create flaws around the edges of the product and as a near-line solution. The speed and precision of rotary die require subsequent production steps to remove the scrap cutting make this solution ideal for a wide range of paper and refine the edges. With the “nickless” product coming off stocks and our rotary die cutting process, these additional steps are packaging requirements. Furthermore, our rotary die cutting process allows products to be made completely eliminated from production. without any holding points, or “nicks.” Nicks are required for This solution generally consists of the following modules: Feeder System (Pile, Continuous, or Web) BSR 550 Servo Rotary Die Cutter Inline Scrap and Waste Matrix Removal Shingled Stream Delivery System Additional Modules for Specialty Applications • Folder-Gluer Table • Multiple Plowfolds • Glue Application Systems (Hot or Cold) • Camera Inspection Systems • Card Affixing • Inline Inkjet + Drying for Variable Data • Belt or Roller Pressing Units MBO Binder and Co. of America 4 East Stow Road, Suite 12 Marlton, NJ 08053 Main Office: 609 267 2900 Email: info@mboamerica.com www.mboamerica.com