field-circuit modelling of the resistance spot welding transformers

advertisement

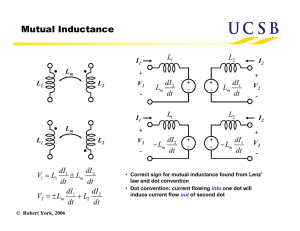

XXIV Symposium Electromagnetic Phenomena in Nonlinear Circuits June 28 - July 1, 2016 Helsinki, FINLAND ______________________________________________________________________________________________________ FIELD-CIRCUIT MODELLING OF THE RESISTANCE SPOT WELDING TRANSFORMERS L. Sakhno, O. Sakhno, D. Likhachev, P. Fedorov St. Petersburg State Polytechnic University, Department of Theoretical Electroengineering, Polytechnicheskaya 29, St. Petersburg, 190251, RUSSIA, LSAHNO2010@yandex.ru Abstract - Transformers of high frequency resistance spot welding systems are considered. The study of the transformers includes both 2D eddy-current FEA analysis for estimation the leakage impedances and the circuit simulation, which gives the output current. The results are used to design economical welding transformers. details.The load is given by the conductor with a DC resistance RL of 100 μΩ and the inductance LL of 700 nH . I. INTRODUCTION Resistance spot welding (RSW) are mainly used in automotive industry in welding systems. The RSW system size and mass are limited due to use on a robotic arm. In order to achieve the required compact design and high welding current, the high frequency RSM system (Fig.1) consists of an input H-bridge inverter, welding transformer (TR) and a fullwave centre tapped output rectifier that consists of diodes (D1, D2 ). a) Fig.2. Design of the transformer b) III. CIRCUIT MODELLING OF HIGH FREQUENCY RSW SYSTEM Fig.1. The transformer impedance affects the load current and power consumption. In this regard, in the literature a lot of attention is paid to calculation of the transformer impedance and the equivalent circuit of the RSW transformer [1-3]. The current in the massive conductors is not uniformly distributed due to skin effect and proximity effect. In [4] power losses of the transformers with the parallel-connected secondary windings are analyzed. A method of optimizing copper winding dimensions in order to reduce copper losses and design were proposed in [5]. II. RSW TRANSFORMER The article deals with the transformers which have armored magnetic cores, primary winding and two secondary windings Figure 2 shows one of the transformer designs. The primary winding consists of four series-connected coils made.of wire with rectangular cross-section. The two secondary coils are made of copper tubes through which cooling water flows. The primary winding consists of 36 turns. The transformers considered differ in the number of coils of the primary winding and interleaving of primary and secondary windings. The frequency is 10 kHz. Frequency of the H- bridge inverter is defined production requirements when welding some For high RSW system simulation the equivalent circuit of the three-winding transformer is needed. The circuit given in fig.3a allows to study influence of the transformer design on the load current of RSW system. This circuit differs from well-known circuit of the three-winding transformer [6] and it was succesfully used for studing transformers of doublebridge rectifiers [7,8]. The two secondary windings of the transformer are not condactively coupled. All inductances in the circuit are always positive. Therefore, the circuit is suitable for the standard simulation program (P-Spice) [9]. It is important that the circuit parameters have the clear physical sense and can be easily evaluated by FEA [10]. This circuit is based on replacing the three-winding transformer with two transformers: one with windings 1, 2 and the second with windings 1, 3 (further denoted as transformers 1-2 and 1-3). The mutual impact of transformers 1-2 and 1-3 is modelled as a change of EMF on the terminals of their secondary windings by magnetic leakage fields. Equations of three-winding transformer, referred to the secondary windings, for sinusoidal currents and voltages are: r E02 r12 I 2 jL12 I 2 1 I 3 jMI 3 U LOAD 2 k12 k13 (1) r1 E03 r13 I 3 jL13 I 3 I 2 jMI 2 U LOAD 3 k12 k13 where I 2 , I 3 are complex currents in windings 2 and 3, 2f , f is frequency, j 1 , E02 , E03 are open ______________________________________________________________________________________________________ 123 circuit EMF in windings 2 and 3, L12 , r12 are leakage inductance and active resistance of transformer 1-2, L13 , r13 are leakage inductance and active resistance of transformer 13, r 1 is active resistance of winding 1, M - the mutual inductance of the leakage fluxes of transformers 1-2 and 1-3, U LOAD 2 is complex voltage on the terminal of winding 2, U LOAD 3 is complex voltage on the terminal of winding 3. The mutual inductance of the leakage fluxes can be found: L L13 L23 , (2) M 12 2k12 k13 where L23 is the leakage inductance of transformer 2–3. All the leakage inductances in (2) are referred to winding 1. The magnetic leakage fields in transformers 1-2 and 1-3 (short-circuit tests for transformers 1-2, 1-3) have been modelled by 2D FEA software QuickField [9]. The leakage flux of the transformer 1-2 in the window is shown in Fig.2b. In Figure The circuits parameters L12, L13, r12, r13 evaluate by 2D FEA model. For evaluating the magnetic leakage mutual inductance M we have made the FEA simulation of another short-circuit field in transformer 2- 3. a) b) Fig.3. Equivalent circuit of three-winding transformer and the model of RSW system The model for the high frequency RSW system simulation is shown in Fig. 3b. Calculation of transient in the circuit in Fig.3b have been made using the Microcap [10] software. IV. THE CALCULATION RESULTS Due to the centre tapped rectifier (Fig.1) the current only flows in one of the secondary windings at the same time. It causes the increased leakage inductances of the transformers 1-2 and 1-3. Calculations have shown that it is necessary to reduce the leakage inductances of transformers 1-2 and 1-3 for increasing the operating current if open circuit voltage is constant. The magnetic coupling factor for the leakage fluxes: M (3) k L12 L13 has a great influence on the operating current. The mutual inductance M can be either positive, when the leakage flux in winding 3 caused by the transformer 1-2 is directed opposite to the main core flux, or negative , if above fluxes have the same direction. Dependence of the operating current on the magnetic coupling factor for the leakage fluxes is approximately the same for any value of the leakage inductances of transformers 1-2 and 1-3. In this regard, the dependence of the relative operating current (IL/IL0 , IL0 – load current at k=0) on the coupling factor is shown in Fig.4. Fig.4. The influence of the coupling factor on the load current It shows that when k > 0 the load current is less than when k< 0. This effect can be explained by the appearance of additional EMF at the terminals of winding 2 when current flows in winding 3 caused by leakage flux. Increased EMF reduces diodes switching times, which in turn leads to an increase load current. We investigated several transformer designs for RSW system with frequency of 10 kHz. Designs differs interleaving of primary and secondary windings and the number of primary winding coils. They have different leakage inductance and different coupling factors for the leakage flux. All options have the same number of turns of the primary winding. For example, the transformer in Fig.2 has L12 = L13 =83 μH (referred to the primary windings), coupling factor k= -0.5. The field-circuit modelling of RSW transformer allowed us to optimize the transformer. The transformer with two coils of primary winding and secondary windings located between them appeared to be the most economical. REFERENCES [1] X. Margueron, A. Besi, Y. Lembeye , J.P. Keradec “ Current sharing between parallel turns of a planar transformer: prediction and improvement using a circuit simulation software”, IEEE Trans. on Industry Application, vol.46, no.3, pp.1064-1071, 2010 [2] J-P. Keradec, Besi A., Lembeye Y., B.Cogitore and F. Blache,”Power transfer in a two-winding transformer from 1-D propogation to an equivalent circuit”, IEEE Trans. on Magn., vol.32, no.1, pp. 274-280, Jan. 1996. [3] X. Margueron, J-P. Keradec, “Analitical calculation of leakage inductances of HF transformers using PEEC formulas”, IEEE Trans. on Ind. Applications., vol.43, no.4, pp. 884-892, Jan. 1996. [4] J.M. Cukovic, M. Petrum, B. Klopсiс, B. Polajzer, D. Dolinar, “Optimization of resistance spot welding transformer winding using analytical successive approximation and differential evolution”, IEEE Trans. on Magn., vol.50, 2014 [5] M. Petrum, D. Dolinar, B. Klopсiс, G. Stramberger G., Transformer and method of setting winding coils, European patent office, CN103811156, applic no.: CN2031313394,15 pages,2014 [6] Sakhno L.I., An investigations of double-bridge rectifiers with steeply falling external characteristics for supplying an electric arc. Electrical Technology Russia, No 1: 96-104 (2002). [7] Sakhno L.I., Two-bridge welding rectifiers with single-phase transformers with a three-rod magnetic system. Welding International, 17 (7): 565-569 (2003). [8] L. Sakhno , O. Sakhno, S. Dubitsky. Field-Circuit Modelling of an Advanced Welding Transformer with Two Parallel Rectifiers. Archives of electrical engineering, 2015, vol.64 (252) , p.249-257 [9] Claycomb J. R. Applied Electromagnetics Using QuickField and MATLAB. – Laxmi Publications, Ltd. (2010). [10] Vladimirescu A. The SPICE Book, John Wiley & Sons, Inc., First Edition (1994). ______________________________________________________________________________________________________ 124 Proceedings of EPNC 2016, June 28 - July 1, 2016 Helsinki, FINLAND